Abstract

Penetration of distributed generation (DG) units in distribution network has increased rapidly stimulated by reduced network power loss, improved bus voltage profile, and better power quality. Appropriate size and allocation of DG units play a significant role to get beneficial effects. The objective of this study is to demonstrate a simple and fast technique to determine appropriate location and size of DG units. A voltage stability indicator (VSI) is derived which can quantify the voltage stability conditions of buses in distribution network. According to VSI, vulnerable buses of the network are arranged rank-wise to form a priority list for allocation of DG units. To determine the size of DG units, a feed forward artificial neural network is prepared in MATLAB environment (The MathWorks, Inc., Massachusetts, USA). The effectiveness of the proposed methodology has been tested on a 52-bus radial distribution network. After appropriate allocation of DG units, voltage profiles of most of the buses are increased significantly. The results also indicated that the total loss of the distribution network has reduced by nearly 76.39%, and voltage stability conditions of buses are improved considerably. Voltage stability conditions of bus-13, bus-36, and bus-44 are raised by 23.16%, 29.23%, and 37.64% respectively.

Similar content being viewed by others

Background

Distributed generation (DG) is going to play a very important role in power systems worldwide. Penetration of DG units in distributed system presents a significant impact on system reliability, power flow, voltage profile, stability, and power quality. Renewable energy source-based DG can alleviate the energy poverty by utilizing abundant wind and solar photovoltaic available in the region [1]. Most of the radial distribution networks suffer with voltage instability at feeders. DG units can boost up the low voltage at the end of the feeders. The planned application of DG units can provide the transmission capacity release, reduction in network losses, and avoidance of high investment costs for network upgrades. But, unplanned uses of DG units may increase the problems. Therefore, some tools or techniques are needed to be examined for the allocation and sizing of the DG units.

A method for placement of DG units using continuation power flow analysis has been proposed by Hedayati et al. [2]. They have not studied about the size of DG units. Kashem et al. have discussed about optimal use of DG units to support voltage in distribution feeders [3]. They have applied sensitivity analysis to determine appropriate location of voltage support DG units. The effect of DG real and reactive power injections for the inclusion of DG units is also investigated. Rafidah et al. [4] have discussed about a methodology to evaluate appropriate DG size and its impact on power losses and voltage profile in distribution system. They have proposed complex artificial immune system optimization algorithm for sizing of DG units. Islam has presented a methodology to optimize the size of pumped hydro-storage system using optimization software HOMER (NREL, Washington DC, USA) [5]. Acharya et al. [6] have derived an expression to calculate size and location of DG units to minimize distribution losses. The size of DG units is calculated updating the loss coefficients of network loss formula. With proposed methodology by Acharya et al., appropriate size of DG units can be estimated after running a number of load flow iterations. A genetic algorithm-based optimal sizing and placement of DG units considering the system energy loss minimization in different load conditions have been presented by Singh et al. [7]. However, this method needs extensive calculations. Analytical approaches to choose optimal location for DG units in radial distribution network to minimize loss have been presented by Caisheng et al. [8]. They have not discussed sizing issue of DG units in the literature. Recent researches focus on the selection of best places for the allocation of DG units in large distribution network, but appropriate size calculation of DG units using simple and fast techniques has not been emphasized yet.

The paper is organized as follows: At first, a voltage stability indicator (VSI) is developed from conventional power flow equation to determine the stability condition of buses. Then, a priority list is set up using VSI to allocate DG units. In the next section, artificial neural network (ANN) technique is used to determine the proper size of the DG units to ensure the permissible static voltage of each bus. After that, a proposed methodology is tested on a 52-bus radial distribution network, and the impact of the DG units on static voltage profile is illustrated. In the last section, some relevant conclusions are given.

Methods

Allocation of DG units

In developing countries, most of the distribution networks are operated with radial structure, leading to larger voltage drop. Inefficient utilization of energy is another reason to get low quality power at customer end [9]. Considering the fact that most DG units are located at the distribution level, determination of the best locations for DG units to maximize their benefits is very important in system design and expansion. By analyzing the voltage sensitivity of lines, weakness of network voltage may be identified and opportunities for improvement with active or reactive power compensation via DG units can be examined.

Proposed VSI

Power networks are becoming heavily stressed to meet ever-increasing load demand. This situation has resulted into deterioration of voltage magnitudes at buses. One of the major problems that may associate with such a stressed system is voltage collapse. From the necessity of accurate analysis of voltage stability, a number of analytical and computational tools have been discussed [10–12]. In this section, a VSI is formulated for radial distribution network to estimate the distance of voltage collapse. The indicator uses the bus voltage and network information provided by load flow program. Any branch r i + jx i connected between bus i and bus i + 1 of the radial distribution system may be represented by an equivalent circuit model, shown in Figure 1. The conventional power flow equations of the receiving bus and branch connect the receiving bus can be written as follows:

where PL,i and QL,i are the active and reactive power loss of the line connected between two nodes.

Power balance equation is always maintained in each section of the network for steady operation.

As the value of PL,i and QL,i from Equations (6) and (7) have used in Equation (3),

Equation (8) is solved according to the fact that the right hand side of Equation (8) is always positive for any value of Pi + 1, Qi + 1, r i , x i .

Roots of Equation (9) are real if

From Equation (10), the VSI is given as

In practice, the distribution system operators always try to maintain the system within a given voltage stability margin so that small contingencies do not make the system unstable. Therefore, Li + 1 must be less than 1.0 for maintaining stability at that bus. The smaller VSI, the more stable is the distribution network.

Priority list

Voltage stability level of each bus is calculated using the VSI. The buses are ranked in descending order according to their VSIs to form a priority list. The top-ranked buses are chosen first for allocation of DG units. Subsequently, lower-ranked buses are fed with power from the DG units. A number of DG units would be installed depending on the sizing issues of the DG units. After the installation of each DG unit, load flow solution is performed to monitor voltage magnitude of buses, network power losses, and therefore voltage stability condition of the system.

Sizing of DG units

A DG unit is a small scale power generation ranging from multi-kilowatt to few megawatt and is usually connected to a distribution network. The impact of the DG unit on distribution network may be positive or negative, depending upon the size and operating condition of the DG unit. Usually, the DG unit size should be consumable within the distribution substation boundary. Further increase of the DG size can cause reverse flow of power through DG buses and then high system losses.

ANN model

For a particular bus, as the size of the DG unit is increased beyond its appropriate size, network losses start increasing rather than decreasing. So, appropriate size evaluation of DG is very significant. The use of ANN [13] is capable of indicating the best solution for a given distribution system. This is because of the advantage of high computation rate of three-layered feed forward ANN in approximating a complex nonlinear mapping. A feed forward ANN works on the basis of propagation of signal in only one direction from an input stage to an output stage through intermediate neurons. The number of hidden layer is chosen to match the complexity of the function. Error backpropagation learning algorithm is used to train the ANN for the faster learning and reliable convergence. The error function chosen for the learning process is mean square error (MSE) of outputs. The architecture of the three-layered ANN is shown in Figure 2.

The appropriate size of a DG unit for a particular bus can be determined for desired voltage profile of that bus. With random change of DG unit at that bus, values of voltage magnitudes are determined from power flow solutions. Feed forward ANN is trained rigorously with DG size corresponding to voltage magnitudes at poor-voltage stable bus obtained from load flow solution. Then, for any required bus voltage, the appropriate size of the DG unit (MVA) for that particular bus is evaluated. The proposed methodology for the allocation and size evaluation of the DG units is shown in Figure 3. In the flowchart of Figure 3, the iteration starts with calculating the VSI of each bus at base case of the network. After iterations, on view point of voltage profile improvement of buses beyond 0.90 p.u., the appropriate size and location of the DG units are obtained at modified network.

Computational procedure

The installation of non-optimal size DG unit results in an increase of system losses, implying the reduction of voltage magnitudes of buses in the network. A fast systematic approach to allocate DG units and then determination of their sizes need step-by-step computational procedure. The procedure for proposed methodology is as follows:

-

1.

Run the power flow solution at base case of the system.

-

2.

Calculate the VSI of each bus and store.

-

3.

Arrange the VSI of the buses in descending order to form a priority list.

-

4.

Place the DG unit at top-ranked bus.

-

5.

Change the size of the DG unit randomly within a certain limit and calculate the voltage magnitude of the highest priority bus to form the training data set of the proposed ANN.

-

6.

Train the three-layered feed forward ANN properly with training data set.

-

7.

Evaluate the MVA for the voltage profiles of 0.90 p.u. for buses using the ANN model.

-

8.

Repeat steps 5 to 7 to allocate the DG units subsequently at other weak voltage stable buses and continue until all buses of the network reach to desired voltage.

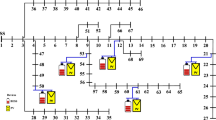

Test network

The proposed technique has been tested on practical 11 kV, 52-bus radial distribution network. There are three main feeders supplying a total load of 4.184 + j2.025MVA [14]. Only bus-1 is connected to the substation, and the rest of the buses in the network are load buses. The schematic diagram of the test network is shown in Figure 4. The line impedance of the system is 0.0086 + j0.0037 Ω/km. A Newton–Raphson algorithm is written in MATLAB 7 to solve the power flow problem.

Single line diagram of the 52-bus radial distribution network [[14]].

Results and discussion

The method to allocate DG units to improve voltage profile and voltage stability condition of the distribution network is demonstrated through the simulation of the test network. The base power and the voltage for simulation of the system are taken as 10 MVA and 11 kV, respectively. The VSI of each bus is calculated with the network data of base configuration. The priority list is prepared and presented in Table 1.

According to the load flow, the active and reactive power losses of the system are obtained as 741 kW and 307 kVAR, respectively. Voltage magnitudes of the system are also noted and shown in Figure 5. From Figure 5, it is seen that many buses (bus-18, bus-19, bus-35, bus-36, etc.) suffer with low voltage problem and having a voltage lower than 0.8 p.u.

According to the priority list, the first DG unit is placed at bus-44 because it is with highest value of VSI. The size of the distribution system in term of loads plays an important role in selecting the size of the DG unit. To obtain a reasonable solution, the size of the DG unit should not be so small or so large with respect to load value. Therefore, the DG range is between 0.4648 MVA (10% of total load) and 1.3944 MVA (30% of total load) for this system. The optimal size of the DG unit is quantified through raising the voltage magnitude of low voltage stable bus to 0.95 p.u. The appropriate size of the DG unit at bus-44 is calculated using ANN. Figure 6 obtained from the simulation of ANN model shows training and target output data at bus-44. Very low MSE (0.00069) confirms the validation of the proposed model.

The appropriate DG size at bus-44 is 0.7123MVA, i.e., 15.06% of the total load. In the same way, two DG units are installed consecutively at bus-36 and at bus-13. The minimum size of the DG unit, i.e., 0.4648 MVA, is sufficient to raise the voltage beyond 0.95 p.u at bus-36. For bus-13, the size of DG unit is determined from ANN as shown in Figure 7. Appropriate sizes of DG units along with MSEs are tabulated in Table 2. From Table 2, it is to be noted that the appropriate size of DG unit is 12.82% of the total load of the test network.

After the allocation of the three DG units, it is seen that the voltage profile of all the buses are raised above 0.90 p.u. as shown in Figure 8. From Figure 8, it is seen that the voltage magnitudes of bus-18, bus-19, bus-35, and bus-36 are increased by 19.07%, 19.44%, 19.12%, and 21.78%. The voltage stability condition of all the buses has improved considerably compared to the initial condition and shown in Figure 9. It is noted from the figure that the voltage stability condition of bus-13, bus-36, and bus-44 are improved by 23.16%, 29.23%, and 37.64%. The active and reactive power losses of the network are reduced significantly as shown in Table 3. It is noted from Table 3 that the active and reactive power losses are reduced by 76.25% and 77.20%, respectively, after proper allocation of three DG units in the test distribution system.

Conclusions

In this study, a priority list is developed using VSI to accommodate DG units. The appropriate allocation of the DG unit has been done easily using the priority list. Proposed methodology for the determination of appropriate size of DG units for desired voltage profile using ANN technique has emerged as a very fast and efficient tool. The appropriate size of the DG units varies from bus to bus, depending on connected loads. The results reveal that the integration of DG units is highly effective in reducing power losses in the distribution network. It is shown that with appropriate sizing and allocation of DG units, voltage magnitudes of the poor-voltage buses can be raised above 0.90 p.u. Results also indicate that there is a significant improvement of voltage stability for most of the buses. The study may be further facilitated considering economical and geographical location factors of DG units.

Authors’ information

PK has completed B. Tech. in Electrical Engineering in 2008 from West Bengal University of Technology, India. He received his masters degree in Electrical Engineering from Bengal Engineering and Science University, Shibpur, India in 2010. He joined the Future Institute of Engineering and Management, Kolkata, India as an Asst. Professor in 2010. Currently, he is working on his Ph.D. at Bengal Engineering and Science University, Shibpur, India. CKC has received his B.E. with honors from Regional Engineering College, Durgapur, (presently National Institute of Technology, Durgapur), India in 1983. He received M. Tech. from the Department of Electrical Engineering, Indian Institute of Technology, Kharagpur, India in 1989. He received his Ph.D. degree from the Bengal Engineering and Science University, Shibpur, India in 2003. Now, he is a professor at Bengal Engineering and Science University, Shibpur, India. He was formerly a lecturer in Regional Engineering College, Durgapur, India.

Abbreviations

- P i :

-

Active power demand at bus i

- Q i :

-

Reactive power demand at bus i

- V i :

-

Voltage magnitude at bus i

- r i :

-

Resistance of branch i

- x i :

-

Reactance of branch i

- P L + i :

-

Active power loss of branch i

- Pi + 1 Active power demand at bus i:

-

+ 1

- Qi + 1 Reactive power demand at bus i:

-

+ 1

- Vi + 1 Voltage magnitude at bus i:

-

+ 1

- Li + 1 VSI of bus i:

-

+ 1

- SDG:

-

Size of DG unit (MVA).

References

Lal S, Laturi A: Techno-economic analysis of a hybrid mini-grid system for Fiji islands. Int. J. Energy. Environ. Eng. 2012, 3: 10. 10.1186/2251-6832-3-10

Hedayati H, Nabaviniaki SA, Akbarimajd A: A method for placement of DG units in distribution networks. IEEE T. Power Deliv. 2008, 23(3):1620–1628.

Kashem MA, Ledwich G: Multiple distributed generators for distribution feeder voltage support. IEEE T. Energy Conver. 2005, 20(3):676–684. 10.1109/TEC.2004.832090

Rafidah S, Rahim A: Implementation of DG for loss minimization and voltage profile in distribution system. In the 4th international power engineering and optimization conference, Shah Alam, Malaysia; 2010.

Islam SM: Increasing wind energy penetration level using pumped hydro storage in island micro-grid system. Int. J. Energy. Environ. Eng. 2012, 3: 9. 10.1186/2251-6832-3-9

Acharya A, Mahat P, Mithulananthan N: An analytical approach for DG allocation in primary distribution network. Electr. Pow. and Energy Syst. 2006, 28: 669–678. 10.1016/j.ijepes.2006.02.013

Singh D, Singh D, Verma KS: GA based energy loss minimization approach for optimal sizing and placement of distributed generation. Int. J. of Knowledge-based and Intelligent Eng. Syst. 2008, 12: 147–156.

Caisheng W, Nehrir MH: Analytical approaches for optimal placement of distributed generation sources in power system. IEEE T. Pow. Syst. 2004, 19(4):2068–2076. 10.1109/TPWRS.2004.836189

Oyedepo SO: Efficient energy utilization as a tool for sustainable development in Nigeria. Int. J. Energy. Environ. Eng. 2012, 3: 11. 10.1186/2251-6832-3-11

Dey S, Chanda CK, Chakraborti A: Development of global voltage security indicator (VSI) and role of SVC on it in longitudinal power supply (LPS) system. Electr. Pow. Syst. Res. 2004, 68: 1–9. 10.1016/S0378-7796(03)00125-1

Gubina F, Strmcnik B: A simple approach to voltage stability assessment in radial network. IEEE T. Pow. Syst. 1997, 12(3):1121–1128. 10.1109/59.630451

Shin JR: A new optimal routing algorithm for loss minimization and voltage stability improvement in radial power systems. IEEE T. Pow. Syst. 2007, 22(2):648–657.

Ismail KS: Neural network based load balancing and reactive power control by static VAR compensator. Int. J. of Computer and Electr. Eng. 2009, 1(1):1793–8198.

Thukaram D, Khincha HP, Vijaynarasimha HP: Artificial neural network and support vector machine approach for locating faults in radial distribution system. IEEE T. Pow. Deliv. 2005, 20(2):710–721. 10.1109/TPWRD.2005.844307

Acknowledgments

The authors are thankful to the editors and reviewers of the International Journal of Energy and Environmental Engineering for their valuable suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interest

The authors declare that they have no competing interests.

Authors’ contributions

PK has carried out the survey and the simulation of the methodology. CKC analyzed the results and made the conclusion. Both authors have participated in drafting the manuscript. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Kayal, P., Chanda, C.K. A simple and fast approach for allocation and size evaluation of distributed generation. Int J Energy Environ Eng 4, 7 (2013). https://doi.org/10.1186/2251-6832-4-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2251-6832-4-7