Abstract

Moso bamboo (Phyllostachys heterocycla (Carr.) Mitford cv. Pubescens) was subjected to heat treatment with saturated steam at 140, 160, and 180 °C for 10–30 min to evaluate the effects of the treatment on the properties of bamboo. The changes in the physical, mechanical, and chemical properties as well as microscopic structures of moso bamboo were analyzed in this study. Results indicated that its equilibrium moisture content (EMC) decreased gradually after being treated by high-temperature saturated steam mostly due to the hemicelluloses’ degradation. Both the temperature and duration of treatment affect the mechanical properties of bamboo. The modulus of elasticity (MOE) of bamboo was prone to be affected by heat treatment with saturated steam as compared to the modulus of rupture (MOR). The MOR and MOE increased as compared to the control when the sample was treated at 140 °C. However, a severe treatment negatively affects the mechanical properties of bamboo. The MOR and MOE decreased by 47% and 20% as compared to the control when the sample was heated at 180 °C for 30 min.

Similar content being viewed by others

Introduction

Due to its short growth and renewal cycles and great mechanical strength, bamboo has been deemed as a promising wood substitute [1, 2]. In the past decades, bamboo-based panels such as laminated bamboo lumber and bamboo scrimber have been rapidly used in the field of interior decoration and constructions [3,4,5,6]. However, the bamboo-based panel especially bamboo scrimber has lost the natural appearance of bamboo. Thus, bamboo in its natural form (culms or poles) is becoming one of the promising non-conventional sustainable building materials for the coming decades [7]. In comparison with bamboo-based panels, the pristine bamboo culm is prone to be affected by moisture, ultraviolet light, and fungi, which may restrict its application for outdoor use. Clearly, improving the dimensional stability and resistance to biodegradation of bamboo is of great importance to widen the outdoor application of bamboo culms.

Along to the years, some typical treatment processes have been applied on bamboo to improve the environmental resistance of bamboo, such as acetylation [8], chemical impregnation [9, 10], and thermal treatment [11,12,13]. Thermal treatment has been proven to be a cost-effective and eco-friendly method to improve the hydrophobic properties and dimensional stability of woody materials. Dry saturated steam, inert gas (nitrogen), hot oil, and water were commonly used as heat treatment medium with the treatment temperature between 150 and 250 °C and the treatment time of 2–6 h [14, 15]. When the temperature is above 150 °C, the heat treatment will reduce the hygroscopic property of the wood, consequently reduce its shrinkage and swelling properties, and thus improve the dimensional stability [16]. At 180 °C or higher temperature, heat treatment can significantly improve the anti-fungi performance of wood [17]. However, high-temperature heat treatment also leads to a decrease in its mechanical properties, which in turn limits its application. During the heat treatment of bamboo, the superheated steam or oil is generally used as the treatment medium [18,19,20]. The conventional temperature of superheated steam treatment process is 180–210 °C. Generally, the moisture in bamboo has been evaporated completely at this temperature at normal pressure. The mechanical properties of bamboo decrease greatly with the increasing treatment time due to the pyrolysis of oven-dried bamboo during the treatment. Moreover, oil treatment is considered to be an environmental-unfriendly process and may also affect the service performance of bamboo including finishing etc.

Saturated steam is the steam that is in equilibrium with heated liquid water at the same pressure, which has not been heated more than the boiling point for that pressure. Studies on the heat treatment of bamboo using saturated steam as medium have rarely been reported. In our previous work, moso bamboo culms were pretreated by saturated steam and then dried by kiln drying method [21]. Results indicated that saturated steam pretreatment has a positive effect on the drying quality of the bamboo culms. The non-uniform shrinkage in the thickness of bamboo culms attributed to the typical multilayered structure during the drying has been eliminated because bamboo can be completely softened under the saturated steam. However, the effect of saturated steam on the basic properties of bamboo culms is still unclear.

In this study, 4-year-old bamboo was heat-treated with saturated steam under different temperatures and durations. The changes in microstructures, physical, chemical, and mechanical properties of bamboo culms after heat treatment were investigated to prove the feasibility of the thermal modification of bamboo culms using saturated steam as medium gas.

Materials and methods

Materials

The material used in this study was the 4-year-old moso bamboo (Phyllostachys heterocycla (Carr.) Mitford cv. Pubescens) harvested in Zhejiang Province from China. The bamboo culms with the average dimensions of 800 (length) × 11 (wall thickness) × 115 mm (diameter) were taken at a height of more than 1000 mm from the roots. The bamboo knots were punched by a drilling and milling machine so that saturated steam can pass through the bamboo culms. Then the fresh bamboo culms with the initial moisture content of 90% were directly applied to the high-temperature saturated steam.

Heat treatment

The bamboo culms were placed in a pressurized tank (12R3426-1, Hangzhou Rongda Boiler Container Co., Ltd.) for heat treatment under the saturated steam. The steam pressure was set up to 3.6 atm, 6.2 atm, and 10 atm, corresponding to the temperature of 140 °C, 160 °C, and 180 °C, respectively. Six repeated bamboo culms for each group were treated at the set temperature for the duration increasing from 10 min to 30 min in steps of 5 min. The bamboo culms were dried in a constant temperature and humidity incubator (DS-408, Xinda laboratory equipment Co., Ltd. China) according to an optimized drying schedule in the previous work [21]. Finally, the bamboo culms were conditioned at 65 ± 3% relative humidity (RH) and temperature of 20 ± 2 °C until reaching constant moisture content.

Oven-dried density

The samples with size of 10 (length) × 10 (width) × t mm (bamboo wall thickness) were prepared from bamboo culms for testing the density by oven-drying method. Totally 36 repeated samples obtained from the control and each treatment group was tested for analysis.

Thickness shrinkage

8 test points were selected and marked separately at both ends of each bamboo culms. The thicknesses of bamboo culms were measured on the test points by micrometer screw (accurate 0.01 mm) before treatment. The thicknesses on the same test points were measured again to calculate the thickness shrinkage individually and then obtained the average shrinkage of bamboo culms after treatment.

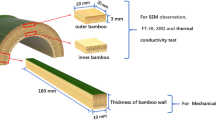

Mechanical properties

As is known to all, bamboo culms have a certain degree of curvature and taperingness, which may affect the testing of mechanical properties. As shown in Fig. 1, the bamboo strips with the dimensions of 160 × 10 × 8 mm (Longitudinal × tangential × radial) were prepared by the processing of splitting, cross-cutting, and outer-inner layer removing for mechanical testing. 12 repeated samples of each experimental set were tested in the 3-point bending test in accordance with the standard of ASTM D1037-12 to analyze the modulus of rupture (MOR) and modulus of elasticity (MOE) [22].

Microstructure observation

Scanning electron microscope (SEM) (Quanta 200, FEI, Netherlands) was employed to analyze the effect of saturated steam treatment on the cross-section microstructure of bamboo culms.

Chemical composition determination

The control and treated bamboo strips were grounded and screened into powders with the size of 40 to 60 mesh for chemical composition determination. The relative content of cellulose, hemicelluloses, and lignin in bamboo was determined according to the international energy analysis and processing procedures and methods in NREL’S LAPS [23,24,25].

FTIR analysis

The chemical functional groups of the residue powders from the chemical composition determination were further analyzed using a VERTEX 80 V FTIR spectrometer (Bruker Corporation, Karlsruhe, Germany). All spectra were collected in the range 1800–400 cm−1 with a resolution of 4 cm−1.

Equilibrium moisture content (EMC)

The bamboo strips with the dimensions of 20 × 20 × 8 mm (L × T × R) were kept at 20 ± 2 °C and 65 ± 3% RH until constant mass. The equilibrium moisture content (EMC) after moisture absorption was calculated:

where m0 is the initial mass of an oven-dried sample and m1 the mass after equalization.

Results and discussion

Microstructure

SEM images on the cross-sections of untreated and high-temperature saturated steam-treated bamboo are shown in Fig. 2. The cross-sectional images of the untreated bamboo sample show intact vascular bundles densely surrounded by intact parenchyma cells. When the bamboo culms were treated at 140 °C/30 min, there is almost no change in the microstructure as compared to the untreated sample. As the temperature of steam increased to 160 °C, the parenchyma cells in the bamboo culm shrinked and the volume of cellular became smaller, which may be resulted from the external high pressure on the soften cells. However, the structure of cell wall and the connection between vascular bundles and parenchyma cells were rarely destroyed. Nevertheless, as the bamboo culm was treated at 180 °C for a long duration, e.g., 180 °C/30 min, the structure of parenchyma cell wall has been changed a lot and the parenchyma cells almost separated from vascular bundles, which may not only attributed to the external high pressure but also the degradation of cell-wall materials.

Oven-dried density and thickness shrinkage

The results of oven-dried density and thickness shrinkage of bamboo after treatment at different temperatures and duration are shown in Fig. 3. Under the saturated steam with the temperature of 140 °C, the density of bamboo increased with the treatment duration. Bamboo does not undergo hydrolysis and pyrolysis processing, and the chemical composition may change slightly at 140 °C. At this condition, the bamboo cells shrink due to the external pressure and the plasticization of materials attributed to the high-temperature steam. After treatment, the bamboo becomes compacted and results in the increase in the density of bamboo comparing with the control. When the temperature was above 160 °C, the shrinkage in the thickness of bamboo increased with the increasing temperature and duration, while the density decreased with the increasing duration. The chemical composition of bamboo may change obviously due to the degradation of chemical components, resulting in a decrease in the density of the treated bamboo.

Major chemical composition

To determine the effects of the treatment temperature on thermal degradation of bamboo chemical components, the major chemical composition including cellulose, hemicellulose, and acid-insoluble lignin content in bamboo are measured. As shown in Table 1, the relative content of cellulose, hemicellulose, and acid-insoluble lignin in bamboo did not change substantially under saturated steam at a temperature of 140 °C. Nevertheless, the major chemical components of bamboo changed a lot when the treatment temperature was up to 160 °C. With the increase of treatment temperature and duration, the relative content of cellulose and hemicellulose showed a general downward trend, while the relative content of acid-insoluble lignin shows an upward trend when treated at 160 °C. This finding is in agreement with the results reported by Zhao et al. [19] and Lee et al. [12]. The polysaccharides in hemicellulose have a low thermal stability under high temperature due to their branched structure and amorphous structure, making it easier to decompose hemicellulose than other chemical components in bamboo.

At the temperature of 140 °C, the content of cellulose does not change substantially with the increasing duration. When the treatment extended to 10 min, the relative content of cellulose increases comparing to the untreated sample, which is mainly due to the loss of volatile materials. At 160 °C, the cellulose content reduces slightly with the extension of treatment duration because of the hydrolysis of cellulose at the presence of water. At higher temperature of 180 °C, the thermal cracking reaction of cellulose is gradually active. Under saturated steam condition, the acetic acid produced by the degradation of acetyl group in hemicellulose has a certain effect on the stability of cellulose, which causes partial degradation of cellulose [26]. The relative content of the acid-insoluble lignin in bamboo increased after high-temperature saturated steam treatment comparing to the untreated bamboo, which ascribes to the pyrolysis and hydrolysis of hemicellulose and the possible lignin condensation reactions during heat treatment [27].

FTIR analysis

The chemical property of bamboo is furthermore confirmed by the FTIR analysis. As shown in Fig. 4, the peak at 897 cm−1 represents the CH bending vibration of β-glucosamine bond of cellulose in bamboo. As compared to the untreated bamboo, there is no significant change, indicating that no damage in the chain structure of cellulose molecular occurs. The peak at 1730 cm−1 is attributed to the linkage of the acetyl group with the ester group or carboxyl group in hemicellulose [28, 29]. The decrease in the peak of 1730 cm−1 indicates the degradation of hemicellulose. The absorption peak near the C–O–C stretching vibration (1159 cm−1) and the O–H stretching vibration (1318 cm−1) also decreases, which further confirms that the hemicellulose is greatly degraded. The acetyl group on the polysaccharide molecule of hemicellulose is hydrolyzed under hydrothermal conditions to form acetic acid, and the resulting acetic acid reduces the number of carbonyl C=O band (near 1600 cm−1) and influences the stability of cellulose. The intensity of the peak at 1590 cm−1 (C=C stretching vibrations in lignin) increased in the spectra of bamboo treated at 180 °C, which further confirmed the lignin condensation reactions during the treatment [12].

Equilibrium moisture content (EMC)

Figure 5 shows that the equilibrium moisture content (EMC) of sample treated by saturated steam at temperature of 160 °C for 30 min is 33.4% lower than that of the untreated. As compared to oil treatment, saturated steam treatment reduced the EMC more efficiently with the short treatment duration. For instance, the reduction in EMC is 46.7% for the sample treated at temperature of 180 °C for 30 min. Hemicellulose has the strongest moisture absorption capacity among the three main chemical components while it started to decompose at a temperature of 160 °C. Thus, the decomposition of hemicellulose caused the decrease in the equilibrium moisture content. Furthermore, during the high-temperature saturated steam treatment, ‘bridge’ reaction occurred between the hydroxyl groups in the cellulose molecular chains of the cellulosic cell wall of bamboo, which releases water and produces ether bonds. The crystallization in quasicrystalline (“paracrystalline”) regions of cellulose may also contribute to the low EMC [30,31,32].

Mechanical properties

The mechanical properties of the bamboo after the high-temperature treatment with saturated steam were measured and summarized in Fig. 6. It can be found that the modulus of rupture (MOR) of bamboo increased after saturated steam treatment at 140 °C. Under the treatment of 140 °C/30 min, the MOR of bamboo reached the maximum value of 196.6 MPa by increasing 10.8% in comparison with the untreated bamboo, which is mainly because of the increased density of bamboo due to the shrinkage of bamboo thickness. After being treated at 160 °C for 10 min, the MOR increased by 4.6%, while the treatment time extended to 30 min, the MOR reduced by 7.4%. According to previous studies, bamboo is first softened under high temperature and humidity and then pyrolyzed at the softening point. In particular, the hemicellulose starts to degrade and hydrolyze by the saturated steam significantly when the temperature reaches to 160 °C [33]. Increasing temperatures from 160 to 180 °C had a significant effect on MOR of bamboo. As the duration of treatment increases, the degradation of the hemicellulose intensifies, resulting in a decrease in the static bending strength of the bamboo. MOE values of moso bamboo showed a 3.2–46.8% reduction in stiffness with increasing duration of treatment compared with untreated samples. The degradation of hemicellulose causes the loss of hemicellulose binding in the cell wall, weakening the bonding strength with cellulose and lignin. At the same time, the formed ether chain structure in cellulose reduced the crystallinity of cellulose and the lignin also gradually lost its support for strength in cellulose. At this stage, the degradation occurs in the major elements of bamboo and consequently, the chemical composition changed significantly causing a dramatic change in the static bending strength of bamboo [18, 34].

Compared with the effect of heat treatment on the static bending strength of bamboo, the change on MOE is relatively less intensive. The inflection point of the decrease in elastic modulus occurs under the condition of saturated steam at 180 °C, and the decreasing trend is obviously increased. At 140 °C, the MOE of bamboo increased by 17.3% comparing to untreated bamboo, which may resulted from the reduction of moisture content [35].

At 160 °C, the change in MOE of bamboo is not obvious compared with untreated material. The MOE increases by 2.3% after treating for 10 min which may be explained by the higher the surface area of cellulose quasi-crystallized is high under high temperature, and the increase in crystallinity leads to a rise in the modulus of elasticity of the bamboo. The elastic modulus tends to decrease as the duration of treatment increases. At 180 °C, the elastic modulus of bamboo shows a rapid reduction under the treatment duration of 10–30 min. The elastic modulus of bamboo treated at 180 °C for 30 min decreased by about 20%.

Conclusions

High-temperature saturated steam treatment effectively reduced the equilibrium moisture content (EMC) of bamboo culms with a lower temperature and duration as compared to the conventional heat treatment process, which resulted from the rapid degradation of hemicelluloses and increased relative content of lignin. The decreased moisture absorption may make a positive contribution to improve the dimensional stability and durability of bamboo culms. Under the saturated steam of 140 °C, the oven-dried density, static bending strength and elastic modulus of bamboo increase slightly. However, the change trend is opposite to that at 140 °C when the saturated steam temperature is above 160 °C. High-temperature saturated steam treatment at 160 °C/30 min or 180 °C/10 min shall be a better condition for bamboo, which holds great promise for the outdoor utilization of round bamboo.

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request

Abbreviations

- EMC:

-

Equilibrium moisture content

- MOE:

-

Modulus of elasticity

- MOR:

-

Modulus of rupture

- SEM:

-

Scanning electron microscope

References

Bhavna S, Ana G, Maximilian B, Michael R (2015) Engineered bamboo for structural applications. Constr Build Mater 81:66–73

Akinlabi ET, Anane-Fenin K, Akwada DR (2017) Applications of Bamboo. Bamboo. Springer, Cham, pp 179–219

Asif M (2009) Sustainability of timber, wood and bamboo in construction. In sustainability of construction materials. Woodhead Publishing Limited, Cambridge, pp 31–54

Febrianto F, Sahroni W, Hidayat ES, Bakar GJ, Kwon GJ, Kwon JH, Hong SI, Kim NH (2012) Properties of oriented strand board made from Betung bamboo (Dendrocalamus asper (Schultes. f) Backer ex Heyne). Wood Sci Technol 46:53–62

Qi J, Xie J, Huang X, Yu W, Chen S (2014) Influence of characteristic inhomogeneity of bamboo culm on mechanical properties of bamboo plywood: effect of culm height. J Wood Sci 60:396–402

Sun X, He M, Li Z (2020) Novel engineered wood and bamboo composites for structural applications: state-of-art of manufacturing technology and mechanical performance evaluation. Constr Build Mater 249:118751

Lorenzo R, Mimendi L (2020) Digitisation of bamboo culms for structural applications. J Build Eng 29:101193

Chen H, Miao M, Ding X (2011) Chemical treatments of bamboo to modify its moisture absorption and adhesion to vinyl ester resin in humid environment. J Compos Mater 45(14):1533–1542

Li W, Chen L, Li Y, Li X (2019) Bamboo modification with 1,3-dimethylol-4,5-dihydroxyethyleneurea (DMDHEU) catalyzed by maleic anhydride. J Wood Chem Technol 40(2):126–135

Anwar UMK, Paridah MT, Hamdan H, Sapuan SM, Bakar ES (2009) Effect of curing time on physical and mechanical properties of phenolic-treated bamboo strips. Ind Crop Prod 29:214–219

Yang TH, Lee CH, Lee CJ, Cheng YW (2016) Effect of different thermal modification media on physical and mechanical properties of moso bamboo. Constr Build Mater 119:251–259

Lee CH, Yang TH, Cheng YW, Lee CJ (2018) Effects of thermal modification on the surface and chemical properties of moso bamboo. Constr Build Mater 178:59–71

Tang T, Zhang B, Liu X, Wang W, Chen X, Fei B (2019) Synergistic effects of tung oil and heat treatment on physicochemical properties of bamboo materials. Sci Rep 9:12824

Esteves B, Pereira H (2009) Wood modification by heat treatment: a review. BioResources 4(1):370–404

Sandberg D, Kutnar A, Mantanis G (2017) Wood modification technologies—a review. iForest 10:895–908

Li T, Cheng D, Avramidis S, Walinder EP, Zhou D (2017) Response of hygroscopictiy to heat treatment and its relation to durability of thermally modified wood. Constr Build Mater 144:671–676

Salman S, Thévenon MF, Pétrissans A, Dumarçay S, Candelier K, Gérardin P (2017) Improvement of the durability of heat-treated wood against termites. Maderas-Cienc Tecnol 19(3):317–328

Manalo R, Acda M (2009) Effects of hot oil treatment on physical and mechanical properties of three species of Philippine bamboo. J Trop For Sci 21:19–24

Zhao R, Jiang Z, Hse C, Shupe T (2010) Effects of steam treatment on bending properties and chemical composition of Moso bamboo (Phyllostachys pubescens). J Trop For Sci 22:197–201

Nguyen CT, Wagenführ A, Phuong LX, Dai VH, Bremer M, Fischer S (2012) The effects of thermal modification on the properties of two Vietnamese bamboo species, Part I: effects on physical properties. BioResources 7:5355–5366

Wang X, Song L, Cheng D, Liang X, Xu B (2019) Effects of saturated steam pretreatment on the drying quality of moso bamboo culms. Eur J Wood Wood Pro 77(5):949–951

American Society for Testing and Materials (2012) ASTM D1037-12 Standard: test methods for evaluating properties of wood-base Fiber and Particle Panel Materials

Templeton DW, Scarlata CJ, Sluiter JB, Wolfrum EJ (2010) Compositional analysis of lignocellulosic feed stocks. 2. Method uncertainties. J Agric Food Chem 58:9054–9062

Sluiter JB, Ruiz RO, Scarlate CJ, Sluiter AD, Templeton DW (2010) Compositional analysis of lignocellulosic feed stocks. 1. Review and description of Methods. J Agric Food Chem 58:9043–9053

Sluiter AD, Hames BR, Ruiz RO, Scarlata CJ, Templeton DW, Crocker D (2011) Determination of Structural Carbohydrates and Lignin in Biomass. NREL Laboratory Analytical Procedure (LAP), Technical Report NREL/TP-510-42618, USA

Windeisen E, Strobel C, Wegener G (2007) Chemical changes during the production of thermo-treated beech wood. Wood Sci Technol 41:523–536

Nuopponen M, Vuorinen T, Jamsa S, Viitaniemi P (2004) Thermal modifications in softwood studied by FT-IR and UV resonance Raman spectroscopies. J Wood Chem Technol 24(1):13–26

Wang X, Li Y, Wang S, Yu W, Deng Y (2017) Temperature-dependent mechanical properties of wood-adhesive bondline evaluated by nanoindentation. J Adhesion 93(8):640–656

Boonstra MJ, Tjeerdsma B (2006) Chemical analysis of heat treated softwoods. Eur J Wood Wood Prod 64:204–211

Li Y, Huang C, Wang L, Wang S, Wang X (2016) The effects of thermal treatment on the nanomechanical behavior of bamboo (Phyllostachys pubescens Mazel ex h. de Lehaie) cell walls observed by nanoindentation, XRD, and wet chemistry. Holzforschung 71(2):129–135

Tang T, Chen X, Zhang B, Liu X, Fei B (2019) Research on the physico-mechanical properties of moso bamboo with thermal treatment in tung oil and its influencing factors. Materials 12:599

Zhan T, Sun F, Chao Lyu, He Qian Xu, Kang Zhang Y, Cai L, Huang Z, Lyu J (2020) Moisture diffusion properties of graded hierarchical structure of bamboo: longitudinal and radial variations. Constr Build Mater 259:119641

Yu Q, Zhuang X, Yuan Z, Wang W, Qi W, Wang Q, Tan X (2012) Hydrolysis of sweet sorghum slag hemicellulose in high temperature liquid water and its mechanism. J Chem Indus Eng 63(2):599–605

Sundqvist B, Karlsson O, Westremark U (2006) Determination of formic-acid and acid concentrations formed during hydrothermal treatment of birch wood and its relation to color, strength and hardness. Wood Sci Technol 40(7):549–561

Marcon B, Goli G, Matsuo-Ueda M, Denaud L, Umemura K, Gril J, Kawai S (2018) Kinetic analysis of poplar wood properties by thermal modification in conventional oven. IForest 11:131–139

Acknowledgements

Not applicable.

Funding

The project was funded by the project of “13th Five-Year” National Key R&D Plan (2017YFD0600801), National Natural Science Foundation of China (31901374), National Natural Science Foundation of China (31700488), and Foundation of High-level Talents of Anhui Province (18030701150).

Author information

Authors and Affiliations

Contributions

XW performed the experiments and wrote the majority of the manuscript. DC and XH interpreted the results and wrote a part of the manuscript. LS and WG collected the samples and discussed the results. XL and YL designed the experiments and interpreted the results. BX supervised the overall work. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Wang, X., Cheng, D., Huang, X. et al. Effect of high-temperature saturated steam treatment on the physical, chemical, and mechanical properties of moso bamboo. J Wood Sci 66, 52 (2020). https://doi.org/10.1186/s10086-020-01899-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s10086-020-01899-8