Abstract

Background

The main purpose of this study is to develop a nonlinear model of a batch adsorption and to evaluate the model's capability in the prediction of experimental adsorption data. Additionally, results of the nonlinear model were compared with data of pseudo first- and second-order models. Experimental data were extracted from the adsorption of zinc ions using calcium alginate beads prepared via electrospray method. In order to study the effects of biosorbent porosity and the initial concentration of the zinc solution on adsorption kinetics, calcium alginate beads were prepared with two different porosities and zinc concentrations.

Results

The results revealed that the nonlinear model offers a much more accurate prediction compared with other models as the average root mean square deviation of the nonlinear model was calculated to be only 2.66%, which was smaller at least four times than that of others. Furthermore, the nonlinear model showed that diffusive transport through beads was limited by pore diffusion.

Conclusions

The nonlinear model provided a good fit to the experimental data as the calculated equilibrium adsorptions were shown to be in good agreement with their experimental counterparts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

In certain industries, the adsorption of heavy metals from various waste streams which are cleaned using a sorbent is a crucial separation process [1]. Although there are numerous commercial absorbents that are available for this purpose, biodegradable polymers such as chitosan and sodium alginate can be considered to be more beneficial, cost-effective, and more abundant in nature than others [2, 3]. Sodium alginate extracted from brown algae is a linear copolymer of a-l-guluronate and a-d-mannuronate [4]. In addition, sodium alginate could be ionically gelated by the divalent cations such as Ca2+ and be converted to a stable and cross-linked structure [5], which has been used for the removal of some heavy metals such as cadmium [6, 7], chromium [8], lead [6], cobalt [9], iron, copper [7], mercury [6], and zinc [10] from aqueous solutions. Furthermore, prediction of the adsorptive behavior of sorbents is important as a consequence of the investigation of adsorption mechanism [11–17]. In order to investigate the mechanisms of the adsorption of heavy metals into adsorbents, pseudo first- and second-order models have been usually used to assess experimental data [2, 12]. Since the model should be fitted by existing experimental data due to the model's nature, they can only predict the rate-controlling steps [2]. On the other hand, in almost all previous research in the adsorption processes, no mathematical model such as nonlinear ones has been applied [18, 19] as the adsorption data have been extracted and undergone a simple investigation in their mechanisms via some pseudo models. The nonlinear model is instrumental and rational for the modeling and predicting of adsorption systems. The physiochemical conditions such as the type of ionic solutions (liquid diffusion coefficient), bead size, agitation rate, and porosity of beads are effective factors in an adsorption process that can be considered in the nonlinear model while their effects could be investigated in detail [14, 20]. Implementing the mathematical model, once it has been endorsed, has the advantages of minimizing the number of experiments related to new operating conditions. In the nonlinear model, the interactive behavior between solutes and adsorbent is certainly described using essential isotherm equations such as that of Freundlich and Langmuir for modeling an adsorption system [2, 3, 9, 21].

In the present study, biosorbents were produced with sodium alginate using the electrospray method, and their capability in removing zinc ions from an aqueous solution under batch adsorption was investigated. The main objectives were to investigate the zinc adsorption mechanism onto the calcium alginate beads, to develop a mathematical model for description of the adsorption, and to assess the flexibility of the mathematical model in comparison with some pseudo-kinetic models in the prediction of absorptive behavior. In addition, some effective parameters such as porosity and concentration of aqueous solution could not be clearly investigated on adsorption processes with pseudo models; on the contrary, the nonlinear model is able to provide a framework of analysis of these parameters. Therefore, the effects of some parameters such as porosity of the beads and initial zinc concentration in the adsorption process were considered on the adsorptive behavior of the models.

Methods

General assumptions

For quantitative depiction of the sorption process, the following assumptions have been made:

-

1

Each prepared calcium alginate bead was idealized as a sphere.

-

2

The mass transfer into calcium alginate beads was only considered in the radius direction, and other directions were deemed negligible.

-

3

Transport of the ions was from the bulk solution to the bead surface and across the boundary layer.

-

4

Adsorption was considered at the inner site of the beads.

-

5

The physical properties of the calcium alginate beads and the solutions' properties were constant in the isotherm of the adsorption processes.

-

6

Pore diffusion was considered onto calcium alginate sorbent.

-

7

Radius of the beads was constant with the adsorption of the water and the heavy metal (i.e., no swelling).

-

8

Bulk convection was neglected onto the beads.

Model description

Mass balance development

Based on the assumptions, the nonlinear model for the prepared sphere beads is as follows [7, 20]:

where C (mg-solute/L) is the concentration of the dissolved solute inside the porous beads, t (s) is the time, ρ b (g-alginate/L) is the medium bulk density, ε (dimensionless) is the porosity, P (mg-solute/g-alginate) is the adsorbed concentration, D l is the liquid diffusion coefficient (m2/s), τ (dimensionless) is the tortuosity factor, and r (m) is the radial distance. The characteristics of calcium alginate beads and initial zinc solution are presented in Table 1. The adsorbed concentration can be defined using the Freundlich and Langmuir isotherm [2, 22].

Langmuir isotherm

The Langmuir isotherm assumes that the monolayer coverage of sorption of each molecule onto the surface has equal sorption activation energy [13]. It has been usually applied to determine the quantity and compare the performance of different biosorbents and is expressed as follows:

where Pmax (mg/g) is the maximum amount of adsorption, and K f (L/mg) is the sorption equilibrium constant. Substitution of the Langmuir isotherm into Equation 1, the nonlinear model for a solute inside a porous bead becomes Equation 3:

where D a is the apparent diffusion coefficient, which is determined as follows:

Solution technique

Boundary and initial conditions, which were determined based on general assumptions and experimental conditions, were needed to solve Equation 1. Accordingly, the following boundary and initial conditions were used:

In the derived model, the bead radius was divided into N stages using implicit finite difference method. According to the initial condition, it was considered that the prepared calcium alginate beads were devoid of zinc at the initial time of adsorption. Concentration of the center was parallelized to the next stage that was shown in Equation 6. As shown in Equation 7, the flow of solute onto the bead on the surface and the flow through the boundary layer into the bead as k c which is the mass transfer coefficient (m/s), and C b and C R are the bulk solute concentration and the solute concentration at the bead surface, respectively [14, 20]. Because the nonlinear model was applied to calculate solution concentration at different times, the implicit method was used to find the concentration profiles in the bead. Solving the numerical equation needs an assumption of the value of fitting parameters in Equation 3. The fitting parameters are τ and k c which depend on the bead size, initial concentration of heavy metal in the solution, and agitation rate [14, 20]. The mass transfer coefficient (k c ) can be regulated using the amount of equilibrium adsorption. In order to adjust the fitting parameters, k c was first determined by calculating the minimum deviation between experimental and calculated adsorption equilibrium data at a constant τ, and then τ was estimated as the last and only remaining fitting parameter, which is independent from the calculated data of k c as the estimated amount of equilibrium adsorption was constant during the determination of τ. The satisfied amount of tortuosity factor was confirmed when the deviation between experimental and calculated data was minimum.

Results and discussion

Adsorption isotherm

The adsorption capacities of the calcium alginate beads were compared at different concentrations in Figure 1. The beads were prepared with two different polymer concentrations, 1% and 2% w/v. It indicates that the saturation adsorption capacity increases with the increasing amount of initial zinc concentration at both polymer concentrations. On the other hand, regarding to the same diameter of all beads, the change in the polymer concentration was effective on the porousness. Therefore, the saturation adsorption capacities of the prepared beads with the different concentrations were slightly dissimilar, owing to their near porosities. The Langmuir model was adaptively applied to describe the equilibrium data of zinc adsorption onto the beads. Results show that Langmuir isotherm has been much perfectly fitted to the equilibrium data compared with other isotherms. The Langmuir equilibrium constants and corresponding R2 adjustment coefficients, which were calculated through the application of the least squares method, are shown in Table 2.

Pseudo first- and second-order models

The pseudo first- and second-order models were applied to test the experimental data for investigating the mechanism of the adsorption. The first-order rate expression of Lagergren [22] is given as follows:

where P e and P (mg/g) are the amounts of zinc ions, which were adsorbed into the adsorbents at equilibrium and at the time t, respectively, and k1 (1/min) is the rate constant of the pseudo first-order model. The experimental data could be fitted with a straight line of log (P e − P) versus t, which can determine the flexibility of the model to predict the data. On the other hand, the second-order kinetic model is expressed as follows [22]:

where k2 (g/mg min) is the rate constant of the pseudo second-order model. There should be a linear relationship in the plot of t/P versus t if second-order kinetics is applicable. The slopes and intercepts of the plots give the second-order rate constant k2 and P e . The model is capable of predicting the behavior of all range of adsorption data without any parameters in advance and to show a rapport with chemical adsorptions, which are the rate-controlling steps [2, 22, 25]. Table 3 represents the calculated results obtained from the first- and second-order kinetic models and a comparison of the results with correlation coefficients (R2). The correlation coefficients for the first-order model were low. Figure 2 shows both pseudo-model behaviors in prediction of the experimental data.

The pseudo-kinetic models are not in good agreement with the pre-equilibrium times of adsorptions, but the prediction of the second-order model shows a better convergence at equilibrium time rather than the first-order model.

The second-order kinetic model generally presents a more or less rational prediction as it showed high correlation coefficients in certain samples. The calculated P e values resulted from second-order kinetic model were in a good fit with the experimental P e values.

Furthermore, the first-order model of Lagergren could not support perfectly all ranges of contact time and was not generally adjustable in the initial stage of the adsorption processes [2, 22, 25]. Figure 2 illustrates that second-order model tends to follow the experimental data better than first-order model as the correlation coefficients for the second-order kinetic model (that are displayed in Table 3) are higher than those of first-order adsorption model. In order to determine the deviations between all calculated and experimental data, root mean square deviation (σRMSD) was calculated as follows:

Table 4 shows that the first-order model could not follow the data as it has an average σRMSD of 15.61%, but the second-order model has a comparatively more rational agreement. Although a better agreement was shown for samples I and II, the average σRMSD was calculated to be 10.59%. Overall, Table 4 shows a high value of σRMSD of the models, indicating a poor agreement with the experimental data. It is obviously alleged that the adsorption of zinc ions onto the prepared calcium alginate beads could be the rate-limiting step, owning to the better agreement of the second-order model [2].

Nonlinear model

The nonlinear diffusion model was applied to model the experimental data. The adsorption behavior has been described with the Langmuir adsorption equation. The Langmuir equation constants are shown in Table 2. Therefore, the results indicate a single molecule layer adsorption [2, 22]. The nonlinear model was numerically solved with the implicit, finite difference approximation using the Newton-Raphson's method [26]. The data were fitted using τ and k c as a lumped parameter applied to describe the boundary layer effect as the fitting parameters. Figure 2a shows that the calculated amount of adsorbed zinc ions increased as the time increases and reached an equilibrium value after 130 min, which is approximately equal to the experimental equilibrium time. In addition, a reasonable agreement is shown in the following experimental data and in fitting the balanced adsorption amount. The fitting parameters (which depend on some effective conditions such as the agitation rate and initial concentration of the solutions [14, 20]) were determined with the calculation of σRMSD between the predicted and experimental data. Furthermore, Figure 2b,c,d shows the same adaptive behaviors in estimating the experimental data with high accuracies as the predicted data are fitted at the balanced adsorption data. Table 5 shows the estimated fitting parameters and the equilibrium adsorption data in different conditions. The factor of tortuosity was calculated from 9.52 to 16.8 with the changing of porosity and initial concentration of the zinc solution. The value of τ depends on the characteristics of the beads, and the high value of τ indicates a slow diffusion into the adsorbent. It is worth mentioning that the calculated τ is independent on the conditions of initial solution and sorbent loading characteristics [14, 20]. It is important to notice that increasing the porosity of the beads from 0.794 to 0.85 decreases the factor of tortuosity, but the changes of porosity do not have any significant effect on the τ values at high zinc concentration in the initial solution (300 mg/L). The fitted values of k c were estimated to be 1.39 × 10−7 to 2.21 × 10−7 m/s, showing the independence of the uptake kinetics on agitation rate. Therefore, the diffusive transport in the prepared calcium alginate beads at high-speed agitation rate (250 rpm) was limited by pore diffusion that indicated the rate-limiting step [14, 20]. Although it seems that the kinetic pseudo models are flexible for the data, the nonlinear model comes with lower σRMSD values compared with the pseudo models. The calculated σRMSD values of the pseudo models showed a disparity in the prediction of experimental data (Table 4). Interestingly, the nonlinear model has an average σRMSD value of 2.66% which is at least four times smaller than that of the pseudo models, indicating a more reliable prediction capability of the nonlinear model in the adsorption process. In all samples, the mathematical model provided an adjustable behavior and perfectly fitted the data.

Experimental

Materials

Sodium alginate (medium viscosity, 3,500 cps, 2% w/v aqueous solution at 25°C) was purchased from Sigma-Aldrich Corporation (St. Louis, MO, USA). Zinc sulfate pentahydrate (ZnSo4∙5H2O), sodium hydroxide (NaOH), hydrochloride acid (HCl), and calcium chloride (CaCl2) were purchased from Merck AG (Darmstadt, Germany) and were used as received without further purification.

Preparation of the porous calcium alginate beads

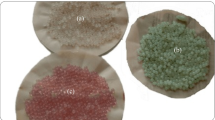

Calcium alginate beads were prepared according to the method of Moghadam et al. [27]. Briefly, sodium alginate solution was prepared by dissolving 1 and 2 g of the polymer in 99 and 98 mL of distillated water, respectively. The solution of the sodium alginate flowed through a stainless steel nozzle via a syringe pump at a 100-mL/h flow rate. Electric field strength was set using a high voltage, DC power supply. The liquid meniscus at the tip of the nozzle was affected by the adjusted electric field where droplets were formed and inundated. The droplet was dripped into a container where ionotropic gelation occurred. The solution made in the container was calcium chloride (3% w/v). The solution was gently stirred for 5 min while the droplets were cured. The prepared calcium alginate beads were washed with distillated water and acetone and dried until the water completely evaporated. The size of the dried calcium alginate beads was measured randomly using the images processor (SAIRAN Co., Iran). Figure 3 shows the size and shape of the prepared calcium alginate beads.

Calculation of the porosity of calcium alginate beads

Porosity of the calcium alginate beads was calculated from the density of the alginate and the weight change before and after drying [1]; the following formula was applied:

where ε is the porosity of the calcium alginate beads, W W (g) is the weight of the wet calcium alginate bead before drying, W D (g) is the weight of the dried calcium alginate bead, ρ W is the density of water, and ρAL is the density of the alginate (Table 1).

Adsorption process

Standard zinc solutions with certain concentrations were prepared by dissolving ZnSO4∙H2O into 500 mL of distillated water. In experiments of the batch kinetic adsorption, 50 mL of standard solution with an adjusted pH (4.5) and 25 mg of the calcium alginate beads were shaken with the use of a shaker (250 rpm) in a thermostat water bath. The concentration of zinc was determined by an atomic absorption spectrophotometer (SPCA-626D, Shimadzu Corporation, Kyoto, Japan). The amount of zinc absorbed onto the calcium alginate beads, P (mg/g dried beads), was calculated using the following equation:

where V (L) is the volume of the zinc solution, C0 (mg/L) is the initial zinc concentration, C (mg/L) is the zinc concentration at a certain time, and W D (g) is the weight of the dried calcium alginate beads [2, 3].

Conclusions

In this study, calcium alginate beads were prepared using the electrospray method as a biosorbent, and adsorption of zinc ions was investigated using the batch equilibrium method. In addition, the effective parameters on adsorption such as porosity were analyzed with the suggested nonlinear model, and the predicted behavior of the nonlinear model in the prediction of experimental data was compared with that of the pseudo-kinetic models. The pseudo models could not follow the experimental data at pre-equilibrium time spans of the adsorption processes as high deviations from the experimental data were observed by the calculation of σRMSD.

The fitting parameters (τ and k c ) of the nonlinear model were estimated using minimum σRMSD between the experimental and calculated data. According to porosity and solution concentration, τ and k c (m/s) were calculated from 9.52 to 16.8 and from 1.39 × 10−7 to 2.21 × 10−7 m/s, respectively. The nonlinear model demonstrated that diffusive transport through the beads was limited by pore diffusion. The nonlinear model was shown to possess a superb adaptive behavior in the prediction of zinc adsorption in the different samples as its average σRMSD was calculated to be 2.66%, which was the lowest σRMSD compared to all other models. The nonlinear model provided a good fit to the experimental data as the calculated equilibrium adsorptions were shown to be in good agreement with their experimental counterparts.

Authors' information

MHK is a PhD student in Material Science. MM is a PhD student in Chemical Engineering. MK is an associate professor of Chemical Engineering. SRK is a PhD student in Material Science.

Abbreviations

- C:

-

Zinc concentration (mg/L)

- Cb:

-

Bulk solute concentration (mg/L)

- Ce:

-

Equilibrium zinc concentration (mg/L)

- CR:

-

Solute concentration at the surface of the sphere (mg/L)

- C0:

-

Initial zinc concentration (mg/L)

- Da:

-

Apparent diffusion coefficient

- Dl:

-

Diffusion coefficient (m2/s)

- k1:

-

Rate constant of pseudo first-order model (1/min)

- k2:

-

Rate constant of pseudo second-order model (g/mg∙min)

- kc:

-

Mass transfer coefficient (m/s)

- Kf:

-

Langmuir constant (mg/g)

- n :

-

The number of experimental data

- P:

-

Adsorbed concentration (mg/g)

- PCal:

-

Calculated adsorbed concentration (mg/g)

- Pe:

-

Equilibrium adsorbed concentration (mg/g)

- PExp:

-

Experimental adsorbed concentration (mg/g)

- Pmax:

-

Maximum monolayer amount of adsorption (mg/g)

- R:

-

Radius (m)

- R2:

-

Correlation coefficient

- T:

-

Time (s)

- WD:

-

Weight of dried calcium alginate bead (g)

- WW:

-

Weight of wet calcium alginate bead before drying (g)

- V:

-

Volume of zinc solution (L)

- τ :

-

Tortuosity factor

- ρ b :

-

Bulk density (g/cm)

- ε :

-

Porosity

- ρ W :

-

Density of water

- ρ AL :

-

Density of sodium alginate

- σ RMSD :

-

Root mean square deviation.

References

Zhao F, Yu B, Yue Z, Wang T, Wen X, Liu Z, Zhao C: Preparation of porous chitosan gel beads for copper(II) ion adsorption. J Hazard Mater 2007, 14: 67–73.

Liang ZP, Meng YQFSX, Liang ZY: Equilibrium and kinetic modeling of adsorption of urea nitrogen onto chitosan coated dialdehyde cellulose. Process Biochem 2005, 40: 3218–3224. 10.1016/j.procbio.2005.03.041

Vieira RS, Beppu MM: Dynamic and static adsorption and desorption of Hg(II) ions on chitosan membranes and spheres. Water Res 2006, 40: 1726–1734. 10.1016/j.watres.2006.02.027

Kafshgari MH, Khorram M, Mansouri M, Samimi A, Osfouri S: Preparation of alginate and chitosan nanoparticles using a new reverse micellar system. Iran Polym J 2012, 21: 99–107. 10.1007/s13726-011-0010-1

George M, Abraham TE: Polyionic hydrocolloids for the intestinal delivery of protein drugs: alginate and chitosan. J Controlled Release 2006, 114: 1–14. 10.1016/j.jconrel.2006.04.017

Bayramoğlu G, Tuzun I, Celik G, Yilmaz M, Arica MY: Biosorption of mercury(II), cadmium(II) and lead(II) ions from aqueous system by microalgae Chlamydomonas reinhardtii immobilized in alginate beads. Int J Miner Process 2006, 81: 35–43. 10.1016/j.minpro.2006.06.002

Papageorgiou SK, Kouvelos EP, Katsaros FK: Calcium alginate beads from Laminaria digitata for the removal of Cu+2 and Cd+2 from dilute aqueous metal solutions. Desalination 2008, 224: 293–306. 10.1016/j.desal.2007.06.011

Bajpai J, Shrivastava R, Bajpai AK: Dynamic and equilibrium studies on adsorption of Cr(VI) ions onto binary bio-polymeric beads of cross linked alginate and gelatin. Colloids Surf A 2004, 236: 81–90. 10.1016/j.colsurfa.2004.01.021

Ozdemir G, Ceyhan N, Manav E: Utilization of an exopolysaccharide produced by Chryseomonas luteola TEM05 in alginate beads for adsorption of cadmium and cobalt ions. Bioresour Technol 2005, 96: 1677–1682. 10.1016/j.biortech.2004.12.031

Choi J-W, Yang K-S, Kim D-J, Lee CE: Adsorption of zinc and toluene by alginate complex impregnated with zeolite and activated carbon. Curr Appl Phys 2009, 9: 694–697. 10.1016/j.cap.2008.06.008

Al-Dujaili AH, Awwad AM, Salem NM: Biosorption of cadmium (II) onto loquat leaves (Eriobotrya japonica) and their ash from aqueous solution, equilibrium, kinetics, and thermodynamic studies. Int J Ind Chem 2012. 10.1186/2228-5547-3-22

Chen Z, Ma W, Han M: Biosorption of nickel and copper onto treated alga (Undaria pinnatifida): application of isotherm and kinetic models. J Hazard Mater 2008, 155: 327–333. 10.1016/j.jhazmat.2007.11.064

Clercq JD: Removal of mercury from aqueous solutions by adsorption on a new ultra stable mesoporous adsorbent and on a commercial ion exchange resin. Int J Ind Chem 2012, 3: 1–6.

Evans JR, Davids WG, MacRae JD, Amirbahman A: Kinetics of cadmium uptake by chitosan-based crab shells. Water Res 2002, 36: 3219–3226. 10.1016/S0043-1354(02)00044-1

Moon DJ, Chung MJ, Kim H, Lee BG, Lee SD, Park KY: Adsorption equilibria of chloropentafluoroethane on activated carbon powder. Korean J Chem Eng 1998, 15: 619–624. 10.1007/BF02698988

Pouretedal H, Kazemi M: Characterization of modified silica aerogel using sodium silicate precursor and its application as adsorbent of Cu2+, Cd2+, and Pb2+ ions. Int J Ind Chem 2012, 3: 1–8.

Sheibani A, Shishehbor MR, Alaei H: Removal of Fe(III) ions from aqueous solution by hazelnut hull as an adsorbent. Int J Ind Chem 2012, 3: 1–3.

Crank J: Mathematics of Diffusion. Clarendon, Oxford; 1970.

Ruthven D: Principles of Adsorption and Adsorption Processes. Wiley, New York; 1984.

Merrifield JD, Davids WG, MacRae JD, Amirbahman A: Uptake of mercury by thiol-grafted chitosan gel beads. Water Res 2004, 38: 3132–3138. 10.1016/j.watres.2004.04.008

Ozer A, Gürbüz G, Calimli A, Körbahti BK: Investigation of nickel(II) biosorption on Enteromorpha prolifera: optimization using response surface analysis. J Hazard Mater 2008, 152: 778–788. 10.1016/j.jhazmat.2007.07.088

Malkoc E: Ni(II) removal from aqueous solutions using cone biomass of Thuja orientalis. J Hazard Mater 2006, 137: 899–908. 10.1016/j.jhazmat.2006.03.004

Gao C, Liu M, Chen J, Zhang X: Preparation and controlled degradation of oxidized sodium alginate hydrogel. Polym Degrad Stab 2009, 94: 1405–1410. 10.1016/j.polymdegradstab.2009.05.011

Guerra E, Bestetti M: Physicochemical properties of ZnSO4-SO4-H2O electrolytes of relevance to zinc electrowinning. J Chem Eng Data 2006, 51: 1491–1497. 10.1021/je0600911

Saygideger S, Gulnaz O, Istifli ES, Yucel N: Adsorption of Cd(II), Cu(II) and Ni(II) ions by Lemna minor L.: effect of physicochemical environment. J Hazard Mater 2005, 126: 96–104. 10.1016/j.jhazmat.2005.06.012

Lindfield G, Penny J: Numerical Methods Using MATLAB. Ellis Horwood, New York; 1995.

Moghadam H, Samimi M, Samimi A, Khorram M: Electro-spray of high viscous liquids for producing mono-sized spherical alginate beads. Particuology 2008, 6: 271–275. 10.1016/j.partic.2008.04.005

Acknowledgments

The authors gratefully thank the helpful comments of Dr. Abdolreza Samimi and Hamid Moghadam and the facilities provided by the University of Sistan and Baluchestan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors' contributions

MHK carried out the experiments, studied the mechanisms of the adsorption, wrote the adsorption nonlinear model program, analyzed the data, and drafted the manuscript. MM helped in some parts of the experiments. MK participated in the interpretation of results. SRK read and edited the manuscript and commented on it. All the authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License ( https://creativecommons.org/licenses/by/2.0 ), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Kafshgari, M.H., Mansouri, M., Khorram, M. et al. Kinetic modeling: a predictive tool for the adsorption of zinc ions onto calcium alginate beads. Int J Ind Chem 4, 5 (2013). https://doi.org/10.1186/2228-5547-4-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2228-5547-4-5