Abstract

Manufacturing enterprises globally have already largely adopted the product-service strategy into their operations. However, due to gradual commoditization of services, manufacturing enterprises will have to further extend this strategy. One possibility is for manufacturers to servitize, not only their final products, but also a part of their value chain, with the aim of increasing their long-term competitive advantage. In this article, the application of servitization to remanufacturing, as a set of operational and business competences and processes, is conceptualized. By offering remanufacturing as a service, manufacturers will create an additional revenue stream. The synergies created from integrating remanufacturing into an enterprise with a product-service system are scrutinized. The impact of offering remanufacturing as a service (servitizing) is then assessed from the perspective of the competitive advantage of both, the provider and the consumer of the service. Three main sets of implications are identified. The first is that the integration of remanufacturing into a product-service system could increase customer satisfaction through a larger service scope and higher service quality, while decreasing operational costs. Furthermore, it is shown that the higher the level of servitization, the stronger is the positive impact of remanufacturing. The second set of results shows that servitizing remanufacturing can substantially increase the competitive advantage of both the provider and the consumer. While the first two sets of results have industrially oriented implications, the third set constitutes a theoretical contribution through the proposal and conceptual validation of extension of the application of servitization theory. Finally, while the reasoning is of a conceptual nature, it is based on established theories and includes remanufacturing-related industrial cases as a basis for assessment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

This section first depicts two main concepts of the article product-services and remanufacturing. Afterwards, the aim and hypotheses are introduced.

Product-services (P-S) comprise an integrated combination of products and services that deliver value to the customer. The term is found under multiple names; however, Baines [1] proposed a synthesis of those terms, servitization being the broadest one. It is defined as ‘market packages or bundles of customer-focused combinations of goods, services, support, self-service and knowledge’ [2]. Servitization has become a very successful strategy in manufacturing enterprises, 20% of such enterprises having already integrated some kinds of services [3]. The result of this is that, due to the pervasiveness of servitization as a strong basis for differentiation against competitors, it is going to slowly fade away in the future, implying that product-service bundling will slowly become commoditized or, put differently, customers' expectations will increase with time so that manufacturers will have to find new ways to satisfy them. Consequently, servitization is shifting from representing a distinctive basis for competitive advantage towards being a necessary, though not sufficient, condition for sustaining its competitive advantage. This implies that new business approaches capable of creating synergy with the existing servitization strategy need to be sought. One such path in industry and research that is becoming more and more established is the collaboration between product-service system (PSS) and remanufacturing. The latter is ‘the process of transforming durable products that are worn, defective, or discarded to a “like new or better” condition through a production-batch process of disassembly, cleaning, refurbishment and replacement of parts, reassembly, and testing’ [4].

Synergies between the two strategies have already been identified. Remanufacturing for instance can be enhanced if selling the functionality of a product and not directly the product itself [5]. In this case, the larger part of the risk associated with a remanufactured product lies with the supplier rather than the user [6]. The synergy also enables the manufacturing enterprises to have better control over the products, as they can more readily plan and manage the manufacturing process [5]. In such cases, profit margins can be sustained or improved compared to the one from new sales [7]. Furthermore, remanufacturing can constitute an essential part of, or even a condition for, economically and environmentally advantageous service selling [8]. However, discussion of only functional sales can be very restrictive, since it represents only one level among the four levels of servitization [9] through which enterprises undertake the shift from products to services. Namely, those levels are also very pervasive among manufacturing enterprises and hence are essential. Consequently, although that there exist some synergies between P-S and remanufacturing strategies, their detailed relation is not yet clear [10]. This is preventing managers of manufacturing enterprises to fully exploit those synergies in order to increase their long-term level of competitiveness.

The aim of this article is to help managers of manufacturing enterprises evolve their service-oriented strategies after integrating a PSS. The evolution of the service-oriented strategies is achieved in two steps, each expressed by a single objective. The first step is to scrutinize the impact of integrating a remanufacturing strategy into a manufacturing enterprise that is already offering P-S, i.e. already servitizing and is aiming to improve its competitive advantage through the evolvement of service-oriented strategies. The focus is thus on manufacturing enterprises that have already servitized their business, as their share has already become substantial, and in which the synergies between P-S and remanufacturing have already partially been identified; this relationship has not been studied in detail, except in some cases like those of Sundin, Bjorkman and Jacobsson [8] and Sakao and Mizuyama [10]. If the relations between P-S and remanufacturing are identified as being positive, then it would imply that the number of manufacturing enterprises that will integrate remanufacturing will increase. Regarding the future potential demand of remanufacturing and its high knowledge intensity, the second objective deals with enterprises that are already providing P-S and have already set up its own remanufacturing activities. The objective has scrutinized the impact of offering remanufacturing-based developed capabilities (competences and processes) to design and set up such remanufacturing activities from an operational and business perspective, as a service to other manufacturing enterprises. Remanufacturing can be offered in a variety of business modes. We have chosen the widely accepted servitization framework to support the analysis. This means that the objective will be to analyse, how remanufacturing activities can be offered as a service in four different modes, where each refers to one of the servitization levels. This will be followed by an analysis of how those remanufacturing activities, offered as a service, impact on the competitive advantage of both the provider and the consumer of such services. Accordingly, the following two hypotheses have been formulated:

-

H1 - The higher the level of servitization of a manufacturing enterprise, the greater the relevance of its remanufacturing strategy for the enterprise in question.

-

This hypothesis contributes to defining the relationship between servitization and remanufacturing, which has first to be clarified. As established earlier in the previous paragraphs, multiple synergies exist between functional sales, as the higher level of servitization, and remanufacturing; however, for other levels, the relation is unknown. Due to the characteristics of servitization, however, it is expected that the relevance of remanufacturing increases with the level of servitization, i.e. the higher the servitization level, the more motivated is the manufacturer to minimize costs through the product life cycle. This hypothesis will consequently depict the relevance of remanufacturing as a strategy integrated into the existing business model of an enterprise that has already servitized or that is going to servitize its products.

-

The second hypothesis is divided into two sub-hypotheses.

-

H2/A - A manufacturing enterprise that provides P-S and has integrated its own remanufacturing activities can increase its competitive advantage by providing remanufacturing - the competences and processes needed to set up a remanufacturing operation from an operational and business perspective - as a service to other manufacturing enterprises.

-

H2/B - A manufacturing enterprise that already provides P-S can increase its competitive advantage by acquiring the service of remanufacturing (design and set-up) from another manufacturing enterprise.

The sub hypotheses H2/A and H2/B contribute to the identification of the exploitation possibilities of introducing an integrated remanufacturing strategy into an already servitized business from the perspectives of the provider and consumer of such a service. The first hypothesis, H1, is introduced to explain the relations between remanufacturing and P-S strategies. The second set of hypotheses H2 (A and B) are formulated to investigate the possibility that a manufacturing enterprise can exploit its already developed remanufacturing activities (competences and processes) by offering them as a service (through the four servitization levels) to other manufacturing enterprises. Offering in this way, remanufacturing, which is a specific part of the manufacturer's value chain, is in line with the concept of servitizing the manufacturer's value chain [11], in this way applying the concept of servitization to a specific part of the value chain. The concept of servitizing the manufacturer's value chain thus lies at the core of the proposed concept, although made specific for the case of remanufacturing. This method proposes that manufacturing enterprises offer high added-value, knowledge-intensive parts of their value chain to other manufacturing enterprises. Thus, in this article, the offering of remanufacturing is made through four servitization levels. Servitization [9] is based on the presumption that the core of the offering is a product and that, in each further servitization level, different types of services are added, while the ownership of the product changes. However, in this case, remanufacturing is a service per se and not a product. Thus, a service-dominant logic [12] is adopted, implying that the services (the process of providing benefits) are in the centre of the value exchange, using products as units of output that are sometimes used to support the delivery of the service itself [13]. This perspective was adopted because the parts of the manufacturer's value chain (in this case, remanufacturing) are not products but services. In addition, different types of service levels fit some of the main rationales for a service-dominant logic introduced by Vargo and Lusch [14], especially the one stating that skill and knowledge are the fundamental units of exchange. The latter is the case when remanufacturing is offered as a service. Remanufacturing is seen as an interesting part of the value chain to be servitized, since it can be a complex process from the operational standpoint and from the business perspective of making a valid business case. Finally, due to multiple factors (among others also legislative in some industries), remanufacturing activities are becoming more and more pervasive; hence, the demand for such competences and skills will increase.

With the objective of reinforcing the findings of the hypothesis, a research question (RQ) is set. It can be referred to as a productive research question [15], with the aim of reinforcing conceptual findings from the previous hypotheses, thus as follows:

RQ: What are the risks associated with the introduction of offering remanufacturing as a service, as investigated in the previous set of sub-hypothesis H2A and H2/B?

Relation to existing work

Remanufacturing

Remanufacturing preserves most of the added value of a product by giving it a second life and, typically, reduces the energy used by eliminating production steps [16], hence being a sustainable approach in manufacturing. The now already famous case of remanufacturing from Caterpillar that has 17 dedicated manufacturing facilities in eight countries provides remanufactured products of the same quality as new products [17], but with the preservation of approximately 85% of original energy added [18]. The benefits of remanufacturing are not only environmental, but in many cases, it enables the original equipment manufacturer (OEM) to benefit from a secondary market, opening new business opportunities over which the manufacturer previously had no control, since independent operators entered the market and competed for returned ‘cores’ and thus a share of the market with remanufactured products [19]. These authors established the frequent occurrence of such a situation; namely, based on the assessment of Guide Jr. [20] that 95% of remanufacturing programs are not managed by their OEMs. The potential benefit of remanufacturing is not limited to the remanufacturer but extends also to the consumers, since the remanufactured product can be sold at a price 20% to 30% lower than that of the new product, while the production costs constitute only 35% to 60% of the original manufacturing cost [21]. Regardless of the positive impact of remanufacturing, its integration into existing business models is not always self-evident. Some of the main barriers to integrating remanufacturing into an existing business are consumer acceptance and lack of understanding of the required business model and of a broad enough skill set within a single company to cope with differences of the product entering the business [6]. Such barriers can, to some extent, be alleviated through integration into a P-S strategy. Thus, implementation of remanufacturing practices may be risky without a comprehensive understanding of the factors governing the complex set of remanufacturing activities [22]. For instance, in order to maximize profit, a remanufacturer must be able to balance the return of the product's cores with the demand from customers for remanufactured products [23], which in relation to reverse logistic is a major challenge [24]. However, the barriers are not only those of internal organization and operation, but are also market related. For example, the demand for machine remanufacture is falling because of the introduction of cheaper alternative products into mature markets like the one in UK [25]. Companies find it difficult to implement and consolidate remanufacturing activities [26], being for many still a new topic. Thus, even if remanufacturing has multiple positive impacts, its integration, from a business and operation perspective, is not obvious and can represent a serious challenge to managers. Hence, the research path of integrating remanufacturing, and thus its more pervasive usage, deserves special attention. This article adopts the perspective of Barquet et al. [26] on remanufacturing as an integrated system with its elements and complex set of relationships. Thus, this article studies how to expand remanufacturing activities, seen as a system, through PSS. This also contributes to increasing sustainability in manufacturing.

Service-oriented strategies in manufacturing

For some time now, profit margins from products are not the primary criterion for managers deciding which market to enter with what kind of customer offerings. The more significant profit margins have shifted away from the products, towards the services, one step closer to the customer. For instance, the cost of acquisitioning a train represents only 10% of the product life-cycle costs, while the other 90% represents train-related services [27]. However, the trend of services related to products is not new, although the term servitization was only coined in 1988. Two cases indicated by Schmenner [28] points to that. The first is the company Cyrus McCormick that manufactured reapers that, in the 1860s, were some of the most complex machines. They built an organization through which they reached farmers with services like sales, repair and also credit. The second case - that of Singer who produced a sewing machine that had no technical competitive advantage - still used the English manufacturing system but were nevertheless still the market leaders. This was due to a network of their own retail stores where sales and repairs were made, where inventories were kept, and where they demonstrated the sewing machine for customers. Thus, services in manufacturing were already impacting positively on their competitive advantage. The other mainstream in service-oriented strategies, in addition to servitization, is the PSS. It is a Scandinavian concept offering a promising avenue to achieve, or at least to increase, sustainable consumption and production and to improve the competitiveness of industrial manufacturers [29-31]. In referring to service-oriented strategies in manufacturing, there are various terms like servicizing [32], functional sales [33] and full-service contracts [34].

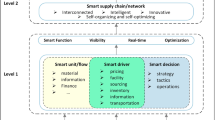

Servitization is the widest term employed to refer to service-oriented strategies. Thoben's [9] representation of four servitization levels will therefore be used. It is depicted as part of Figure 1 in the form of four blue and white circles, each one representing a single level of servitization. The first level deals with the pure product and does not include any services whatsoever (e.g. no warranty, no maintenance, no consultancy). The second includes services that support the product and can in some cases also generate revenues (e.g. warranty, maintenance), although the product still remains in the ownership of the customer. The third level adds services that enable a manufacturer to differentiate its product from others (e.g. drilling machine leasing). At this level, the product can remain the property of the manufacturer. In the last level, the product is still part of the offering, although it remains in the property of the manufacturer and its characteristics are not essential anymore to the consumer, as here only the functionality is sold and not the product (e.g. the manufacturer sells a constant temperature in a specific place and not the heating system or Hilti International's ‘pay per hole model’ [35]). This is the highest level of servitization that can be found in the literature and is referred to as a functional sale.

The application of the concept of servitization on remanufacturing. The figure depicts the application of servitization onto another part of the value chain, i.e. remanufacturing. Three main levels: the value chain (with remanufacturing), the servitization framework (with its four levels) and the output of conceptual simulation of servitizing remanufacturing (offered as a service) through four different servitization levels.

All servitization levels have in common is that they apply to the usage phase of the product, thus the benefits of the service-oriented approaches are intended solely for consumers that use the final products. However, the final product is not the only valuable and tradable resource in manufacturing enterprises and/or along the manufacturer's value chain. Those resources comprise tangible (e.g. a machine) and intangible (e.g. sales and distribution networks or specific competences) ones. Those hold certainly a certain added value. Thus, by applying servitization (as defined in Figure 1) onto high added value parts of the value chain, manufacturers are able to offer those parts as services (through different levels of servitization) to other business entities. Furthermore, the core product, around which servitization revolves, is not necessarily always a ‘pure’ product but can also be a ‘pure’ service. For instance, such a service that is offered through servitization can be constituted from formalized relations with different manufacturers with a set of predefined business terms (price, flexible delivery, etc.), which could be termed according to its function (e.g. sales, distribution or development channel) or its form (e.g. network, chain or system). This concept is called servitizing the manufacturer's value chain and was introduced by Opresnik et al. [11], however not yet applied on industrial cases. Nonetheless, this concept was identified in quickly growing innovative manufacturing enterprises; one is textile and the other in the automotive industry. The authors showed that a manufacturing enterprise, by servitizing a part of its value chain, can increase its competitive advantage. Furthermore, it can also increase the competitive advantage of the buyer (consumer) of the part of the value chain in question. Thus, the provider and consumer of the value chain both have benefits. Their business in both cases becomes harder to imitate, their offers become more personalized and both become more flexible on the market (i.e. the seller designed a new product by servitizing its supply chain, while the buyer can more quickly enter new knowledge-intensive markets with smaller risks).

In this article, remanufacturing as a specific part of the value chain is chosen, to which servitization is applied (Figure 1). The figure depicts three main levels: the value chain (with remanufacturing), the servitization framework (with its four levels) and the output of conceptual simulation of servitizing remanufacturing (offered as a service) through four different servitization levels. The four circles represent the four servitization levels that serve as the framework for the process of servitization, based on Thoben [9]. Till now, servitization has been applied during product usage (in Figure 1 depicted as in the value chain in the rectangle ‘Usage’) while, in the present case, servitization is applied to another part of the value chain, i.e. remanufacturing. In Figure 1, below the servitization framework, the value chain of a manufacturer is depicted together with the process of remanufacturing, based partially on Rathore et al. [36].

The next section provides the main methodological steps upon which the article is based and positions the article's theoretical contribution in the theory building process. Thus, the conceptual application is presented in two main steps. In the first, the impact of integrating remanufacturing into a manufacturing enterprise that is already servitizing; in the second, the impact of ‘remanufacturing as a service’ is analysed in relation to its competitive advantage. Finally, a discussion is offered, including new questions that have arisen as a consequence of this research.

Methods

The following section is divided into two main parts. In the first, the main research steps are defined. In the second part, the theory presented is positioned within the existing theory building process in the field of servitization and remanufacturing, in order to enable easier and more valid advancement of the overall theory.

Main research steps

Since applying servitization to a specific item on the manufacturer's value chain, in this case remanufacturing, is novel, much information is missing, and there are consequently many uncertainties. The lack of information and uncertainty presents the methodology of conceptual simulation as suitable to be applied in such case [37]. Conceptual simulation is based on three main steps: a) visualizing the situation, b) operating on the situation and c) observing what results, thus enabling causal reasoning [37]. Consequently, we have employed the methodology of conceptual simulation in three main steps. In the first, the impact of integrating remanufacturing into a manufacturing enterprise with a PSS in place is identified. This is based, among other factors, on a meta-analysis of published industrial cases and defines the state of the concept. In the second step, servitization is applied conceptually to a specific part of the value chain, i.e. remanufacturing. This step represents the execution of the application. The third step scrutinizes the impact of the operation on the competitive advantage of the provider and the consumer of such service, while indicating the advantages and risks arising. This is where causal reasoning is performed, based also on established theories from strategic management. Regardless of the fact that, in the first step, sound theories are employed and that, in the second step, the simulation is based on a meta-analysis of cases of manufacturing enterprises providing remanufacturing, the validity of the reasoning being reinforced using Resource-Based View (RBV) [38,39], the article is still presented on the conceptual level, although specific for remanufacturing.

In the first step, multiple industrial cases of remanufacturing are analysed through the lens of servitization. Where possible, all levels of servitization are used in order to identify the benefits that could arise from the collaboration of both strategies. The results are summarized in Table 1. In the second step, servitization of the manufacturer's value chain [11] will be applied to a specific part of the value chain - remanufacturing. The concept of servitizing the manufacturer's value chain has to be put into context in order to able to accept or refute the possibility of applying servitization on the value chain. The application has to depict the main circumstances, hence the contingencies. Thus, the characteristics of the part of the value chain that would be suitable for servitization should be the following:

-

The demand for those kinds of services is on the increase;

-

It should be highly knowledge intensive;

-

It should be complex to integrate into an existing business model; and

-

It should create high added value.

Remanufacturing is becoming more and more pervasive (depending on the industries) and relevant but highly complex to manage from operational and managerial perspectives. It thus constitutes a part of the value chain with extremely high added value. Thus, remanufacturing fits those criteria. In order to further increase the validity of the conceptual application, remanufacturing cases have been taken from the literature as the basis for applying the concept of servitization. The conceptual application is thus a step closer to a real industrial environment. In order to identify the impact of the servitization on a specific part of the value chain, some of the most prominent theories and perspectives from strategic management are used. Scrutinizing the impact of servitization through other research disciplines increases the possibility of identifying tensions, thus potentially leading to a more valid theory [40], which is a crucial objective in theory-building [41]. The impact within the field of strategic management will be observed through various lenses within the same field, using multiple theoretical foundations for competitive advantage, thus enabling the results to be meta-triangulated [42].

The main research steps that are undertaken in this article can be useful for managers of manufacturing enterprises needing to be able to exploit better the synergies between remanufacturing and servitization. The process of theory building in the field of servitization is presented in the following section, while positioning the theoretical contribution of this article.

Positioning within the process of theory development

The impact of the present study on the development of the theory of servitization and on remanufacturing is now presented. The impact of servitization is scrutinized through the theory-building process originating from Christensen [40]. He has depicted the process in a pyramid with four main stages of theory building. We populate this structure with the process of theory building for servitization. Described from the top of the pyramid towards the bottom, servitization is not yet a paradigm, since that would require that there are no phenomena within the known field of investigation that do not fall into this category [40], as also multiple perspectives are developed. In the second stage, servitization (as the term encompassing product-service-oriented strategies) could be categorized as a theory as, to some extent, it answers the following questions mandatory for a good theory - what causes what, why and under which circumstances [40]? Hence, it could be said that servitization, thus the integration of services into the customer offering, creates higher added value, as it can more precisely satisfy customers' needs. The third stage involves multiple categorization of servitization, as for the last stage, it refers to different types of studies available for servitization. However, a theory per se should not necessarily be accepted as being static. One of the primary purposes of the deductive process of the theory building cycle is to seek anomalies in theories, being the way how a theory is improved [15]. Thus, when observing the manufacturing industry, their strategic positioning and their competitive advantages, an anomaly was identified that the theory of servitization - is not able to explain directly. The theory never explicitly encompassed the possibility of servitizing anything other than the final product (in Figure 1, it is depicted as part of the ‘Usage’ phase) - although it did not refute it. Hence, by proposing the concept of servitizing the manufacturer's value chain [11], the process of theory building went from the top of the pyramid towards the bottom by noting the anomaly (details see in Figure 2). The research in this article proposes an improvement or extension of the application of the existing theory of servitization, thus going towards the top of the pyramid. However, in order to propose a valid improvement of an existing theory, its proposed application must be clear and sufficiently contingent upon statement of cause and effect [40]; otherwise, it is not falsifiable and cannot be improved or rejected.

Positioning of the contribution of this article within the theory of servitization. The figure depicts the process of theory building in servitization by proposing the application of servitization onto other parts of the value chain than the product. The process of theory building went from the top of the pyramid towards the bottom by noting the anomaly.

A review of the field of remanufacturing from the same structural perspective has to start somewhat differently, from the explicit needs of the manufacturing enterprises asking themselves how to make remanufacturing more profitable and/or how to introduce the process into their existing business model. This would place the topic of the research at the bottom of the pyramid, cycling up towards an attempt to propose a causality, thus having a theory at the end with predictive power. However, regardless of the fact that the theoretical development is positioned into a specific context, which is remanufacturing and substantiated by industrial cases from existing scientific publications, this research is still conceptual in its nature, though based on strong theoretical foundations and clear industrial needs and implications.

Conceptual application

Two main applications are performed. The first subsection studies the impact of integrating remanufacturing into a P-S-oriented manufacturing enterprise, relating to the first hypothesis. In the second subsection, the second application is undertaken, studying the impact of offering ‘remanufacturing as a service’. The second application can be seen as the logical continuation of the exploitation of a service-oriented strategy, which is seen in Figure 3. The following model positions all hypotheses within the evolvement of the service-oriented strategies adopted in this article. The initial status of a manufacturing enterprise is as a provider of P-S. In the first step, remanufacturing is integrated, as a way to create additional added value, based on the synergies arising with the PSS. In the second step, the manufacturing enterprise after establishing its own remanufacturing activities and acquiring the related capabilities, it offers those and any potential related infrastructure as a service to other manufacturing enterprises. This step increases the exploitation level of the newly obtained competences from remanufacturing, hence creating the possibility to additionally increase profitability with the existing set of resources (tangible and intangible).

Evolvement of the service-oriented strategies through remanufacturing. The following model positions all hypotheses within the evolvement of the service-oriented strategies adopted in this article. The initial status of a manufacturing enterprise is as a provider of P-S; in a second step remanufacturing is integrated, as a way to create additional added-value; while in the third step, the manufacturers offer remanufacturing as a service to other manufacturing enterprises.

Impact of integrating remanufacturing into enterprises provisioning P-S

This relevance is observed through the impact of remanufacturing on the PSS that is used to provision the P-S, resulting in improved performance indicators like cost efficiency, time to delivery or in P-S quality, customer satisfaction etc. The first level of servitization (pure product) is not part of this analysis, as it represents a pure product offering, without any services. Thus, this level is excluded. Published industrial use cases are used for the analysis.

The first case is that of photocopy machines described by Matsumoto and Umeda [43]. Fuji Xerox started remanufacturing in 1990s, and Ricoh and Canon began selling remanufactured machines ten years later. The price of such remanufactured photocopiers was smaller by 30% or even 50% than that of new products, and profits were larger than those from newly produced machines [43]. As photocopiers need frequent maintenance, such services are classified into the second level of servitization, i.e. offering supporting services like repair and classic maintenance. With a remanufacturing operation in place at this level of servitization, the costs of spare parts could decrease and hence increase customer satisfaction. Abdulrahman et al. [22], who rests on, among others, Hauser and Lund's report [44], describe how the reduced cost of raw materials, energy, manufacturing plants, equipment and extended product life cycles reduce the product price, in turn resulting in a larger customer base. Further on, Fuji Xerox products can be sold, guaranteeing a fixed price per copy from products/processes designed for remanufacturing [1]; in such case, the printers can be completely managed by the provider of the printers including cartridges, maintenance, optimization of use, security, governance, compliance and assuring cost savings as also having a positive environmental impact [45]. Such services, referred to as managed print services (MPS), enable a product to be produced in such way that it is differentiated from others, positioning it in the third servitization level, at which the product can remain in the ownership of the provider (e.g. leased, not sold) or can be part of a take-back program. Another study, also based on Fuji Xerox photocopiers, though in Australia [46], found that remanufacturing can reduce resource consumption and waste generation over the life cycle of the photocopier by up to a factor of 3, with greatest reductions if a product is designed for disassembly and remanufacturing. Thus, when providing MPS in the third servitization level, since the printer provider is motivated to increase the durability of its products, reducing maintenance costs and integrating remanufacturing would have a strong impact on reducing its operational costs throughout its life cycle and/or reducing the final product price (depending on the exact service provided). However, in the third servitization level, there is another possibility in relation to the MPS and remanufacturing, namely, the printer manufacturer could integrate its remanufacturing operations before offering MPS. In this situation, integrating MPS would mean to provide services at least at the third servitization level. This would make remanufacturing much more beneficial, as the manufacturer has a much greater motivation, than at lower servitization levels (e.g. basic maintenance), to reduce life-cycle costs. In the fourth and highest level of servitization, the manufacturer still owns the machine and provides only the functionality of the product (according, of course, to certain agreed specifications). The latter could be like those offered by MPS. At this level there is also the well-known formula referred to as ‘pay-per-print’, where the consumer pays for the actual use. At this level, the manufacturer bears all the product life cycle costs and is thus even more motivated to reduce them. Thus, on this level, remanufacturing gains an even greater relevance. Namely, the incentive to provide a certain functionality with minimized costs is even greater. Through remanufacturing, the manufacturer can increase its profit and/or increasing customer satisfaction by delivering a more reliable service with a higher level of quality. It was seen that the impact of remanufacturing clearly increases with the increase of the level of servitization. Thus, if remanufacturing activities are already in place, it would be sound to servitize the products through MPS or vice versa. If MPS is already in place, integrating remanufacturing would considerably reduce costs.

The next case is presented by Walsh [7] and deals with game consoles PlayStations. Sony Computer Entertainment Europe (SCEE) is responsible for sales, marketing, distribution and software development for the PlayStation® 2, PSP and PS3 video game and multimedia consoles. Warranty returns are also the responsibility of SCEE. As licensing fees to third party game developers are charged, it is in the interest of SCEE to have a maximum number of end users in order to attract game developers, making customer loyalty vital to the success of the product [7]. Thus, SCEE must offer a high level of quality of the supporting services in addition to their product (console). Basic warranty and maintenance services positions SCEE within the second servitization level. However, by introducing remanufacturing into their operations, SCEE was able to design the following service: when a defective unit is reported to SCEE and a pickup time is arranged for the unit, a remanufactured unit is offered to the customer in exchange for the cost of a service [7]. Consequently, the introduction of remanufacturing not only additionally reinforced customer satisfaction (i.e. minimized the time their customer remains without a working product) but also differentiated additionally their product by introducing this service, that represents also an additional revenue stream. Thus, through the introduction of remanufacturing, SCEE was able to increase customer satisfaction in a market where this indicator is vital, gaining an additional competitive advantage over its competitors.

The third case also comes from Walsh [7] and concerns Edwards Vacuum, one of the leading organisations in the world specialising in the design and manufacture of vacuum products for both general and semiconductor applications. This enterprise established its remanufacturing operations near its larger customers. Even a small downtime, caused in this case by loss of pumping capacity, can far outweigh the cost of repairing or replacing a pump, so the fabricator may opt for an on-site service team. Remanufacturing can play different roles in relation to the product; for instance, it can provide a temporary replacement in order to minimize downtime or as a new (remanufactured) product it decreases the product price for the buyer of the P-S. Hence, when remanufacturing is seen as a service, it is seen to increase customer satisfaction, by decreasing machine downtime and by decreasing costs of the final product (pump), while providing the same product characteristics and quality. The impact of remanufacturing is even more relevant here, where it is integrated into a business model in two ways. Remanufacturing thus enables the assortment of services supporting the product to be broadened, through remanufacturing.

The positive impact of remanufacturing increases throughout the increase of the servitization levels. Thus, at the latest level of servitization (i.e. product as a service, functional sale), the risks of providing the functionality lie completely on the P-S provider, as do the costs of providing it. This requires a fundamental shift not only in the revenue stream but also in the costs structure [47], where remanufacturing can play an important role. For example, the manufacturer has to bear all the costs of maintenance, so it is motivated to minimize the costs and at the same time to provide the widest possible range of services of the highest quality. Both objectives are accessible through remanufacturing which becomes a basis for an innovative paradigm shift in the manufacturing industry from selling physical products to supplying services [5]. The results from the analysis of the industrial cases that have already integrated remanufacturing into their operations are synthesized in Table 1. The first level of servitization is excluded from the analysis, as it is a pure product, while the other three servitization levels are included. The main benefits are categorized in two types of benefits, one is from the customers' perspective, while the other is from the P-S provider's perspective. The benefits from remanufacturing can be direct or indirect.

It can be seen from Table 1 that the higher the servitization level, the more manufacturers bear responsibility for the life-cycle costs. Remanufacturing is contributing considerably to reducing those costs. This analysis strongly indicates that, the higher the servitization level, the greater is the impact of remanufacturing. This benefit is on the side of the provider, who has the possibility of transferring part of this benefit to the consumer of the P-S for instance in the form of lower product, maintenance price, product reliability and/or wider service scope. As for the first level of servitization, i.e. the ‘pure’ product, manufacturing has a constant level of relevance. This relevance is higher at each succeeding level of servitization. The relevance of remanufacturing is highest in the last level of servitization, the fourth. The main limitation of this representation is that it assumes that the level of intensiveness within the servitization level increases linearly, although this increase is probably case- or industry-specific. Consequently, it can be deduced that the manufacturing enterprises that will servitize, the more relevant and beneficial it becomes for them to include remanufacturing.

The servitization of remanufacturing

The current section aims to analyse the sub-hypotheses H2/A and H2/B, thus studies the impact of offering remanufacturing (i.e. its related processes and competences) as a service to other manufacturers that already servitize and would like to increase their competitive advantage by evolving their current service-oriented strategy.

The application of the concept of servitization onto a part of the manufacturer's value chain is presented. The impact of remanufacturing on the competitive advantages of the provider and the consumer of such service is analysed. Risks that arise are emphasized.

Before commencing with the conceptual application, this paragraph depicts the starting situation. Remanufacturing comprises a very complex set of activities that have to be integrated into an enterprise. They provide considerable value to enterprises from an operational (e.g. patents for a flexible production, product redesign, special skills), and from a business perspective (i.e. how to integrate remanufacturing into an existing P-S business model). The provider and consumer of ‘remanufacturing as a service’ are first presented. The provider of remanufacturing as a service is a manufacturing enterprise that first has competences in servitization, secondly in remanufacturing and thirdly in exploiting synergy between the two. In order to offer remanufacturing as a service, the provider of such a service has to design it in a way that it can be offered to a new market. From a strategic point of view, the provider is trying to diversifying its business, creating a new revenue stream and entering a new market with high added value that is extremely knowledge-intensive. Offering such service is in line with the strategy of maximal exploitation of valuable internal resources. As for the consumer, buyer of remanufacturing as a service, it is an enterprise that has already servitized its products and is in search for a new basis for competitive advantage, where remanufacturing is one potential solution. Such an enterprise usually would like to move fast through markets, reducing the learning curve and reducing related risks to a minimum, while evolving its service-oriented strategy.

The conceptual application of remanufacturing as a service through all the four servitization levels, critical to H2/A and H2/B, is described as follows. In the first level of servitization, where only the product is present in the customer offering, remanufacturing constitutes a set of one-time activities, including a full (operational and business) or partial plan for integration (operational or business), without any further support. The entire risk, i.e. functionality, reliability and efficiency relies in the hand of the consumer of the service, and the ownership of the remanufacturing system passes over entirely to the consumer. In such case, it is a one-off transaction. In the second servitization level, services are aimed to support the product. Remanufacturing, although it is a service, represents also in this case the ‘product’ (as already explained, it is actually in this case the service of remanufacturing), the nexus of the offering, while its maintenance, optimisation and modularisation are supporting the service core. Thus, the ‘product’ is sold with some additional services, which can be either included in the price of the remanufacturing or offered separately; hence the ‘product’ represents the design and set-up of the remanufacturing service, while further optimisation and maintenance are supporting services. In the third level of servitization, the aim of new services is to differentiate the core offering, which is remanufacturing service. In this level, the ownership of the core offering remains in the hands of the manufacturer that provides remanufacturing. In this case, remanufacturing could be even set up for free (i.e. similar to the product model, that is not actually sold), but the provider of this service can be paid monthly with a fixed or variable amount that could depend on the actual savings achieved by the manufacturer based on using the remanufacturing system. This way, the consumer of remanufacturing as a service does not bear the risk of inefficiency, and the provider of the P-S is actually highly motivated to provide a viable business and operationally efficient solutions. This concept is similar to the energy retrofitting of buildings through the energy service company (ESCO) model, where the provider of the solution is paid according to the savings. As for the fourth servitization level, only the functionality of the product is provided - how it is provided is completely in the domain of the provider, only the result (functionality) is agreed upon. In this way, the functionality of the remanufacturing activities is provided. The consumer of the remanufacturing activities does not own the processes, infrastructure and business network tied to this set of activity but only pays for its use (e.g. per remanufactured piece). The risk lies in the hand of the provider of such service who, in this case, has a strong incentive to fully optimize the functionality of the service since, by creating savings; he can increase its profit. The entire remanufacturing service does not have to be offered as a functionality - only one part may be, for example the development of the network of recovering product cores. Otherwise, providing such a complete service would be to set up the recovery of the cores and its actual remanufacturing process. From the perspective of the consumer, this would mean a complete outsource of the remanufacturing activity.

The concept of servitizing the manufacturer's value chain has been exemplified through the context of remanufacturing. Its impact on the competitive advantage of both provider and consumer are presented, commencing with the former. According to Porter [48] there are two main determinants for relatively long-term performance – the operational effectiveness and the choice of strategic positioning or simply the choice of strategy. The latter defines which activities to perform and in what combinations [49], while operational effectiveness defines how efficiently those activities are performed. The provider, by providing a part of its value chain through servitization, partially changes its strategic positioning. Even though it cannot be said that such a provider is entering or even creating a completely new market, since consulting enterprises do already exist, it is nonetheless an unusual approach, creating new offerings and innovative markets. According to Mintzberg [50], the development of new environments is the role of the entrepreneur, which is the prime basis for economic development. From the perspective of the RBV, the provider develops and frames new, valuable resources to be offered onto the market. However, in the long-term, RBV predicts a competitive advantage only if the enterprises' resources have the following characteristics [51]: a) valuable, b) rare, c) imperfectly imitable and d) non-substitutable. Remanufacturing as a service meets the first three criteria, and is, to some extent, imitable, by consulting enterprises, that become competitors of the provider on this market. It can be concluded that servitizing this part of the value chain improves the competitive advantage of the provider. However, if remanufacturing represents a core element of the provider's basic strategy and if it is hard to imitate, then offering such a service to competitors could have negative consequences. This would be called coopetition, where two enterprises can compete and cooperate simultaneously [52]. In order to avoid that an enterprise offers its strategic resources, it must know very well what its core strengths and weaknesses are. The second risk could be to put too much emphasis on developing the new product and moving away too much from their core business, endangering their current competitive advantage, although, the change of core businesses and basis of competitive advantage is not always negative, as it was seen in the development case of Nokia.

The consumers of the service of remanufacturing will now be scrutinized. By the acquisition of such a service, the possibility of swiftly obtaining valuable, rare and difficultly imitable resources opens up to the consumers of services of remanufacturing. This will enable to make their own business as a whole even more hard to imitate, more efficient and thus more competitive. Furthermore, through the acquisition of such a service, new revenue streams can be created and operational costs lowered, while improving customer satisfaction. Consequently, their long-term competitive advantage is improved. Furthermore, the consumption of service enables also to jump market much more quickly and with smaller risks; for instance, a manufacturer can enter the market of remanufactured parts that was previously in the domain of third party enterprises. However, the impact of acquiring the service of remanufacturing is not without risks. The first risk deals with acquiring a part of the value chain, remanufacturing, that does not fit the current business model. This is referred to as strategic fit. The second risk is related to the lack of experience of the provider in the targeted industrial sector (e.g. the provider has experience in the automotive sector, while the targeted application is in the sector of consumer electronics).

In conclusion, the long-term competitive advantage of both the provider and consumer can increase through the application of servitization to remanufacturing, but both parties run risks that they have to manage carefully. The risk for the provider is highest at the highest servitization level (functional sale), while the risk for the consumer is highest at the first servitization level.

Discussion

Based on the results from both applications in the previous section, each in its independent sub-section, two things are seen. First, multiple synergies between remanufacturing and the PSS can be exploited. Secondly, offering remanufacturing as a service can considerably increase the long-term competitive advantage of the provider as well as the consumer of the service, although while encountering some risks.

The first application demonstrated the impact of integrating remanufacturing into a manufacturing enterprise that is already servitizing. Its integration was observed based on the changes inflicted on the PSS; through the PSS, the P-S is designed, manufactured, delivered and maintained. It has been concluded that the higher the level of servitization, the higher is the impact of remanufacturing on the PSS. Consequently, the first hypothesis is accepted. This indicates that a manufacturing enterprise that is remanufacturing should seriously consider the integration of a PSS and vice versa, the enterprise that is providing P-S should seriously review the possibility to integrate remanufacturing. Although the limitation has to be taken into account, this conclusion was based on a limited number of industrial cases. The synergies between remanufacturing and P-S were already introduced by Sundin [53], specifying that remanufacturing can constitute an essential part of, or even a condition for, economically and environmentally advantageous service selling. However, synergies exist also in the lower servitization levels (i.e. services to support the product and services to differentiate the product), that are extremely common in industry. Interestingly, remanufacturing can improve customer satisfaction (as expressed in Table 1) and can decrease the cost of provisioning the P-S. Remanufacturing has often been applied to spare parts and intermediate products but not to final products, which can partially explain the strong impact of remanufacturing on customer satisfaction through improved scope and quality of maintenance services. Table 1 depicts the impact of introducing remanufacturing in an enterprise with a PSS; however, the impact is bidirectional. When a manufacturing enterprise that already remanufactures starts providing P-S at the third or fourth servitization level, thus the product stays in the ownership of the P-S provider, he gains an open access to the ‘product's cores’ that represent a major challenge in remanufacturing [54]. Consequently, by starting servitizing, manufacturing enterprises can resolve this challenge. With regard to the characteristics of refurbishment, the results regarding relations with servitization would be similar. However, remanufacturing and refurbishment can also be applied separately or interchangeably.

Furthermore, it has been identified that, in relation to servitization, other motives for remanufacturing can arise for manufacturers - a wider service scope, higher service quality, a higher level of P-S adaptability and thus, higher customer satisfaction, which is also the nexus of servitization. Thus, although this is not the focus of this paper, it can be seen that P-S also makes a positive impact on encouraging remanufacturing activities. This would imply that, if a manufacturing enterprise only remanufactures but does not also servitize, multiple synergies are lost. Understandably, some products cannot be servitized more than on the second servitization level, but even so, remanufacturing still can bring a lot of benefits (e.g. service quality and scope). The most ideal product to servitize and to remanufacture would be one that is expensive, with high maintenance costs and has a long product life-cycle; such a product could be a specific type of a machine tool.

As a synthesized observation from the first application, remanufacturing makes a P-S strategy more competitive, since it:

-

Makes the PSS more sustainable in production (through lower needs for resources and energy);

-

Enables new and/or more reliable services to be set up;

-

Increases customer satisfaction, while decreasing costs;

-

Partially closes the product life-cycle loop, making the offering of product functionalities even more efficient.

In the second application, the impact of servitizing a specific part of the manufacturer's value chain, remanufacturing, was assessed. There are two main findings related to the second application. The first finding is that the application of servitizing remanufacturing activities can substantially increase the long-term competitive advantage of the provider. Such a provider develops specific competences when designing a remanufacturing system that exploits synergies with the existing PSS. Those competences and processes in turn represent a new and valuable resource for the manufacturing enterprise despite the fact that they are mostly of intangible nature. Their lack of tangibility does not infer a lack of relevance, since investments in intangible resources in the UK are estimated to have more than doubled between 1970 and 2004 [55], although, according to Zadrozny [56], management awareness about how to take advantage of intangible resources still remains surprisingly low. This is problematic, since it is the role of the strategy of an enterprise to identify the intangible resources that could form the basis for sustainable advantage [57]. From this perspective, servitization serves as a framework with which to review the best possible exploitation opportunities for such intangible resources. Consequently, there is a need for manufacturing enterprises to develop mechanisms for recognizing those parts along the value chain that are valuable and then applying the appropriate exploitation strategy. Nonetheless, there are various possible risks. The manufacturer could risk making public a core part of its value chain that, until then, could not have been imitated by competitors. The provider of such a service would therefore have to define clear limits to what is defined by the ‘service’, in such way that it does not reveal the strategic core related to this set of activity.

The second finding states that the long-term competitive advantage of the consumer of such a service can also be increased through the acquisition or consumption of such a servitized part of the value chain. This is due to the ability to rapidly set up a knowledge-intensive (at the operational and managerial levels) activity through which new synergies can be created in the core business. Furthermore, this enables manufacturing enterprises that were not previously able to servitize their products (e.g. spare part manufacturer) to now use the concept of servitization, however not on their core product (e.g. fuel pump), but onto their value chain, in this case remanufacturing. Consequently, the servitization framework and its related strategies can be seen as a framework for transferring a structured set of competences to other enterprises, thus making intangible resources transferrable. In the case of integrating remanufacturing, such enterprise can enter new markets with smaller risks and quicker.

Both presented applications had not only managerial implications but also theoretical. Namely, the possibility to apply servitization to other parts of the value chain, besides the final product, was the theoretical anomaly discovered already in Opresnik et al. [11] and visible in Figure 2. The applications analysing the impact of remanufacturing and then the possibility to offer this as a service were steps undertaken with the aim to try to extend the application of the theory of servitization. The feasibility of servitizing a part of the value chain was seen to be conceptually valid. More exactly, this means that the proposal has been conceptually verified, but not validated through industrial application. Hence, we cannot talk about ‘real’ validation, because this would demand further investigations. If the findings from this article will be found valid in future researches, it would indicate that the theory of servitization was enriched by applying to other parts of the value chain then the product (for details, see Figure 2).

Finally, another synergy between remanufacturing and PSS has been identified. Remanufacturing is a kind of sustainability initiative (from an environmental perspective at least), and its business benefits are strongly reinforced when products are servitized. This means that servitization contributes considerably in making a sound business case for sustainability initiatives. This contribution becomes more relevant the higher the servitization level. Such a relation is quite natural, since the third and, especially, the fourth servitization levels (where the product actually remains in the ownership of the manufacturer, who has to take care of all the costs throughout the product life-cycle) force the manufacturer to adopt a life-cycle perspective over the product. Hence, the costs during this time are born by the manufacturer, creating a strong incentive to optimize all processes, which is done in this article through remanufacturing. Thus, for manufacturing enterprises that are already servitized, remanufacturing represents an excellent example of such synergies. However, further research is needed to identify in which industries those effects are the strongest.

Although this article proposed answers to the introduced hypotheses, it opened even more questions leaning towards operationalization of the concept. The questions are the following:

-

How to identify which part of the value chain to offer through servitization?

-

How to delineate the core part of the ‘product’ that will be offered, so not to reveal the strategic core of its primary business? The response is most certainly multi-layered, for instance taking into consideration the maturity of the industry, the level of technological advancement, the position of the provider of the service in the market (leader, niche innovator etc.).

-

How can a consumer of a servitized part of the value chain trust the provider? Trust can be a barrier, especially if the provider can be seen as a competitor. For that purpose, the concept of business ecosystems are set up, with the aim of increasing trust and knowledge sharing, among others, by setting clear IP rules.

The final question that arose in this article is the following. Are the synergies created between PSS and remanufacturing and the additional benefits created from providing or consuming remanufacturing as a service strong enough to disrupt the classical idea or business model to sell as much products as possible, which is not being adequate in terms of sustainability? Thus, does the proposed approach in this article represent a potential solution or mean to the need of carefully revising such (unsustainable) models [58]? Namely, from the synergies of remanufacturing and PSS arise the benefit of increased customer satisfaction and/or reduced operational costs. While from providing the remanufacturing as a service, additional revenue stream that is sustainable (from the environmental perspective) is created. While consuming such service, it enables the manufacturer to obtain access to the first set of synergies described, as also to enter into new markets (e.g. market of used parts). Are the visible impacts sufficient to develop models that could stipulate more sustainable consumption and production?

To synthesize, the manufacturing enterprises that servitize their business, should strongly consider the integration of remanufacturing. Secondly, as the number of enterprises that servitize is increasing around the world, this means that the market for offering remanufacturing as a service is also developing itself.

Conclusion

An important share of manufacturing enterprises is already servitizing, which is slowly making their additional competitive advantage fading away, thus awakening the need to evolve the servitization strategy further. In this article, such a development path was proposed, based on the concept of servitizing the manufacturer's value chain, being in this case remanufacturing, as a knowledge intensive part of the value chain. Its use is becoming more and more pervasive, but still presents operational and managerial challenges to manufacturing enterprises. To test the applicability and impact of applying servitization (through all four levels) on remanufacturing, the methodology of conceptual simulation was employed. At first, it was scrutinized whether remanufacturing has a positive impact on the PSS, since otherwise a proposal to servitize remanufacturing to manufacturing enterprises would not make sense. The results show that considerable synergy is achieved by integrating remanufacturing into an existing PSS, but through all the servitization levels and not just in the last one, i.e. functional sale. The two most significant benefits were shown to be increased customer satisfaction and lowered operational costs related to the P-S provision. Furthermore, the higher the servitization level, the greater the benefits arising from the synergy between remanufacturing and PSS are. The main incentives for remanufacturing are long-term economic and environmental. When remanufacturing is integrated into an enterprise with PSS, the economic incentives become much stronger. The business case for remanufacturing has, therefore, been strongly reinforced because of the way products are offered to customers, through servitization. Thus, this reinforcement is amplified, through the increase of the servitization level.

Secondly, the impact of servitizing remanufacturing activities through all four servitization levels has been analysed. The impact on both partakers (provider and consumer of remanufacturing activities) was positive, and it was found that both could increase their long-term competitive advantage while, however, encountering certain risks. The higher the servitization level, the more risk was born by the provider of the service of remanufacturing. Although of conceptual nature, the paper is based on established theories of servitization, remanufacturing and competitive advantage. Furthermore, examples from journal-based industrial cases based on meta-analysis were used. The results are relevant for managers of manufacturing enterprises that already recognize the value of servitization as also its limitations. It is proposed that remanufacturing should first be integrated, and then offered as a service. Finally, it is concluded that the application of servitization strategy should be extended onto the value chain, as well as the final product. Real industrial validation is still needed, while also conceptual application on other parts of the value chain.

Abbreviations

- MPS:

-

managed print services

- P-S:

-

product-service

- PSS:

-

product-service system

- RBV:

-

Resource-Based View

References

Baines, TS, Lightfoot, HW, Evans, S, Neely, A, Greenough, R, Peppard, J, Roy, R, Shehab, E, Braganza, A, Tiwari, A, Alcock, JR, Angus, JP, Bastl, M, Cousens, A, Irving, P, Johnson, M, Kingston, J, Lockett, H, Martinez, V, Michele, P, Tranfield, D, Walton, IM, Wilson, H: State-of-the-art in product-service systems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 221, 1543–1552 (2007)

Vandermerwe, S, Rada, J: Servitization of business: adding value by adding services. Eur. Manag. J. 6, 314–324 (1988)

Santamaría, L, Jesús Nieto, M, Miles, I: Service innovation in manufacturing firms: evidence from Spain. Technovation 32, 144–155 (2012)

Ijomah, WL: Addressing decision making for remanufacturing operations and design-for-remanufacture. Int. J. Sustain. Eng. 2, 91–102 (2009)

Sundin, E, Bras, B: Making functional sales environmentally and economically beneficial through product remanufacturing. J. Clean. Prod. 13, 913–925 (2005)

Rosamond, E: The application of product services system in remanufacturing activities. In: IMS2020-Proceedings from the IMS2020 Summer School on Sustainanable Manufacturing (2010)

Walsh, B: {PSS} for product life extension through remanufacturing. In: CIRP IPS2 Conference. pp. 261–268. Linköping (2010)

Sundin, E, Bjorkman, M, Jacobsson, N: Analysis of service selling and design for remanufacturing. In: Proc {IEEE} Int Symp Electron Environ, pp. 272–277. (2000)

Thoben, K-D, Eschenbächer, J, Jagdev, H: Extended products: evolving traditional product concepts. In: 7th Int Conf Concurr Enterprising Bremen. (2001)

Sakao, T, Mizuyama, H: Understanding of a product/service system design: a holistic approach to support design for remanufacturing. J. Remanufacturing 4, 1 (2014)

Opresnik, D, Zanetti, C, Taisch, M: Servitization of the manufacturer's value chain. In: Prabhu, V, Taisch, M, Kiritsis, D (eds.) Advances in Production Management Systems. Sustainable Production and Service Supply Chains. IFIP Advances in Information and Communication Technology, pp. 234–241. Springer, Berlin Heidelberg (2013)

Vargo, SL, Lusch, RF: From goods to service(s): divergences and convergences of logics. Ind. Mark. Manag. 37, 254–259 (2008)

Lusch, RF, Vargo, SL, O'Brien, M: Competing through service: insights from service-dominant logic. J. Retail. 83, 5–18 (2007)

Vargo, SL, Lusch, RF: Evolving to a new dominant logic for marketing. J. Mar. Sci. 68, 1–17 (2004)

Christensen, CM: The ongoing process of building a theory of disruption. J. Prod. Innov. Manag. 23, 39–55 (2006)

Bernard, S: Remanufacturing. J. Environ. Econ. Manage. 62, 337–351 (2011)

Fiksel, J: A systems view of sustainability: the triple value model. In: Sustainable Futures: Multi-Disciplinary Perspectives on Multi-Level Transitions, 2nd edn, pp. 138–141. (2012)

Cat® Reman Products - Sustainability [http://parts.cat.com/en/catcorp/cat-reman-products] (accessed 5.20.2015)

Bulmus, SC, Zhu, SX, Teunter, R: Competition for cores in remanufacturing. Eur. J. Oper. Res. 233, 105–113 (2014)

Guide Jr, VDR: Production planning and control for remanufacturing: industry practice and research needs. J. Oper. Manag. 18, 467–483 (2000)

Giutini, R, Gaudette, K: Remanufacturing: the next great opportunity for boosting US productivity. Bus. Horiz. 46, 41–48 (2003)

Abdulrahman, MD-A, Subramanian, N, Liu, C, Shu, C: Viability of remanufacturing practice: a strategic decision making framework for Chinese auto-parts companies. Journal of Cleaner Production, 1–13 (2014). doi:10.1016/j.jclepro.2014.02.065 IN PRESS

Sundin, E, Dunbäck, O: Reverse logistics challenges in remanufacturing of automotive mechatronic devices. J. Remanufacturing 3, 1–8 (2013)

Östlin, J, Sundin, E, Björkman, M: Importance of closed-loop supply chain relationships for product remanufacturing. Institutional. Perspect. Supply. Chain. Manag. 115, 336–348 (2008)

Butler, P: Machine Tools: A Report on the Remanufacture of Manual and CNC Tooling Machinery in the UK. Centre for Remanufacturing and Reuse, UK (2006)

Barquet, AP, Rozenfeld, H, Forcellini, FA: An integrated approach to remanufacturing: model of a remanufacturing system. J Remanufacturing 3, 1 (2013)

Wise, R, Baumgartner, P: Go downstream. Harv. Bus. Rev. 77, 133–141 (1999)

Schmenner, RW: Manufacturing, service, and their integration: some history and theory. Int. J. Oper. Prod. Manag. 29, 431–443 (2009)

Goedkoop, MJ, te Riele, HRM, Rommens, PJM: Product Service Systems, Ecological and Economic Basics. Report for Dutch Ministries of Environment (VROM) and Economic Affairs (EZ). PricewaterhouseCoopers NV/Pi!MC, Storrm CS/PRé consultants (1999)

Tukker, A, Tischner, U: Product-services as a research field: past, present and future. Reflections from a decade of research. J. Clean. Prod. 14, 1552–1556 (2006)

Tukker, A: Eight types of product-service system: eight ways to sustainability? Experiences from {SusProNet}. Bus. Strateg. Environ. 13, 246–260 (2004)

Rothenberg, S: Sustainability through servicizing. MIT SLoan. Management. Review. 48, 83–89 (2007)

Markeset, T, Kumar, U: Product support strategy: conventional versus functional products. J. Qual. Maint. Eng. 11, 53–67 (2005)

Stremersch, S, Wuyts, S, Frambach, RT: The purchasing of full-service contracts. Ind. Mark. Manag. 30, 1–12 (2001)

Reinartz, W, Ulaga, W: How to sell services more profitably. Harv. Bus. Rev. 86, 91–96 (2008)

Rathore, P, Kota, S, Chakrabarti, A: Sustainability through remanufacturing in India: a case study on mobile handsets. J. Clean. Prod. 19, 1709–1722 (2011)

Trickett, SB: Trafton, JG: {“What} if…”: the use of conceptual simulations in scientific reasoning. Cogn. Sci. 31, 843–875 (2007)

Peteraf, MA: The cornerstones of competitive advantage: a resource-based view. Strateg. Manag. J. 14, 179–191 (1993)

Wernerfelt, B: A resource-based view of the firm. Strateg. Manag. J. 5, 171–180 (1984)

Christensen, CM: The ongoing process of building a theory of disruption. J. Prod. Innovat. Manag. 23(1), 39–55 (2006)

Yin, RK: Case Study Research: Design and Methods. Volume 5. Sage (2009)

Lewis, MW, Grimes, AJ: Metatriangulation: building theory from multiple paradigms. Acad. Manag. Rev. 24, 672 (1999)

Matsumoto, M, Umeda, Y: An analysis of remanufacturing practices in Japan. J. Remanufacturing. 1, 1–11 (2011)

Hauser, WM, Lund, RT: The Remanufacturing Industry: Anatomy of a Giant: A View of Remanufacturing in America Based on a Comprehensive Survey Across the Industry, p. 165. (2003)

Managed Print Service Solutions - Xerox [http://services.xerox.com/managed-print-services/managed-print-service-solutions/enus.html], accessed: 7.5.2014

Kerr, W, Ryan, C: Eco-efficiency gains from remanufacturing. J. Clean. Prod. 9, 75–81 (2001)

Johnson, MW, Christensen, CM, Kagermann, H: Reinventing your business model. Harv. Bus. Rev. 86(12), 57–68 (2008). Harvard Business Publishing.

Porter, ME, Kramer, MR: The competitive advantage of corporate philanthropy. Harv. Bus. Rev. 80, 56–68 (2002)

Porter, ME: What is strategy? Harv. Bus. Rev. 57(2), 61–78 (1996)

Mintzberg, H: The strategy concept 1: five P's for strategy. Calif. Manag. Rev. 30(1), 11–24 (1987). Berkley.

Barney, J: Firm resources and sustained competitive advantage. J. Air Waste Manage. Assoc. 17, 99–120 (1991)

Nalebuff, BJ, Brandenburger, A: Co-Opetition. Harper Collins. Business, New York (1996)

Sundin, E, Bjorkman, M, Jacobsson, N: Analysis of service selling and design for remanufacturing. In Electronics and the Environment, 2000. ISEE 2000. Proceedings of the 2000 IEEE International Symposium on (pp. 272–277). IEEE, San Francisco

Östlin, J, Sundin, E, Björkman, M: Product life-cycle implications for remanufacturing strategies. Journal of Cleaner Production 17, 999–1009 (2009)

OECD: New sources of growth: intangible assets. OECD. http://www.oecd.org/sti/inno/46349020.pdf. Accessed 15 May 2014.

Zadrozny, W: Leveraging the power of intangible assets. MIT Sloan. Manag. Rev. 48, 85–91 (2006)

Hall, R: A framework linking intangible resources and capabilities to sustainable competitive advantage. Strateg. Manag. J. 14, 607–618 (1993)

Garetti, M, Taisch, M: Sustainable manufacturing: trends and research challenges. Prod. Plan. Control. 23, 83–104 (2012)

Acknowledgements

This work has been partly funded by the European Commission through the FoF-ICT Project MSEE: Manufacturing SErvice Ecosystem (No. 284860).

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

DO and MT conceptualized the application of servitizing the value chain on the case of remanufacturing and designed in detail the application. D.O. prepared the drafted manuscript. Both authors reviewed critically the manuscript and gave the final approval of the version to be published.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0), which permits use, duplication, adaptation, distribution, and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Opresnik, D., Taisch, M. The manufacturer's value chain as a service - the case of remanufacturing. Jnl Remanufactur 5, 2 (2015). https://doi.org/10.1186/s13243-015-0011-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13243-015-0011-x