Abstract

Background

Palm oil mill effluent and palm press fiber are problematic wastes generated by the palm oil mill industries in Malaysia. This study has endeavored to assess the possibility of the vermicomposting of residue from the palm oil mills using epigeic earthworms Lumbricus rubellus under laboratory conditions. The study was conducted over 50 days using four combinations in three replicates of each treatment as palm oil mill effluent: palm press fiber in 50:50 ratio (T1), palm oil mill effluent/palm press fiber/cow dung in 50:25:25 ratio (T2), palm oil mill effluent/palm press fiber/cow dung/lawn clipping in 50:20:15:15 ratio (T3), and only palm press fiber (T4). Twenty healthy adult L. rubellus with average weight of 3.92 g was introduced.

Results

Results showed that T3 has a significant decrease in C/N ratio (14.81 ± 0.07) compared to the other treatments. The presence of cow dung and lawn clipping in the mixtures makes it more suitable for vermicomposting process as early compost productions were recorded in T2 and T3.

Conclusion

The study showed that the major polluting problem in palm oil mills can be tackled through vermicomposting technique. Based on the results, vermicompost is found suitable for agriculture purposes as an organic fertilizer as well as soil conditioner.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

The large amount of wastes generated from palm oil mill industry in Malaysia creates economic and environmental problems. The total oil palm plantation area was about 4,051,374 ha in 2005 and is expected to increase to 5.10 million ha in 2020 (Jalani et al. 2002). Meanwhile, the Malaysian Palm Oil Board (MPOB) reported that the global production of oil palm and the plantation area has increased to 41% of the world production (Rupani et al. 2010). Palm oil mills (381) in Malaysia generate about 26.7 million tonnes of solid biomass such as palm press fiber (PPF) and about 30 million tonnes of palm oil mill effluent (POME) (Yacob et al. 2005). Therefore, large area of land is needed to dispose POME and other by-products produced in large quantity during the oil palm plantation and production (Chan 2000). Yacob et al. (2006) estimated that about 0.5 to 0.75 tonnes of POME will be discharged from a mill for every tonne of fresh fruit bunch processed. POME is acidic in nature (pH = 3), but it is a major source of organic carbon (OC) and nitrogen.

PPF is another by-product being produced in abundant amount by palm oil mill as a solid biomass. PPF is usually left as solid waste after oil extraction (Sreekala et al. 1997). Part of the oil is lost in the fiber after screw press extraction of crude palm oil, and the rest of the oil remain in the fiber, making it suitable as a combustible material (Lim Siong et al. 2009). Although PPF is similar to rice straw, it contains a higher percentage of lignin which cannot be easily digested by animals (Prasertsan and Prasertsan 1996).

Since oil palm by-products decompose slowly under normal condition, soil micro- and macro-organisms are required to enhance the decomposition process. One of the possible bioconversion techniques is vermicomposting which is a cost effective solution to waste disposal problems (Lofs-Holmin 1986). Vermicomposting with earthworms produces humus-like product at a lower processing time, with low phytotoxicity, high in N content, greater fertilizer value, and additional production of earthworms (Lorimor et al. 2001). Therefore, vermicomposting can be considered to be a suitable and an efficient technology to convert such industrial wastes into valuable resources.

Some species of epigeic earthworms such as Lumbricus rubellus can live in decaying organic waste materials and tolerate temperatures ranging from 0°C to 40°C at neutral or near neutral conditions, and the final product is rich in nitrogen content (Nagavallemma et al. 2004), odor-free, and has fine particle materials which are highly available nutrients for plants (Marsh et al. 2005; Suthar 2007a, b). The utility of epigeic earthworms for successful degradation of organic wastes is predictable for different industries such as paper and pulp (Elvira et al. 1998; Elvira et al. 1997), sugar processing (Kale 1998 Reddy and Shantaram 2005), and olive oil mill wastes (Macci et al. 2009; Macci et al. 2010).

The aim of this study was to evaluate the effectiveness of vermicomposting of POME and PPF produced from palm oil mill industries, and to determine the suitable combination of wastes in terms of rapid degradation and potential for plant establishment and growth. The experiment used PPF as a media for earthworms and to characterize the vermicompost quality.

Methods

POME and PPF were obtained from Malpom Industry, Pulau Pinang, Malaysia. Fresh cow dung (CD) was procured from a local cowshed around Penang. The earthworm species used was L. rubellus which is epigeic and considered as a potential organic-waste-composting worm (Edwards and Bohlen 1996). Lawn clipping (LM) was taken from the University campus. Cow dung and lawn clipping were used as amendment materials (bulking material) during this study. Chemical characteristics of POME and PPF are reported in Table 1.

Experimental layout

Four treatment groups with three replicates each were set up. Each mixture consisted of different ratio of POME, PPF, CD, and LM on weight basis. Small holes were drilled at the bottom of each plastic container (34 cm × 36 cm × 11 cm) to drain away excess water. The composition of different feed substrates is illustrated in Table 2.

The vermicomposting unit was set up for 45 days as the sexual maturity period for this species is 4 to 6 weeks under favorable condition (Ismail 1997). The substrates were placed in the plastic container as vermireactors and placed in laboratory condition (25°C ± 2°C). After 120 h of pre-composting, 20 clitellate earthworms of L. rubellus having average live weight of 3.92 g were introduced to each setup containing 2,000 g (on wet weight basis) of substrate material (adapted from Kaviraj and Sharma (2003)).

Moisture was maintained between 70% and 80% throughout the study by sprinkling of adequate quantity of tap water. In order to prevent moisture loss, vermireactors were covered with jute bags. During pre-composting, the waste material was allowed to compost, turned periodically in order to become palatable for the earthworms and eliminate volatile gases that may be toxic for the earthworms.

The worms were separated from the reactors by hand sorting, counted, and weighted weekly. The weighed earthworms were returned to their respective reactors. After 45 days, the earthworms were removed manually, and the total biomass of the earthworms was determined. Two days prior to termination, all treatments were not watered in order to sieve the compost easier.

Compost analysis

Chemical parameters were analyzed in all treatments before the introduction of earthworms and after every 15 days, up to 45 days. Compost was harvested after 45 days of vermicomposting. The following analyses were done: pH and electrical conductivity (EC) in water using a ratio of 1:10; the CNH analyzer was used to determine carbon and nitrogen. C/N ratio was calculated from the measured value of C and N. Nutrients such as Na, K, and Ca were determined after extracting the sample using ammonium acetate method (Simard 1993) and analyzed by atomic absorption spectrophotometer.

Statistical analysis

One way ANOVA was analyzed using PSAW Statistics 18, and all values are presented as the mean ± standard deviation. The probability levels used for statistical significance were P < 0.05.

Results and discussion

The POME used in this study contains high level of organic matter which is indicated by high BOD (Table 1). Once the material with high organic matter is added into the PPF which is high in cellulosic material, heat is generated in the composting pile due to metabolic heat generation from biodegradation (Miyatake and Iwabuchi 2005). The temperature profiles of the first 15 days of the experiment are illustrated in Figure 1. The highest temperatures attained were at 48°C and 35°C in treatments 1 and 4, respectively, at the first 24 h of composting. Two more peaks occur at 35°C and 38°C in treatments 1 and 3 after the turning over of compost at day three. After 120 h of composting, the mean temperature of all the treatments was stable at 30°C ± 3°C, and the room temperature throughout the experiment was 25°C ± 2°C.

Temperature profile during the vermicomposting of different treatments. Day 5 is a time of adding earthworms. T1, T2, T3, and T4 represent treatment compositions (see Table 2). RT, room temperature.

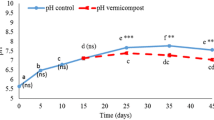

As presented in Table 3, the pH value in the vermicomposted material is lower than the initial value (Table 4) (P < 0.05). The reduction in pH was significant in all treatments. Maximum reduction of pH occurred in T3, where the initial pH was at the 8.6 ± 0.01 and reduced to 7.4 ± 0.01 at the time of termination. The minimum reduction was in T4, with pH 7.6 ± 0.01 at the end of the experiment. These reductions of pH in vermicompost have also been recorded by other authors (Garg et al. 2006 Suthar and Singh 2008). According to Ndegwa et al. (2000), the reduction of pH during vermicomposting is due to the bioconversion of organic material into various intermediate types of organic acids. Also, higher mineralization of nitrogen and phosphorus into nitrites/nitrates and orthophosphate causes the lower pH (Ndegwa et al. 2000). Furthermore, it occurs due to the production of CO2 and organic acids by microbial metabolism during decomposition of different substrates in the feed mixtures. EC increased significantly in all the treatments (Table 3). Minimum and maximum EC recorded at the end of vermicomposting experiment were in T1 (2.20 ± 0.01) and T4 (2.9 ± 0.04), respectively. Kaviraj and Sharma (2003) reported that the increase in EC at the end of the vermicomposting process is due to the loss of organic matter and the release of different mineral salts. Similar trends in increasing the EC at the time of termination are recorded by others (Warman and AngLopez 2002). The EC of all the treatments did not exceed the threshold value of 3 ds m−1 which is recommended by Soumaré et al. (2002).

OC decreased in all the treatments at the final point of the vermicomposting process (Table 3). Maximum OC was recorded in T4 treatment (42.21 ± 0.55), whereas minimum OC was observed in T3 (30.44 ± 0.13). As compared to the initial substrates (Table 4), the vermicomposted material showed loss of organic carbon as expected in a composting process (P < 0.01, for all the treatments). Through the muscular action of the earthworm gut, the ingested material gets fragmented and homogenized, and this increases the surface area for further microbial action, whereas the microorganisms within the earthworms' gut degrade the wastes and provide extra-cellular enzymes that are required for organic waste decomposition. Therefore, the combined action of earthworms and microorganisms causes organic carbon loss from the substrate through respiration (Edwards 1988). However, the difference in OC loss between the treatments was related to the different mixture of organic combinations in the vermireactors. The mineralization as observed in T3 could be due to the suitable microbial condition in this treatment as compared to the other treatments.

There is a significant increase of nitrogen observed in all the treatments (Table 3). Final nitrogen in vermicomposted material was in the range 1.29 ± 0.01 to 2.31 ± 0.36 (percentage) in different treatments. Treatment 4 shows significantly less nitrogen content as compared to the other treatments; this is due to the cellulose content of fiber. As it was expected, due to the mineralization of organic carbon, the nitrogen percentage at the end of the vermicomposting process in the different treatments increased significantly. A similar trend has been observed by Kaushik and Garg (2004) who had reported a TKN increase of 2.0 to 3.2 times in textile mill sludge vermicompost. It is suggested that earthworms could increase N levels in vermicompost by the addition of their excretory products, mucus, etc. (Tripathi and Bhardwaj 2004). In general, different nitrogen pattern and mineralization activities depend on total amount of nitrogen in the initial waste and on the earthworm activity in the waste decomposition (Kale 1998; Suthar 2007b).

In the present study, C/N ratio offers an indication of degree of decomposition. The C/N of the vermicompost reflects the mineralization and stabilization of the substrate. The loss of carbon as carbon dioxide through microbial respiration and addition of nitrogen by earthworms in the form of mucus and nitrogenous excretory material causes the reduction of C/N ratios (Suthar 2008). Maximum and minimum C/N ratio was observed in treatment 4 (32.72 ± 0.33) and treatment 2 (13.23 ± 0.06) (Table 3). The C/N ratio in T2 and T3 did not show a significant result, whereas T1 and T4 showed significant results at the end of the vermicomposting process. The differences between all the treatments was significant (P <0.001, for all treatments). Figure 2 shows that the initial C/N ratio ranges between 30 and 100 decreased to 13 and 32 in different treatments. All the treatments except treatment 4 show C/N ratio below 20, which is an indication of advanced degree of organic matter stabilization. Moreover C/N ratio below 20 reflects a satisfactory degree of organic waste maturity (Senesi 1989).

Nutrients such as Calcium (Ca) and potassium (K) concentration of vermicompost were presented in Table 3. Both Ca and K concentration in vermicompost was significantly higher than that in the initial mixture in all the treatments. Maximum Ca concentration in the final vermicompost was observed in T3 (0.75 ± 0.1), while the maximum K concentration was in T1 (11.97 ± 0.28) (Table 3). The minimum Ca concentration was recorded in T2 (0.54 ± 0.12), and minimum K was in T4 (7.79 ± 0.72). When organic waste passes through the gut of the earthworm, calcium oxalate crystals get converted to calcium bicarbonate, which consequently enriches the worm cast with higher quality plant nutrient (Spiers et al. 1986). Similar results of calcium enrichments have been recorded by Gupta and Garg (2008b), Hartenstein and Hartenstein (1981), and Suthar (2007a, b, c). Reports show inconsistent results regarding K in the final vermicompost of different industrial wastes. Higher potassium content has been observed in sewage sludge compost (Delgado et al. 1995), whereas Orozco et al. (1996) reported lower K in coffee pulp waste after vermicomposting. These differences in observation are generally due to the different chemical characteristics of initial feed mixtures.

Earthworm growth during vermicomposting process

A significant difference for growth and reproduction of L. rubellus is illustrated in Table 5. The biomass weight gain at the end of the experiment was significant in all treatments (P < 0.001). L. rubellus achieved the maximum weight after the fourth week of the vermicomposting process in T1, T2, and T3, whereas in T4, the maximum weight achieved was occurred on the third week of the vermicomposting process. Also, the maximum biomass weight gain at the end of the vermicomposting process (45 days) was higher in T4 (1.61 ± 0.36), and it was significantly higher than the other treatments (P < 0.001) which could be due to the initial characteristics of the material (mainly lignin). The maximum weight gain was followed by weight loss by the end of the experiment which is followed in all the treatments particularly in the treatments 2 and 3. The biomass gain weight percentages were also calculated at the end of experiment. T2 and T3 show negative growth at the time of termination having −7.16% and −26.91%, respectively. A similar trend of weight loss at the time of termination of vermicomposting experiment was shown by other authors (Gupta and Garg 2008a; Suthar and Singh 2008). They described the weight loss caused by conversion of most of the used substrate to vermicompost that cannot support their growth. These results show that the addition of cow dung and lawn clipping can accelerate the vermicomposting process. Also, it is likely that earthworms digested the substrate with the addition of cow dung and/or lawn clipping before 45 days. This causes a decrease in their population due to insufficient food available to support further growth.

A positive correlation coefficient r = 0.90 was noted between the earthworm growth and the C/N ratio after 45 days of vermicomposting. The result indicated that high C/N ratio would positively increase the earthworm growth (Figure 3), as found by Gupta and Garg (2008a) and Suthar and Singh (2008). Ismail (2005) stated that the earthworms are not just sensitive to the pH of the material but also to the ingredients that are present there. While the pH range is acceptable, the components have to be auspicious. We can conclude here that the decomposition of POME and PPF mixed with cow dung and lawn clipping caused biological speed up in the vermicomposting process and reproduction of earthworms.

Conclusion

Bioconversion of palm oil mill effluent (pH 3.9) is possible through vermicomposting technology, employing epigeic earthworm L. rubellus. Cow dung and lawn clipping play a significant role in stabilizing the mixture and accelerate vermicomposting process. The study revealed that earthworm growth, biomass gain of L. rubellus, and vermicompost nutrients are higher when the POME–PPF is mixed with cow dung/lawn clipping. The study suggested that the vermicomposting is significantly effective in nutrient transformation in waste mixture. This study advocated the candidature of POME for vermicomposting operation to address the issue of sustainable industrial development.

Authors’ information

PFR is a PhD student in the Environmental Science Division, School of Industrial Technology, Universiti Sains Malaysia. Her keen interest is in vermicomposting and waste management researches. MHI is a lecturer in the Environmental Science Division at School of Industrial Technology, Universiti Sains Malaysia. His latest research interests are in ecological technology (involving composting, vermicomposting, and vermifiltration of agricultural and domestic waste) and strategic environmental rethinking (STEER) in relation to capitalism and environmental problems. SAI is the head of the Department of Biotechnology, The New College, India. He is a pioneer in vermitechnology. SAI is known as an ecologist of repute. He has been a visiting professor to the School of Industry Technology at the USM, Penang, Malaysia.

References

Chan KW: Soil management for sustainable oil palm cultivation. In Advanced in oil palm research. Edited by: Basiron Y, Jalani BS, Chan KW. Bangi, Selangor, Malaysia: Malaysian Palm Oil Board; 2000.

Delgado M, Bigeriego M, Walter I, Calbo R: Use of California red worm in sewage sludge transformation. Turrialba 1995, 45: 2.

Edwards CA: Breakdown of animal, vegetable and industrial organic wastes by earthworms. In Earthworms in waste and environmental management. Edited by: Edwards CA. The Hague, Netherlands: SPB Academic Publishing; 1988:21–31.

Edwards CA, Bohlen PJ: Biology and ecology of earthworms. London: Chapman & Hall; 1996.

Elvira C, Sampedro L, Benitez E, Nogales R: Vermicomposting of sludges from paper mill and dairy industries with Eisenia andrei : a pilot-scale study. Bioresour Technol 1998, 63: 205–211. 10.1016/S0960-8524(97)00145-4

Elvira C, Sampedro L, Dominguez J, Mato S: Vermicomposting of wastewater sludge from paper-pulp industry with nitrogen rich materials. Soil Biol Biochem 1997, 29: 759–762. 10.1016/S0038-0717(96)00202-7

Garg P, Gupta A, Satya S: Vermicomposting of different types of waste using Eisenia foetida : a comparative study. Bioresour Technol 2006, 97: 391–395. 10.1016/j.biortech.2005.03.009

Gupta R, Garg V: Stabilization of primary sewage sludge during vermicomposting. J Hazard Mater 2008a, 153: 1023–1030. 10.1016/j.jhazmat.2007.09.055

Gupta R, Garg VK: Stabilization of primary sewage sludge during vermicomposting. J Hazard Mater 2008b, 153: 1023–1030. 10.1016/j.jhazmat.2007.09.055

Hartenstein R, Hartenstein F: Physicochemical changes effected in activated sludge by the earthworm Eisenia foetida . J Environ Qual 1981, 10: 377.

Ismail SA: Vermicology: the biology of earthworms. Hyderabad: Orient Longman Press; 1997:92.

Ismail SA: The earthworm book. Mapusa: Other India Press; 2005:101.

Jalani B, Basiron Y, Darus A, Chan K, Rajanaidu N: Prospects of elevating national oil palm productivity: a Malaysian perspective. Oil Palm Ind Econ J 2002, 2: 1–9.

Kale R Paper presented at the fifth international symposium on earthworm ecology, Columbus, Ohio, 5–9 July 1994. Earthworms: nature's gift for utilization of organic wastes 1998.

Kaushik P, Garg VK: Dynamics of biological and chemical parameters during vermicomposting of solid textile mill sludge mixed with cow dung and agricultural residues. Bioresour Technol 2004, 94: 203–209. 10.1016/j.biortech.2003.10.033

Kaviraj S, Sharma S: Municipal solid waste management through vermicomposting employing exotic and local species of earthworms. Bioresour Technol 2003, 90: 169–173. 10.1016/S0960-8524(03)00123-8

Lim SH, Azhari SB, Mohd NA, Umi KMS, Nor' AAR, Suraini AA, Mohd AH, Shirai Y: Physicochemical changes in windrow co-composting process of oil palm mesocarp fiber and palm oil mill effluent anaerobic sludge. AJBAS 2009, 3: 2809–2816.

Lofs-Holmin A: Processing of municipal sludges through earthworms ( Dendrobaena veneta ). Swed J Agric Res 1986, 16: 67–71.

Lorimor J, Fulhage C, Zhang R, Funk T, Sheffield R, Sheppard DC, Newton GL: Manure management strategies/technologies. Ames, Iowa: National Center for Manure and Animal Waste Management and Midwest Plan Services; 2001.

Macci C, Masciandaro G, Ceccanti B: Vermicomposting of olive oil mill wastewaters. Waste Manag Res 2009, 28: 738.

Macci C, Masciandaro G, Ceccanti B: Vermicomposting of olive oil mill wastewaters. Waste Manag Res 2010, 28: 738. 10.1177/0734242X09345278

Marsh L, Subler S, Mishra S, Marini M: Suitability of aquaculture effluent solids mixed with cardboard as a feedstock for vermicomposting. Bioresour Technol 2005, 96: 413–418. 10.1016/j.biortech.2004.06.002

Miyatake F, Iwabuchi K: Effect of high compost temperature on enzymatic activity and species diversity of culturable bacteria in cattle manure compost. Bioresour Technol 2005, 96: 1821–1825. 10.1016/j.biortech.2005.01.005

Nagavallemma KP, Wani SP, Stephane Lacroix PVV, Vineela C, Babu Rao M, Sahrawat KL: Vermicomposting: recycling wastes into valuable organic fertilizer. Andhra Pradesh: ICRISAT; 2004.

Ndegwa PM, Thompson SA, Das KC: Effects of stocking density and feeding rate on vermicomposting of biosolids. Bioresour Technol 2000, 71: 5–12. 10.1016/S0960-8524(99)00055-3

Orozco F, Cegarra J, Trujillo L, Roig A: Vermicomposting of coffee pulp using the earthworm Eisenia fetida : effects on C and N contents and the availability of nutrients. Biol Fertil Soils 1996, 22: 162–166. 10.1007/BF00384449

Prasertsan S, Prasertsan P: Biomass residues from palm oil mills in Thailand: an overview on quantity and potential usage. Biomass Bioenergy 1996, 11: 387–395. 10.1016/S0961-9534(96)00034-7

Reddy K, Shantaram M: Potentiality of earthworms in composting of sugarcane byproducts. Asian J Microbiol Biotechnol Environ Sci 2005, 7: 483.

Rupani PF, Singh RP, Ibrahim MH, Esa N: Review of current palm oil mill effluent (POME) treatment methods: vermicomposting as a sustainable practice. World Appl Sci J 2010,10(10):1190–1201.

Senesi N: Composted materials as organic fertilizers. Sci Total Environ 1989, 81: 521–542.

Simard R: Ammonium acetate extractable elements. In Soil sampling and methods of analysis. Edited by: Carter MR. Boca Raton: CRC; 1993:39–42.

Soumaré M, Demeyer A, Tack F, Verloo M: Chemical characteristics of Malian and Belgian solid waste composts. Bioresour Technol 2002, 81: 97–101. 10.1016/S0960-8524(01)00125-0

Spiers G, Gagnon D, Nason G, Packee E, Lousier J: Effects and importance of indigenous earthworms on decomposition and nutrient cycling in coastal forest ecosystems. Can J Forest Res 1986, 16: 983–989. 10.1139/x86-172

Sreekala M, Kumaran M, Thomas S: Oil palm fibers: morphology, chemical composition, surface modification, and mechanical properties. J Appl Polym Sci 1997, 66: 821–835. 10.1002/(SICI)1097-4628(19971031)66:5<821::AID-APP2>3.0.CO;2-X

Suthar S: Production of vermifertilizer from guar gum industrial wastes by using composting earthworm Perionyx sansibaricus (Perrier). Environmentalist 2007a, 27: 329–335. 10.1007/s10669-007-9032-9

Suthar S: Vermicomposting potential of Perionyx sansibaricus (Perrier) in different waste materials. Bioresour Technol 2007b, 98: 1231–1237. 10.1016/j.biortech.2006.05.008

Suthar S: Nutrient changes and biodynamics of epigeic earthworm Perionyx excavatus (Perrier) during recycling of some agriculture wastes. Bioresour Technol 2007c, 98: 1608–1614. 10.1016/j.biortech.2006.06.001

Suthar S: Bioconversion of post harvest crop residues and cattle shed manure into value-added products using earthworms Eudrilus eugeniae Kinberg. Ecol Eng 2008, 32: 206–214. 10.1016/j.ecoleng.2007.11.002

Suthar S, Singh S: Feasibility of vermicomposting in biostabilization of sludge from a distillery industry. Sci Total Environ 2008, 394: 237–243. 10.1016/j.scitotenv.2008.02.005

Tripathi G, Bhardwaj P: Comparative studies on biomass production, life cycle and composting efficiency of Eisenia foetida (Savigny) and Lampito mauittii (Kinberg). Bioresource Technol 2004, 92: 275–283. 10.1016/j.biortech.2003.09.005

Warman P, Anglopez M: The chemical properties of vermicompost derived from different feedstocks. Columbus, Ohio: Proceedings of the international composting and compost science symposium; 2002. CD Rom CD Rom

Yacob S, Hassan MA, Shirai Y, Wakisaka M, Subash S: Baseline study of methane emission from open digesting tanks of palm oil mill effluent treatment. Chemosphere 2005, 59: 1575–1581. 10.1016/j.chemosphere.2004.11.040

Yacob S, Ali Hassan M, Shirai Y, Wakisaka M, Subah S: Start-up operation of semi-commercial closed anaerobic digester for palm oil mill effluent treatment. Process Biochem 2006,41(4):962–964. 10.1016/j.procbio.2005.10.021

Acknowledgments

The financial support by Universiti Sains Malaysia under the Short Term Research Grant (304/PTEKIND/6310003) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interest

The authors’ declare that they have no competing interests.

Authors’ contributions

PFR is the main author, carried out the vermicomposting studies and laboratory tasks, and drafted the manuscript. MHI and SAI gave supervisions and participated in the correction of the manuscript. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Rupani, P.F., Ibrahim, M.H. & Ismail, S.A. Vermicomposting biotechnology: recycling of palm oil mill wastes into valuable products. Int J Recycl Org Waste Agricult 2, 10 (2013). https://doi.org/10.1186/2251-7715-2-10

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2251-7715-2-10