Abstract

Background

Recent forms of translucent zirconia material have been developed, offering a wide range of options and varieties for enhancing aesthetics, making it a preferred choice in the field of prosthetic dentistry. However, there is insufficient understanding regarding the recent types of zirconia materials and their optical behavior. Understanding the variables that influence the translucency of zirconia and identifying strategies to enhance its esthetics are crucial.

Purpose

The current systemic review highlights a comprehensive understanding of different zirconia generations in relation to their optical characteristics and evaluates material-related variables affecting their translucency.

Methods

The present review studied in-vitro studies that evaluated the optical characteristics of different yttria content of yttria stabilized materials. The topics explored were: (1) the different zirconia material generations and their optical behavior; (2) material-related factors that affect their translucency. The research was restricted to online publication in the English language from July 1, 2010, to July 31, 2023, using PubMed, Scopus, and Science Direct resources. The search key terms and their combinations were “zirconia,” “translucent zirconia,” “cubic zirconia,” “highly translucent zirconia,” “yttria partially stabilized zirconia,” “monolithic zirconia,” “translucency,” “optical properties,” and “light transmission.”

Results

The data obtained from fifty-three studies addressed the optical characteristics of various zirconia generations. They reported that changing yttria content had a significant impact on translucency. Different kinds of zirconia ceramics of the same generation have varying translucencies. Achieving optimum aesthetics with monolithic zirconia is challenging due to factors related to material aspects such as the presence of additives, point defects, microstructure, thickness, phase distribution, and sintering conditions.

Conclusions

Newly developed monolithic dental zirconia ceramics have improved aesthetics and translucency. However, additional research is necessary to evaluate their performance and long-term durability.

Trial Registration

This systematic review was registered in PROSPERO, under number CRD42023474482.

Similar content being viewed by others

Background

Achieving natural-looking dental restorations in dentistry can be challenging due to the complex optical characteristics of natural teeth. When light travels through a material, it undergoes partial reflection, scattering, and transmission. Translucency refers to the amount of light that can pass through a subject, and it is an important indicator of aesthetic outcomes of restoration. The degree of translucency is directly related to the amount of light that can pass through a material [1].

There are three numerical indicators used to assess the translucency of a material: the translucency parameter (TP), contrast ratio (CR), and light transmittance (T%). Johnston et al. were the first to use the translucency parameter as a direct way to measure translucency and analyze the optical properties of various dental materials [2, 3]. The TP is used to measure the color difference of a material against a black and white background, indicating its ability to mask different backgrounds. It is calculated using the equation [3, 4]:

L* refers to the degree of lightness between black (L = 0) and white (L = 100) and a range of gray shades in between. a* refers to redness and greenness [redness (a > 0) and greenness (a < 0)]. b* refers to yellowness to blueness [yellowness (b > 0) or blueness (b < 0) [3, 4]. A TP value of 100 indicates full transparency, while a value of 0 indicates complete opacity. The higher the TP value, the greater the translucency [5,6,7,8]:

To account for differences in texture, background, and otherfactors, a new formula incorporates weighting functions (SL, SC, and SH) and parametric factors (kL, kC, and kH) for the lightness, chroma, and hue, respectively. According to Yu et al. (2009), [9] human dentin at 1.0 mm thickness has a TP value of 16.4, while enamel is 18.7. Restorative materials should closely mimic the aesthetic of natural teeth.

CR refers to the opacity of materials, and is defined as the ratio of luminous reflectance (Y) of a given material against a black (Yb) and white (Yw) backgrounds [2, 5, 10,11,12]. When the values of two luminous reflectance values are equal, a CR value of 0 referring to completely translucent and 1 referring to completely opaque. Materials are classified into four translucency classes based on their CR values [13]:

-

(1)

CR up to 0.50 is considered a highly translucent material.

-

(2)

CR 0.50 to 0.75 is considered a medium translucent material.

-

(3)

CR 0.75 to 0.90 is considered a low translucent material.

-

(4)

CR 0.90 to 1.00 is considered very low translucent materials (highly masking).

Another approach to assessing translucency is by calculating the transmission coefficient of light passing through a material, and This coefficient is determined by the ratio of specimen luminance to the source of luminance with wavelengths ranging between 400 and 700 nm. The measured spectrum of light transmittance ranges from 0% (completely opaque) to 100% (completely transparent) [14, 15].

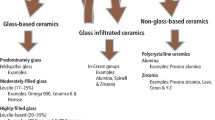

Recent advancements have been made in enhancing the translucency of zirconia materials, particularly yttria partially stabilized zirconia (Y-PSZ) [16, 17]. Yttria partially stabilized zirconia (Y-PSZ) has considered now a highly demanded restorative material [18, 19]. The first generation of zirconia introduced in the late 1990s was the yttria-tetragonal zirconia polycrystal (3Y-TZP). It contains 0.25–0.5 wt% alumina, has superior mechanical qualities (a flexural strength of about 900–1200 MPa), but has insufficient translucency. It served as a framework and was covered with feldspathic porcelain [20]. The opaque color of 3Y-TZP and porcelain veneer chipping were the main drawback [21]. To overcome this problem, a second generation of monolithic (fully anatomic) 3% mol yttria partial stabilized zirconia (3YPSZ) was produced in 2011 [18, 22]. Enhancing the heat treatment conditions, reducing alumina content (0–0.2 wt% alumina), and increasing the sintering temperature, the cubic content increased from 6–12% to 20–30% and grain size increased to (0.5 –0.7 μm). As a result, translucency is enhanced while the biaxial strength is reduced from 1150 to 900 MPa [23]. Despite the improved translucency of this generation in comparison to the first one, It does not satisfy the higher aesthetic demands. Lithium disilicate exhibit greater translucency, yet it is considered to have lower mechanical characteristics compared to zirconia [24,25,26].

In 2014, a third generation of 5% mol yttria partial stabilized zirconia (5YPSZ) (high translucent) was introduced. This generation has an increase in yttria content (which contains up to 9.42 wt% in comparison to about 5.15 wt% for traditional zirconia) and an improvement in translucency due to the increased amount of the isotropic cubic phase. However, the flexural strength was reduced to 700–800 MPa [27]. In 2015, a multi-layered zirconia was created to accurately mimic the color gradient of natural teeth. Two varieties of multi-layered zirconia are available: (1) polychromatic multilayer uniform composition type (M5Y PSZ), where all layers gradually change in chroma from darker cervically to lighter incisal but have the same composition and opacity, and (2) polychromatic and hybrid composition multilayer (M3Y –5Y PSZ), where the layers vary in composition, chroma, and opacity [28].

In 2018, a fourth generation of PSZ (4Y PSZ), was developed, which falls between high-translucent zirconia (5Y PSZ) and high-strength (3Y PSZ) zirconia, having a flexural strength of 600 to 900 MPa. [18, 29] In addition, polychromatic multilayer type (M4Y) was introduced from 2018 to 2019. Recently, the fifth generation of ultra-high translucent zirconia (6Y-PSZ) and multilayered (M6Y-PSZ) were introduced, which have a higher yttria content (6 mol%), resulting in greater translucency but lower mechanical properties [18].

Overall, the evolution of zirconia materials in dentistry has provided practitioners with a wider range of options to meet the diverse needs of their patients. While previous researchers have conducted studies and provided classifications for dental zirconia, there is a lack of recent advances and updates to the optical behavior of these various types of highly translucent zirconia. Furthermore, the optical characteristics of zirconia could be affected by more than just its change in yttria concentration. Therefore, the current systematic review was conducted to provide a comprehensive and up-to-date overview of the recent types of translucent zirconia and to determine material-related factors that contribute to the translucency of zirconia material.

Methods

This systematic review complied with the guidelines of the Preferred Reporting Items for Systematic Reviews (PRISMA) [30] and it was registered in the International Prospective Register of Systematic Reviews – PROSPERO under number CRD42023474482. Figure 1 summarizes the search strategy following the PRISMA guidelines.

The main PICO question [4] (P: population; I: intervention; C: control; O: outcome) was: (P) translucent zirconia with yttria content higher than 3 mol% yttria stabilized zirconia, (I) changing in yttria concentration in different zirconia materials would affect translucency. C: control group: 3% mol yttria stabilized zirconia. O: outcome of interest was the optical characteristics of these materials and the variables that influenced them.

Eligibility criteria

All English in-vitro studies measuring translucency parameters, contrast ratio, or light transmission with uniform-thickness specimens were included in the review. As the sintering procedure is of such great significance for the densification behavior of zirconia, which reflects on the microstructure, mechanical, and optical properties of zirconia, the type of sintering used was mentioned in the review. Studies that combined zirconia core with veneering porcelain, zirconia veneer, crowns, implants, zirconia with a stabilizer other than Y2O3, or zirconia that has been processed via raw powder or additively manufactured zirconia were all excluded.

Studies that examine the optical characteristics of various layers within multilayer pre-colored zirconia, as well as external variables affecting the optical properties of zirconia material, including the underlying dental background, cement, or glazing, were not included in the study. In studies that examined how translucency changed after different processes, like aging, low-temperature degradation, or any kind of surface treatment, the current review only included the results of the control group that was not affected by the variables being tested.

Search strategy

The search strategy used PubMed, Scopus, and Science Direct resources. The search was limited to English-language opened research articles published from 2010 to 2023. Boolean operators were used along with the following search keywords to identify relevant articles: “zirconia” OR “translucent zirconia” OR “cubic zirconia,” OR “highly translucent zirconia,” OR “yttria partially stabilized zirconia” OR “monolithic zirconia” AND “translucency” OR “optical properties” OR “light transmission”. The last database search was conducted on July 31, 2023. All identified keywords were adapted for each included information source and is provided in Appendix 1.

Study screening and data extraction

Two reviewers (MY, MH) individually assessed the study titles and abstracts, choosing those that mostly satisfied the inclusion criteria for full study screening. The two reviewers conducted an independent evaluation of the chosen full-text publications, taking into consideration the predetermined inclusion and exclusion criteria. If there was disagreement, a third reviewer (MA) was consulted before the final decision on which papers to include had been made. Cohen’s kappa test was applied to assess the agreement between reviewers. The results were also expressed as the concordance between reviewers (%). The extracted data obtained for analysis were as follows: the authors, publication year, test method, material used/brand name, specimens tested number, sintering protocol used, specimen thickness, device used for optical measurement, and optical results. Extracted data were recorded using a Microsoft Excel spreadsheet (Microsoft Excel 2019 VL 16.44; Microsoft Corp., WA, USA).

Quality assessment

The risk of bias assessment of the included studies were performed using “Guidelines for Reporting Pre-Clinical In-Vitro Studies on Dental Materials” formulated by Faggion [31]. The risk of bias criteria were modified from prior studies [32,33,34,35], and assessed based on several parameters, including a structured summary in the abstract, the calculation of sample size, randomization of the specimens, an obvious description of sample preparation methods, adherence to the manufacturer’s recommendation for sintering, a clear description of methods used for optical properties, a clear reporting of outcomes with defined numbers and standard deviations, and statistical analysis used. The data-collection process involved using a predetermined table to evaluate the included articles. The ranking of each category ranged from 0 to 2, with 0; indicating clear reporting of the parameter by the author (s). 1; indicating that the author (s) reported the category but did not specify the parameter accuracy; and 2; if the author (s) have not obviously indicated the category or when the data is absent, the overall number of assigned values was documented, and every study was categorized based on the following criteria: studies with a sum between 0 and 4 were considered to have a low risk, those with a sum between 5 and 9 were considered to have a medium risk, and those with a sum between 10 and 14 were considered to have a high risk of bias. A predetermined table was used for data collection to evaluate the final articles.

Meta-analysis

The systematic review did not include light transmittance since there was insufficient data for a meta-analysis. The outcome of translucency parameter and contrast ratio under different thicknesses (1.5, 1, 0.5, and 0.4 mm) were evaluated and compared between studies by meta-analysis using the RevMan software (Review Manager 5.4.1, The Nordic Cochrane Center, Copenhagen, Denmark) employing a random effect model [36]. Mean differences (MDs) and 95% confidence intervals (CIs) were used for the calculations. The control group was 3 mol yttria partially stabilized zirconia and the interventional groups contained more than 3 mol yttria (4,5, and 6 mol yttria). The p-values from the Q and I2 tests were used to identify heterogeneity; heterogeneity was determined to exist when the Q test’s p-value was less than 0.01. Heterogeneity was estimated to be minimal when the I2 test result was 25–50%; moderate when it was 50–75%; and high when it was greater than 75%. The findings were shown in the form of forest plots.

Results

A schematic representation of the process employed for conducting the systematic review, complying with the guidelines outlined in the PRISMA statement, is represented in Fig. 1. The preliminary electronic searches conducted on PubMed, Scopus, and science direct resources yielded a total of 255, 187, and 230 studies, respectively. A total of 292 studies were primarily selected after the removal of duplicate studies to be assessed for their titles and abstracts. 231 studies were excluded as they did not fulfil the eligibility criteria. Consequently, only 62 studies remained and were chosen for a comprehensive analysis of their entire texts. One repeated result data and seven studies tested low temperature degradation, aging, and surface treatment without a control group; all were excluded. So, in the present systematic review, a total of 54 studies were incorporated. A 92% concordance with a Kappa coefficient of 0.78 (SE 0.082, 95% CI [0.619,0.941]) for titles and abstracts and a 93.5% concordance was found between the 2 reviewers, with a Kappa coefficient of 0.84 (SE 0.05, 95% CI [0.742, 0.938]) for full-text studies.

A total of 35 studies exhibited a low risk of bias, while 17 studies revealed a medium risk of bias. Additionally, one article identified a high risk of bias. The assessment of the risk of bias for the included studies is demonstrated in Table 1. All the included studies provided sufficient data regarding the measurements of translucency, except for 10 studies that did not provide numerical values for optical measurement. A comprehensive detail of the studies included in the systematic review analysis is presented in Table 2, including information about each study’s authors, year, material brand names tested, kind of YPSZ, specimens tested number, type of sintering protocol used, specimen thickness, optical device used for measurement, and outcome results of the studies. In 22 studies, the number of tested specimens was 10, while 2 studies tested 12 specimens, 7 studies tested 15 specimens, 10 studies tested 5 specimens, and 3 studies tested 30 specimens. Only one study evaluated three specimens [37]. Luz et al. 2021 did not mention sample size [38]. Twenty-seven studies focused on evaluating different sintering protocols on the translucency. In 29 studies, the traditional CIE equation was used, while in 6 studies, the newest CIEDE2000 equation was applied. Twenty-two studies calculated the contrast ratio, and ten studies tested total transmittance. A full review of the classification of commercial zirconia materials and their brand names is presented in Table 3, as given by manufacturers or in connected references. The translucency parameter (TP) of 5 YPSZ for 1 mm thickness was varied from 9.37 to 29.7, TP of 3 YPSZ for 1 mm thickness was varied from 4.43 to 24, TP of 5 YPSZ for 0.5 mm thickness was varied from 20.4 to 36.7, and the CR of 5 YPSZ varied from 0.4 to 0.94. A total of 28 studies were incorporated into the meta-analysis. Studies that examined various kinds of YSZ or specimen thicknesses were counted on multiple occasions in the meta-analysis. The results showed high heterogeneity between studies except for the studies comparing 3 YPSZ and 5 YPSZ contrast ratio at thickness 1.5 mm. According to translucency parameter, there were statistically significant differences between control group and interventional groups (P value ≤ 0.0001) except between 3Y-PSZ and 4Y-PSZ at 1.5 mm thickness, to be 22.49 with a 95% confidence interval (CI) between 19.85 and 25.13. Meta-analysis found high heterogeneity of translucency parameter and contrast ratio between subgroups, I2 more than 75% (p < 0.0001) (Figs. 2 and 3).

Discussion

The current review presents several studies that have been conducted to examine the optical characteristics of zirconia. However, the findings of these studies have shown high heterogeneity in results seen in some analyses, which can be attributed to a combination of factors, including variances in the instruments used, the wide range of materials tested, the differences in methods used for sample preparation, and the large number of covariables that are associated with heterogeneity. Most of these studies focused on the translucency parameter test. This may be due to the direct calculations in the translucency parameter method, while light transmittance and CR methods have been utilized in spectral or luminous conditions [90]. Furthermore, the translucency parameter values of dentin and enamel can be used as a reference when comparing the values reported in the literature. As it was estimated by Yu 2009 [9], the translucency parameter value of 1 mm of dentin was 16.4 and that of enamel was 18.7. Park 2022, Cho 2020, found that the translucency parameter of highly translucent zirconia (5Y PSZ) at a thickness of 0.8 mm was nearly that of lithium disilicate and dentin [45, 55]. Mourouzis 2022 [47], Reyes 2023 [51], Elsaka 2019 [64], Sen 2018 [71] and Mao 2018 [37] found that the translucency parameter of highly translucent zirconia (5Y PSZ) had a value range from 32.81 to 18.95 at a thickness of 1 mm, which was higher than the estimated TP value of human dentin or enamel at 1 mm.

The control of desired color and aesthetic qualities in zirconia dental restorations is a complex process that can be influenced by a combination of material and clinical variables [13, 79, 82, 83, 86,87,88, 91, 92]. The clinical variables include the underlying tooth structure, cement layer, surface structure, thickness, light sources, glazing, external staining, and the influence of different surface treatment conditions [93]. The current systematic review focused on the material-related variables that affect the translucency of yttria-stabilized zirconia materials, which were the influence of sintering additives, point defects, thickness, sintering condition, microstructure, density, t'-phase, coloring effect, manufacturing processes (blank fabrication), and coloring effect.

Influence of sintering additives

Amount of yttria content (3% or 5–8%)

A common method is adding yttria content to the zirconia composition at a higher percentage to stabilize it, which results in an increased cubic phase and improved translucency. This correlation is related to the isotropic (uniform) feature of the cubic zirconia structure, which allows light to pass through more easily [23, 55, 70, 76]. In comparison to 3Y, the translucency of 5Y is enhanced by 20 to 25% [81].

Alumina content

A change in the aluminum percentage had a notable impact on translucency. When the aluminum exceeded 0.41%, the translucency decreased, as demonstrated by Walczak et al. 2019 [62], Elsaka et al. 2019 [64], Sen et al. 2018 [71], Carrabba 2017 [76], and Vichi et al. 2016 [79] as it has a different refractive index than zirconia (n = 1.76 for alumina and n = 2.21 for zirconia [94]. Reducing alumina content to below 0.05% has no noticeable effect on the material’s mechanical properties [81]. The total removal of alumina content is unnecessary, as the alumina-free 3Y-TZP had similar translucency to the 3Y-0.05 alumina content ceramic [23].

Point defects

In the Y-TZP lattice, defects like oxygen vacancies can form, which were considered intrinsic features of oxides. These lead to an increased absorption coefficient of light and decreased light transmission (increased opacity). Oxygen vacancies can influence the color of zirconia. Based on the concentration and arrangement of oxygen vacancies, zirconia can exhibit different colors [95]. Controlling and manipulating oxygen vacancies in zirconia is an active area of research, as it allows tailoring the material’s properties for specific applications. Techniques like doping with specific elements, optimizing processing conditions, or using nanoscale engineering approaches can be employed to modulate the concentration and behavior of oxygen vacancies in zirconia [95, 96]. It is recommended to do after sintering air-based heat treatment (annealing) at 750 °C to get back oxygen into the crystal structure to get rid of the oxygen vacancies, which lowers the absorption coefficient and allows more transmission of light (increases translucency). However, there would be no change in the grain size or the true porosity at this low temperature [97].

Sintering condition

Several studies focused on evaluating the optical properties of zirconia after different sintering conditions, as it played a significant role in determining optical and mechanical properties [39, 41,42,43,44, 46,47,48, 50, 52,53,54, 56,57,58,59, 65,66,67,68, 71, 75, 85, 87,88,89].

Sintering regulations such as final sintering temperature, total sintering duration, heating rate, and dwell time determine the microstructure, density, grain size, material stability, porosity, and crystalline content of zirconia [67, 84, 87, 88, 98].

Sintering temperature

Stawarczyk et al. 2013,2014 [84, 87] stated that an elevated final sintering temperature results in enhanced translucency through increased grain size, reduced porosity, a more compact crystalline structure, and increased density of zirconia. An increase in the grain size of zirconia was observed when the sintering temperature exceeded 1,300 °C. However, grain expansion caused neighbouring grains to be compressed, and hollow voids formed in the zirconia microstructure when sintering temperatures exceeded 1,600 °C.

Sintering time

There is debate regarding how different sintering times affect the translucency of zirconia. Several studies suggested speed sintering procedures resulted in a reduction in translucency. that further investigations are necessary to find out the effect of different sintering methods on various YSZ [42, 43, 52, 53, 56, 65, 66, 75]. Salah 2023 found that superspeed sintering for 10 min significantly reduced translucency and resulted in a greater change in color [39]. The findings of a study conducted by Lawson 2020 [59] indicated that speed sintering led to an increase in average grain size and pore formation, which decreased the translucency. On the other hand, conventional sintering took longer time, resulting in growth, segregation of the grains, and decreased porosity. Contradictory results were found in previous investigations by Kim 2013 and Vichi 2016, that reducing the sintering process decreases the grain size, which raises the light transmittance of Y-TZP [79, 88]. Microwave sintering was found to improve properties such as larger grain size and greater color value, whereas conventional sintering enhanced translucency slightly [75].

Microstructure

Grain size

Zhang et al. 2012 [99] stated that the preferred grain size is 80 nm or less to increase the translucency of a zirconia ceramic to mimic that of dental porcelains. On the contrary, Jiang et al. 2011 observed that increasing the grain size from 40 to 90 nm, decreased the translucency of zirconia [89]. and this was in agreement with Kim 2013 and Vichi 2016 [79, 88]. Zhang suggested that for optimal translucency, a thickness of 2 mm would require a grain size of 70 nm, and a thickness of 1.3 mm would require a grain size of 82 nm [94]. Another study claimed that translucency is dependent on the average grain size and the number of grain boundaries. Reduced grain size leads to an increase in grain boundaries, which in turn causes a decrease in translucency. The increased sintering temperature of Y-TZP causes an increase in grain size and enhanced translucency [54, 58, 67, 71, 85, 87,88,89, 100].

Pores and grain boundaries

Pores are primarily responsible for the occurrence of light scattering, especially if their size closely matches those of visible light wavelengths, which range between 400 and 700 nm [65, 101]. Interaction with light is caused by different refractive indices at various interfaces, including grain/pore, grain/grain, and distinct crystallographic anisotropic grains. Porosities contribute to light scattering and reduce translucency since air has a refractive index of n = 1 and zirconia has a refractive index of n = 2.1–2.2 [102]. Translucency can be reduced if the size of the porosity is between 200 and 400 nm and the porosity contents are as low as 0.05%. Through the manipulation of sintering parameters, including an increase in temperature and time, porosities can be reduced [84, 87].

Phase distribution

The tetragonal zirconia crystal possesses an anisotropic crystalline structure, which leads to birefringence or optical anisotropy (a single incoming ray is refracted in two directions). This means that due to the dissimilar crystal orientation of adjacent grains in the zirconia structure, the refractive index (∆n) breaks at the boundaries, resulting in the scattering of light [102]. This light scattering led to both refraction and reflection at grain boundaries, with alterations in the incident light beam direction and a resultant diminishment in the light transmittance [54, 58, 71, 85, 87, 89, 94].

t’-phase

By changing the phase composition through a specific cooling process, it was possible to make a translucent monolithic zirconia that contained t’-phase without adding any dopant elements. Kim et al. 2020 found that a rapid-cooling protocol enhanced the translucency of 3–5 mol% Y-PSZ. They attributed that to the formation of t’-ZrO2, which contributes to improving the light that passes through the zirconia, making it more transparent [57]. The material attained a stable state through annealing at 1550 ◦C, and during the rapid cooling process, the c-phase changed into the t’-phase without the t-phase changing into the m-phase. The c-phase underwent a diffusionless transition to the t’-phase, which remained stable at room temperature. The t’-phase in translucent zirconia is formed through a diffusionless mechanism where oxygen ions in the lattice parameter are displaced. Due to this displacement, new domains are created that have crystal parameters close to those of the isotropic structure. This characteristic improves translucency by minimizing birefringence-induced light scattering [57].

Density

To achieve 95% of its theoretical density, the sintering temperature of yttria-stabilized zirconia (YSZ) needs to be raised to 1350 °C. However, a sintering temperature of 1500 °C ensures that zirconia will attain its theoretical density [87, 89, 103]. Furthermore, it has been observed that the density of the material increases when the heating rate is raised from 50 °C to 100 °C. However, it should be noted that above 100 ◦C, the density decreases because of the rapid aggregation of the particles, leading to inadequate densification and pore formation [79, 104].

Thickness

A negative correlation was observed between material thickness and translucency [66]. For highly translucent zirconia, the optimal mechanical and aesthetic range of thickness is likely to be between 0.5 and 1 mm, while a clinical range of 0.5 to 0.75 mm may be considered acceptable for conventional zirconia monolithic restorations [70].

The translucency of e-max CAD LT was higher by 20% than that of 5-YPSZ and 6-YPSZ specimens at 0.5- and 1-mm thickness; however, the 1 mm e-max CAD LT specimen exhibited a lower level of translucency than 0.5 mm of 5-YPSZ and 6-YPSZ. For successful monolithic restorations with reduced occlusal thickness and minimal tooth reduction, 5-YPSZ, 6-YPSZ could be utilized as alternatives to lithium disilicate that requires a thicker occlusal layer for optimal outcomes [81]. Recent studies demonstrated that 5 mol% yttria-partial stabilized zirconia and lithium disilicate exhibited similar levels of translucency [81, 105] which made high-translucent zirconia to be used with a reduced thickness than lithium disilicate in high-aesthetic areas [28, 72, 81, 105]. Increased TP values were found for conventional sintering at 1 and 0.5 mm, while the sintering procedure had no effect on the TP values at 1.5 mm [75].

Manufacturing processes (Blank fabrication)

For manufacturing monolithic ZrO2 blanks, the ZrO2 powder is first grounded to decrease the particle size and then combined with a binder to get rid of the closed pores, increase the density, and compact the green body. This method improves the monolithic ZrO2 light transmission and allows for higher natural shade, as stated by Vichi et al. (2016) who stated that the chemical purity of the powder, granule properties, pressing sort, and treatment before sintering are all important aspects of this manufacturing procedure that determine the final characteristics [79].

Coloring effect

Use of pre-colored blocks, immersion of white zirconia in coloring solutions, or painting of the restorations are all viable options for coloring monolithic zirconia restorations. Elsaka 2019 compared the optical characteristics of multilayer and monochromatic monolithic zirconia. Multilayered zirconia exhibited significantly increased TP and decreased CR values in comparison to monochromatic zirconia; these differences were correlated with the greater number of grains present in the multilayer zirconia [64]. Carrabba 2017, compared three uncolored of different Y-TZP, there were statistically significant differences between groups [76]. Sen et al. 2018 found that the translucency of the noncolored and precolored groups was significantly higher than the translucency of colored YPZ sintered at a final temperature of 1350◦C. Coloring liquid had no effect on the translucency of YPZ, whereas it decreased the translucency of fully stabilized translucent zirconia [71]. Kim 2016 [78] concluded that TP values varied significantly between various shades of the same zirconia brand. There were statistically significant variations in TP values between brands, even for a corresponding shade.

Based on the findings of this review, clinicians are advised to know the recent variations of zirconia and understand the differences among its various types. Furthermore, the management of the desired translucency and color characteristics of zirconia restoration is a complex procedure that can be affected by an interaction of internal factors related to the material used, as well as external factors associated with the substrate and surroundings of the restorations. Understanding these factors aids in choosing the appropriate type of zirconia according to the clinical condition.

According to the present literature, monolithic translucent zirconia has shown promising esthetic outcomes, making it a suitable choice for cases requiring esthetics. However, some limitations were present since detailed data could not be fully obtained on the external variable affecting the translucency of zirconia. Also, the review compared different in vitro studies that used various types of zirconia. However, further research on clinical trials with extended follow-up periods should be conducted to acquire stronger evidence and support the findings.

Conclusions

Within the limitations of this study, it was concluded that recent research has explored the application of yttria partly stabilized zirconia with varying yttria percentages to enhance its translucency. However, achieving the desired translucency and color characteristics of zirconia restorations is a complex process not only influenced by yttria percentage. It can also be affected by interactions with other internal factors related to the material used, as well as external factors associated with the substrate and surroundings of the restorations.

Availability of data and materials

All data generated or analyzed from this study are included in this published article.

References

Vichi A, Louca C, Corciolani G, Ferrari M. Color related to ceramic and zirconia restorations: a review. Dent Mater. 2011;27:97–108.

Johnston WM. Review of translucency determinations and applications to dental materials. J Esthet Restor Dent. 2014;26:217–23.

Johnston WM, Ma T, Kienle BH. Translucency parameter of colorants for maxillofacial prostheses. Int J Prosthodont. 1995;8:79–86.

Soares PV, Spini PH, Carvalho VF, Souza PG, Gonzaga RC, Tolentino AB, Machado AC. Esthetic rehabilitation with laminated ceramic veneers reinforced by lithium disilicate. Quintessence Int. 2014;45:129–33.

Conrad HJ, Seong WJ, Pesun IJ. Current ceramic materials and systems with clinical recommendations: a systematic review. J Prosthet Dent. 2007;98:389–404.

Commission Internationale de l’Eclairage (CIE). Colorimetry-Technical Report. 3rd ed. Vienna: Bureau Central de la CIE; 2004.

Luo MR, Cui G, Rigg B. The development of the CIE 2000 color-difference formula: CIEDE2000. Color Research & Application: Endorsed by Inter‐Society Color Council, The Colour Group (Great Britain), Canadian Society for Color, Color Science Association of Japan, Dutch Society for the Study of Color, The Swedish Colour Centre Foundation, Colour Society of Australia, Centre Français de la Couleur. 2001;26(5):340–50.

Sharma G, Wu W, Dalal EN. The CIEDE2000 color‐difference formula: Implementation notes, supplementary test data, and mathematical observations. Color Research & Application: Endorsed by Inter‐Society Color Council, The Colour Group (Great Britain), Canadian Society for Color, Color Science Association of Japan, Dutch Society for the Study of Color, The Swedish Colour Centre Foundation, Colour Society of Australia, Centre Français de la Couleur. 2005;30(1):21–30.

Yu B, Ahn JS, Lee YK. Measurement of translucency of tooth enamel and dentin. Acta Odontol Scand. 2009;67:57–64.

Lee YK. Translucency of human teeth and dental restorative materials and its clinical relevance. J Biomed Opt. 2015;20:045002.

Barizon KT, Bergeron C, Vargas MA, Qian F, Cobb DS, Gratton DG, Geraldeli S. Ceramic materials for porcelain veneers. Part I: Correlation between translucency parameters and contrast ratio. J Prosthet Dent. 2013;110:397–401.

Standard CI. Colorimetry-part 4: CIE 1976 L* a* b* colour space. International Standard. 2007:2019–06.

Vichi A, Carrabba M, Paravina R, Ferrari M. Translucency of ceramic materials for CEREC CAD/CAM system. J Esthet Restor Dent. 2014;26:224–31.

Bielen V, Inokoshi M, Munck JD, Zhang F, Vanmeensel K, Minakuchi S, et al. Bonding effectiveness to differently sandblasted dental zirconia. J Adhes Dent. 2015;17:235–42.

Scaminaci Russo D, Cinelli F, Sarti C, Giachetti L. Adhesion to zirconia: A systematic review of current conditioning methods and bonding materials. Dent J (Basel). 2019;7:74.

Sturzenegger B, Luthy A, Schumacher M, Loeffel O, Filser F, Kocher P, et al. Klinische studie von Zirkonoxidbrucken im Seitenzahngebiet, hergestellt mit dem DCM-System. Schweiz Monatsschr Zahnmed. 2000;110:131–9.

Kaizer MR, Kolakarnprasert N, Rodrigues C, Chai H, Zhang Y. Probing the interfacial strength of novel multi-layer zirconias. Dent Mater. 2020;36:60–7.

Ban S. Classification and properties of dental zirconia as implant fixtures and superstructures. Materials (Basel). 2021;14:4879.

Ban S. Development and characterization of ultra-high translucent zirconia using new manufacturing technology. Dent Mater J. 2023;42:1–10.

Christel P, Meunier A, Heller M, Torre JP, Peille CN. Mechanical properties and short-term in-vivo evaluation of yttrium-oxide-partially-stabilized zirconia. J Biomed Mater Res. 1989;23:45–61.

Tuncel İ, Turp I, Üşümez A. Evaluation of translucency of monolithic zirconia and framework zirconia materials. J Adv Prosthodont. 2016;8:181–6.

Ghodsi S, Jafarian Z. A review on translucent zirconia. Eur J Prosthodont Restor Dent. 2018;26:62–74.

Zhang Y, Lawn BR. Novel zirconia materials in dentistry. J Dent Res. 2018;97:140–7.

Zarone F, Ferrari M, Mangano FG, Leone R, Sorrentino R. “Digitally Oriented Materials”: focus on lithium disilicate ceramics. Int J Dent. 2016;2016:9840594.

Pieger S, Salman A, Bidra AS. Clinical outcomes of lithium disilicate single crowns and partial fixed dental prostheses: a systematic review. J Prosthet Dent. 2014;112:22–30.

Ziyad TA, Abu-Naba’a LA, Almohammed SN. Optical properties of CAD-CAM monolithic systems compared: three multi-layered zirconia and one lithium disilicate system. Heliyon. 2021;7:e08151.

Ban S. Evolution of dental zirconia and features of new high translucent multi-layer type. Dent Diam. 2016;41:140–51.

Vardhaman S, Borba M, Kaizer MR, Kim D, Zhang Y. Wear behavior and microstructural characterization of translucent multilayer zirconia. Dent Mater. 2020;36:1407–17.

Amano S, Fujisaki H, Nagayama H, Azechi S. Dental zirconia powder “Zpex4.” Tosoh Res Tech Rev. 2019;63:61–5.

Page MJ, McKenzie JE, Bossuyt PM, Boutron I, Hoffmann TC, Mulrow CD, et al. The PRISMA 2020 statement: an updated guideline for reporting systematic reviews. BMJ. 2021;372:n71.

Faggion CM Jr. Guidelines for reporting pre-clinical in vitro studies on dental materials. J Evid Based Dent Pract. 2012;12:182–9.

Pereira GKR, Venturini AB, Silvestri T, Dapieve KS, Montagner AF, Soares FZM, Valandro LF. Low-temperature degradation of Y-TZP ceramics: A systematic review and meta-analysis. J Mech Behav Biomed Mater. 2015;55:151–63.

Zhang CY, Agingu C, Tsoi JKH, Yu H. Effects of aging on the color and translucency of monolithic translucent Y-TZP ceramics: a systematic review and meta-analysis of in vitro studies. Biomed Res Int. 2021;2021:8875023.

Zhang LX, Hong DW, Zheng M, Yu H. Is the bond strength of zirconia-reinforced lithium silicate lower than that of lithium disilicate? - A systematic review and meta-analysis. J Prosthodont Res. 2022;66:530–7.

Hajhamid B, Alfrisany N, Somogyi-Ganss E. The effect of accelerated aging on crystalline structures and optical properties of different monolithic zirconia: A qualitative systematic review. Dent Mater. 2022;38:569–86.

Higgins JPT, Green S. Cochrane Handbook for Systematic Reviews of Interventions. Version 5.1.0. (updated March2011). The Cochrane Collaboration. 2011. Available at: www.cochrane-handbook.org.

Mao L, Kaizer MR, Zhao M, Guo B, Song YF, Zhang Y. Graded ultra-translucent zirconia (5Y-PSZ) for strength and functionalities. J Dent Res. 2018;97:1222–8.

Luz JN, Kaizer MDR, Ramos NC, Anami LC, Thompson VP, Saavedra G, Zhang Y. Novel speed sintered zirconia by microwave technology. Dent Mater. 2021;37:875–81.

Salah K, Sherif AH, Mandour MH, Nossair SA. Optical effect of rapid sintering protocols on different types of zirconia. J Prosthet Dent. 2023;130:253.e1-.e7.

Yousry MA, Hammad IA, El Halawani MT, Aboushelib MN. Effect of sintering time on microstructure and optical properties of yttria-partially stabilized monolithic zirconia. Dent Mater. 2023;S0109–5641:00412–8.

Yılmaz Savaş T, Akın C. Effects of sintering protocol and dipping time on the optical properties of monolithic zirconia. J Prosthet Dent. 2022;127:801.e1-.e8.

Liu H, Inokoshi M, Nozaki K, Shimizubata M, Nakai H, Cho Too TD, Minakuchi S. Influence of high-speed sintering protocols on translucency, mechanical properties, microstructure, crystallography, and low-temperature degradation of highly translucent zirconia. Dent Mater. 2022;38:451–68.

Liu YC, Lin TH, Lin YY, Hu SW, Liu JF, Yang CC, Yan M. Optical properties evaluation of rapid sintered translucent zirconia with two dental colorimeters. J Dent Sci. 2022;17:155–61.

Vafaei F, Shahbazi A, Hooshyarfard A, Najafi AH, Ebrahimi M, Farhadian M. Effect of sintering temperature on translucency parameter of zirconia blocks. Dent Res J (Isfahan). 2022;19:82.

Park JH, Bang HJ, Choi NH, Park EJ. Translucency and masking ability of translucent zirconia; comparison with conventional zirconia and lithium disilicate. J Adv Prosthodont. 2022;14:324–33.

Kongkiatkamon S, Peampring C. Effect of speed sintering on low temperature degradation and biaxial flexural strength of 5Y-TZP Zirconia. Molecules. 2022;27:5272.

Mourouzis P, Tolidis K. Effects of milling method and artificial ageing on optical properties of high translucent zirconia for chairside restorations. Dent Mater. 2022;38:108–20.

Kanpalta B, Burduroğlu D, Kara Ö. Effect of artificial aging on the translucency of monolithic zirconia materials sintered at different temperatures. J Prosthet Dent. 2022;128:91.e1-.e6.

Jerman E, Lümkemann N, Eichberger M, Zoller C, Nothelfer S, Kienle A, Stawarczyk B. Evaluation of translucency, Marten’s hardness, biaxial flexural strength and fracture toughness of 3Y-TZP, 4Y-TZP and 5Y-TZP materials. Dent Mater. 2021;37:212–22.

Lümkemann N, Stawarczyk B. Impact of hydrothermal aging on the light transmittance and flexural strength of colored yttria-stabilized zirconia materials of different formulations. J Prosthet Dent. 2021;125:518–26.

Reale Reyes A, Dennison JB, Powers JM, Sierraalta M, Yaman P. Translucency and flexural strength of translucent zirconia ceramics. J Prosthet Dent. 2023;129:644–9.

Pekkan K. Effect of sintering regimes and thickness on optical properties of zirconia ceramics for dental applications. Int J Appl Ceram Technol. 2021;18:1354–64.

Yang C-C, Ding S-J, Lin T-H, Yan M. Mechanical and optical properties evaluation of rapid sintered dental zirconia. Ceram Int. 2020;46:26668–74.

Cardoso KV, Adabo GL, Mariscal-Muñoz E, Antonio SG, Arioli Filho JN. Effect of sintering temperature on microstructure, flexural strength, and optical properties of a fully stabilized monolithic zirconia. J Prosthet Dent. 2020;124:594–8.

Cho YE, Lim YJ, Han JS, Yeo IL, Yoon HI. Effect of yttria content on the translucency and masking ability of yttria-stabilized tetragonal zirconia polycrystal. Materials (Basel). 2020;13:4726.

Cokic SM, Vleugels J, Van Meerbeek B, Camargo B, Willems E, Li M, Zhang F. Mechanical properties, aging stability and translucency of speed-sintered zirconia for chairside restorations. Dent Mater. 2020;36:959–72.

Kim HK. Effect of a rapid-cooling protocol on the optical and mechanical properties of dental monolithic zirconia containing 3–5 mol% Y (2)O (3). Materials (Basel). 2020;13:1923.

Sanal FA, Kilinc H. Effect of shade and sintering temperature on the translucency parameter of a novel multi-layered monolithic zirconia in different thicknesses. J Esthet Restor Dent. 2020;32:607–14.

Lawson NC, Maharishi A. Strength and translucency of zirconia after high-speed sintering. J Esthet Restor Dent. 2020;32:219–25.

Aljanobi G, Al-Sowygh ZH. The effect of thermocycling on the translucency and color stability of modified glass ceramic and multilayer zirconia materials. Cureus. 2020;12:e6968.

Zhang F, Reveron H, Spies BC, Van Meerbeek B, Chevalier J. Trade-off between fracture resistance and translucency of zirconia and lithium-disilicate glass ceramics for monolithic restorations. Acta Biomater. 2019;91:24–34.

Walczak K, Meißner H, Range U, Sakkas A, Boening K, Wieckiewicz M, Konstantinidis I. Translucency of zirconia ceramics before and after artificial aging. J Prosthodont. 2019;28:e319–24.

Alshamrani AA, De Souza GM. Effect of ionizing radiation on mechanical properties and translucency of monolithic zirconia. J Biomed Mater Res B Appl Biomater. 2020;108:1068–76.

Elsaka SE. Optical and mechanical properties of newly developed monolithic multilayer zirconia. J Prosthodont. 2019;28:e279–84.

Li L, Zhao C, Du Z, Qiu Y, Si W. Rapid-sintered dental zirconia for chair-side one-visit application. Int J Appl Ceram. 2019;16:1830–5.

Jansen JU, Lümkemann N, Letz I, Pfefferle R, Sener B, Stawarczyk B. Impact of high-speed sintering on translucency, phase content, grain sizes, and flexural strength of 3Y-TZP and 4Y-TZP zirconia materials. J Prosthet Dent. 2019;122:396–403.

Juntavee N, Attashu S. Effect of sintering process on color parameters of nano-sized yttria partially stabilized tetragonal monolithic zirconia. J Clin Exp Dent. 2018;10:e794–804.

Yan J, Kaizer MR, Zhang Y. Load-bearing capacity of lithium disilicate and ultra-translucent zirconias. J Mech Behav Biomed Mater. 2018;88:170–5.

Liebermann A, Freitas Rafael C, Colle Kauling AE, Edelhoff D, Ueda K, Seiffert A, et al. Transmittance of visible and blue light through zirconia. Dent Mater J. 2018;37:812–7.

Inokoshi M, Shimizu H, Nozaki K, Takagaki T, Yoshihara K, Nagaoka N, et al. Crystallographic and morphological analysis of sandblasted highly translucent dental zirconia. Dent Mater. 2018;34:508–18.

Sen N, Sermet IB, Cinar S. Effect of coloring and sintering on the translucency and biaxial strength of monolithic zirconia. J Prosthet Dent. 2018;119:308.e1-.e7.

Kwon SJ, Lawson NC, McLaren EE, Nejat AH, Burgess JO. Comparison of the mechanical properties of translucent zirconia and lithium disilicate. J Prosthet Dent. 2018;120:132–7.

Nassary Zadeh P, Lümkemann N, Sener B, Eichberger M, Stawarczyk B. Flexural strength, fracture toughness, and translucency of cubic/tetragonal zirconia materials. J Prosthet Dent. 2018;120:948–54.

Alghazzawi TF. The effect of extended aging on the optical properties of different zirconia materials. J Prosthodont Res. 2017;61:305–14.

Kim HK, Kim SH. Comparison of the optical properties of pre-colored dental monolithic zirconia ceramics sintered in a conventional furnace versus a microwave oven. J Adv Prosthodont. 2017;9:394–401.

Carrabba M, Keeling AJ, Aziz A, Vichi A, Fabian Fonzar R, Wood D, Ferrari M. Translucent zirconia in the ceramic scenario for monolithic restorations: A flexural strength and translucency comparison test. J Dent. 2017;60:70–6.

Stawarczyk B, Frevert K, Ender A, Roos M, Sener B, Wimmer T. Comparison of four monolithic zirconia materials with conventional ones: Contrast ratio, grain size, four-point flexural strength and two-body wear. J Mech Behav Biomed Mater. 2016;59:128–38.

Kim HK, Kim SH. Optical properties of pre-colored dental monolithic zirconia ceramics. J Dent. 2016;55:75–81.

Vichi A, Sedda M, Fabian Fonzar R, Carrabba M, Ferrari M. Comparison of contrast ratio, translucency parameter, and flexural strength of traditional and “augmented translucency” zirconia for CEREC CAD/CAM system. J Esthet Restor Dent. 2016;28(Suppl 1):S32–9.

Abdelbary O, Wahsh M, Sherif A, Salah T. Effect of accelerated aging on translucency of monolithic zirconia. Futur Dent J. 2016;2:65–9.

Harada K, Raigrodski AJ, Chung KH, Flinn BD, Dogan S, Mancl LA. A comparative evaluation of the translucency of zirconias and lithium disilicate for monolithic restorations. J Prosthet Dent. 2016;116:257–63.

Sulaiman TA, Abdulmajeed AA, Donovan TE, Ritter AV, Vallittu PK, Närhi TO, Lassila LV. Optical properties and light irradiance of monolithic zirconia at variable thicknesses. Dent Mater. 2015;31:1180–7.

Kurtulmus-Yilmaz S, Ulusoy M. Comparison of the translucency of shaded zirconia all-ceramic systems. J Adv Prosthodont. 2014;6:415–22.

Stawarczyk B, Emslander A, Roos M, Sener B, Noack F, Keul C. Zirconia ceramics, their contrast ratio and grain size depending on sintering parameters. Dent Mater J. 2014;33:591–8.

Ebeid K, Wille S, Hamdy A, Salah T, El-Etreby A, Kern M. Effect of changes in sintering parameters on monolithic translucent zirconia. Dent Mater. 2014;30:e419–24.

Kanchanavasita W, Triwatana P, Suputtamongkol K, Thanapitak A, Chatchaiganan M. Contrast ratio of six zirconia-based dental ceramics. J Prosthodont. 2014;23:456–61.

Stawarczyk B, Ozcan M, Hallmann L, Ender A, Mehl A, Hämmerlet CH. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin Oral Investig. 2013;17:269–74.

Kim MJ, Ahn JS, Kim JH, Kim HY, Kim WC. Effects of the sintering conditions of dental zirconia ceramics on the grain size and translucency. J Adv Prosthodont. 2013;5:161–6.

Jiang L, Liao Y, Wan Q, Li W. Effects of sintering temperature and particle size on the translucency of zirconium dioxide dental ceramic. J Mater Sci Mater Med. 2011;22:2429–35.

Ueda K, Güth JF, Erdelt K, Stimmelmayr M, Kappert H, Beuer F. Light transmittance by a multi-coloured zirconia material. Dent Mater J. 2015;34:310–4.

Kim HK, Kim SH, Lee JB, Han JS, Yeo IS, Ha SR. Effect of the amount of thickness reduction on color and translucency of dental monolithic zirconia ceramics. J Adv Prosthodont. 2016;8:37–42.

Contrepois M, Soenen A, Bartala M, Laviole O. Marginal adaptation of ceramic crowns: a systematic review. J Prosthet Dent. 2013;110:447-54.e10.

Shahmiri R, Standard OC, Hart JN, Sorrell CC. Optical properties of zirconia ceramics for esthetic dental restorations: A systematic review. J Prosthet Dent. 2018;119:36–46.

Zhang Y. Making yttria-stabilized tetragonal zirconia translucent. Dent Mater. 2014;30:1195–203.

Zhang F, Batuk M, Hadermann J, Manfredi G, Mariën A, Vanmeensel K, et al. Effect of cation dopant radius on the hydrothermal stability of tetragonal zirconia: grain boundary segregation and oxygen vacancy annihilation. Acta Mater. 2016;106:48–58.

Fabris S, Paxton AT, Finnis MW. A stabilization mechanism of zirconia based on oxygen vacancies only. Acta Mater. 2002;50:5171–8.

Anselmi-Tamburini U, Woolman JN, Munir ZA. Transparent nanometric cubic and tetragonal zirconia obtained by high-pressure pulsed electric current sintering. Adv Funct Mater. 2007;17:3267–73.

Al-Zordk W, Saker S. Impact of sintering procedure and clinical adjustment on color stability and translucency of translucent zirconia. J Prosthet Dent. 2020;124:788.e1-.e9.

Zhang H, Li Z, Kim B-N, Morita K, Yoshida H, Hiraga K, Sakka Y. Effect of alumina dopant on transparency of tetragonal zirconia. J Nanomater. 2012;2012:1-.

Attachoo S, Juntavee N. Role of sintered temperature and sintering time on spectral translucence of nano-crystal monolithic zirconia. J Clin Exp Dent. 2019;11:e146–53.

Alaniz J, Perez-Gutierrez F, Aguilar G, Garay J. Optical properties of transparent nanocrystalline yttria stabilized zirconia. Opt Mater. 2009;32:62–8.

Klimke J, Trunec M, Krell A. Transparent tetragonal yttria-stabilized zirconia ceramics: influence of scattering caused by birefringence. J Am Ceram Soc. 2011;94:1850–8.

Rhodes WH. Agglomerate and particle size effects on sintering yttria-stabilized zirconia. J Am Ceram Soc. 1981;64:19–22.

Shongwe MB, Ramakokovhu MM, Diouf S, Durowoju MO, Obadele BA, Sule R, et al. Effect of starting powder particle size and heating rate on spark plasma sintering of FeNi alloys. J Alloys Compd. 2016;678:241–8.

Baldissara P, Wandscher VF, Marchionatti AME, Parisi C, Monaco C, Ciocca L. Translucency of IPS e.max and cubic zirconia monolithic crowns. J Prosthet Dent. 2018;120:269–75.

Acknowledgements

Not applicable.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The authors have no funding to report.

Author information

Authors and Affiliations

Contributions

Mahinour Yousry wrote the main manuscript text, data curation, editing, and prepared tables and figures. Mahinour Yousry and Mohamed El Halawani study screening, data extraction, and methodology. Ihab Hammad: Supervision, Investigation, Validation, Formal analysis. Mohamed El Halawani: Investigated, drafted, and substantively revised the work. Moustafa Aboushelib: Visualization, Conceptualization, Supervision. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

This study is secondary research based on in vitro studies and involving literature that is in the public domain.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Yousry, M., Hammad, I., Halawani, M.E. et al. Translucency of recent zirconia materials and material-related variables affecting their translucency: a systematic review and meta-analysis. BMC Oral Health 24, 309 (2024). https://doi.org/10.1186/s12903-024-04070-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12903-024-04070-7