Abstract

Background

Whole-cell biocatalysis based on metabolically active baker’s yeast with engineered transamination activity can be used to generate molecules carrying a chiral amine moiety. A prerequisite is though to express efficient ω-transaminases and to reach sufficient intracellular precursor levels.

Results

Herein, the efficiency of three different ω-transaminases originating from Capsicum chinense, Chromobacterium violaceum, and Ochrobactrum anthropi was compared for whole-cell catalyzed kinetic resolution of racemic 1-phenylethylamine to (R)-1-phenylethylamine. The gene from the most promising candidate, C. violaceum ω-transaminase (CV-TA), was expressed in a strain lacking pyruvate decarboxylase activity, which thereby accumulate the co-substrate pyruvate during glucose assimilation. However, the conversion increased only slightly under the applied reaction conditions. In parallel, the effect of increasing the intracellular pyridoxal-5′-phosphate (PLP) level by omission of thiamine during cultivation was investigated. It was found that without thiamine, PLP supplementation was redundant to keep high in vivo transamination activity. Furthermore, higher reaction rates were achieved using a strain containing several copies of CV-TA gene, highlighting the necessity to also increase the intracellular transaminase level. At last, this strain was also investigated for asymmetric whole-cell bioconversion of acetophenone to (S)-1-phenylethylamine using l-alanine as amine donor. Although functionality could be demonstrated, the activity was extremely low indicating that the native co-product removal system was unable to drive the reaction towards the amine under the applied reaction conditions.

Conclusions

Altogether, our results demonstrate that (R)-1-phenylethylamine with >99% ee can be obtained via kinetic resolution at concentrations above 25 mM racemic substrate with glucose as sole co-substrate when combining appropriate genetic and process engineering approaches. Furthermore, the engineered yeast strain with highest transaminase activity was also shown to be operational as whole-cell catalyst for the production of (S)-1-phenylethylamine via asymmetric transamination of acetophenone, albeit with very low conversion.

Similar content being viewed by others

Background

Chiral amines are prevalent functional groups in a wide range of bioactive compounds, so efficient, sustainable, and economically feasible methods for their synthesis are highly desirable [1, 2]. In lieu of chemical catalysis, the use of ω-transaminase (ω-TA) (E.C. 2.6.1.18) has emerged as a competitive alternative for bio-catalysed production of chiral amines, either via asymmetric transamination of ketones or via kinetic resolution of racemic amines. Asymmetric transamination of prochiral ketones to chiral amines can be more advantageous than kinetic resolution of racemic substrates since in theory all substrate can be converted to the product as opposed to a maximum yield of 50% for kinetic resolution. Direct conversion of ketones to amines by transamination however often suffer from an unfavourable thermodynamic reaction equilibrium, which makes the reaction reliant on a functional co-product removal system [3]. Biocatalytic transamination is most often performed with purified enzymes or with cell extracts from recombinant bacteria over-expressing the required enzymes [3–5]. Processes where ω-TAs are used include for instance the synthesis of Sitagliptin, (S)-Rivastigmine, and precursors for the synthesis of Pregabalin and Brivaracetam [6–8].

From a process perspective, the use of intact whole microbial cells that over-express specific recombinant ω-TAs may be advantageous, since it offers a more simple overall process configuration with a reduced number of upstream unit operations and less generation of waste material [9, 10]. Additionally, cell metabolism can be exploited for the (re)-generation of co-factors and co- substrates provided that there is an attendant assimilation of a carbon and energy source during the reaction [11]. So far however there are no reported whole-yeast cell systems expressing recombinant ω-TAs that are operational in the direction from carbonyl to amine. For kinetic resolution on the other hand, recombinant yeast have previously been shown to be active in an aqueous buffer system supplemented with glucose as co-substrate [12]. Yet the whole-cell system demonstrated low specific activity, resulting in very low productivity and yield in the whole-cell biotransformation process. Further improvements of the whole-cell biocatalyst were achieved by coupling the transamination to a KRED (ketone reductase)-catalysed reduction to remove the co-product and thereby relieve product inhibition [13, 14]. Still, the catalytic activity of currently reported engineered yeast strains needs to be improved manifold in order to be competitive with current state-of-the art for ω-TA catalysis [3].

A potential limitation for kinetic resolution of racemic amines with metabolically active yeast cells is the availability of amine acceptors provided from glucose. ω-TAs of both bacterial [15–17] and plant [18–20] origin are able to utilize pyruvate as amine acceptor. Together with the central position of pyruvate in the carbon metabolism makes this a promising potential target to engineer for the improvement of whole-cell transamination. Elevated production of pyruvate in Saccharomyces cerevisiae was previously achieved by metabolic engineering of the pyruvate node by deletion of the pyruvate decarboxylase (PDC) genes PDC1, PDC5, and PDC6 [21, 22]. The Pdc negative strain accumulated pyruvate, but was unable to grow on glucose without an external source of C2 compounds for synthesis of acetyl-CoA. Directed evolution of the Pdc negative strain in a long-term continuous cultivation setup led to the phenotypic trait of growth at high glucose concentration and pyruvate accumulation in aerobic batch mode without the necessity to add acetate [23]. It can be speculated that this strain would be an efficient platform for resolution of racemic amines by whole-cell transamination.

Another engineering target that was previously shown to influence whole-cell transamination activity is the concentration of pyridoxal-5′-phosphate (PLP) [12, 24], which is an essential co-factor for all aminotransferases. To increase the activity of PLP-dependent reactions, PLP is typically supplemented directly to the reaction solution thereby relieving potential limitations in availability [12, 25, 26]. An alternative to supplementation is the increase of intracellular levels by metabolic engineering of PLP biosynthetic pathways. PLP is synthetized in two pathways: the ribose 5-phosphate-dependent de novo pathway [27–31], and the PLP-salvage pathway where the pyridoxine, pyridoxal, and pyridoxamine scaffolds are interconverted and phosphorylated at the 5′-hydroxyl group [32, 33]. It was recently shown that by introducing PdxS and PdxT encoding a PLP synthase complex originating from Bacillus subtilis into Escherichia coli, the intracellular PLP levels increased 2.4-fold [24]. This resulted in similar specific whole-cell activity for biotransformation of l-lysine to cadaverine by a PLP-dependent lysine decarboxylase (CadA), with or without the addition of PLP in the reaction solution [24]. In yeast, PLP biosynthesis has been found to correlate to extracellular concentration of thiamine, which is an essential vitamin for cell growth and is typically part of defined mineral media [34]. Regulation of de novo biosynthesis of PLP and thiamine are thus closely intertwined, and the biosynthetic activity required for their formation is inversely correlated with extracellular availability [35, 36]. Based on this knowledge, we hypothesize that the omission of thiamine in the cultivation medium that lead to an increased intracellular PLP concentration will result in an improvement in specific whole-cell activity.

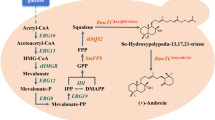

In the present study, we investigated different bioengineering strategies to modify the intracellular environment of S. cerevisiae with the aim to increase specific in vivo transamination activity. As model reaction, we used kinetic resolution of racemic 1-phenylethylamine (PEA) to (R)-1-PEA with sole addition of glucose to supply PLP and pyruvate as amine acceptor (Fig. 1a). First, the specific in vivo transaminase activity of three ω-TAs with the same substrate and stereo-selectivity, but with distinct origin (plant and bacteria), different pH optima, and reaction kinetics were compared. Differences in specific in vivo activities were observed, which sheds light into potential desirable enzyme characteristics for optimal transamination with intact yeast cells. Subsequently, a previously developed Pdc negative pyruvate accumulating strain [23] was evaluated for its potential as platform host for whole-cell kinetic resolution. Furthermore, we analysed the effect of thiamine omission in the cultivation medium with the aim to increase intracellular PLP levels and thereby decrease the dependence of adding PLP to the reaction solution. We also increased the TA gene copy number sixfold, which in combination with cultivation in thiamine-free medium and with an increased biomass concentration during the bioconversion resulted in complete kinetic resolution of 25 mM racemic 1-PEA to (R)-1-PEA in a reaction configuration with glucose as co-substrate. Finally, the most active yeast catalyst was investigated for direct asymmetric transamination of acetophenone to (S)-1-PEA with l-alanine as amine donor (Fig. 1b). We speculated that the endogenous pyruvate dissimilating pathways, e.g. conversion of pyruvate to acetaldehyde and CO2 by Pdc, would function as an efficient co-product removal system. We could indeed confirm that the desired reaction was operational by whole-cell transamination, however, at extremely low conversion.

a Whole-cell kinetic resolution of racemic 1-PEA with (S)-selective ω-transaminase to (R)-1-PEA and acetophenone. The mechanism for enzymatic transamination consists of two half-reactions under which the co-factor PLP is regenerated, and the amine acceptor/donor is converted into the corresponding amine/ketone. PLP and the amine acceptor pyruvate is formed in the cell by concomitant conversion of glucose. b Whole-cell asymmetric conversion of acetophenone to (S)-1-PEA by (S)-selective ω-transaminase. The co-product pyruvate is removed from the system by further conversion catalysed by PDC and ADH resulting in formation of CO2 and ethanol

Results

Comparison of three different ω-transaminases for whole-cell transamination in S. cerevisiae

S. cerevisiae expressing ω-TA gene from the chili pepper plant C. chinense (CC-TA) was previously shown to be functional as whole-cell biocatalyst for the kinetic resolution of racemic 1-phenylethylamine (PEA) to (R)-1-PEA, but with relatively low specific activity [12]. To investigate if there was a more suitable transaminase for the yeast bio-catalytic system, two additional S. cerevisiae strains were constructed containing two other TAs: the well-characterized ω-TA from the beta-proteobacterium C. violaceum (CV-TA) [15, 37, 38] and the previously reported ω-TA from the alpha-proteobacterium O. anthropi (OA-TA) [17, 42], which has shown neither substrate nor product inhibition. The three enzymes all possess similar substrate specificity and enantio-selectivity; however, they have differences in acetophenone inhibition kinetics and optimal pHs (Table 1). In the present study, the codon-optimized synthetic genes were cloned into a yeast integrative vector (YIpNW) (Table 2) and transformed into the parental strain TMB4150 generating CV-TA strain (TMB4369) and OA-TA strain (TMB4371) (Table 3). The three strains were compared for the kinetic resolution of racemic 1-PEA in a reaction configuration where PLP was supplemented and glucose was used as co-substrate for the supply of amine acceptors. As previously observed [12], CC-TA strain converted (S)-1-PEA to acetophenone (ACP) during 48 h after which the reaction stopped, reaching only 6.1% final conversion (Fig. 2). The reaction rate of OA-TA strain was similar to CC-TA strain during the first 4 h (0.16 mmol (S)-1-PEA/g dw/h vs. 0.15 mmol (S)-1-PEA/g dw/h, respectively), however, the OA-TA strain continuously resolved racemic 1-PEA until 120 h, thereby achieving almost threefold higher conversion (17.2%). The best result was obtained with CV-TA strain that had a more than fourfold higher initial specific activity (0.64 mmol (S)-1-PEA/g dw/h) than the CC-TA strain. Although the reaction rate decreased between 4 and 120 h, 38.5% conversion was achieved after 120 h, resulting in the highest ee (64.4%) of (R)-1-PEA.

Kinetic resolution of racemic 1-phenylethylamine (PEA) with whole cells of TMB4367 (CC-TA) (diamond), TMB4369 (CV-TA) (triangle), and TMB4371 (OA-TA) (square) S. cerevisiae strains. Experiments were performed at least in biological duplicates using 100 g/l glucose, 25 mM racemic 1-PEA, 0.1 mM PLP, and 5 g/l dw cells. The conversion (%) refers to racemic 1-PEA, with a theoretical maximum of 50%. No error bar is visible if the standard deviation lies below 5%

Influence of intracellular pyruvate accumulation on whole-cell transamination

The intracellular pyruvate derived from glucose through glycolysis may be limited for transamination due to the presence of endogenous pyruvate-catalysing enzymes such as the pyruvate dehydrogenase complex (Pdh), pyruvate decarboxylase (Pdc), and pyruvate carboxylase (Pyc) [39]. In order to verify this hypothesis, whole-cell transamination was performed using the pyruvate-accumulating TAM strain [23]. As CV-TA had the best properties for whole-cell transamination, the TAM strain was transformed with plasmid pNW12 resulting in CV-TA TAM strain (TMB4374) (Tables 2, 3). To prepare biomass for the subsequent whole-cell reaction, CV-TA and CV-TA TAM strains were grown in a mineral medium containing 20 g/l glucose as well as 3 g/l ethanol to increase the growth rate of CV-TA TAM strain as previously reported [40]. Under these conditions, the latter reached a final OD620 of 5.3 ± 0.2 after 31 h, compared to OD620 7.1 ± 0.1 after 24 h for CV-TA strain (Additional file 1: Figure S1). Glucose consumption was nearly sixfold faster for CV-TA strain with ethanol as primary by-product, compared to CV-TA TAM strain that did not produce ethanol. Under the evaluated conditions, both strains produced pyruvate concentrations below the detection limit.

When investigated for whole-cell transamination, the CV-TA strain showed 34.6% conversion after 70 h (Fig. 3), while the CV-TA TAM strain had slightly higher conversion (40.1% conversion after 70 h). The conversion for the CV-TA strain was the same as for the experiments described above (Fig. 2), thereby demonstrating that supplementation of ethanol in the medium during the pre-cultivation step did not influence the specific activity of the whole-cell biocatalyst. Glucose consumption and formation of ethanol and glycerol during the progress of the reaction were significantly lower for the CV-TA TAM strain as compared to the control (Fig. 4a, b). Thus, the amount of glucose required to provide sufficient levels of amine acceptor was lower in the TAM strain background. Extracellular pyruvate accumulation was not detected for either of the strains, which in the case of the TAM strain is most probably due to a combination of depletion by the transaminase-catalysed reaction and an insufficient aeration under the applied reaction conditions.

Comparison of TMB4369 (CV-TA) (triangle) and TMB4374 (CV-TA TAM) strain (circle) for the kinetic resolution of racemic 1-PEA using whole cells. The experiments were performed in biological duplicates with 100 g/l glucose, 25 mM racemic 1-PEA, 0.1 mM PLP, and 5 g/l dw cells. No error bar is visible if the standard deviation lies below 5%

Omission of thiamine in the cultivation medium during biocatalyst production improves whole-cell biocatalyst activity

Availability of intracellular PLP contributes to a significant degree to the activity of PLP-dependent enzymes in living cells, as has been observed previously [12]. We therefore investigated whether the omission of thiamine in the cultivation medium, which previously was shown to result in increased PLP levels, would also result in higher specific whole-cell transamination activity in a subsequent bioconversion step. When cultivated in a medium without thiamine, the CV-TA strain (TMB4369) displayed a substantially reduced maximal specific growth rate (0.24 ± 0.0/h) as compared to when thiamine was added (0.31 ± 0.0/h), but no substantial effect on the by-product distribution (ethanol, glycerol, acetate) was observed. Electrospray Ionization Mass Spectrometry (ESI–MS) analysis was used for measurement of intracellular PLP, and it could indeed be demonstrated that the omission of thiamine led to a 1.5- to 2-fold increase in concentration (data not shown).

To see the effect of thiamine on whole-cell bioconversion, the yeast cells were used for transamination with and without further addition of PLP. When thiamine was present in the cultivation medium, a substantially higher conversion was obtained with PLP added to the reaction solution (38.5% as compared to 25.4% without addition of thiamine; Fig. 5). In contrast, when thiamine was omitted in the culture step, the addition of PLP in the biotransformation step had a smaller effect on the conversion, i.e. 40.5% conversion was obtained compared to 36.7% conversion without the addition of PLP. Thus, it can be concluded that omission of thiamine during cultivation indeed increased the whole-cell activity in the subsequent reaction step.

Kinetic resolution of racemic 1-PEA with TMB4369 (CV-TA) with and without addition of PLP to the reaction solution. Prior to the reaction cells were pre-cultivated with or without thiamine in the medium. Experiments were performed in biological triplicates using 100 g/l glucose, 25 mM racemic 1-PEA, and 5 g/l dw cells. Symbols: empty square (0 mM PLP in the reaction, 0 µM thiamine in culture medium); empty triangle (0.1 mM PLP in the reaction, 0 µM thiamine in culture medium); filled square (0 mM PLP in the reaction, 3.3 µM thiamine in culture medium); filled triangle (0.1 mM PLP in the reaction, 3.3 µM thiamine in culture medium). No error bar is visible if the standard deviation lies below 5%

Influence of TA gene copy number and cell loading on whole-cell transamination

It has previously been shown that an increased transaminase gene copy number led to higher specific in vivo transaminase activity [13]. To evaluate if this observation still held with a ω-TA having higher specific in vivo enzyme activity in yeast, a strain with sixfold higher number of copies of the CV-TA gene (TMB4375) was constructed and used for whole-cell transamination. The whole-cell biocatalyst was produced without adding thiamine in the medium during the cultivation step, and glucose was used as sole co-substrate in the subsequent reactions that were performed without addition of PLP to the solution. Indeed, when using the same amount of cells (5 gdw/l) for the reaction, a considerable higher conversion (44.7%) was reached (Fig. 6) compared to the strain carrying only onefold copies of CV-TA gene (36.7%) (Fig. 5).

To see if it would be possible to reach full conversion by increasing the amount of the whole-cell biocatalyst with high TA-gene copy-number, kinetic resolution of 25 mM racemic 1-PEA was carried out with two cell loadings (5 and 25 g/l dw). The initial reaction rate for both cell loadings was very similar (0.33 mmol (S)-1-PEA/g dw/h with 25 g/l dw vs. 0.32 mmol (S)-1-PEA/g dw/h with 5 g/l dw) during the first 24 h. However, with 25 g/l dw whole-cell biocatalyst, 50% conversion and an ee of (R)-1-PEA > 99% was reached within 72 h (Fig. 6).

Whole-cell transamination of acetophenone to (S)-1-phenylethylamine

As an alternative to kinetic resolution of a racemic substrate, chiral amines can be produced by direct asymmetric transamination of the ketone. However, the reaction equilibrium for ω-transaminations often lies in the direction towards the ketone which is a major challenge for reaching high conversion. In the case for direct synthesis of (S)-1-PEA from acetophenone using amino acids (e.g. l-alanine) as amine donor, the Gibbs free energy was calculated using the group contribution method [41] to be ΔG0′ = +4.01 kcal/mol, i.e. the reaction is thus not thermodynamically favourable. It can be hypothesised that the native pyruvate dissimilating enzymes in yeast, e.g. Pdc, pyruvate dehydrogenase (Pdh), and pyruvate carboxylase (Pyc), in principle may be used for co-product removal and thereby drive the reaction towards the amine. To shed some light into the potential of the native pyruvate metabolism to drive asymmetric transamination, the conversion of acetophenone to (S)-1-PEA with addition of an excess of l-alanine was evaluated with the yeast strain expressing six copies of the CV-TA gene (TMB4375) and thereby having the highest transaminase activity. Indeed, the product was detected after bioconversion for 24 h, but at very low titers (0.35 mM (S)-1-PEA, Additional file 1: Figure S2), demonstrating that the reaction indeed is possible but significantly limited under the conditions used. In addition to (S)-1-PEA, the formation of low amount (S)-1-phenylethanol was also detected, demonstrating that endogenous acetophenone reductases are also active in the whole-cell system under the applied reaction conditions (Additional file 1: Figure S2).

Discussion

In this study, major improvements in whole-cell transamination with engineered S. cerevisiae were achieved through the identification of relevant parameters, such as the type and intracellular level of ω-transaminase. Also, the need to increase the intracellular concentration of the involved co-substrates and co-factors was investigated. The use of a S. cerevisiae strain with elevated pyruvate concentration enabled slightly higher conversion than the reference strain. Furthermore, cells grown in the absence of thiamine gave higher conversion under conditions where PLP was omitted. Notably, complete kinetic resolution of 25 mM racemic 1-phenylethylamine was achieved with glucose as co-substrate and using a strain containing six copies of CV-TA, high cell density, and no added PLP. To the best of our knowledge, the yeast catalyst TMB4375 described herein thus has the highest ω-TA activity so far reported for a metabolically active whole-cell system that exploits cell metabolism to supply both PLP and amine acceptor for the reaction.

Enzymes that are optimized for purified systems might not be optimal for a whole-cell system due to factors such as incompatible pH optima, temperature optima, or enzyme kinetics. pH optima of 7–8, 9, and 8.5–9 were previously recorded for the ω-TA from C. chinense [18], O. anthropi [42] and C. violaceum [37], respectively, which should be compared with S. cerevisiae intracellular cytosolic pH of 7–7.5 (depending on extracellular pH, and growth phase) [43, 44]. Therefore, this parameter does not per se explain the highest conversion observed with CV-TA. Comparison of in vitro activities of the different enzymes does not clarify the better performance of CV-TA in the whole-cell system either, since CV-TA showed more than twofold higher conversion than CC-TA but nearly fourfold lower conversion than OA-TA in cell extracts (Additional file 1: Figure S3). In whole cells however, the intracellular level of substrate, co-substrates, and co-factors is highly dependent on cell metabolism and intermembrane transport, which contrasts with isolated enzyme catalysts where the levels of the different components can be freely adjusted. This leads to the observation that the enzyme and host metabolism need to be compatible and enzyme evaluation should be performed in combination with the host. It has been claimed that OA-TA has no substrate or product inhibition [17], and it indeed displayed minor reduction of the reaction rate during the whole-cell process compared to CV-TA and CC-TA. OA-TA has previously been reported to have a greater Km value compared to other ω-TAs [17]. Therefore, we believe that the observed lower reaction rates for OA-TA in the whole-cell system was due to lower substrate affinity and suboptimal intracellular substrate concentration, as the substrate has to diffuse through the cell membrane.

In addition to the role of enzyme kinetics, we also highlighted the necessity to provide sufficient amount of the biocatalyst as full conversion was achieved by both increasing the TA gene copy number, i.e. the intracellular TA level, and to provide an increased amount of cells. It is likely that an even faster process can be achieved by introducing a reductase, which will further convert ACP to its less inhibitory alcohol product, as efficiently demonstrated previously by over-expressing a KRED from Lactobacillus kefir together with CC-TA in S. cerevisiae [13], or by the use of endogenous reductases to releave inhibition of recombinant Vibrio fluvialis JS17 ω-TA in Pichia pastoris [45].

We previously demonstrated that glucose could represent a significantly cheaper co-substrate than pyruvate for whole-cell transamination, by providing not only intracellular pyruvate through glycolysis, but also giving higher cell viability and higher conversion without the addition of co-factor PLP [12]. In order to limit pyruvate dissimilation through ethanol formation, the deletion of Pdc activity [23] was seen as the next step in process optimization as more pyruvate should be made available inside the cells. Previous trials using the Pdc negative strain indeed led to about 20 g/l extracellular pyruvate production after 24 h from 100 g/l glucose. During the cultivation of CV-TA TAM strain a significantly lower amount (1.5–2 g/l) pyruvate was measured. This may be explained by the drastic reduction of the pH (2.7 after 24 h) and limitation in aeration, which is needed for the re-oxidation of NADH. Despite of this, slightly higher conversion of racemic 1-phenylethylamine was achieved compared to the control strain with PDC activity.

Omission of thiamine in the culture medium used for production of the whole-cell biocatalyst led to substantially improved transamination in the absence of added PLP co-factor. Thiamine (vitamin B1) has previously been suggested to inhibit PLP (one form of vitamin B6) synthesis in Saccharomyces carlsbergensis 4228 [35]. Also a S. cerevisiae laboratory strain derived from S288C had a substantially lower specific growth rate when thiamine and no pyridoxine were added to the culture medium [46]. This was suspected to be due to a high affinity of THI10 encoded thiamine transporter [47], which led to increasing intracellular thiamine concentration and repression of PLP biosynthesis. There is also a connection between thiamine and PLP on a biosynthetic level, as PLP, or one of its closely related forms, and histidine are building blocks for one of the precursors (4-amino-5-hydroxymethyl-2-methylpyrimidine monophosphate (HMP-P)) of thiamine [48, 49]. It has additionally been reported that genes SNO2, SNO3, SNZ2, and SNZ3 are up-regulated in the absence of thiamine [36], and that overexpression of these genes in a laboratory strain leads to nearly the same specific growth rate when thiamine and not pyridoxine were added to the culture medium [46]. SNO1 and SNZ1, which are genes coding for enzymes synthesizing PLP in the de novo pathway in S. cerevisiae [28, 31, 50], have a very high sequence similarity to SNO2, SNO3 and SNZ2, SNZ3 respectively. Here we demonstrated that thiamine deficiency indeed led to higher intracellular PLP concentration. Even if the maximal growth rate was reduced by 20%, the final cell density was in a similar range after 24 h (OD620 = 7.0 ± 0.4 with thiamine, OD620 = 6.6 ± 0.4 without thiamine). Overall, the omission of thiamine led to a higher conversion, and improved the process by two factors: first the addition of thiamine and PLP was avoided and second, higher conversion was achieved.

In conclusion, the best reaction set-up for kinetic resolution of racemic 1-phenylethylamine with glucose as only co-substrate consists of using the strain with several copies of CV-TA with high cell loading, and performing cultivation without thiamine. The use of metabolically active yeast over-expressing selective transaminases for biocatalytic transamination is a promising strategy, since it is simple and requires only glucose as co-substrate for the supply of both the amine acceptor and the co-factor PLP.

We report also the use of S. cerevisiae for asymmetric synthesis of (S)-1-PEA, albeit with low conversion. To combat the unfavourable reaction equilibrium that lies in direction of the ketone, co-product removal has previously been shown to improve reaction efficiency. For the use of l-alanine as amine donor, a multitude of enzymatic in vitro co-product removal systems have previously been developed, e.g. based on the conversion of pyruvate back to l-alanine by alanine dehydrogenase (Aldh) [26, 51], or pyruvate to acetaldehyde and CO2 by Pdc [52]. Yeast possess a number of enzymes that catalyse the conversion of pyruvate, e.g. into acetaldehyde by Pdc and further to ethanol by alcohol dehydrogenase. However, in our hands the engineered yeast catalyst was operational with only very low activity in the direction towards the amine, which indicates that the native pyruvate metabolism was either not functional efficiently or that it did not have the capacity to remove pyruvate under the tested conditions. It is likely that engineering of process conditions in combination with further increase of transaminase activity and of pyruvate dissimilatory pathways may improve conversion. An alternative strategy may be to explore other amine donors that have a more favourable thermodynamic equilibrium and/or more efficient co-product removal.

Methods

Chemicals

Acetophenone (ACP), racemic 1-phenylethylamine (1-PEA), (R)-1-PEA and (S)-1-PEA were bought from Merck (Hohenbrunn, Germany), pyridoxal-5′-phosphate (PLP) from AppliChem (Darmstadt, Germany), and all other chemicals from VWR (Leuven, Belgium).

Strains, media, and cell growth

Escherichia coli strain DH5α (Life Technologies, Rockville, MD, USA) was used for subcloning. S. cerevisiae strain TMB4150 (MAT a, ura3-52 MAL2-8 C SUC2) was kindly provided by Jan Knudsen, Applied Microbiology, Lund University, Sweden. TAM strain was kindly provided by Antonius van Maris, Department of Biotechnology, Delft University of Technology, Netherlands. S. cerevisiae strains TMB4367, TMB4369, TMB4371, TMB4374, and TMB4375 (see construction below; Tables 2, 3) were used for whole-cell transamination. Strains were kept as 20% glycerol stocks at −80 °C and grown on solid media for 2 days prior to experiments.

Transformation and cell growth was performed as described previously [12] except that defined mineral medium [53] was used instead of YPG medium. The mineral medium without thiamine contained the same concentration as previously described except for thiamine [53]. For cultivation of the pyruvate decarboxylase deletion mutant TAM, 3 g/l ethanol was added to the mineral medium.

Nucleic acid manipulation

Plasmid DNA was prepared with the GeneJET Plasmid Miniprep Kit (Thermo Scientific, Rockford, IL, USA) and agarose gel DNA extraction was performed using QIAquick® Gel Extraction Kit (Qiagen GmbH, Hilden, Germany). Primers from MWG-Biotech AG (Ebersberg, Germany) and Phusion Hot Start II DNA Polymerase and dNTPs from Thermo Scientific (Rockford, IL, USA) were used for polymerase chain reactions (PCR) and performed in a GeneAmp PCR system 9700 (Applied Biosystems, Foster City, CA, USA). PCR products were purified with the GeneJET PCR Purification Kit (Thermo Scientific, Rockford, IL, USA). Sequencing was performed by MWG-Biotech AG (Ebersberg, Germany). InFusion® HD Cloning Kit (Clontech Laboratories, Mountain View, CA, USA) was used for DNA manipulation.

Strain construction

The yeast-codon optimized coding regions of the ω-TA genes from C. violaceum (GenBank: WP011135573.1, Swiss-Prot: Q7NWG4) and from O. anthropi (GenBank: YP001368759.1, Swiss-Prot: A6WVC6) were PCR amplified from pUC57-CV and pUC57-OA (Table 2), respectively, using the primers listed in Additional file 1: Table S1. YIpOB7 was cut with BglII to remove XDH gene and self-ligated to create YIpNW, which was cut with XbaI and the PCR fragments inserted by InFusion® cloning, thus creating pNW12 and pNW14 (Table 2). Correct orientation of the inserts and sequences were verified by restriction enzyme analysis and sequencing. Integrative vectors pNW12 and pNW14 were cleaved with ApaI within the URA3 marker gene and then used to transform the haploid laboratory strain TMB4150, resulting in CV-TA strain (TMB4369) and OA-TA strain (TMB4371), or the TAM strain, which resulted in CV-TA TAM strain (TMB4374) (Table 3). The 6× CV-TA strain (TMB4375) was constructed by transforming the haploid laboratory strain TMB4150 with pNW12 and screening a large number of transformants with qPCR for multiple single-crossing over integration events. Determination of relative gene copy number by qPCR was performed as described previously [13] except that qPCR primers named AMP were used (Additional file 1: Table S1). TPI1 qPCR primers were used as internal standard.

Whole-cell transamination

50 ml sealed serum flasks with magnetic stirring (140 rpm) and 5 or 25 g/l cell dry weight (dw) at 30 °C were used for whole-cell transamination. The reaction solution contained 10 ml 100 mM sodium phosphate buffer (pH 7.0), 100 g/l glucose, 25 mM racemic 1-PEA, and 0–0.1 mM PLP. For direct asymmetric transamination of acetophenone to (S)-1-PEA, the reaction solution contained the same buffer, 25 g/l cell dry weight (dw), 500 mM l-alanine, 0.1 mM PLP, 50 g/L glucose and 10 mM acetophenone.

Analyses

Growth was monitored by measuring optical density at a wavelength of 620 nm (OD620) with an Ultrospec 2100pro spectrophotometer (Amersham Biosciences, Sweden). Cell dry weight determination was performed as previously described, as was the determination by normal and reverse phase HPLC of (R)-1-phenylethylamine, (S)-1-phenylethylamine, (R)-1-phenylethanol, (S)-1-phenylethanol, acetophenone, glucose, glycerol, acetate, succinate, and ethanol [12]. Pyruvate was detected by the same HPLC method as previously described for glucose and its metabolites [12], except that a UV spectrophotometric detector (Shimadzu SPD-6A) at 214 nm was used instead.

References

Höhne M, Bornscheuer UT. Biocatalytic routes to optically active amines. ChemCatChem. 2009;1:42–51.

Nugent TC, El-Shazly M. Chiral amine synthesis—recent developments and trends for enamide reduction, reductive amination, and imine reduction. Adv Synth Catal. 2010;352:753–819.

Tufvesson P, Lima-Ramos J, Jensen JS, Al-Haque N, Neto W, Woodley JM. Process considerations for the asymmetric synthesis of chiral amines using transaminases. Biotechnol Bioeng. 2011;108:1479–93.

Koszelewski D, Tauber K, Faber K, Kroutil W. ω-Transaminases for the synthesis of non-racemic alpha-chiral primary amines. Trends Biotechnol. 2010;28:324–32.

Gundersen M, Tufvesson P, Rackham EJ, Lloyd RC, Woodley JM. A Rapid selection procedure for simple commercial implementation of ω-transaminase reactions. Org Process Res Dev. 2016;20:602–8.

Savile C, Janey J, Mundorff E, Moore J, Tam S, Jarvis W, et al. Biocatalytic asymmetric synthesis of chiral amines from ketones applied to sitagliptin manufacture. Science. 2010;329:305–9.

Fuchs M, Koszelewski D, Tauber K, Kroutil W, Faber K. Chemoenzymatic asymmetric total synthesis of (S)-Rivastigmine using ω-transaminases. Chem Commun. 2010;46:5500–2.

Zepeck F, Nerdinger S, Krouth W, Fuchs C, Simon R. Stereoselective reductive amination of α-chiral aldehydes using ω-transaminases for the synthesis of precursors of pregabalin and brivaracetam. Patent Pub. No. WO/2016/075082.

Satianegara G, Rogers PL, Rosche B. Comparative studies on enzyme preparations and role of cell components for (R)-phenylacetylcarbinol production in a two-phase biotransformation. Biotechnol Bioeng. 2006;94:1189–95.

Tufvesson P, Lima-Ramos J, Nordblad M, Woodley JM. Guidelines and cost analysis for catalyst production in biocatalytic processes. Org Process Res Dev. 2011;15:266–74.

Schrewe M, Julsing MK, Buhler B, Schmid A. Whole-cell biocatalysis for selective and productive C–O functional group introduction and modification. Chem Soc Rev. 2013;42:6346–77.

Weber N, Gorwa-Grauslund M, Carlquist M. Exploiting cell metabolism for biocatalytic whole-cell transamination by recombinant Saccharomyces cerevisiae. Appl Microbiol Biotechnol. 2014;98:4615–24.

Weber N, Gorwa-Grauslund M, Carlquist M. Engineered baker’s yeast as whole-cell biocatalyst for one-pot stereo-selective conversion of amines to alcohols. Microb Cell Fact. 2014;13:118.

Knudsen JD, Hägglöf C, Weber N, Gorwa-Grauslund M, Carlquist M. Increased availability of NADH in metabolically engineered baker’s yeast improves transaminase-oxidoreductase coupled asymmetric whole-cell bioconversion. Microb Cell Fact. 2016;5:37.

Kaulmann U, Smithies K, Smith MEB, Hailes HC, Ward JM. Substrate spectrum of ω-transaminase from Chromobacterium violaceum DSM30191 and its potential for biocatalysis. Enz Microb Tech. 2007;41:628–37.

Yun H, Hwang B-Y, Lee J-H, Kim B-G. Use of enrichment culture for directed evolution of the Vibrio fluvialis JS17 ω-transaminase, which is resistant to product inhibition by aliphatic ketones. Appl Environ Microbiol. 2005;71:4220–4.

Park ES, Shin JS. ω-Transaminase from Ochrobactrum anthropi is devoid of substrate and product inhibitions. Appl Environ Microbiol. 2013;79:4141–4.

Weber N, Ismail A, Gorwa-Grauslund M, Carlquist M. Biocatalytic potential of vanillin aminotransferase from Capsicum chinense. BMC Biotechnol. 2014;14:25.

Clark SM, Di Leo R, Dhanoa PK, Van Cauwenberghe OR, Mullen RT, Shelp BJ. Biochemical characterization, mitochondrial localization, expression, and potential functions for an Arabidopsis γ-aminobutyrate transaminase that utilizes both pyruvate and glyoxylate. J Exp Bot. 2009;60:1743–57.

Clark SM, Di Leo R, Van Cauwenberghe OR, Mullen RT, Shelp BJ. Subcellular localization and expression of multiple tomato γ-aminobutyrate transaminases that utilize both pyruvate and glyoxylate. J Exp Bot. 2009;60:3255–67.

Flikweert MT, Van Der Zanden L, Janssen WM, Steensma HY, Van Dijken JP, Pronk JT. Pyruvate decarboxylase: an indispensable enzyme for growth of Saccharomyces cerevisiae on glucose. Yeast. 1996;12:247–57.

Flikweert MT, de Swaaf M, van Dijken JP, Pronk JT. Growth requirements of pyruvate-decarboxylase-negative Saccharomyces cerevisiae. FEMS Microbiol Lett. 1999;174:73–9.

van Maris AJ, Geertman JM, Vermeulen A, Groothuizen MK, Winkler AA, Piper MD, et al. Directed evolution of pyruvate decarboxylase-negative Saccharomyces cerevisiae, yielding a C2-independent, glucose-tolerant, and pyruvate-hyperproducing yeast. Appl Environ Microbiol. 2004;70:159–66.

Ma W, Cao W, Zhang B, Chen K, Liu Q, Li Y, et al. Engineering a pyridoxal 5′-phosphate supply for cadaverine production by using Escherichia coli whole-cell biocatalysis. Sci Rep. 2015;5:15630.

Rios-Solis L, Bayir N, Halim M, Du C, Ward J, Baganz F, et al. Non-linear kinetic modelling of reversible bioconversions: application to the transaminase catalyzed synthesis of chiral amino-alcohols. Biochem Eng J. 2013;73:38–48.

Klatte S, Wendisch VF. Redox self-sufficient whole cell biotransformation for amination of alcohols. Bioorg Med Chem. 2014;22:5578–85.

Dong YX, Sueda S, Nikawa J, Kondo H. Characterization of the products of the genes SNO1 and SNZ1 involved in pyridoxine synthesis in Saccharomyces cerevisiae. Eur J Biochem. 2004;271:745–52.

Burns KE, Xiang Y, Kinsland CL, McLafferty FW, Begley TP. Reconstitution and biochemical characterization of a new pyridoxal-5′-phosphate biosynthetic pathway. J Am Chem Soc. 2005;127:3682–3.

Hanes JW, Keresztes I, Begley TP. 13C NMR snapshots of the complex reaction coordinate of pyridoxal phosphate synthase. Nat Chem Biol. 2008;4:425–30.

Neuwirth M, Strohmeier M, Windeisen V, Wallner S, Deller S, Rippe K, et al. X-ray crystal structure of Saccharomyces cerevisiae Pdx1 provides insights into the oligomeric nature of PLP synthases. FEBS Lett. 2009;583:2179–86.

Zhang X, Teng Y-B, Liu J-P, He Y-X, Zhou K, Chen Y, et al. Structural insights into the catalytic mechanism of the yeast pyridoxal 5-phosphate synthase Snz1. Biochem J. 2010;432:445–54.

Loubbardi A, Marcireau C, Karst F, Guilloton M. Sterol uptake induced by an impairment of pyridoxal phosphate synthesis in Saccharomyces cerevisiae: cloning and sequencing of the PDX3 gene encoding pyridoxine (pyridoxamine) phosphate oxidase. J Bacteriol. 1995;177:1817–23.

Kanellis P, Gagliardi M, Banath JP, Szilard RK, Nakada S, Galicia S, et al. A screen for suppressors of gross chromosomal rearrangements identifies a conserved role for PLP in preventing DNA lesions. PLoS Genet. 2007;3:e134.

Verduyn C, Postma E, Scheffers WA, van Dijken JP. Effect of benzoic acid on metabolic fluxes in yeasts: a continuous-culture study on the regulation of respiration and alcoholic fermentation. Yeast. 1992;8:501–17.

Nakamura I, Nishikawa Y, Kamihara T, Fukui S. Respiratory deficiency in Saccharomyces carlsbergensis 4228 caused by thiamine and its prevention by pyridoxine. Biochem Biophys Res Commun. 1974;59:771–6.

Rodriguez-Navarro S, Llorente B, Rodriguez-Manzaneque MT, Ramne A, Uber G, Marchesan D, et al. Functional analysis of yeast gene families involved in metabolism of vitamins B1 and B6. Yeast. 2002;19:1261–76.

Schell U, Wohlgemuth R, Ward JM. Synthesis of pyridoxamine 5′-phosphate using an MBA:pyruvate transaminase as biocatalyst. J Mol Catal B Enz. 2009;59:279–85.

Humble MS, Cassimjee KE, Hakansson M, Kimbung YR, Walse B, Abedi V, et al. Crystal structures of the Chromobacterium violaceum ω-transaminase reveal major structural rearrangements upon binding of coenzyme PLP. FEBS J. 2012;279:779–92.

Pronk JT, Steensma HY, van Dijken JP. Pyruvate metabolism in Saccharomyces cerevisiae. Yeast. 1996;12:1607–33.

Oud B, Flores CM, Gancedo C, Zhang X, Trueheart J, Daran JM, et al. An internal deletion in MTH1 enables growth on glucose of pyruvate-decarboxylase negative, non-fermentative Saccharomyces cerevisiae. Microb Cell Fact. 2012;11:131.

Jankowski MD, Henry CS, Broadbelt LJ, Hatzimanikatis V. Group contribution method for thermodynamic analysis of complex metabolic networks. Biophys J. 2008;95:1487–99.

Park ES, Kim M, Shin JS. Molecular determinants for substrate selectivity of ω-transaminases. Appl Microbiol Biotechnol. 2012;93:2425–35.

Valkonen M, Mojzita D, Penttilä M, Bencina M. Noninvasive high-throughput single-cell analysis of the intracellular pH of Saccharomyces cerevisiae by ratiometric flow cytometry. Appl Environ Microbiol. 2013;79:7179–87.

Valli M, Sauer M, Branduardi P, Borth N, Porro D, Mattanovich D. Intracellular pH distribution in Saccharomyces cerevisiae cell populations, analyzed by flow cytometry. Appl Environ Microbiol. 2005;71:1515–21.

Bea HS, Seo YM, Cha MH, Kim BG, Yun H. Kinetic resolution of α-methylbenzylamine by recombinant Pichia pastoris expressing ω-transaminase. Biotechnol Bioprocess Eng. 2010;15:429–34.

Stambuk B, Dunn B, Alves S, Duval E, Sherlock G. Industrial fuel ethanol yeasts contain adaptive copy number changes in genes involved in vitamin B1 and B6 biosynthesis. Genome Res. 2009;19:2271–8.

Enjo F, Nosaka K, Ogata M, Iwashima A, Nishimura H. Isolation and characterization of a thiamin transport gene, THI10, from Saccharomyces cerevisiae. J Biol Chem. 1997;272:19165–70.

Ishida S, Tazuya-Murayama K, Kijima Y, Yamada K. The direct precursor of the pyrimidine moiety of thiamin is not uracanic acid but histidine in Saccharomyces cerevisiae. J Nutr Sci Vitaminol. 2008;54:7–10.

Lai R, Huang S, Fenwick M, Hazra A, Zhang Z, Rajaskankar K, et al. Thiamin pyrimidine biosynthesis in Candida albicans: a remarkable reaction between histidine and pyridoxal phosphate. J Am Chem Soc. 2012;134:9157–9.

Mooney S, Leuendorf J, Hindrickson C, Hellmann H. Vitamin B6: a long known compound of surprising complexity. Molecules. 2009;14:239–351.

Klatte S, Wendisch VF. Role of l-alanine for redox self-sufficient amination of alcohols. Microb Cell Fact. 2015;14:9.

Höhne M, Kuhl S, Robins K, Bornscheuer UT. Efficient asymmetric synthesis of chiral amines by combining transaminase and pyruvate decarboxylase. ChemBioChem. 2008;9:363–5.

Postma E, Verduyn C, Scheffers W, van Dijken J. Enzymic analysis of the Crabtree effect in glucose-limited chemostat cultures of Saccharomyces cerevisiae. Appl Environ Microbiol. 1989;55:468–77.

Bengtsson O. Genetic traits beneficial for xylose utilisation by recombinant Saccharomyces cerevisiae. PhD Thesis. Lund: Lund University; 2008.

Authors’ contributions

NW participated in the design of the study, performed all the experiments, analysed the data, and drafted the manuscript. MGG participated in the design of the study and helped drafting the final manuscript. MC participated in the design and coordination of the study, and helped drafting and revising the manuscript. All authors read and approved the final manuscript.

Acknowledgements

We would like to thank Alisa Rizvanovic for the construction of the plasmids pNW12 and pNW14 and the strains TMB4369 and TMB4371, Dário Jorge Silva Neves for help with experiments on pyruvate accumulation, and Lei Ye (Lund University, Sweden) for ESI–MS measurements. We would like to thank Antonius van Maris (Delft University of Technology, Netherlands) for providing us with the TAM strain.

Competing interests

The authors declare that they have no competing interests.

Availability of data and materials

The datasets supporting the conclusions of this article are included within the article. Strains constructed in the current study are available from the corresponding author on request.

Funding

This work was supported by the Swedish Research Council FORMAS (Grant Number 229-2011-1052).

Author information

Authors and Affiliations

Corresponding author

Additional file

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

Weber, N., Gorwa-Grauslund, M. & Carlquist, M. Improvement of whole-cell transamination with Saccharomyces cerevisiae using metabolic engineering and cell pre-adaptation. Microb Cell Fact 16, 3 (2017). https://doi.org/10.1186/s12934-016-0615-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12934-016-0615-3