Abstract

Background

The alginate oligosaccharides have been widely used in agriculture, medicine, and food industries due to their versatile physiological functions such as antioxidant, anticoagulant, and antineoplastic activities. The bifunctional alginate lyases can degrade the alginate polysaccharide more efficiently into alginate oligosaccharides. Therefore, it is crucial to discover new bifunctional alginate lyase for alginate oligosaccharide production.

Results

Herein, a novel bifunctional alginate lyase FsAlgB was cloned and identified from deep-sea bacterium Flammeovirga sp. NJ-04, which exhibited broad substrate specificity and the highest activity (1760.8 U/mg) at pH 8.0 and 40 °C. Furthermore, the Km values of FsAlgB towards polyG (0.69 mM) and polyMG (0.92 mM) were lower than that towards sodium alginate (1.28 mM) and polyM (2.06 mM). Recombinant FsAlgB was further characterized as an endolytic alginate lyase, and it can recognize the tetrasaccharide as the minimal substrate and cleave the glycosidic bonds between the subsites of − 3 and + 1.

Conclusion

This study provided extended insights into the substrate recognition and degrading pattern of alginate lyases with broad substrate specificity.

Similar content being viewed by others

Background

Alginate is the main component of the cell wall of brown algae such as Laminaria japonica [1]. It is a linear acidic polysaccharide consisting of β-d-mannuronate (M) and its C5 epimer α-l-guluronate (G). These units are arranged into three different kinds of blocks, namely poly β-d-mannuronate (polyM), poly α-l-guluronate (polyG) and the heteropolymer (polyMG) [2]. As the most abundant marine biomass and low-cost material, alginate has been widely used in food and medical industries due to its favorable chemical properties and versatile activities. Insufficiently, the applications of this linear polysaccharide have been greatly limited due to its high molecular weight and low bioavailability. Recently, the degradation products of alginate, namely the alginate oligosaccharides, have attracted increasing attention due to their biological activities and excellent solubility. For instance, they have been widely used as plant growth accelerators, anticoagulants, and tumor inhibitors due to their versatile physiological functions such as antioxidant, anticoagulant, and antineoplastic activities [3,4,5]. Moreover, they can also regulate the blood sugar and lipid content [6]. As a result, it is more promising to prepare the functional oligosaccharides by utilizing the abundant polysaccharides.

Alginate lyase and can degrade alginate into unsaturated oligosaccharides by β-elimination [7]. On the basis of their substrate specificities, alginate lyase can be classified into G block-specific lyase (polyG lyase, EC4.2.2.11) and M block-specific lyase (polyM lyase, EC4.2.2.3) [8]. While according to the mode of action, it can be sorted into endolytic and exolytic ones [9]. Endolytic enzymes can recognize and cleave glycosidic bonds inside alginate polymers with unsaturated oligosaccharides (such as di-, tri-, and tetra-saccharides) as main products [10], while exolytic ones can further degrade oligosaccharides into monomers [11]. In addition, according to protein sequence similarity, alginate lyases are organized into the PL-5, 6, 7, 14, 15, 17, and 18 families (http://www.cazy.org/fam/acc_PL.html) [12].

So far, alginate lyases have been widely used to elucidating fine structures of the alginate and prepare protoplast [13, 14]. Moreover, it also shows great potential in treating cystic fibrosis by degrading the polysaccharide biofilm of pathogen bacterium such as Pseudomonas aeruginosa [15, 16].

In this study, we cloned and identified a novel bifunctional alginate lyase of PL7 family FsAlgB. Like most of alginate lyases of PL 7 family, it can degrade alginate into oligosaccharides in an endolytic manner [17]. It is reported that the A1-II′ from Sphingomonas sp. A1, a member of PL 7 family, displays a β-sandwich jelly roll-fold, and can bind tetrasaccharide as its minimal substrate and hydrolyzed it into disaccharide and trisaccharide. The structure of A1-II′ complexed with tetrasaccharide indicated that Gln189 and Arg146 act as a neutralizer for the substrate carboxyl group, His191 as a general base, and Tyr284 as a general acid [18]. However, the substrate degradation mode of PL 7 family enzymes is still unclear. The Flammeovirga sp. NJ-04 is an alginate-degrading bacterium isolated from deep-sea area and a gene cluster for degrading alginate has been identified [19]. In this paper, the degradation mode of FsAlgB was discussed, and the biochemical characteristics, action mode, and product analysis were also studied.

Methods

Materials and strains

Sodium alginate from Macrosystis pyrifera (M/G ratio 77/23) was purchased from Sigma-Aldrich (viscosity ≥ 2000 Cp, St. Louis, MO, USA). PolyM and polyG (purity: about 95%; M/G ratio: 97/3 and 3/97; average degree of depolymerization (DP): 39; average molecular weight: 7200 Da) were purchased from Qingdao BZ Oligo Biotech Co., Ltd (Qingdao, China). PolyMG (M/G ratio 48/52, average DP: 50, and average molecular weight: 8000 Da) was donated by the bioengineering group of our college. Marine bacterium Flammeovirga sp. NJ-04 was previously isolated from South China Sea and conserved in our laboratory [20]. Escherichia coli DH5α was used for plasmid construction, and E. coli BL21 (DE3) was used for gene expression. These two strains were grown in Luria–Bertani (LB) broth or on LB broth agar plates (LB broth supplemented with 1.5% agar) containing 100 μg/mL ampicillin.

Sequence analysis

The conserved domains of FsAlgB were predicted using the InterProScan 4 running the HMM Pfam application (http://www.ebi.ac.uk/Tools/pfa/iprscan/). The homology protein sequence was performed with NTI vector. The phylogenetic tree was constructed based on related alginate lyase protein sequences of PL 7 family using Molecular Evolutionary Genetics Analysis (MEGA) Program version 6.0. The homology modeling and docking was built by Protein Homology/analogY Recognition Engine V 2.0.

Expression and purification of FsAlgB

As previously reported, the strain Flammeovirga sp. NJ-04 was identified to be close to Flammeovirga sp. OC4 [20]. Therefore, the primers for cloning FsAlgB were designed on the basis of sequence of putative alginate lyase gene sequence (WP_044204802.1) within the genome of Flammeovirga sp. OC4. The FsAlgB gene was amplified with primers designed as follows: the forward primer: 5′-GGCCATATGATGAACAGACTTTTTACTTT-3′ and the reverse primer: 5′-GGCCTCGAGTTGATGTGTTACCGACAAGT-3′ from the genomic DNA of Flammeovirga sp. NJ-04.

The alginate lyase gene was subcloned and ligated into pET-21a (+) expression vector. The recombinant E. coli BL21 (DE3) harboring the pET-21a (+)/FsAlgB was cultured in an LB medium (containing 100 μg ampicillin/mL) for 2–3 h with shaking at 200 rpm and 37 °C up to an OD600 of 0.4–0.6. The cells were induced by adding 0.1 mM IPTG and then cultured at 20 °C for 30 h. The purification of FsAlgB was carried out as previously described as follows [20]. The cell homogenate containing the recombinant protein was loaded onto Ni–NTA Sepharose column (GE Healthcare, Uppsala, Sweden) equilibrated with lysis buffer. The column was washed with wash buffer [50 mM Tris-HCl (pH 8.0), 300 mM NaCl, and 20 mM imidazole], and the recombinant enzyme was eluted with elution buffer [50 mM Tris-HCl (pH 8.0), 300 mM NaCl, and 300 mM imidazole]. The active fraction was collected and desalted using HiTrap™ desalting column (Amersham Biosciences, Buckinghamshire, UK) and then analyzed by 12% sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE).

Substrate specificity and enzymatic kinetics

The activity of FsAlgB was determined according to the ultraviolet absorption method described by Inoue [21]. The reaction system was constructed as follows: the purified enzyme (0.1 mL 50 mM Tris-HCl buffer of pH 8.0 containing 0.042 mg of enzyme) was mixed with 0.9 mL substrate in 50 mM Tris-HCl buffer with 1% sodium alginate (pH 8.0) and the mixture was incubated at 40 °C for 10 min. The reaction was stopped by heating in boiling water for 10 min. The enzyme activity was then determined by measuring the increased absorbance at 235 nm. One unit was defined as the amount of enzyme required to increase the absorbance at 235 nm by 0.1 per min. Each experiment consisted of three replicates. In addition, the protein concentrations were determined by a protein quantitative analysis kit (Beyotime Institute of Biotechnology, Nantong, China).

To investigate the substrate specificity, the purified FsAlgB (~ 0.19 ng) in 1 mL of 50 mM Tris-HCl buffer of pH 8.0 was reacted with 1% of sodium alginate, polyMG, polyM, and polyG, respectively. The assay of enzyme activity was defined as described previously. The kinetic parameters of the FsAlgB towards these four kinds of substrates were determined by measuring the enzyme activity with substrates at different concentrations (0.1–8.0 mg/mL). The concentrations of the substrates and velocity (V) were calculated as previously reported [20]. The concentrations of the product were determined by monitoring the increase in absorbance at 235 nm using the extinction coefficient of 6150 M−1 cm−1. Velocity (V) at the tested substrate concentration was calculated as follows: V (mol/s) = (milliAU/min × min/60 s × AU/1000 milliAU × 1 cm)/(6150 M−1 cm−1) × (2 × 10−4 L). The Km and Vmax values were calculated by hyperbolic regression analysis as previously described [22, 23]. The turnover number (kcat) of the enzyme was calculated by the ratio of Vmax versus enzyme concentration ([E]). Each experiment consisted of three replicates.

Biochemical characterization of FsAlgB

The effects of temperatures (20–80 °C) on the purified FsAlgB in 50 mM Tris-HCl buffer of pH 8.0 were investigated at pH 8.0. The thermal stability of the enzyme was determined under the standard assay conditions after incubating the purified FsAlgB at 20–80 °C for 30 min. In addition, the thermally induced denaturation was also investigated by measuring the residual activity after incubating the enzyme at 20–40 °C for 0–180 min. The effects of pH on the enzyme activity of FsAlgB were evaluated by incubating the purified enzyme in buffers with different pH (4.0–11.0) under the standard conditions. The buffers with different pHs used are 50 mM phosphate citrate (pH 4.0–5.0), 50 mM NaH2PO4-Na2HPO4 (pH 6.0–8.0), 50 mM Tris-HCl (pH 7.0–9.0), and glycine-NaOH (pH 9.0–10.0). The pH stability was characterized by determining the residual activity after the enzyme was incubated in buffers with different pH (4.0–11.0) for 24 h. Each experiment consisted of three replicates.

The influences of metal ions on the activity of FsAlgB were performed by incubating the purified enzyme in 50 mM Tris-HCl buffer of pH 8.0 at 4 °C for 24 h in the presence of various metal compounds with a final concentration of 1 mM. Then, the activity was measured under standard conditions and the reaction mixture without any metal ion was taken as 100%. The effects of NaCl on enzyme activity of FsAlgB were measured in buffers with different concentrations of NaCl (0–800 mM) and the maximal enzyme activity served as control. Each experiment consisted of three replicates.

Action pattern and degradation product analysis

To determine the smallest substrate and identify the number of substrate-binding subsites of FsAlgB, hydrolysis reactions (10 μL reaction mixture) were performed at 40 °C for 24 h using FsAlgB in 50 mM Tris-HCl buffer of pH 8.0 and oligosaccharides (10 mg/mL) with different DPs (DP2–8). The degradation products were analyzed by ESI-MS in a positive-ion mode using the following settings: ion source voltage, 4.5 kV; capillary temperature, 275–300 °C; Tube lens, 250 V; sheath gas, 30 arbitrary units (AU); scanning mass range, 150–2000 m/z.

To determine the cleavage selectivity of the enzyme, the ESI-MS was used to analyze the degradation products in the hydrolysis procedure of FsAlgB toward sodium alginate, polyMG, polyM, and polyG, respectively. The reaction mixtures (800 μL containing 1 μg purified enzyme and 2 mg substrates) were incubated at 40 °C for 72 h. Then, the mixtures were centrifuged at 8000g rpm for 10 min to remove the undissolved materials. In addition, the hydrolysates were loaded onto a carbograph column (Alltech, Grace Davison Discovery Sciences, United Kingdom) to remove salts, and then, the eluate was concentrated, dried and re-dissolved in 1 mL methanol. The degradation products were then analyzed by TLC plate as previously reported [20]. In brief, the degradation products were developed by TLC plate (TLC silica gel 60 F254, Merck KGaA, Darmstadt, Germany) with the solvent system (1-butanol/acetic acid/water 3:2:3) and visualized by heating TLC plate at 130 °C for 5 min after spraying with 10% (v/v) sulfuric acid in ethanol. The ESI-MS was also employed to determine the composition of the hydrolysates using analysis conditions as described above.

Molecular modeling and docking analysis

The three-dimensional structure of FsAlgB was constructed using Protein Homology/analogY Recognition Engine V 2.0 on the basis of homologues of known structure (alginate lyase A1-II′ from Sphingomonas sp. A1 with PDB ID: 2ZAB) with sequence similarity of 39%. The molecular docking of the FsAlgB and tetrasaccharide (GGGG) was performed using MOE (Molecular Operating Environment, Chemical Computing Group Inc., Montreal, Canada). The ligand-binding sites were defined using the bound ligand in the crystal structures. PyMOL (http://www.pymol.org) was used to visualize and analyze the modeled structure and to construct graphical presentations and illustrative figures.

Results

Sequence analysis of the alginate lyase gene

The gene FsAlgB was cloned and sequenced (accession number: MG063276). As shown in Additional file 1: Figure S1, the open reading frame (ORF) of FsAlgB consists of 900 bp and encodes a putative alginate lyase composed of 299 amino acids with a theoretical molecular mass of 34.50 kDa. According to the conserved domain analysis, FsAlgB possesses only a C-terminal catalytic domain consisting of 231 amino acids (Thr54–Glu284).

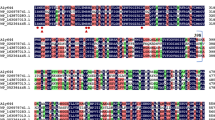

As shown in Fig. 1, FsAlgB shares the highest identity of 65% with FsAlgA from the same strain Flammeovirga sp. NJ-04 (GenBank accession no. ASA33934.1) [20] and exhibits rare similarity with the other characterized alginate lyases, which indicates that FsAlgB is a novel alginate lyase of PL 7. According to the analysis of amino acid sequence, FsAlgB contains the conserved regions such as “PRT/V/SELRE”, “YFKA/VGN/VY”, and “QIH” (as marked in Fig. 1), which contribute to the substrate binding and catalytic activity [18]. These conserved amino acid residues are all located in strand A3, A4, and A5 (as shown in Fig. 1), which is similar with the other alginate lyase of PL 7 family [18]. It has been reported that G block- and M block-degrading enzymes contain QIH and QVH in the conserved region, indicating that the amino acid residue I may recognize the polyG block or MG block [24]. To further determine the subfamily of FsAlgB, the phylogenetic tree (using the full-length sequence of FsAlgB) was constructed based on to compare the sequence homology (Fig. 2). It can be observed that FsAlgB clusters with representative enzymes of subfamily 3, and thus, FsAlgB is a member of the subfamily 3 alginate lyases.

Multiple amino acid sequence alignment of FsAlgB and other alginate lyases of PL 7 family: AlyA (AAA25049) from Klebsiella pneumoniae subsp. Aerogenes, AlyA5 (CAZ96266) from Zobellia galactanivorans DsiJT, PA1167 (AAG04556) from Pseudomonas aeruginosa PAO1, AlyPG (BAA83339) from Corynebacterium sp. ALY-1, AlyA1 (CAZ95239) from Zobellia galactanivorans DsiJT, and A1-II′ (BAD16656) from Sphingomonas sp. A1. Identical and similar amino acid residues among the alginate lyases are shaded in yellow. The locations of three conserved regions are marked and the key amino acid “I” is marked with red star. SA3-5 indicated the common strands located in the sequence alignments

Phylogenetic tree of FsAlgB (the full-length enzyme) and other alginate lyases of PL 7 family based on amino acid sequence comparison. The species names are indicated along with accession numbers of corresponding alginate lyase sequences. Bootstrap values of 1000 trials are presented in the branching points

Cloning and expression of FsAlgB

For further characterization, the alginate lyase FsAlgB was heterologously expressed in E. coli BL21 (DE3), followed by being purified by Ni–NTA Sepharose affinity chromatography and analyzed by SDS-PAGE. As shown in Fig. 3, a clear band (about 35 kDa) of purified FsAlgB can be observed at the gel, which is close to the predicted molecular mass of 34.50 kDa. Afterwards, four kinds of substrates (sodium alginate, polyMG, polyM, and polyG) were employed to investigate the substrate specificity of FsAlgB. As shown in Table 1, recombinant FsAlgB showed higher activity towards polyG (2445.6 U/mg) and polyMG (2103.2 U/mg) than to sodium alginate (1760.8 U/mg) and polyM (1124.9 U/mg). Thus, FsAlgB possesses broad substrate specificity.

The kinetics of FsAlgB towards sodium alginate, polyMG, polyM, and polyG were calculated according to the hyperbolic regression analysis. The non-linear fit curves for the degradation of the four kinds of substrates are shown in Additional file 1: Figure S2. As shown in Table 1, the Km values of FsAlgB with sodium alginate, polyMG, polyM, and polyG as substrates were 1.28 mM, 0.92 mM, 2.06 mM, and 0.69 mM, respectively. Thus, FsAlgB had a much lower Km values towards polyG and polyMG, indicating that it exhibited higher affinity towards G block than that to M block. The kcat values of FsAlgB towards sodium alginate, polyMG, polyM, and polyG were 2.22 s−1, 2.73 s−1, 1.48 s−1, and 3.33 s−1, respectively. It indicated that FsAlgB exhibited the higher catalytic efficiency towards G block and hybrid MG block than that towards M block.

Biochemical characterization of FsAlgB

The biochemical characterization of FsAlgB was further performed. It showed maximal activity at 40 °C and was stable below 40 °C (Fig. 4a). The optimal pH of FsAlgB was 8.0 and the enzyme retained more than 80% activity after being incubated at a broad pH range of pH 6.0–9.0 for 24 h (Fig. 4b). However, this enzyme was mostly stable at pH 8.0. Thus, FsAlgB was an alkaline-stable lyase and it could retain stable in a broad pH range. This enzyme possessed approximately 80% activity after incubation at 40 °C for 30 min and was gradually inactivated as temperature increased (Fig. 4c).

Biochemical characterization of FsAlgB. a The optimal temperature and thermal stability of FsAlgB. The thermal stability was evaluated by determining the residual activity after incubating enzyme at different temperatures for 30 min. The activity of the untreated enzyme was regarded as 100% and the relative activity was determined. b The optimal pH and the pH stability of FsAlgB. The pH stability was evaluated by determining the residual activity after incubating enzyme at different pH buffers for 24 h. The residual activity was measured in 50 mM Tris-HCl buffer (pH 8.0) at 40 °C. The maximal activity was regarded as 100% and the relative activity was determined. c The thermal-induced denaturation of FsAlgB. The residual activity was measured in 50 mM Tris-HCl buffer (pH 8.0) at 40 °C. d The effect of NaCl on enzymatic activity. The maximal activity in the test was relatively taken as 100%. The assay was measured in 50 mM Tris-HCl buffer (pH 8.0) at 40 °C (data shown are the mean ± SD, n = 3)

The effects of metal ions on enzyme activity were also studied. As shown in Table 2 and Fig. 4d, the activity of FsAlgB can be activated by K+, Na+, and Ca2+ like other enzymes originated from the marine environment [24,25,26,27,28]. However, the activity can be inhibited by some divalent ions such as Zn2+, Cu2+, and Co2+.

Action pattern analysis and substrate docking of FsAlgB

To elucidate the action pattern and determine the number of substrate-binding subsites, we compared degradation capability of FsAlgB towards oligosaccharide with different DPs (DP2-8). As shown in Fig. 5, disaccharide and trisaccharide cannot be further degraded by FsAlgB with even higher concentration and longer incubation time (data not shown). Thus, tetrasaccharide was the shortest substrate that can be recognized and cleaved by FsAlgB, releasing monosaccharide, disaccharide, and trisaccharide (Fig. 5a). The degradation products of pentasaccharide, hexasaccharide, heptasaccharide, and octasaccharide were all similar, including oligosaccharides with DP of 1–4 (Fig. 5b–e). According to the results above, the putative bond cleavage of FsAlgB is depicted in Fig. 5f, it is presumed that FsAlgB can cleave the subsites between − 2 and + 1 within tetrasaccharide substrate to release mono-, di-, and trisaccharide, while, for penta-, hexa-, hepta-, and octasaccharide, they can be degraded into mono-, di-, tri-, and tetrasaccharide by cleaving the subsites of − 3 to + 1.

ESI-MS analysis of products with a tetrasaccharide, b pentasaccharide, c hexasaccharide, d heptasaccharide, and e octasaccharide as substrate. f Putative action pattern of FsAlgB towards different substrates. Arrows indicate possible cleavage sites of FsAlgB toward saturated oligosaccharide chains. Solid arrow represented prior cleavage, while dotted arrow represented secondary cleavage. ΔDPn(n = 1–4) represents unsaturated oligosaccharides with DP of 1–4

The three-dimensional model of the FsAlgB was constructed based on the homologues structure of Sphingomonas sp. A1 alginate lyase A1-II′ (PDB ID: 2ZAB) with similarity of 39% using PHYRE2, and an alginate tetrasaccharide model (GGGG) was docked into the FsAlgB. Despite the low-sequence similarity between FsAlgB and A1-II′, the protein model was successfully constructed with 100% confidence, because the related proteins with divergent sequences share the same folding pattern of β-jelly roll [12]. As shown in Fig. 6a, the overall structure of the FsAlgB was predicted to fold into a β-sandwich jelly roll with two anti-parallel β sheets. The outer convex sheet includes five β-strands, and the inner concave sheet contains seven β-strands, forming a groove that harbors the catalytic active site. To identify the key residues for substrate recognition, the sequence alignment and protein–substrate interactions were analyzed. As indicated in Fig. 6b, the residues R172, Q159, His161, and R119 are highly conserved, and involved in the interaction between the protein and substrates in subsites − 1, + 1, + 2, and + 3, respectively. According to the docking, the residues Y258, Q159, H161, and R119 form hydrogen bonds with the carboxyl groups in subsites + 1, + 2, and + 3, respectively. According to the structural analysis, the active site of FsAlgB is located within two flexible loops (Fig. 6a). In addition, it has been reported that the flexibility of the two loops played an essential role in substrate recognizing and binding [18]. Both M and G in substrate molecules could be bound to the active site, and this structural characteristic provided basis for the broad substrate specificity of FsAlgB. Considering the docking results and the interaction between catalytic residues and tetrasaccharide substrate, it could be postulated that Q159 and R119 neutralized the negative charge of the carboxyl group, H161 abstracts the proton of C5, and Y258 donates proton to the glycoside bond to be cleaved.

a Stereo view of the alginate tetrasaccharide (GGGG) bound to the tunnel-shaped active site of FsAlgB and b sequence alignments of FsAlgB and two alginate lyases with resolved structures (A1-II′ from Sphingomonas sp. A1 and AlyA1 from Zobellia galactanivorans DsiJT). The conserved key residues are marked with green triangles

TLC and ESI-MS analysis of degradation products

The degradation products of FsAlgB towards four kinds of substrates for different times (0–24 h) were analyzed by TLC (Fig. 7). As the proceeding of degradation, oligosaccharides with various DPs (2–6) appeared. After incubation for 72 h, dimers and trimers turn to be main products. The results above indicate that FsAlgB can split the substrates in an endolytic manner. To further determine the composition of the degradation products, the hydrolysates were then analyzed by ESI-MS (Fig. 8). It can be observed that oligomers with DP of 2–5 were released with alginate and polyMG as substrate (Fig. 8a, b). While, for hydrolysates with polyM and polyG, the degradation products were trimers and tetramers with dimers as the main products, trimers, and tetramers accounting for a small fraction (Fig. 8c, d).

TLC analysis of the degradation products of FsAlgB. Lanes 1–4 represent degradation products of alginate sodium for 0, 3, 12, and 24 h, lanes 5–8 represent degradation products of polyMG for 0, 3, 12, and 24 h, lanes 9–12 represent degradation products of polyM for 0, 3, 12, and 24 h, and lanes 13–16 represent degradation products of polyG for 0, 3, 12, and 24 h. Lane M represents the oligosaccharide standards

Discussion

As described in our previous work, Flammeovirga sp. NJ-04 was previously isolated from South China Sea and exhibited versatile abilities for degrading algal polysaccharides. In addition, an endolytic alginate lyase, FsAlgA, with heat stability has been cloned and identified from the strain [20]. In this study, a new endo-type alginate lyase was identified from Flammeovirga sp. NJ-04 and its action pattern was further elucidated. The sequence alignment indicated that FsAlgB shares the highest identity of 65% with FsAlgA, which indicated that it is a new member of PL 7 family. In addition, it contained three conserved regions, namely “PRT/V/SELRE”, “YFKA/VGN/VY”, and “QIH”. Especially, the region of QIH was reported to be involved in substrate specificity; the residue “I” may recognize the polyG block or MG blocks [29]. Thus, it was reasonable that FsAlgB preferred polyG as the substrate just as other alginate lyases containing the QIH region, such as ALY-1 from Corynebacterium sp. strain ALY-1 [30], A1-I from Sphingomonas sp. A1 [31], and A1m from Agarivorans sp. JAM-A1m [32], while, for other alginate lyases containing the QVH region of PL 7 family, polyM is the optimal substrate, such as alginate lyaseA9m from Vibrio sp. JAM-A9m [24], alginate lyases AlyVOA, and AlyVOB from Vibrio sp. O2, degraded in activity assays [33].

While compared with the other PL 7 family enzymes, FsAlgB had lower Km values. For instance, AlgMsp from Microbulbifer sp. 6532A possessed Km values of 1.8–6.8 mM towards different substrates [22]. AlyA1 from Zobellia galactanivorans DsiJT showed Km values varying from 1.7 mM to 6.2 mM [17]. The kcat/Km values of FsAlgB towards polyG (4.83 mM−1 s−1) and polyMG (2.97 mM−1 s−1) were higher than to sodium alginate (1.73 mM−1 s−1) and polyM (0.72 mM−1 s−1), which indicated that the enzyme showed higher catalytic efficiency towards polyG and polyMG than to polyM.

As to biochemical characteristics, most of alginate lyases exhibit the optimal activity in the range of pH 7–8.5. For instance, FsAlgA from Flammeovirga sp. NJ-04 [20], AlyA1 from Zobellia galactanivorans [17], and Alg7D from Saccharophagus degradans [10] show the optimal activity at pH 7.0, while AlgMsp from Microbulbifer sp. 6532A [22], Algb from Vibrio sp. W13 [25], and A1-II′ from Sphingomonas sp. A1 [33] possess the optimal pH of 8.0. As to the optimal temperature, most of alginate lyases exhibit the optimal activity around 30–40 °C, while FlAlyA from Flavobacterium sp. UMI-01 had a highest optimal temperature of 55 °C [21]. In addition, AlgMsp from Microbulbifer sp. 6532A [22] and Alg7D from Saccharophagus degradans [10] displayed their maximal activity at 50 °C. Moreover, they could maintain most of the activities below 40 °C, except the Alg7D from Saccharophagus degradans which showed lower heat stability and retained only 40% of its maximum activity below 30 °C.

The effects of metal ions on FsAlgB were similar to that on Aly510-64 from Vibrio sp. 510-64 [26] and AlyAL-28 from Vibrio harveyi AL-28 [27]. Specifically, the activity of FsAlgB can be enhanced by NaCl with different concentrations (100–600 mM) and the maximal activity can be reached with 300 mM NaCl (Fig. 4d). Therefore, FsAlgB is a salt-activated alginate lyase. Since these salt-activated enzymes are usually isolated from marine bacteria, it is easy to understand the activation of NaCl [28]. Furthermore, it is assumed that high ionic strength might be essential to maintain the uronic acid units at a minimal interunit period for proper fitting of the enzyme [34]. The enhanced effects of NaCl with high concentration may be partly caused by the removal of bound water from alginate molecules or the stabilization of the transition state [27].

As to the action mode, ALY-1 from Corynebacterium sp. ALY-1 could degrade oligosaccharides larger than pentasaccharides, indicating that it possessed a subsite corresponding to hexasaccharide unites. The action pattern of the enzyme towards hexamers was confirmed by the HPLC analysis, and the main products were identified to be dimers and tetramers, which suggested that the catalytic site of the enzyme was matched to the linkage the second (− 2) and the third (− 1) residues from the nonreducing end [35]. Aly272 from Alteromonas sp. No272 exhibited no activity towards trimeric mannuronate or guluronate, but can degrade oligosaccharides larger than tetramers. The kinetic analysis kcat/Km combined with intrinsic reaction rate constant (kint) and intrinsic substrate-binding constant (kint) indicated that it most likely consisted of six binding sites [36]. Almost all alginate lyases of PL7 family are endolytic enzymes and can degrade the alginate into oligosaccharides with low DP of 2–5 as the main product. Exceptionally, AlyA5 from Zobellia galactanivorans can release disaccharides in an exolytic manner [17]. Due to various biological activities, alginate oligosaccharides have been widely used in various fields [37, 38]. While considering the drawbacks and defects of chemical method, the alginate lyases, especially the enzymes with broad substrate specificity and high activity, are crucial in producing functional oligosaccharides. FsAlgB is a novel alginate lyase with broad substrate specificity and high activity, which can effectively degrade alginate and produce oligosaccharides with lower DPs, so it may be a potent tool to produce oligomers. Furthermore, this work also provided extended insights into the substrate recognition and degrading pattern of alginate lyases with broad substrate specificity.

Conclusions

In this study, a novel bifunctional alginate lyase FsAlgB has been identified from Flammeovirga sp. NJ-04, which exhibited the highest activity (1760.8 U/mg) at pH 8.0 and 40 °C. In addition, it possessed broad substrate specificity, showing high activities towards not only polyM (polyβ-d-mannuronate) but also polyG (poly α-l-guluronate). And for further applications in industry, its action mode was also elucidated. Remarkably, FsAlgB can recognize the tetrasaccharide as the minimal substrate and cleave the glycosidic bonds between the subsites of − 3 and + 1 within the polysaccharide producing oligosaccharides with DP of 2–4. TLC and ESI-MS analysis indicated that it can degrade the substrates in an endolytic manner to release a series of oligosaccharides. Thus, with high activity, broad substrate specificity, and product specificity, it might be a potential candidate for degrading alginate to produce oligosaccharides.

Abbreviations

- DP:

-

degree of depolymerization

- PolyM:

-

polyβ-d-mannuronate

- PolyG:

-

polyα-l-guluronate

- SDS-PAGE:

-

sodium dodecyl sulfate polyacrylamide gel electrophoresis

References

Gacesa P. Enzymic degradation of alginates. Int J Biochem. 1992;24:545.

Lee KY, Mooney DJ. Alginate: properties and biomedical applications. Prog Polym Sci. 2012;37:106.

An QD, Zhang GL, Wu HT, Zhang ZC, Zheng GS, Luan L, et al. Alginate-deriving oligosaccharide production by alginase from newly isolated Flavobacterium sp. LXA and its potential application in protection against pathogens. J Appl Microbiol. 2009;106:161.

Iwamoto M, Kurachi M, Nakashima T, Kim D, Yamaguchi K, Oda T, et al. Structure–activity relationship of alginate oligosaccharides in the induction of cytokine production from RAW264.7 cells. FEBS Lett. 2005;579:4423.

Tusi SK, Khalaj L, Ashabi G, Kiaei M, Khodagholi F. Alginate oligosaccharide protects against endoplasmic reticulum- and mitochondrial-mediated apoptotic cell death and oxidative stress. Biomaterials. 2011;32:5438.

Zhang R, Zhou J, Jia Z, Zhang Y, Gu G. Hypoglycemic effect of Rehmannia glutinosa oligosaccharide in hyperglycemic and alloxan-induced diabetic rats and its mechanism. J Ethnopharmacol. 2004;90:39.

Wong TY, Preston LA, Schiller NL. Alginate lyase: review of major sources and enzyme characteristics, structure-function analysis, biological roles, and applications. Annu Rev Microbiol. 2000;54:289.

Zhu BW, Yin H. Alginate lyase: review of major sources and classification, properties, structure-function analysis and applications. Bioengineered. 2015;6:125.

Wang B, Ji SQ, Lu M, Li FL. Biochemical and structural characterization of alginate lyases: an update. Curr Biotechnol. 2015. https://doi.org/10.2174/2211550104666150723231423.

Kim HT, Ko HJ, Kim N, Kim D, Lee D, Choi IG, et al. Characterization of a recombinant endo-type alginate lyase (Alg7D) from Saccharophagus degradans. Biotechnol Lett. 2012;34:1087.

Hirayama M, Hashimoto W, Murata K, Kawai S. Comparative characterization of three bacterial exo-type alginate lyases. Int J Biol Macromol. 2016;86:519.

Lombard V, Bernard T, Rancurel C, Brumer H, Coutinho PM, Henrissat B. A hierarchical classification of polysaccharide lyases for glycogenomics. Biochem J. 2010;432:437.

Inoue A, Kagaya M, Ojima T. Preparation of protoplasts from Laminaria japonica using native and recombinant abalone alginate lyases. J Appl Phycol. 2008;20:633.

Inoue A, Mashino C, Kodama T, Ojima T. Protoplast preparation from Laminaria japonica with recombinant alginate lyase and cellulase. Mar Biotechnol. 2011;13:256.

Alipour M, Suntres ZE, Omri A. Importance of DNase and alginate lyase for enhancing free and liposome encapsulated aminoglycoside activity against Pseudomonas aeruginosa. J Antimicrob Chemother. 2009;64:317.

Alkawash MA, Soothill JS, Schiller NL. Alginate lyase enhances antibiotic killing of mucoid Pseudomonas aeruginosa in biofilms. APMIS. 2006;114:131.

Thomas F, Lundqvist LC, Jam M, Jeudy A, Barbeyron T, Sandström C, et al. Comparative characterization of two marine alginate lyases from Zobellia galactanivorans reveals distinct modes of action and exquisite adaptation to their natural substrate. J Biol Chem. 2013;288:23021.

Ogura K, Yamasaki M, Mikami B, Hashimoto W, Murata K. Substrate recognition by family 7 alginate lyase from Sphingomonas sp. A1. J Mol Biol. 2008;380:373.

Liu Y, Yi Z, Cai Y, Zeng R. Draft genome sequence of algal polysaccharides degradation bacterium, Flammeovirga sp. OC4. Mar Genomics. 2015;21:21.

Zhu BW, Ni F, Sun Y, Yao Z. Expression and characterization of a new heat-stable endo-type alginate lyase from deep-sea bacterium Flammeovirga sp. NJ-04. Extremophiles. 2017;21:1027.

Inoue A, Nishiyama R, Ojima T. The alginate lyases FlAlyA, FlAlyB, FlAlyC, and FlAlex from Flavobacterium sp. UMI-01 have distinct roles in the complete degradation of alginate. Algal Res. 2016;19:355.

Swift SM, Hudgens JW, Heselpoth RD, Bales PM, Nelson DC. Characterization of AlgMsp, an alginate lyase from Microbulbifer sp. 6532A. PLoS ONE. 2014;9:e112939.

Studnicka GM. Hyperbolic regression analysis for kinetics, electrophoresis, ELISA, RIA, Bradford, Lowry, and other applications. CABIOS. 1987;3:9.

Uchimura K, Miyazaki M, Nogi Y, Kobayashi T, Horikoshi K. Cloning and sequencing of alginate lyase genes from deep-sea strains of Vibrio and Agarivorans and characterization of a new Vibrio enzyme. Mar Biotechnol. 2010;12:526.

Zhu BW, Tan HD, Qin YQ, Xu QS, Du YG, Yin H. Characterization of a new endo-type alginate lyase from Vibrio sp. W13. Int J Biol Macromol. 2015;75:330.

Hu XK, Jiang XL, Hwang HM. Purification and characterization of an alginate lyase from marine bacterium Vibrio sp. mutant strain 510-64. Curr Microbiol. 2006;53:135.

Kitamikado M, Tseng CH, Yamaguchi K, Nakamura T. Two types of bacterial alginate lyases. Appl Environ Microb. 1992;58:2474.

Xiao TF, Hong L, Sang MK. Purification and characterization of a Na+/K+ dependent alginate lyase from turban shell gut Vibrio sp. YKW-34. Enzyme Microb Technol. 2007;41:828.

Deng SP, Ye J, Xu QQ, Zhang HZ. Structural and functional studies on three alginate lyases from Vibrio alginolyticus. Protein Pept Lett. 2014;21:179.

Matsubara Y, Kawada R, Iwasaki K, Kimura Y, Oda T, Muramatsu T. Cloning and sequence analysis of a gene (aly PG) encoding poly(alpha-l-guluronate)lyase from Corynebacterium sp. strain ALY-1. J Biosci Bioeng. 2000;89:199.

Yoon HJ, Hashimoto W, Miyake O, Okamoto M, Mikami B, Murata K. Overexpression in Escherichia coli, purification, and characterization of Sphingomonas sp. A1 alginate lyases. Protein Express Purif. 2000;19:84.

Kobayashi T, Uchimura K, Miyazaki M, Nogi Y, Horikoshi K. A new high-alkaline alginate lyase from a deep-sea bacterium Agarivorans sp. Extremophiles. 2009;13:121.

Kawamoto H, Horibe A, Miki Y, Kimura T, Tanaka K, Nakagawa T, et al. Cloning and sequencing analysis of alginate lyase genes from the marine bacterium Vibrio sp. O2. Mar Biotechnol. 2006;8:481.

Nakada HI, Sweeny PC. Alginic acid degradation by eliminases from abalone hepatopancreas. J Biol Chem. 1967;242:845.

Matsubara Y, Iwasaki K, Muramatsu T. Action of poly (alpha-l-guluronate)lyase from Corynebacterium sp. ALY-1 strain on saturated oligoguluronates. Biosci Biotechnol Biochem. 1998;62:1055.

Iwamoto Y, Araki R, Iriyama K, Oda T, Fukuda H, Hayashida S, et al. Purification and characterization of bifunctional alginate lyase from Alteromonas sp. strain no. 272 and its action on saturated oligomeric substrates. Biosci Biotechnol Biochem. 2001;65:133.

Kawada A, Hiura N, Tajima S, Takahara H. Alginate oligosaccharides stimulate VEGF-mediated growth and migration of human endothelial cells. Arch Dermatol Res. 1999;291:542.

Iwasaki K, Matsubara Y. Purification of alginate oligosaccharides with root growth-promoting activity toward lettuce. Biosci Biotechnol Biochem. 2000;64:1067.

Authors’ contributions

BWZ and LMN conducted experiments. All authors designed experiments and interpreted data and BWZ with FN drafted the manuscript, while funding was secured by YS and ZY. All authors read and approved the final manuscript.

Competing interests

The authors declare that they have no competing interests.

Availability of data and materials

Not applicable.

Author agreements

All authors agree to publish this article.

Consent for publication

Not applicable.

Ethics approval and consent to participate

Not applicable.

Funding and acknowledgements

The work was supported by the National Natural Science Foundation of China (Grant Nos. 31601410, 81503463).

Statement of informed consent

No conflicts, informed consent, and human or animal rights applicable.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Author information

Authors and Affiliations

Corresponding authors

Additional file

Additional file 1: Figure S1.

Nucleotide and deduced protein sequence of FsAlgB. The conserved catalytic domain (Thr54–Glu284) is marked with red box. Figure S2. Non-linear fit curves for the degradation of sodium alginate (A), polyMG (B), polyM (C), and polyG (D) by FsAlgB. The initial rates were determined with 0.1–10 mg/mL of each substrate at 40 °C. The data represent the mean of three experimental repeats with SD ≤ 5%.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

Zhu, B., Ni, F., Sun, Y. et al. Elucidation of degrading pattern and substrate recognition of a novel bifunctional alginate lyase from Flammeovirga sp. NJ-04 and its use for preparation alginate oligosaccharides. Biotechnol Biofuels 12, 13 (2019). https://doi.org/10.1186/s13068-019-1352-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13068-019-1352-8