Abstract

Purpose of Review

Yttria-stabilized zirconium dioxide, 3 mol% Y-TZP (zirconia, 3Y-TZP) was introduced as a prosthetic material to provide metal-free, tooth-colored, and durable material option for the patients. However, its optical properties are not ideal. This review describes the different strategies to increase translucency of zirconia material and summarizes the current knowledge of translucent zirconia for fixed prosthodontic applications.

Recent Findings

One of the most common ways of increasing the translucency of zirconia is to add the cubic phase by increasing Y2O3 content. Y2O3 4Y mol% and Y2O3 5Y mol% partially stabilized zirconia materials seem to have better optical properties compared to 3Y-TZP materials but with less favorable mechanical properties.

Summary

Despite the attempts to develop a translucent zirconia material, its optical properties are still far from those of natural tooth structures. Possible solution for achieving more translucent and durable zirconia material could be utilizing nanocrystalline zirconia. The production of nanocrystalline zirconia is yet very technique-sensitive, and the sintering process needs to be well controlled. Additional research in this field is needed before recommendation for clinical use. In the future, the challenge will be in achieving balance between improved translucency without sacrificing from mechanical properties. This would apply not only for subtractive but also additively manufactured zirconia ceramics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

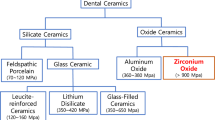

Dental materials used for restoring teeth attempt to imitate translucency and light reflectance of natural tooth structure. Glass ceramic materials suit best for this purpose, as their optical properties resemble the ones of enamel and dentine [1]. However, the lower mechanical properties of glass ceramic-based materials limit their use in load-bearing areas of the mouth [2, 3]. Yttria-stabilized zirconium dioxide, 3 mol% Y-TZP (zirconia, 3Y-TZP) was introduced as a prosthetic material to provide metal-free, tooth-colored, and durable material option for the patients [4]. However, due to polycrystal material structure, zirconia has some optical restrictions.

Color and translucency are essential components in esthetic appearance of a tooth or a dental restoration. Human perception of color is based on the light emission and its transmission, absorption, and reflection on the surface of an object [5]. Individual interpretation of a color as well as the material properties and surrounding conditions (illumination and light) play a role in perception and producing a color in dentistry.

Different Phases of Zirconia

Un-stabilized zirconia exists in three different phases, depending on the surrounding temperature: monoclinic (m) <1170 °C, tetragonal (t) 1170–2370 °C, and cubic (c) >2370 °C [6]. Monoclinic zirconia grains are 3–5% larger compared to tetragonal ones. When un-stabilized zirconia material cools down from >1170 °C, tetragonal grains are transformed into monoclinic where 3–5% volume expansion occurs. The sudden volume expansion causes cracks and defects in the material, decreasing mechanical strength of monoclinic zirconia. Tetragonal zirconia instead has better mechanical properties, although it does not exist as such at room temperature. By partially stabilizing the zirconia with 3 mol% of Y2O3 tetragonal zirconia can be maintained also at room temperature [6, 7].

As a meta-stable material, tetragonal zirconia has ability to resist crack propagation up to certain extend. The stress caused by a crack induces t-m transformation at the crack tip, which leads to local volume expansion of 3–5%, and the compressive stresses are preventing the crack propagation [6, 7]. This phenomenon, called transformation toughening, is the basis of high mechanical properties of tetragonal zirconia. On the other hand, t-m transformation can also lead to detrimental changes on material surface which occur due to environmental stresses such as presence of water, body fluids, or steamed water [8]. This phenomenon, low-temperature degradation or aging, can be caused for example by steam pressure in autoclave. Due the effect of water steam, tetragonal grains on material surface turn into monoclinic, which is leading to sudden volume expansion and water penetration into the material [9, 10].

Mechanical Properties of 3Y-TZP

Zirconia is by far the strongest ceramic material for dental applications. Flexural strength of 3% mol yttria-stabilized zirconia (3Y-TZP) is high, varying from 900 to 1400 MPa [11,12,13] and fracture toughness from 7.4 to 11.5 MPa m1/2 [14,15,16]. On the other hand, flexural strength of lithium disilicate-based glass ceramic materials is varying between 330 and 550 MPa and fracture toughness from 1.39 to 2.04 [17, 18]. However, it has been shown that flexural strength of lithium disilicate-based glass ceramic materials is higher after adhesive bonding [19].

3Y-TZP as a Prosthetic Material

Dental zirconia is a polycrystal material, which does not contain any glass phase [1]. Therefore, it is very opaque and can be used mainly as framework material for dental crowns and FDPs. For esthetic purposes, the framework has to be veneered with feldspathic ceramic.

In clinical studies about 3Y-TZP material, minor amounts of 1.9–5.9% framework fractures of multiple-unit FDPs have been seen in 5 to 10 years of follow-up time [20,21,22]. Typically, the multi-unit FDPs fracture on the connector area, and the frameworks are therefore often designed bulky in order to achieve enough stability for the connector areas. Veneering ceramic seems to be clinically the weakest link of 3Y-TZP restorations. Several factors can affect to the chipping rate of veneering ceramic including non-anatomical framework design, thickness of the veneering ceramic, fast cooling phase during porcelain firing process, uneven heat distribution in zirconia material, and glass transition temperature and thermal expansion of veneering ceramic as well as roughness of the veneering ceramic after occlusal adjustments [23,24,25,26,27,28]. Minor and major ceramic chippings, varying from 12 to 32 %, are reported in clinical studies on teeth over 8- to 10-year follow-up time [21, 29] and up to 50% in implant-supported restorations in 10-year follow-up time [30]. Size of the restoration affects the reported chipping rate as well. Single crowns have shown lower chipping rates [21] compared to long-span multiple-unit FDPs, as in a 10-year randomized controlled clinical trial, 4- to 5-unit FDPs have shown higher chipping rates compared to 3-unit FDPs [29]. Figure 1 illustrates a fractured 3Y-TZP multiple-unit FDP after 3.7 years of use.

In order to avoid the chipping of the veneering ceramic, more translucent zirconia materials were introduced [31, 32•, 33]. These materials can be used monolithic, without veneering ceramic. Figure 2 illustrates a monolithic implant crown made of 5Y-TZP material.

Color and Translucency in Dentistry

The relationship between the colors is defined by Munsell color space [34]. The Munsell color space consists of three different parameters: hue, chroma, and value. Hue is defined as a color shade; value is describing lightness/brightness of a color shade; and chroma is the intensity of the color shade. When white light is passing through a prism, each hue of visible light range has different wave length, varying from 400 nm for violet to 700 nm for red color [35]. When white light is interacting with an object, some of the wavelengths are absorbed and some reflected. The reflected wavelengths produce the visual color. Hence, certain object can appear in different colors when different light sources are used. In human eye, more precise in the retina, cone and rod cells register the light and send to the brain signals, which will be interpreted as colors [36].

Numerical values of color can be calculated by using CIELAB color space. The International Commission on Illumination (CIE) has defined a system where values given by spectrophotometric device can be translated into color parameters of L*, a*, and b* [37]. L* applies to lightness of an object, a* to a hue scale of red to green, and b* to a hue scale of yellow to blue. Using the CIELAB color space enables comparison of different materials and objects in terms of color and appearance. However, the results of the CIELAB color space can be difficult to interpret in a clinical environment. CIEDE2000 color difference formula was therefore introduced for better correlation with visual inspection [38, 39]. In CIEDE2000 system, the total color difference (△E00) is calculated from lightness (L), chroma (C), and hue (H). The system has also thresholds for visual perceptibility (△E00=0.8) and acceptability (△E00=1.8), which is functioning as a quality control tool for clinical assessments.

A recent in vitro study was comparing the color of anterior monolithic (ML) and veneered zirconia crowns [40]. The veneered crowns were fabricated with cutback technique and layered with either enamel layering material (bilayer, BL) or enamel and dentine layering materials (tri-layer, TL). The CIE L*a*b* values of the crowns (n=5) were measured with spectrophotometer, and the color differences were calculated with CIEDE2000 formula. The lowest color differences were seen on BL and TL crowns compared to ML in cervical and middle areas of the crowns. In all crown types, the cervical and middle areas were mostly under the visual perceptibility level (△E00≤0.8).

Light refraction, dispersion, transmission, and absorption affect to the optical behavior and color appearance of each object. Translucency describes the extent to which light is transmitted through the object instead of being absorbed or reflected [35]. Translucency can be evaluated by contrast ratio (CR), translucency parameter (TP), and refractory index (RI). CR is measured by evaluating the ratio of reflectance of a specimen placed on a black background compared to a white background [41], whereas TP represents a color difference of a specimen placed on a black background compared to a white background [42]. Higher the TP value means higher translucency value. Materials with TP values ≤ 2 are considered opaque, while they are blocking black background [43].

Thickness of the material affects directly the translucency parameter (TP) of the zirconia materials. TP values of different generation zirconia materials in an in vitro study varied between 16.59–20.40 for 0.5-mm-thick specimens to 5.10–9.17 for 2.0-mm-thick specimens, showing that the thinner the material, the more translucent it is [44]. For 1-mm-thick specimens, TP values were varying between 11.16 and 15.82, whereas the previously reported TP value is 18.7 1-mm-thick enamel and 16.4 for 1 mm dentin [45].

The contrast ratio is known to decrease by increasing translucency [44]. The contrast ratio value 0 is considered translucent and a value of 1 as fully opaque [46]. The effect of sintering temperature to contrast ratio (CR) was investigated in an in vitro study [47]. CR values were measured on specimens sintered in 9 different temperatures from 1300 to 1700 °C. CR was varying from 0.85 for 1300 °C to 0.68 for 1700 °C differences being statistically significant. In other words, CR was decreasing by increasing sintering temperature.

Refractive index (RI) defines how much the path of light is refracted when entering a material. It depends on different wavelengths of light and interaction of light in different interfaces (grain/grain vs grain/pore) [48, 49]. 3Y-TZP material has higher RI than other ceramic materials, meaning that the material has high surface reflection and low light transmission [49].

Strategies to Increase Translucency in Zirconia Material

There are several methods to increase the translucency of zirconia material. It is possible to modify the material structure by changing the sintering protocol and amount and type of dopants, leading to less light refraction and scattering from the material structure.

During the development of translucent zirconia, modifying 3Y-TZP microstructure was considered as one of the first actions. Zirconia was made more translucent trying by increasing material density by eliminating the pores [48, 50]. The large difference in refractive index between the pores and zirconia material is causing the light scattering by the porosity and generating opaque optical appearance.

For the first-generation zirconia materials, alumina was used as sintering aid (3mol% of Y2O3 and 0.25 wt% Al2O3), which additionally stabilized the material and made it more resistant to low-temperature degradation [48]. However, alumina dopant was making the material look opaquer. By decreasing the alumina content as well as adding other dopants like lanthanum oxide, the material translucency could be improved [51]. The optimal level of Al2O3 dopant used in more translucent generations of 3Y-TZP is <0.25 wt%, providing higher density and better translucency [51]. Other suggested dopants are lanthanum oxide La2O3, magnesium oxide MgO, and neodymium oxide Nd2O3 [52]. From different dopants, the Al3+, La3+, Mg2+, and Nd3+ cations are segregated to the grain boundaries providing hydrothermal stability. Dopants seem to have effect to grain size, since 3Y-TZP materials doped with different concentrations of Al2O3 only showed larger grain size than 3Y-TZP materials doped with Al2O3 and La2O3 [51]. When yttria content was increased to 5 mol% (5Y-TZP with 0.05 wt% Al2O3), the grain size was significantly larger. However, in the market, mainly Al2O3 doped zirconia materials have been available.

Other option for increasing translucency of zirconia is to increase the grain size. The larger the grains, the less light reflection and scattering there will be from grain boundaries, leading to higher translucency [48, 53, 54]. Larger grain size can be achieved by increasing sintering time and temperature [11, 47]. Decreasing the grain size would also provide more translucent zirconia material. Also, in nanocrystalline structure, the translucency is dependent on grain size and thickness. Zhang was estimating in his study that for optimal translucency, 1.3 mm thick specimen would need a grain size of 82 nm, and 2 mm thick specimen would need a grain size of 70 nm [48]. Nanocrystalline structure could be a perfect solution for achieving a zirconia material with high translucency and high mechanical properties. However, the production process is still inaccurate resulting to defects and porosities.

Adding the amount of cubic phase by increasing yttria content is commonly used way of making zirconia more translucent [55, 56]. Cubic zirconia is optical isotropic, and therefore, light scattering at the grain boundaries is not seen [51, 52]. On the contrary, tetragonal zirconia is anisotropic in crystallographic directions (i.e., in optical properties tetragonal zirconia grains are birefringent) [55]. When the adjoining tetragonal grains do not have same crystallographic orientation, refractory index shows discontinuity at the grain boundaries leading to reductions in light transmittance and more opaque appearance.

There are several translucent zirconia materials with varying yttria content, most commonly 4 mol % and 5 mol% partially stabilized Y-TZP and 8 mol% fully yttria-stabilized zirconia (YSZ) [48, 57, 58].

Graded zirconia was introduced more than a decade ago for making the optical and adhesive properties of 3Y-TZP better [31]. Glass powder composition was infiltrated on 3Y-TZP surface, creating a structure where outer surface of an object had more esthetic layer, dense 3Y-TZP layer in the middle and inner glass layer for adhesive bonding. Specimens (thickness 1.4mm) with graded structure showed promising results in terms of critical load for radial cracking (1990 N) compared to monolithic specimens (1388 N). However, the method might be technique-sensitive and time-consuming, and the scientific evidence is still scarce.

Finally, one of the more modern options for achieving better optical and esthetic outcomes is to combine layers of different Y2O3 mol% zirconia material (i.e., different translucency) as a multi-layered zirconia block/puck. The layers have different contents and pigment types, which leads to natural shade [59]. When fabricating a restoration with computer-aided design/computer-aided manufacturing (CAD/CAM) methods, the restoration is milled in such a way that the more translucent layer of zirconia is situated on the incisal edge of the restoration. A recent in vitro study was showing that there was no difference in translucency between the multi-layered 5 Y2O3 mol% and 4 Y2O3 mol% zirconia blocks [59]. However, another in vitro study was showing that fracture resistance of crown-shaped specimens was lower for multi-layered materials compared to conventional 3Y- and 4Y-TZP materials [60].

Effect of Dopants to 3Y-TZP Material Properties

Zhang and co-workers were testing 3Y-TZP materials with different microstructure, and it could be seen that adding 0.25 wt% Al2O3 and 0.2 wt% La2O3 as a co-dopant resulted in higher amount of c-ZrO2 compared to 3Y-TZP material doped with 0.25 wt% Al2O3 only [51]. Similar significant difference could also be seen in TP of these materials, 3Y-TZP 0.25 wt% Al2O3, and 0.2 wt% La2O3 being more translucent and having lower CR. By manipulating the grain boundaries with co-dopants, good long-term hydrothermal stability and higher mechanical properties could be achieved [52].

Mechanically, the bending strength was higher for 3Y-0.25Al specimens (997 MPa, SD 202) compared to 3Y-0.25Al-0.2La specimens (651 Mpa, SD 77). However, there were no differences between 3Y-0.25Al-0.2La specimens and other specimens doped with different concentrations of La2O3 and Al2O3 [51].

Consequences of Making Zirconia Translucent

Changing the yttria content of zirconia material can have effect to several material properties. Additionally, when more c-phase is present, yttria is concentrated on tetragonal grains. Cubic zirconia is more brittle, and tetragonal zirconia has lower ability to transformation toughening, leading to lower mechanical properties [61].

Various in vitro studies show differences in mechanical properties between different Y2O3 mol% zirconia materials with tendency to lower mechanical strength when increasing Y2O3 mol% and translucency [32•, 57, 62,63,64,65]. Flexural strength, fracture toughness, TP and CR values for different generations of zirconia are summarized in Table 1. The possible explanation for decrease in mechanical properties lies in the phase content of zirconia material, since c-phase does not seem to have as high mechanical properties as t-phase.

Same trend has also been seen in crown-shaped specimens. An in vitro study about implant crowns made of different generations of zirconia materials was showing that the fully stabilized (Y2O3 8 mol%) zirconia crowns connected directly to the implant exhibited significantly lower fracture load values (140 N) compared to partially stabilized (Y2O3 3 mol%) translucent zirconia crowns connected directly to implant (259 N) and partially stabilized (Y2O3 3 mol%) translucent zirconia crowns connected with titanium base to implant (453 N) [75].

Previous in vitro studies show that the airborne particle abrasion increases the flexural strength of 3Y-TZP material [76, 77]. This is based on the t-m phase transformation-induced volume expansion on material surface, creating compressive stresses [77]. Another in vitro study comparing different generations of zirconia was showing that airborne particle abrasion was increasing the flexural strength of partially stabilized Y2O3 3 mol% opaque and Y2O3 3 mol% translucent zirconia but decreasing the flexural strength of fully stabilized Y2O3 8 mol% zirconia [57]. The authors attributed the lower mechanical properties of Y2O3 8 mol% zirconia are related to the high c-phase content and lower t-phase content of the material. When less t-grains are present, also less transformation toughening occurs. On the other hand, a study by Chevalier and co-workers demonstrated that the presence of cubic grains tend to reduce the material resistance to low-temperature degradation [78]. Yttrium stabilizer ions seem to enrich the cubic grains, while the adjacent tetragonal grains are less stable, and therefore, more t-m phase transformation takes place. This does not apply to longer sintering times or higher sintering temperatures but to aging conditions like moist environment.

The microstructure and phase content of zirconia material seem to have an impact on bond strength as well. Microtensile bond strength of airborne particle-abraded conventional zirconia (3 mol% Y2O3) was shown to be significantly higher (20.86 Mpa, SD 5.12) than that of airborne particle-abraded translucent zirconia (5 mol% Y2O3) (16.39 Mpa, SD 4.36) [79]. This could be also related to the higher number of cubic grains in the material.

Micro-layering, Staining, and Glazing

Despite attempts to develop a translucent zirconia material, its optical properties are still far from those of natural tooth structures. Possible solution for overcoming the translucency mismatch between zirconia material and natural dental structures and to avoid extensive veneering ceramic chippings could be micro-layering of the esthetic (buccal) surfaces of dental restorations [80]. In micro-layering workflow, zirconia framework is fabricated from translucent material block with no or very minimal cutback and veneered with <0.5-mm-thin ceramic layer which consist of fine-ground ceramic particles and a viscose liquid. Although in thin layer, the felspathic ceramic forms a three-dimensional network with natural looking depth effect as well as translucent, fluorescent, and opalescent optical properties. However, scientific evidence of micro-layering method is still lacking, and the potential risk of veneer chipping cannot be excluded at this point.

More natural looking appearance and depth effect can also be achieved by staining and glazing the zirconia framework. Staining of green-stage 3Y-TZP opaque zirconia might weaken the material’s mechanical properties [81]. In an in vitro study, staining was performed by dipping the specimens into the coloring liquid, and the increasing staining time was negatively affecting to flexural strength [81]. Similar effect was seen with 3Y-TZP translucent zirconia specimens stained by painting the surface with a brush [82], while increased flexural strength and decreased translucency parameter values were seen in specimens fabricated from 8 mol% fully yttria-stabilized zirconia. The differences between different zirconia materials might be due to the material content and the amount of cubic zirconia present. Additionally, it has been shown that tension forces might cause delamination of the glazing layer on disc-shaped specimens [83]. However, clinically, this has not been reported so far, and it might not be a relevant problem.

Conclusions and Future Perspectives

When developing monolithic zirconia materials, more translucent nanocrystalline structures seem to be promising option [48]. They would provide substantial improvements in translucency while preserving strength properties. However, it seems to be difficult to produce well-dispersed homogenous starting powder containing controlled concentrations of stabilizing additives [84••]. Additional challenge is to avoid excessive grain growth and porosities during sintering process. The problems with producing methods remain to be solved by scientists in the future. Other possible options for developing more translucent and durable zirconia materials are further optimizing of the sintering process, grain size, and addition of different dopants.

The development of translucent zirconia materials continues, and new challenge will be in achieving the balance between improved translucency without sacrificing from mechanical properties. This would apply not only for subtractive but also additively manufactured zirconia ceramics [85,86,87,88].

References

Papers of particular interest, published recently, have been highlighted as: • Of importance •• Of major importance

Kelly JR, Benetti P. Ceramic materials in dentistry: historical evolution and current practice. Aust Dent J. 2011;56(Suppl 1):84–96. https://doi.org/10.1111/j.1834-7819.2010.01299.x.

Fehmer V, Muhlemann S, Hammerle CH, Sailer I. Criteria for the selection of restoration materials. Quintessence Int. 2014;45(9):723–30. https://doi.org/10.3290/j.qi.a32509.

Gracis S, Thompson VP, Ferencz JL, Silva NR, Bonfante EA. A new classification system for all-ceramic and ceramic-like restorative materials. Int J Prosthodont. 2015;28(3):227–35. https://doi.org/10.11607/ijp.4244.

Filser F, Kocher P, Weibel F, Luthy H, Scharer P, Gauckler LJ. Reliability and strength of all-ceramic dental restorations fabricated by direct ceramic machining (DCM). Int J Comput Dent. 2001;4(2):89–106.

Chu SJ. The science of color and shade selection in aesthetic dentistry. Dent Today. 2002;21(9):86–9.

Piconi C, Maccauro G. Zirconia as a ceramic biomaterial. Biomaterials. 1999;20(1):1–25. https://doi.org/10.1016/s0142-9612(98)00010-6.

Garvie RC, Hannink RH, Pascoe RT. Ceramic steel? Nature. 1975;258:703–4.

Swab JJ. Low temperature degradation of Y-TZP materials. J Mater Sci. 1991;26:6706–14. https://doi.org/10.1007/BF00553696.

Chevalier J, Cales B, Drouin JM. Low-temperature aging of Y-TZP ceramics. J Am Ceram Soc. 1999;82:2150–4. https://doi.org/10.1111/j.1151-2916.1999.tb02055.x.

Deville S, Chevalier J. Martensitic relief observation by atomic force microscopy in yttria-stabilized zirconia. J Am Ceram Soc. 2003;86:2225–7. https://doi.org/10.1111/j.1151-2916.1999.tb02055.x.

Hjerppe J, Vallittu PK, Froberg K, Lassila LV. Effect of sintering time on biaxial strength of zirconium dioxide. Dent Mater. 2009;25(2):166–71. https://doi.org/10.1016/j.dental.2008.05.011.

Pittayachawan P, McDonald A, Petrie A, Knowles JC. The biaxial flexural strength and fatigue property of Lava Y-TZP dental ceramic. Dent Mater. 2007;23(8):1018–29. https://doi.org/10.1016/j.dental.2006.09.003.

Yener ES, Ozcan M, Kazazoglu E. The effect of glazing on the biaxial flexural strength of different zirconia core materials. Acta Odontol Latinoam. 2011;24(2):133–40.

Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Evaluation of a high fracture toughness composite ceramic for dental applications. J Prosthodont. 2008;17(7):538–44. https://doi.org/10.1111/j.1532-849X.2008.00346.x.

Guazzato M, Albakry M, Ringer SP, Swain MV. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dent Mater. 2004;20(5):449–56. https://doi.org/10.1016/j.dental.2003.05.002.

Tinschert J, Natt G, Mohrbotter N, Spiekermann H, Schulze KA. Lifetime of alumina- and zirconia ceramics used for crown and bridge restorations. J Biomed Mater Res B Appl Biomater. 2007;80(2):317–21. https://doi.org/10.1002/jbm.b.30599.

Lin WS, Ercoli C, Feng C, Morton D. The effect of core material, veneering porcelain, and fabrication technique on the biaxial flexural strength and weibull analysis of selected dental ceramics. J Prosthodont. 2012;21(5):353–62. https://doi.org/10.1111/j.1532-849X.2012.00845.x.

Belli R, Lohbauer U, Goetz-Neunhoeffer F, Hurle K. Crack-healing during two-stage crystallization of biomedical lithium (di)silicate glass-ceramics. Dent Mater. 2019;35(8):1130–45. https://doi.org/10.1016/j.dental.2019.05.013.

De Angelis F, D'Arcangelo C, Vadini M. The effect of dentin bonding and material thickness on the flexural properties of a lithium-disilicate glass-ceramic. J Adhes Dent. 2021;23(4):309–18. https://doi.org/10.3290/j.jad.b1650013.

Sailer I, Balmer M, Husler J, Hammerle CHF, Kanel S, Thoma DS. 10-year randomized trial (RCT) of zirconia-ceramic and metal-ceramic fixed dental prostheses. J Dent. 2018;76:32–9. https://doi.org/10.1016/j.jdent.2018.05.015.

Tanner J, Niemi H, Ojala E, Tolvanen M, Narhi T, Hjerppe J. Zirconia single crowns and multiple-unit FDPs-An up to 8 -year retrospective clinical study. J Dent. 2018;79:96–101. https://doi.org/10.1016/j.jdent.2018.10.012.

Pjetursson BE, Sailer I, Makarov NA, Zwahlen M, Thoma DS. All-ceramic or metal-ceramic tooth-supported fixed dental prostheses (FDPs)? A systematic review of the survival and complication rates. Part II: multiple-unit FDPs. Dent Mater. 2015;31(6):624–39. https://doi.org/10.1016/j.dental.2015.02.013.

Denry I, Kelly JR. State of the art of zirconia for dental applications. Dent Mater. 2008;24(3):299–307. https://doi.org/10.1016/j.dental.2007.05.007.

Swain MV. Unstable cracking (chipping) of veneering porcelain on all-ceramic dental crowns and fixed partial dentures. Acta Biomater. 2009;5(5):1668–77. https://doi.org/10.1016/j.actbio.2008.12.016.

Fischer H, Weber M, Marx R. Lifetime prediction of all-ceramic bridges by computational methods. J Dent Res. 2003;82(3):238–42. https://doi.org/10.1177/154405910308200317.

Taskonak B, Borges GA, Mecholsky JJ Jr, Anusavice KJ, Moore BK, Yan J. The effects of viscoelastic parameters on residual stress development in a zirconia/glass bilayer dental ceramic. Dent Mater. 2008;24(9):1149–55. https://doi.org/10.1016/j.dental.2008.01.004.

Sailer I, Gottnerb J, Kanelb S, Hammerle CH. Randomized controlled clinical trial of zirconia-ceramic and metal-ceramic posterior fixed dental prostheses: a 3-year follow-up. Int J Prosthodont. 2009;22(6):553–60.

Guess PC, Bonfante EA, Silva NR, Coelho PG, Thompson VP. Effect of core design and veneering technique on damage and reliability of Y-TZP-supported crowns. Dent Mater. 2013;29(3):307–16. https://doi.org/10.1016/j.dental.2012.11.012.

Sax C, Hammerle CH, Sailer I. 10-year clinical outcomes of fixed dental prostheses with zirconia frameworks. Int J Comput Dent. 2011;14(3):183–202.

Larsson C, Vult von Steyern P. Ten-year follow-up of implant-supported all-ceramic fixed dental prostheses: a randomized, prospective clinical trial. Int J Prosthodont. 2016;29(1):31–4. https://doi.org/10.11607/ijp.4328.

Zhang Y, Kim JW. Graded structures for damage resistant and aesthetic all-ceramic restorations. Dent Mater. 2009;25(6):781–90. https://doi.org/10.1016/j.dental.2009.01.002.

• Camposilvan E, Leone R, Gremillard L, Sorrentino R, Zarone F, Ferrari M, et al. Aging resistance, mechanical properties and translucency of different yttria-stabilized zirconia ceramics for monolithic dental crown applications. Dent Mater. 2018;34(6):879–90. https://doi.org/10.1016/j.dental.2018.03.006. This comprehensive in vitro study shows the differences in microstructure, mechanical, and optical properties of different zirconia materials.

Tong H, Tanaka CB, Kaizer MR, Zhang Y. Characterization of three commercial Y-TZP ceramics produced for their high-translucency, high-strength and high-surface area. Ceram Int. 2016;42(1 Pt B):1077-85 https://doi.org/10.1016/j.ceramint.2015.09.033.

Munsell AH. A Grammar of Color. 1st ed. Mittineague, Massachusetts: Strathmore Paper Company; 1921.

Chu SJ, Devigus A, Paravina RD, Mieleszko AJ. Color Theory. Fundamentals of color: shade matching and communication in esthetic dentistry. Illinois, USA: Quintessence Publishing Co, Inc; 2010. p. 7–18.

Graham CH, Hartline HK. The response of single visual sense cells to lights of different wave lengths. J Gen Physiol. 1935;18(6):917–31. https://doi.org/10.1085/jgp.18.6.917.

Johnston WM. Color measurement in dentistry. J Dent. 2009;37(Suppl 1):e2–6. https://doi.org/10.1016/j.jdent.2009.03.011.

Perez Mdel M, Ghinea R, Herrera LJ, Ionescu AM, Pomares H, Pulgar R, et al. Dental ceramics: a CIEDE2000 acceptability thresholds for lightness, chroma and hue differences. J Dent. 2011;39(Suppl 3):e37–44. https://doi.org/10.1016/j.jdent.2011.09.007.

Paravina RD, Ghinea R, Herrera LJ, Bona AD, Igiel C, Linninger M, et al. Color difference thresholds in dentistry. J Esthet Restor Dent. 2015;27(Suppl 1):S1–9. https://doi.org/10.1111/jerd.12149.

Manziuc MM, Gasparik C, Burde AV, Ruiz-Lopez J, Buduru S, Dudea D. Influence of manufacturing technique on the color of zirconia restorations: Monolithic versus layered crowns. J Esthet Restor Dent. 2022;34(6):978–87. https://doi.org/10.1111/jerd.12897.

Miyagawa Y, Powers JM, O'Brien WJ. Optical properties of direct restorative materials. J Dent Res. 1981;60(5):890–4. https://doi.org/10.1177/00220345810600050601.

Johnston WM, Ma T, Kienle BH. Translucency parameter of colorants for maxillofacial prostheses. Int J Prosthodont. 1995;8(1):79–86.

Chaiyabutr Y, Kois JC, Lebeau D, Nunokawa G. Effect of abutment tooth color, cement color, and ceramic thickness on the resulting optical color of a CAD/CAM glass-ceramic lithium disilicate-reinforced crown. J Prosthet Dent. 2011;105(2):83–90. https://doi.org/10.1016/S0022-3913(11)60004-8.

Sulaiman TA, Abdulmajeed AA, Donovan TE, Ritter AV, Vallittu PK, Narhi TO, et al. Optical properties and light irradiance of monolithic zirconia at variable thicknesses. Dent Mater. 2015;31(10):1180–7. https://doi.org/10.1016/j.dental.2015.06.016.

Yu B, Ahn JS, Lee YK. Measurement of translucency of tooth enamel and dentin. Acta Odontol Scand. 2009;67(1):57–64. https://doi.org/10.1080/00016350802577818.

Kingery WD, Bowen HK, Uhlmann DR. Introduction to ceramics. 2nd ed. New York: John Wiley and Sons; 1976.

Stawarczyk B, Ozcan M, Hallmann L, Ender A, Mehl A, Hammerlet CH. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin Oral Investig. 2013;17(1):269–74. https://doi.org/10.1007/s00784-012-0692-6.

Zhang Y. Making yttria-stabilized tetragonal zirconia translucent. Dent Mater. 2014;30(10):1195–203. https://doi.org/10.1016/j.dental.2014.08.375.

Kazuko Y, Kataoka Y, Kobayashi M, Yamaguchi M, Ogawa H, Miyazaki T, et al. Refractive index measurement of dental materials by swept-source optical coherence tomography. Jpn J Conserv Dent 2018;61:368-377. 10.11471/shikahozon.61.368.

Anselmi-Tabmurini U, Woolman JN, Munir ZA. Transparent nanometric cubic and tetragonal zirconia obtained by high-pressure pulsed electric current sintering. Adv Funct Mater. 2007;17(16):3267–73. https://doi.org/10.1002/adfm.200600959.

Zhang F, Inokoshi M, Batuk M, Hadermann J, Naert I, Van Meerbeek B, et al. Strength, toughness and aging stability of highly-translucent Y-TZP ceramics for dental restorations. Dent Mater. 2016;32(12):e327–e37. https://doi.org/10.1016/j.dental.2016.09.025.

Zhang F, Vanmeensel K, Batuk M, Hadermann J, Inokoshi M, Van Meerbeek B, et al. Highly-translucent, strong and aging-resistant 3Y-TZP ceramics for dental restoration by grain boundary segregation. Acta Biomater. 2015;16:215–22. https://doi.org/10.1016/j.actbio.2015.01.037.

Denry I, Kelly JR. Emerging ceramic-based materials for dentistry. J Dent Res. 2014;93(12):1235–42. https://doi.org/10.1177/0022034514553627.

Malkondu Ö, Tinastepe N, Akan E, Kazazoglu E. An overview of monolithic zirconia in dentistry. Biotechnol Biotechnol Equip. 2016;30(4):644–52. https://doi.org/10.1080/13102818.2016.1177470.

Klimke J, Trunec M, Krell A. Transparent tetragonal yttria-stabilized zirconia ceramics: influence of scattering caused by birefringence. J Am Ceram Soc. 2011;94(6):1850-1858. https://doi.org/https://doi.org/10.1111/j.1551-2916.2010.04322.x.

Shahmiri R, Standard OC, Hart JN, Sorrell CC. Optical properties of zirconia ceramics for esthetic dental restorations: a systematic review. J Prosthet Dent. 2018;119(1):36–46. https://doi.org/10.1016/j.prosdent.2017.07.009.

Sulaiman TA, Abdulmajeed AA, Shahramian K, Lassila L. Effect of different treatments on the flexural strength of fully versus partially stabilized monolithic zirconia. J Prosthet Dent. 2017;118(2):216–20. https://doi.org/10.1016/j.prosdent.2016.10.031.

Zhang H, Kim BN, Morita K, Keijiro Hiraga HY, Sakka Y. Effect of sintering temperature on optical properties and microstructure of translucent zirconia prepared by high-pressure spark plasma sintering. Sci Technol Adv Mater. 2011;12(5):055003. https://doi.org/10.1088/1468-6996/12/5/055003.

Kolakarnprasert N, Kaizer MR, Kim DK, Zhang Y. New multi-layered zirconias: composition, microstructure and translucency. Dent Mater. 2019;35(5):797–806. https://doi.org/10.1016/j.dental.2019.02.017.

Badr Z, Culp L, Duqum I, Lim CH, Zhang Y, T AS. Survivability and fracture resistance of monolithic and multi-yttria-layered zirconia crowns as a function of yttria content: a mastication simulation study. J Esthet Restor Dent. 2022;34(4):633–40. https://doi.org/10.1111/jerd.12907.

Chevalier J, Gremillard L, Deville S. Low-temperature degradation of zirconia and implications for biomedical implants. Annu Rev Mater Res. 2007;37:1–32. https://doi.org/10.1146/annurev.matsci.37.052506.084250.

Abdulmajeed A, Sulaiman TA, Abdulmajeed AA, Narhi TO. Strength and phase transformation of different zirconia types after chairside adjustment. J Prosthet Dent. 2022; https://doi.org/10.1016/j.prosdent.2022.06.015.

Kwon SJ, Lawson NC, McLaren EE, Nejat AH, Burgess JO. Comparison of the mechanical properties of translucent zirconia and lithium disilicate. J Prosthet Dent. 2018;120(1):132–7. https://doi.org/10.1016/j.prosdent.2017.08.004.

Pereira GKR, Guilardi LF, Dapieve KS, Kleverlaan CJ, Rippe MP, Valandro LF. Mechanical reliability, fatigue strength and survival analysis of new polycrystalline translucent zirconia ceramics for monolithic restorations. J Mech Behav Biomed Mater. 2018;85:57–65. https://doi.org/10.1016/j.jmbbm.2018.05.029.

Harada A, Shishido S, Barkarmo S, Inagaki R, Kanno T, Ortengren U, et al. Mechanical and microstructural properties of ultra-translucent dental zirconia ceramic stabilized with 5 mol% yttria. J Mech Behav Biomed Mater. 2020;111:103974. https://doi.org/10.1016/j.jmbbm.2020.103974.

Jerman E, Lumkemann N, Eichberger M, Zoller C, Nothelfer S, Kienle A, et al. Evaluation of translucency, Marten's hardness, biaxial flexural strength and fracture toughness of 3Y-TZP, 4Y-TZP and 5Y-TZP materials. Dent Mater. 2021;37(2):212–22. https://doi.org/10.1016/j.dental.2020.11.007.

Arcila LVC, Ramos NC, Campos TMB, Dapieve KS, Valandro LF, de Melo RM, et al. Mechanical behavior and microstructural characterization of different zirconia polycrystals in different thicknesses. J Adv Prosthodont. 2021;13(6):385–95. https://doi.org/10.4047/jap.2021.13.6.385.

Jeong JI, Shin HJ, Kwon YH, Seol HJ. Effect of cooling rate on mechanical properties, translucency, opalescence, and light transmission properties of monolithic 4Y-TZP during glazing. Materials (Basel). 2022;15(12) https://doi.org/10.3390/ma15124357.

Grambow J, Wille S, Kern M. Impact of changes in sintering temperatures on characteristics of 4YSZ and 5YSZ. J Mech Behav Biomed Mater. 2021;120:104586. https://doi.org/10.1016/j.jmbbm.2021.104586.

Baldissara P, Wandscher VF, Marchionatti AME, Parisi C, Monaco C, Ciocca L. Translucency of IPS e.max and cubic zirconia monolithic crowns. J Prosthet Dent. 2018;120(2):269–75. https://doi.org/10.1016/j.prosdent.2017.09.007.

Kongkiatkamon S, Peampring C. Effect of speed sintering on low temperature degradation and biaxial flexural strength of 5Y-TZP zirconia. Molecules. 2022;27(16):5272. https://doi.org/10.3390/molecules27165272.

Salah K, Sherif AH, Mandour MH, Nossair SA. Optical effect of rapid sintering protocols on different types of zirconia. J Prosthet Dent. 2023; https://doi.org/10.1016/j.prosdent.2023.05.001.

Hajhamid B, Bozec L, Tenenbaum H, De Souza G, Somogyi-Ganss E. Effect of artificial aging on optical properties and crystalline structure of high-translucency zirconia. J Prosthodont. 2023; https://doi.org/10.1111/jopr.13648.

de Araujo-Junior ENS, Bergamo ETP, Bastos TMC, Benalcazar Jalkh EB, Lopes ACO, Monteiro KN, et al. Ultra-translucent zirconia processing and aging effect on microstructural, optical, and mechanical properties. Dent Mater. 2022;38(4):587–600. https://doi.org/10.1016/j.dental.2022.02.016.

Moilanen P, Hjerppe J, Lassila LVJ, Narhi TO. Fracture strength and precision of fit of implant-retained monolithic zirconia crowns. J Oral Implantol. 2018;44(5):330–4. https://doi.org/10.1563/aaid-joi-D-17-00249.

Hjerppe J, Narhi TO, Vallittu PK, Lassila LV. Surface roughness and the flexural and bend strength of zirconia after different surface treatments. J Prosthet Dent. 2016;116(4):577–83. https://doi.org/10.1016/j.prosdent.2016.02.018.

Guazzato M, Quach L, Albakry M, Swain MV. Influence of surface and heat treatments on the flexural strength of Y-TZP dental ceramic. J Dent. 2005;33(1):9–18. https://doi.org/10.1016/j.jdent.2004.07.001.

Chevalier J, Deville S, Munch E, Jullian R, Lair F. Critical effect of cubic phase on aging in 3mol% yttria-stabilized zirconia ceramics for hip replacement prosthesis. Biomaterials. 2004;25(24):5539–45. https://doi.org/10.1016/j.biomaterials.2004.01.002.

Ruales-Carrera E, Cesar PF, Henriques B, Fredel MC, Ozcan M, Volpato CAM. Adhesion behavior of conventional and high-translucent zirconia: effect of surface conditioning methods and aging using an experimental methodology. J Esthet Restor Dent. 2019;31(4):388–97. https://doi.org/10.1111/jerd.12490.

Kisel D. Die neue Welt der monolitischen Restaurationen. Quintessenz Zahntechnik. 2021;07:794–801.

Hjerppe J, Narhi T, Froberg K, Vallittu PK, Lassila LV. Effect of shading the zirconia framework on biaxial strength and surface microhardness. Acta Odontol Scand. 2008;66(5):262–7. https://doi.org/10.1080/00016350802247123.

Sulaiman TA, Abdulmajeed AA, Donovan TE, Vallittu PK, Narhi TO, Lassila LV. The effect of staining and vacuum sintering on optical and mechanical properties of partially and fully stabilized monolithic zirconia. Dent Mater J. 2015;34(5):605–10. https://doi.org/10.4012/dmj.2015-054.

Hjerppe J, Fröberg K, Lassila LVJ, Vallittu PK. The effect of heat treatment and feldspathic glazing on some mechanical properties of zirconia. Silicon. 2010;2(3):171–8. https://doi.org/10.1007/s12633-010-9042-y.

•• Zhang Y, Lawn BR. Novel zirconia materials in dentistry. J Dent Res. 2018;97(2):140–7. https://doi.org/10.1177/0022034517737483. This review summarizes in detail the future methods of making zirconia more translucent.

Zenthofer A, Schwindling FS, Schmitt C, Ilani A, Zehender N, Rammelsberg P, et al. Strength and reliability of zirconia fabricated by additive manufacturing technology. Dent Mater. 2022;38(10):1565–74. https://doi.org/10.1016/j.dental.2022.07.004.

Luchtenborg J, Willems E, Zhang F, Wesemann C, Weiss F, Nold J, et al. Accuracy of additively manufactured zirconia four-unit fixed dental prostheses fabricated by stereolithography, digital light processing and material jetting compared with subtractive manufacturing. Dent Mater. 2022;38(9):1459–69. https://doi.org/10.1016/j.dental.2022.06.026.

Revilla-Leon M, Al-Haj Husain N, Barmak AB, Perez-Lopez J, Raigrodski AJ, Ozcan M. Chemical composition and flexural strength discrepancies between milled and lithography-based additively manufactured zirconia. J Prosthodont. 2022; https://doi.org/10.1111/jopr.13482.

Ioannidis A, Bomze D, Hammerle CHF, Husler J, Birrer O, Muhlemann S. Load-bearing capacity of CAD/CAM 3D-printed zirconia, CAD/CAM milled zirconia, and heat-pressed lithium disilicate ultra-thin occlusal veneers on molars. Dent Mater. 2020;36(4):e109–e16. https://doi.org/10.1016/j.dental.2020.01.016.

Acknowledgements

The authors express their gratitude to Dental Technician Andrea Patrizi for providing Fig. 2.

Funding

Open access funding provided by University of Zurich

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The Section Editors for the topical collection Dental Restorative Materials are Mutlu Özcan and Paulo Francisco Cesar. Please note that Dr. Özcan was not involved in the editorial process of this article as she is a co-author.

Conflict of Interest

The authors declare no competing interests.

Human and Animal Rights and Informed Consent

This review article does not contain any new data with human or animal subjects collected by any of the authors. Patient in Fig. 1 signed informed consent for using the photo in this publication.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hjerppe, J., Özcan, M. Zirconia: More and More Translucent. Curr Oral Health Rep 10, 203–211 (2023). https://doi.org/10.1007/s40496-023-00344-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40496-023-00344-1