Abstract

N-acetyl-d-glucosamine (GlcNAc) is the building block of chitin, which is one of the most abundant renewable resources in nature after cellulose. Therefore, a microorganism that can utilize GlcNAc is necessary for chitin-based biorefinery. In this study, we report on the screening and characterization of yeast strains for bioethanol production from GlcNAc. We demonstrate that Scheffersomyces (Pichia) stipitis strains can use GlcNAc as the sole carbon source and produce ethanol. S. stipitis NBRC1687, 10007, and 10063 strains consumed most of the 50 g/L GlcNAc provided, and produced 14.5 ± 0.6, 15.0 ± 0.3, and 16.4 ± 0.3 g/L of ethanol after anaerobic fermentation at 30 °C for 96 h. The ethanol yields of these strains were approximately 81, 75, and 82 % (mol ethanol/mol GlcNAc consumed), respectively. Moreover, S. stipitis NBRC10063 maintained high GlcNAc-utilizing capacity at 35 °C, and produced 12.6 ± 0.7 g/L of ethanol after 96 h. This strain also achieved the highest ethanol titer (23.3 ± 1.0 g/L) from 100 g/L GlcNAc. To our knowledge, this is the first report on ethanol production via fermentation of GlcNAc by naturally occurring yeast strains.

Similar content being viewed by others

Introduction

The search for practical petroleum substitutes from renewable resources has become a global priority to combat the rapid rise in atmospheric carbon dioxide levels. Chitin, which is the principal structural component of cell walls of fungi, yeasts, and algae, exoskeletons of insects, shells of crustaceans, and microfilarial sheathes of nematodes (Flach et al. 1992), is one of the most abundant renewable resources in nature following cellulose (Howard et al. 2003). The estimated annual production of chitin on the Earth is on the order of 1010 to 1011 tons (Gooday 1990). Chitin is currently extracted from crab and shrimp shell wastes. In shrimp production, the shells of these animals make up as much as 75 % of the waste with roughly half being chitin (Bhattacharya et al. 2007). At present, however, only a limited fraction of shell waste is being utilized for animal feed or for the isolation of chitin to be used in medicines, cosmetics, and agriculture. Moreover, the processing of shellfish leads to environmental pollution (Synowiecki and Al-Khateeb 2003). Therefore, chitin derived from unused chitinous wastes is attracting attention as an abundant substrate for potential applications in biorefinery (Hayes et al. 2008).

Chitin is a polymer of β-(1-4) linked aminosugar N-acetyl-d-glucosamine (GlcNAc) residues, and can be hydrolyzed by mineral acids or enzymes into GlcNAc (Cosio et al. 1982). Therefore, a microorganism that can utilize GlcNAc is necessary to establish chitin-based biorefinery. It has been reported that some native microorganisms such as Escherichia coli (Alvarez-Anorve et al. 2005), Clostridium paraputrificum (Evvyernie et al. 2001), dimorphic pathogenic fungi (Kumar et al. 2000; Inokuma et al. 2013), and some oleaginous microorganisms (Rodriguez and Dominguez 1984; Ruiz-Herrera and Sentandreu 2002; Zhang et al. 2011) can use GlcNAc for their growth and as a source of energy.

Recently, ethanol production from GlcNAc by dimorphic fungi Mucor species was reported (Inokuma et al. 2013). Mucor circinelloides NBRC6746 and Mucor ambiguous NBRC8092 produced approximately 18.6 and 16.9 g/L ethanol from 50 g/L GlcNAc, respectively (Inokuma et al. 2013). On the other hand, to our knowledge, the GlcNAc-utilization capacity and ethanol productivity of yeasts, which are the most commonly used microorganisms for industrial ethanol production, have not been quantitatively evaluated.

The objective of this study was to determine the feasibility of using native yeasts to convert GlcNAc into ethanol. First, a screening test was conducted among native ethanol-producing yeasts to evaluate their GlcNAc-utilization capacity. We revealed that a native Scheffersomyces stipitis (formerly known as Pichia stipitis) strain could consume GlcNAc as the sole carbon source. Second, growth assays of five native S. stipitis strains were performed in GlcNAc medium. Finally, anaerobic ethanol fermentation from 50 and 100 g/L of GlcNAc was performed using the S. stipitis strains. To our knowledge, this is the first report of ethanol production via fermentation of GlcNAc by naturally occurring yeast strains.

Materials and methods

Strains and media

The yeast strains used in this study are listed in Table 1. Kluyveromyces lactis NRRL Y-1140 was obtained from the US Department of Agriculture-Agricultural Research Service (USDA-ARS) Culture Collection, and other strains were obtained from the NITE Biological Resource Center (NBRC). Yeast cells were pre-cultured in 5 mL of yeast extract peptone dextrose (YPD) medium [10 g/L yeast extract, 20 g/L Bacto-peptone (Difco Laboratories, Detroit, MI, USA), and 20 g/L glucose] in a shaker incubator (180 rpm at 25 °C for S. stipitis NBRC1720 and 10006 and 30 °C for other strains; BR-43FL; Taitec, Saitama, Japan) for 18 h. The yeast cells were harvested by centrifugation at 1000×g for 5 min, and then washed twice with distilled water. The washed cells were used for screening, growth assays, and ethanol fermentation as described below. Synthetic GlcNAc (SGN) medium [6.7 g/L yeast nitrogen base without amino acids (Difco Laboratories) and 50 g/L GlcNAc (Wako Pure Chemicals, Osaka, Japan)] was used to screen GlcNAc-utilizing strains. YPGN50 medium containing 10 g/L yeast extract, 20 g/L Bacto-peptone, and 50 g/L GlcNAc and YPGN100 medium containing 10 g/L yeast extract, 20 g/L Bacto-peptone, and 100 g/L GlcNAc were used for ethanol fermentation and growth assays.

Screening of GlcNAc-utilizing strains

After pre-cultivation and washing, yeast cells were inoculated in 5 mL SGN medium in test tubes to an initial OD600 of 0.1, and then cultivated at 30 °C in a shaker incubator (180 rpm; BR-43FL; Taitec). After cultivation for 24 h, the GlcNAc consumption of each strain was determined using high performance liquid chromatography (HPLC) as described below.

Growth assay

Growth assays of yeast strains were performed in L-shaped test tubes by using a TVS062CA Bio-photorecorder (Advantec Toyo, Tokyo, Japan). Pre-cultivated cells were inoculated in 5 mL of YPGN50 medium to an initial OD600 of 0.1. The yeast cells were cultured microaerobically (70 rpm), and OD600 of the cell suspension was automatically measured every 30 min. The final cell density (OD600) after 72 h of cultivation was measured by a UV–VIS spectrophotometer (UVmini-1240, Shimadzu, Kyoto, Japan). The μmax values were calculated as described previously (Inokuma et al. 2015).

Ethanol fermentation of GlcNAc

Ethanol fermentation of GlcNAc was anaerobically performed in closed 100 mL bottles equipped with a CO2 outlet. Yeast cells were inoculated in 20 mL of YPGN50 or 100 medium at an initial OD600 of 0.1. Fermentation was initiated by the addition of yeast cells into the fermentation medium, followed by rotation in a shaker incubator (180 rpm; BR-43FL; Taitec). The culture broth was sampled every 24 h, and its GlcNAc, ethanol, and acetate concentrations were determined using HPLC as described below.

Analytical methods

The concentrations of GlcNAc, ethanol, and acetate in the culture medium were determined using HPLC (Shimadzu). An Aminex HPX-87H column (Bio-Rad, Hercules, CA, USA) was used together with a Bio-Rad 125–0131 guard cartridge (Bio-Rad) and a refractive index detector (RID-10A, Shimadzu). The HPLC system was operated at 65 °C with 5 mM H2SO4 (flow rate, 0.6 mL/min) as the mobile phase.

Results

Screening of GlcNAc-utilizing strains

To screen for yeast strains that could utilize GlcNAc, native ethanol-producing yeasts were cultivated aerobically at 30 °C in the synthetic medium containing 50 g/L of GlcNAc as the sole carbon source (SGN medium). After 24-h cultivation, the GlcNAc consumption of these strains was evaluated using HPLC as described in the Materials and Methods. The results are shown in Fig. 1. Among the tested strains, only S. stipitis NBRC1687, which is the type strain of S. stipitis, could consume GlcNAc as the sole carbon source, and no significant GlcNAc consumption (<1.0 g/L) and cell growth were observed in the other strains. The NBRC1687 strain consumed 10.2 ± 0.5 g/L of GlcNAc and the OD600 reached 12.8 ± 0.4 after 24-h cultivation.

Growth assay of S. stipitis strains in GlcNAc medium

Microaerobic cultivation of five S. stipitis strains obtained from NBRC (Table 1) was performed in YPGN50 medium. The yeast cells were cultured at different temperatures (23–37 °C for NBRC1720 and 10006 strains, and 25–40 °C for NBRC1687, 10007 and 10063 strains) for 72 h, and the growth rates and final cell densities of these strains were evaluated. The growth profiles of these strains are shown in Table 2. Significant cell growth was observed in all S. stipitis strains tested in this study. NBRC1720 and 10006 strains exhibited cell growth in the range of 23–30 °C, while no significant growth was observed above 35 °C. On the other hand, NBRC1687, 10007, and 10063 strains were able to withstand cultivation temperatures in the range of 25–37 °C, and increasing growth temperature up to 35 °C did not significantly affect the growth rates. The highest μmax values of these strains were observed at 25 °C (NBRC1720 and 10006) and 30 °C (NBRC1687, 10007, and 10063) (Table 2). Consequently, the next ethanol fermentation experiments were carried out at 25 °C (NBRC1720 and 10006) and 30 °C (NBRC1687, 10007, and 10063).

Ethanol fermentation from 50 g/L of GlcNAc

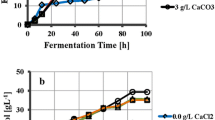

Ethanol fermentation from 50 g/L of GlcNAc using S. stipitis strains was performed under anaerobic conditions because S. stipitis has the characteristics of a Crabtree-negative yeast and is unable to produce ethanol in the presence of fermentable sugars under aerobic conditions (Jeffries and Shi 1999; Passoth et al. 1996). The results are shown in Fig. 2. All S. stipitis strains tested in this study could produce ethanol from GlcNAc, while their ethanol productivities varied depending on the strains. Among these strains, NBRC1687, 10007, and 10063 consumed most of the supplied 50 g/L GlcNAc. These strains produced 14.5 ± 0.6, 15.0 ± 0.3, and 16.4 ± 0.3 g/L of ethanol after 96-h fermentation, and their ethanol yields were approximately 0.338, 0.306, and 0.342 (g/g GlcNAc consumed), respectively (Fig. 2a, d, e). Since the theoretical maximum ethanol yield from GlcNAc by the GlcNAc catabolic pathway (Biswas et al. 2007) and the glycolysis pathway via fructose-6-phosphate is 2 mol ethanol/mol GlcNAc consumed (0.417 g ethanol/g GlcNAc consumed), the ethanol yields of these strains represent approximately 81, 75, and 82 % of the theoretical yield, respectively.

To evaluate the fermentation ability of these strains at elevated temperature, we also performed ethanol fermentation at 35 °C using NBRC1687, 10007, and 10063 strains (Fig. 3). Although the GlcNAc consumptions, cell growth, and the ethanol titers of these strains were lower than those at 30 °C, NBRC10063 demonstrated relatively high fermentation ability at 35 °C. This strain produced 12.6 ± 0.7 g/L of ethanol from GlcNAc, and the yield was approximately 0.303 g/g after 96 h (Fig. 3c).

Ethanol fermentation from 100 g/L of GlcNAc

Ethanol fermentation from 100 g/L of GlcNAc was performed at 30 °C to investigate the maximum ethanol titer of the S. stipitis strains. The results are shown in Fig. 4. These strains could use more than 50 g/L of GlcNAc, while their GlcNAc consumption and ethanol production rates gradually decreased over time and no significant ethanol production was observed after 240 h. Among these strains, NBRC10063 showed the highest GlcNAc consumption (80.2 ± 1.2 g/L) and ethanol titer (23.3 ± 1.0 g/L) after 240 h cultivation. In all fermentation experiments shown in Fig. 4, initial pH was 6.6 and the final pH settled at 5.8–5.9 after 288 h.

Discussion

In this study, we performed screening and characterization of yeast strains for bioethanol production from GlcNAc. We found that natural S. stipitis strains can use GlcNAc as the carbon source and produce ethanol. S. stipitis is able to ferment a wide range of sugars including galactose, mannose, xylose, and cellobiose along with mannan and xylan oligomers (Du Preez et al. 1986; Jeffries and Van Vleet 2009), and is widely studied for its capacity to ferment D-xylose to ethanol. However, there have been no studies concerning its capacity to ferment GlcNAc to ethanol. To our knowledge, this is the first report of ethanol production from GlcNAc by naturally occurring yeast strains.

Scheffersomyces stipitis NBRC10063 gave the highest ethanol titer and yield among the S. stipitis strains used in this study (Fig. 2). In anaerobic fermentation at 30 °C, this strain produced 16.4 g/L ethanol from 50 g/L GlcNAc. This ethanol titer is similar to that reported for M. circinelloides (18.6 g/L) and M. ambiguus (16.9 g/L) (Inokuma et al. 2013). Moreover, this strain achieved the highest GlcNAc consumption (80.2 g/L) and ethanol titer (23.3 g/L) from 100 g/L GlcNAc after 240 h cultivation. Although Wendland et al. (2009) reported ethanol production from GlcNAc by recombinant S. cerevisiae strains transduced with four genes required for the GlcNAc catabolic pathway from Candida albicans, the ethanol titers of these recombinant yeasts (around 3 g/L after 11 days) were much lower than that of NBRC10063. NBRC10063 also showed relatively high ethanol production from GlcNAc at 35 °C (Fig. 3). Applicability to high fermentation temperatures is important for efficient simultaneous saccharification and fermentation (SSF) processes, because high-temperature fermentation will reduce the cooling cost and risk of contamination and enable stable fermentation even in tropical countries (Banat et al. 1998).

In ethanol fermentation from 100 g/L of GlcNAc, GlcNAc consumption and ethanol production rates of S. stipitis strains gradually decreased over time and no significant ethanol production was observed after 240 h even though GlcNAc still remained (Fig. 4). One possible cause for the reduction of the fermentation efficiency is acetate accumulation. Acetate is an inhibitor of ethanol fermentation by yeast. Vanzyl et al. (1991) reported that the volumetric rate of ethanol production of S. stipitis CBS7126 (NBRC10007) from xylose was inhibited 50 % by acetate at concentration of 13.8 g/L at pH 6.5 under anaerobic condition. In this study, S. stipitis strains produced more than 20 g/L acetate as a byproduct after 288 h cultivation (Fig. 4). Similar acetate accumulation has been observed in ethanol fermentation from GlcNAc using Mucor species (Inokuma et al. 2013). Singh and Datta (1979) have reported the GlcNAc-catabolic pathway in C. albicans as follows. GlcNAc transported across the cell membrane can be phosphorylated to form GlcNAc 6-phosphate (GlcNAc 6P) by kinase. Then GlcNAc 6P is deacetylated to glucosamine 6-phosphate (GlcN 6P) followed by deamination to produce fructose 6-phosphate by GlcN 6P deaminase. Therefore, it can be inferred that most of the accumulated acetate is generated by the deacetylation of GlcNAc 6P to GlcN 6P. For further improvement of ethanol production from GlcNAc using S. stipitis strains, removal or convert of the accumulated acetate is necessary. Recently, several reports have demonstrated improvement of ethanol yields in S. cerevisiae by anaerobic reduction of acetate to ethanol (Henningsen et al. 2015). A similar approach would be applicable for the improvement of the ethanol yield from GlcNAc by S. stipitis. If S. stipitis strains can convert acetate into ethanol, these strains will be able to produce a maximum 3 mol of ethanol from 1 mol of GlcNAc (0.625 g ethanol/g GlcNAc) theoretically. The theoretical yield is much higher than those from glucose (0.514 g/g) and xylose (0.511 g/g).

Compared with S. cerevisiae, which is widely used in industrial ethanol fermentation, heterologous gene expressions and targeted gene deletions of S. stipitis are more difficult due to its alternative codon system and frequent random (nonhomologous) integration (Jeffries and Van Vleet 2009). However, researchers have been developing genetic transformation systems based on auxotrophic markers (Yang et al. 1994; Lu et al. 1998; Piontek et al. 1998) and drug resistance markers (Laplaza et al. 2006), the loxP/Cre excision system (Laplaza et al. 2006), and expression vectors available for S. stipitis (Den Haan and Van Zyl 2001; Klabunde et al. 2003). A summary of strain development and genetic tools useful for S. stipitis has been published (Jeffries 2008). Furthermore, Jeffries et al. (2007) sequenced the genome of S. stipitis NBRC10063 (CBS6054, NRRL Y-11545) strain. These genetic tools and genome information can aid in the genetic engineering of S. stipitis strains such as the conversion of acetate into ethanol and the expression of heterologous chitinase genes.

In this study, we evaluated yeast strains based on their cell growth and ethanol production in GlcNAc medium. On the other hand, it has been reported that enzymatic chitin degradation is significantly enhanced by hydrochloric acid treatment (Inokuma et al. 2013). Therefore, comparison of tolerance of S. stipitis strains to hydrochloric acid and other compounds present in the acid-treated chitin hydrolysate would be necessary for further evaluation of their availabilities. If strains are both tolerant to these compounds and can utilize GlcNAc well, they will be more promising for utilization of chitinous wastes.

In this study, we demonstrated that native S. stipitis strains could use GlcNAc as the sole carbon source and produce ethanol efficiently. S. stipitis NBRC10063 showed the highest growth rate, GlcNAc-utilizing capacity, ethanol productivity, and thermal stability in YPGN medium among the yeast strains tested in this study. Our results suggest that the NBRC10063 strain should be regarded as a promising candidate for use in bioethanol production from chitinous waste in the future. However, further analysis of the GlcNAc metabolic pathway of this yeast is necessary to identify the reasons for its high GlcNAc-utilization capacity.

Abbreviations

- GlcNAc:

-

N-acetyl-d-glucosamine

- GlcNAc 6P:

-

GlcNAc 6-phosphate

- GlcN 6P:

-

glucosamine 6-phosphate

- USDA-ARS:

-

US Department of Agriculture-Agricultural Research Service

- NBRC:

-

NITE Biological Resource Center

- YPD:

-

yeast extract peptone dextrose

- SGN:

-

synthetic GlcNAc

- YPGN50:

-

yeast extract peptone with 50 g/L GlcNAc

- YPGN100:

-

yeast extract peptone with 100 g/L GlcNAc

- SSF:

-

simultaneous saccharification and fermentation

References

Alvarez-Anorve LI, Calcagno ML, Plumbridge J (2005) Why does Escherichia coli grow more slowly on glucosamine than on N-acetylglucosamine? Effects of enzyme levels and allosteric activation of GlcN6P deaminase (NagB) on growth rates. J Bacteriol 187(9):2974–2982. doi:10.1128/JB.187.9.2974-2982.2005

Banat IM, Nigam P, Singh D, Marchant R, McHale AP (1998) Ethanol production at elevated temperatures and alcohol concentrations: Part I—Yeasts in general. World J Microb Biot 14(6):809–821. doi:10.1023/A:1008802704374

Bhattacharya D, Nagpure A, Gupta RK (2007) Bacterial chitinases: properties and potential. Crit Rev Biotechnol 27(1):21–28. doi:10.1080/07388550601168223

Biswas S, Van Dijck P, Datta A (2007) Environmental sensing and signal transduction pathways regulating morphopathogenic determinants of Candida albicans. Microbiol Mol Biol Rev 71(2):348–376. doi:10.1128/MMBR.00009-06

Cosio IG, Fisher RA, Carroad PA (1982) Bioconversion of shellfish chitin waste—waste pretreatment, enzyme-production, process design, and economic-analysis. J Food Sci 47(3):901–905. doi:10.1111/j.1365-2621.1982.tb12741.x

Den Haan R, Van Zyl WH (2001) Differential expression of the Trichoderma reesei β-xylanase II (xyn2) gene in the xylose-fermenting yeast Pichia stipitis. Appl Microbiol Biotechnol 57(4):521–527

Du Preez JC, Bosch M, Prior BA (1986) The fermentation of hexose and pentose sugars by Candida shehatae and Pichia stipitis. Appl Microbiol Biotechnol 23(3–4):228–233

Evvyernie D, Morimoto K, Karita S, Kimura T, Sakka K, Ohmiya K (2001) Conversion of chitinous wastes to hydrogen gas by Clostridium paraputrificum M-21. J Biosci Bioeng 91(4):339–343

Flach J, Pilet PE, Jollès P (1992) What’s new in chitinase research? Experientia 48(8):701–716

Gooday GW (1990) The ecology of chitin degradation. Adv Microb Ecol 11:387–430

Hayes M, Carney B, Slater J, Brück W (2008) Mining marine shellfish wastes for bioactive molecules: chitin and chitosan–Part A: extraction methods. Biotechnol J 3(7):871–877. doi:10.1002/biot.200700197

Henningsen BM, Hon S, Covalla SF, Sonu C, Argyros DA, Barrett TF, Wiswall E, Froehlich AC, Zelle RM (2015) Increasing anaerobic acetate consumption and ethanol yields in Saccharomyces cerevisiae with NADPH-specific alcohol dehydrogenase. Appl Environ Microbiol 81(23):8108–8117. doi:10.1128/AEM.01689-15

Howard MB, Ekborg NA, Weiner RM, Hutcheson SW (2003) Detection and characterization of chitinases and other chitin-modifying enzymes. J Ind Microbiol Biotechnol 30(11):627–635. doi:10.1007/s10295-003-0096-3

Inokuma K, Takano M, Hoshino K (2013) Direct ethanol production from N-acetylglucosamine and chitin substrates by Mucor species. Biochem Eng J 72:24–32. doi:10.1016/j.bej.2012.12.009

Inokuma K, Yoshida T, Ishii J, Hasunuma T, Kondo A (2015) Efficient co-displaying and artificial ratio control of α-amylase and glucoamylase on the yeast cell surface by using combinations of different anchoring domains. Appl Microbiol Biotechnol 99(4):1655–1663. doi:10.1007/s00253-014-6250-1

Jeffries TW (2008) Engineering the Pichia stipitis genome for fermentation of hemicellulose hydrolysates. In: Wall JD, Harwood CS, Demain A (eds) Bioenergy. ASM Press, Washington, DC., pp 37–47

Jeffries TW, Shi NQ (1999) Genetic engineering for improved xylose fermentation by yeasts. Adv Biochem Eng Biotechnol 65:117–1161

Jeffries TW, Van Vleet JR (2009) Pichia stipitis genomics, transcriptomics, and gene clusters. FEMS Yeast Res 9(6):793–807. doi:10.1111/j.1567-1364.2009.00525.x

Jeffries TW, Grigoriev IV, Grimwood J, Laplaza JM, Aerts A, Salamov A, Schmutz J, Lindquist E, Dehal P, Shapiro H, Jin YS, Passoth V, Richardson PM (2007) Genome sequence of the lignocellulose-bioconverting and xylose-fermenting yeast Pichia stipitis. Nat Biotechnol 25(3):319–326. doi:10.1038/nbt1290

Klabunde J, Kunze G, Gellissen G, Hollenberg CP (2003) Integration of heterologous genes in several yeast species using vectors containing a Hansenula polymorpha-derived rDNA-targeting element. FEMS Yeast Res 4(2):185–193. doi:10.1016/S1567-1356(03)00148-X

Kumar MJ, Jamaluddin MS, Natarajan K, Kaur D, Datta A (2000) The inducible N-acetylglucosamine catabolic pathway gene cluster in Candida albicans: discrete N-acetylglucosamine-inducible factors interact at the promoter of NAG1. Proc Natl Acad Sci USA 97(26):14218–14223. doi:10.1073/pnas.250452997

Laplaza JM, Torres BR, Jin YS, Jeffries TW (2006) Sh ble and Cre adapted for functional genomics and metabolic engineering of Pichia stipitis. Enzyme Microb Technol 38(6):741–747. doi:10.1016/j.enzmictec.2005.07.024

Lu P, Davis BP, Hendrick J, Jeffries TW (1998) Cloning and disruption of the β-isopropylmalate dehydrogenase gene (LEU2) of Pichia stipitis with URA3 and recovery of the double auxotroph. Appl Microbiol Biotechnol 49(2):141–146

Passoth V, Zimmermann M, Klinner U (1996) Peculiarities of the regulation of fermentation and respiration in the crabtree-negative, xylose-fermenting yeast Pichia stipitis. Appl Biochem Biotechnol 57–58:201–212

Piontek M, Hagedorn J, Hollenberg CP, Gellissen G, Strasser AW (1998) Two novel gene expression systems based on the yeasts Schwanniomyces occidentalis and Pichia stipitis. Appl Microbiol Biotechnol 50(3):331–338

Rodriguez C, Dominguez A (1984) The growth characteristics of Saccharomycopsis lipolytica: morphology and induction of mycelium formation. Can J of Microbiol 30(5):605–612

Ruiz-Herrera J, Sentandreu R (2002) Different effectors of dimorphism in Yarrowia lipolytica. Arch Microbiol 178(6):477–483. doi:10.1007/s00203-002-0478-3

Singh B, Datta A (1979) Induction of N-acetylglucosamine-catabolic pathway in spheroplasts of Candida albicans. Biochem J 178(2):427–431

Synowiecki J, Al-Khateeb NA (2003) Production, properties, and some new applications of chitin and its derivatives. Crit Rev Food Sci Nutr 43(2):145–171. doi:10.1080/10408690390826473

Vanzyl C, Prior BA, Dupreez JC (1991) Acetic-acid inhibition of xylose fermentation by Pichia d-xylose fermentation by Pichia-stipitis. Enzyme Microb Tech 13(1):82–86. doi:10.1016/0141-0229(91)90193-E

Wendland J, Schaub Y, Walther A (2009) N-acetylglucosamine utilization by Saccharomyces cerevisiae based on expression of Candida albicans NAG genes. Appl Environ Microbiol 75(18):5840–5845. doi:10.1128/AEM.00053-09

Yang VW, Marks JA, Davis BP, Jeffries TW (1994) High-efficiency transformation of Pichia stipitis based on its URA3 gene and a homologous autonomous replication sequence, ARS2. Appl Environ Microbiol 60(12):4245–4254

Zhang GC, French WT, Hernandez R, Hall J, Sparks D, Holmes WE (2011) Microbial lipid production as biodiesel feedstock from N-acetylglucosamine by oleaginous microorganisms. J Chem Technol Biotechnol 86(5):642–650. doi:10.1002/jctb.2592

Authors’ contributions

KI designed the study, conducted the experiments and drafted the manuscript. TH and AK supervised the research. All authors read and approved the final manuscript.

Acknowledgements

The authors grateful to Dr. Kazuhiro Hoshino for his helpful advice.

Competing interests

The authors declare that they have no competing interests.

Ethics approval

This article does not contain any studies concerned with experiment on human or animals.

Funding

This work was supported in part by a Special Coordination Fund for Promoting Science and Technology, Creation of Innovative Centers for Advanced Interdisciplinary Research Areas (Innovative BioProduction Kobe) from the Ministry of Education, Culture, Sports, Science and Technology (MEXT).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Inokuma, K., Hasunuma, T. & Kondo, A. Ethanol production from N-acetyl-d-glucosamine by Scheffersomyces stipitis strains. AMB Expr 6, 83 (2016). https://doi.org/10.1186/s13568-016-0267-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13568-016-0267-z