Abstract

Background

The performance of two adsorbents, i.e. a new ultra stable adsorbent SH-ePMO and a commercial ion exchange resin TP-214, for the removal of mercury from aqueous solutions was investigated. The operating variables studied were initial mercury concentration and contact time.

Results

The adsorption isotherms showed favourable adsorption. The adsorption isotherms were analysed using Langmuir and Freundlich models. The Langmuir model yielded the best fit for the SH-ePMO, whereas the Freundlich model fitted best the adsorption on TP-214. The maximum adsorption capacities were 66 and 456 mg/g for SH-ePMO and TP-214, respectively. TP-214 is capable of purifying water to parts per trillion levels.

The adsorption kinetics showed a fast adsorption for both adsorbents. The kinetics was analysed using Lagergren's pseudo-first-order and pseudo-second-order kinetic models. The pseudo-first-order kinetic model showed a good description of the experimental data of both adsorbents.

Conclusions

This study clearly shows the potential of the ultra stable SH-ePMO for removing mercury from aqueous solutions and confirms the performance of the ion exchanger resin TP-214.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Mercury is released into the environment during production processes (e.g. chlor-alkali, battery manufacturing, and others) and during the use and removal of products via waste. Mercury is regarded as one of the most harmful metals found in the environment. Therefore, it is classified by the Water Framework Directive (2000/60/EC) as a priority hazardous substance. This means that by 2015, no more mercury can be discharged. Flanders defines a maximum discharge limit between 0 and 150 ppb for mercury, depending on the industry, and the quality standard in Flanders is 1 ppb Hg for surface water and ground water. Consequently, removal of mercury from water and wastewater is required.

Mercury can be removed from (waste)water by several methods, such as chemical precipitation, membrane filtration, ion exchange, electrodialysis, solvent extraction and adsorption. Adsorption ((bio)-adsorption/ion exchange) appears to be the most promising technique to remove mercury from aqueous solutions with mercury concentrations below 100 ppm [1, 2].

Several materials such as activated carbon, resins, clays and silica - some of them are modified with organic functional groups to improve the selectivity - have been studied for adsorption of mercury [3].

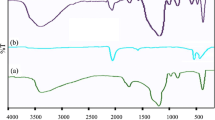

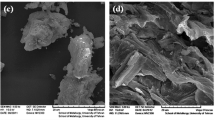

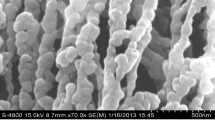

A new, stable mesoporous adsorbent, i.e. a thiol-containing ethene bridged periodic mesoporous organosilica (PMO) (SH-ePMO), is developed for the selective removal of mercury [4]. PMOs have well-defined pore sizes and pore shapes, high specific surface areas and uniform distribution of the functionalities [5]. This adsorbent combines the adsorption efficiency of the thiol group towards mercury ions with the stability of ethene bridged PMOs [6, 7]. Moreover, it preserves the amount of organic functionalities after multiple regeneration cycles, allowing recycling and reuse of the adsorbent [4].

The objective of this study was to evaluate the adsorption properties of this new material and a commercial ion exchange resin, Lewatit MonoPlus TP-214 (LANXESS Deutschland GmbH, Leverkusen, Germany). It is known that ion exchangers are capable of purifying the water below the mercury discharge limit [8]. TP-214 is a monospherical, macroporous chelating resin with thiourea groups and has a high affinity for mercury. It cannot be regenerated. The effect of initial concentration and contact time on the mercury adsorption was investigated. The adsorption equilibrium data and kinetics data were analysed using Langmuir and Freundlich models and pseudo-first/second-order kinetic models, respectively.

Methods

Materials and reagents

The aqueous solution of divalent mercury was prepared by diluting a specified volume of a mercury nitrate volumetric standard, 0.05 N aqueous solution (Sigma-Aldrich, Bornem, Belgium), in distilled water.

The preparation of SH-ePMO has been described in a previous study [4]. SH-ePMO has a specific surface area of about 640 m2/g and contains 0.4 mmol SH/g. Lewatit MonoPlus TP-214 was obtained from LANXESS (LANXESS Deutschland GmbH, Leverkusen, Germany) and contains at least 1.35 N functional groups.

Equilibrium studies

Batch adsorption tests were carried out by adding a fixed amount of adsorbent (150 mg) into a number of sealed glass flasks containing 50 mL of mercury solution of different concentrations (0 to 900 ppm) without changing the pH. The flasks were placed in a thermostatic shaker incubator Multitron (Infors AG, Bottmingen, Switzerland) and agitated at 21°C and 200 rpm for 3 h. Samples were filtered through 0.45 μm Rotilabo syringe filters (Carl Roth GmbH, Karlsruhe, Germany). The filtrate was analysed for mercury concentration with cold vapour atomic absorption spectrometry (GBC Scientific Equipment PTY LTD, Braeside, Australia). The amount of mercury adsorbed is calculated using the following equation:

with q e the amount of mercury adsorbed (milligrams per gram), Ci and Ce the initial and equilibrium mercury concentrations in the solution (milligrams per litre), V the volume of solution (litres), and W the weight of adsorbent (grams).

All experiments were performed in tri- or duplicate, and the mean values are reported. For the triplicate data, the relative standard deviation was lower than 0.6%. Blank tests were performed as well.

Kinetic studies

Batch kinetic tests were carried out in a sealed flask at a fixed ratio (3 g/L) of adsorbent mass to volume of the mercury solution (10 and 100 ppm). Kinetic tests with 1 ppm mercury solutions and TP-214 were performed as well. The mixtures were agitated at approximately 200 rpm with a magnetic stirrer. At predetermined intervals of time, samples were withdrawn, filtered through syringe filters and analysed for mercury concentration with cold vapour atomic absorption spectrometry (GBC Scientific Equipment PTY LTD, Braeside, Australia).

Results and discussion

Adsorption equilibrium

The effect of the initial mercury concentration on the adsorption and adsorptivity (percentage of mercury adsorbed) is shown in Figure 1. The adsorptivity decreases with increasing mercury concentrations, whereas the adsorption capacity increases. An increasing initial mercury concentration results indeed in an increasing driving force, the concentration gradient. At lower initial concentrations (lower than 400 ppb and 100 ppm for SH-ePMO and TP-214, respectively), total removal of mercury was observed, i.e. for these mercury concentrations, the adsorbents are effective for complete mercury removal. TP-214 contains more functional groups and therefore removes more mercury than SH-ePMO. After adsorption, the pH of the solution decreased, i.e. protons were released during the adsorption, as expected.

The adsorption isotherms are shown in Figure 2. The adsorption isotherms exhibit initially a very steep increase, which indicates high adsorption at lower concentrations. Both isotherms are type I according to the classification, i.e. favourable or strongly favourable isotherms. The isotherms of Figure 2 were fitted to Langmuir and Freundlich isotherm models:

with qmax as the maximum adsorption capacity (milligrams per gram), b the Langmuir isotherm constant (1/ppm), KF the Freundlich constant litres to the power n multiplied by milligrams to the power (1-n) per grams (Lnmg1-n/g) and n the heterogeneity factor. The fitted parameters of both models are reported in Table 1. The values of the heterogeneity factor (range 1 to 10) indicate favourable adsorption. The maximum adsorption capacity of SH-ePMO is 66 mg/g. This confirms the 1:1 stoichiometry of mercury towards the thiol group of the mesoporous material [4] and is consistent with previously reported literature [9–11]. The maximal adsorption capacity of SH-ePMO is lower than the capacities of mesoporous organosilicas reported in literature [12, 13]. However, it should be taken into account that the amount of thiol groups on the adsorbent is lower. The maximum adsorption capacity of TP-214 is 456 mg/g. The calculated minimum capacity of TP-214 is ca. 446 mg/g, considering a 1:1 stoichiometry and the number of functional groups (minimum 1.35 mol/L), the water retention (43 to 48 wt.%) and the density (ca. 1.1 g/mL). Therefore, a 1:1 stoichiometry of mercury towards the thiourea groups of the ion exchanger could also be proposed. The essential characteristics of the Langmuir isotherm can be expressed in terms of a dimensionless constant separation factor RL[1]:

The RL values (Figure 3) show that (1) the adsorption was favourable (0 ≪ RL ≪ 1) for all initial concentrations and (2) more favourable for higher initial concentrations.

The R2 values show that the Langmuir isotherm fits the adsorption on SH-ePMO better than the Freundlich isotherm, while the opposite is observed for TP-214.

It is interesting to calculate the equilibrium concentration for very low initial mercury concentration, e.g. 50 ppb, for both adsorbents, considering 50 mL of solution and 150 mg of adsorbent [7]. The equilibrium concentration is calculated with the mass balance for mercury:

and with the respective isotherm models. The equilibrium concentration for SH-ePMO is about 6 ppb, while it is 2 × 10−4 ppb for TP-214. The efficiency of TP-214 is very high: if equilibrium is reached, the water can be purified to very high levels. Of course, for full-scale applications, the equilibrium time should not be too high.

Adsorption kinetics

The adsorption depends not only on the equilibrium adsorption of the material adsorbent (based on a contact time ‘infinity’), but also on the kinetics of adsorption. The kinetics of adsorption is governed by mass transfer and shown in Figures 4 and 5. The adsorption capacity increased with time until equilibrium is reached. The equilibrium time increased with the initial concentration. This can be explained by the fact that at low concentrations, the mercury was adsorbed faster, while at higher concentrations, the mercury needed to diffuse deeper into the adsorbent particle before adsorption took place [1]. The adsorption can be considered very fast (1 h or more). The initial rate of adsorption was higher for higher initial mercury concentration due to the higher driving force for mass transfer [1].

Two models are frequently used to describe the adsorption kinetics of mercury [1, 9], i.e. the Lagergren pseudo-first-order model and the Ho linear form of pseudo-second-order model [14]:

with q t (milligrams per gram) as the adsorption capacity at time t (minutes); k1 (litres per minute) and k2 (grams per milligram per minute), the pseudo-first-order and pseudo-second-order constants, respectively. Figures 4 and 5 and Table 2 show the results of the fit to both kinetic models. A more precise fit was shown by the pseudo-first-order kinetic model. This confirms the 1:1 stoichiometry of the mercury towards the functional groups of both adsorbents. The values of adsorption capacity, qe, calculated from the pseudo-first-order model are close to the values observed experimentally, except for the 100 ppm and SH-ePMO, where there is some scatter in the experimental data. The initial rate of adsorption, i.e. the pseudo-first-order constant multiplied by the equilibrium adsorption capacity, increases with initial mercury concentration, as expected, since the driving force is increased [15].

Conclusions

The performance of two adsorbents, i.e. a new ultra stable adsorbent SH-ePMO and a commercial ion exchange resin TP-214, was investigated for the removal of mercury from aqueous solutions.

The Langmuir model yielded the best fit for the SH-ePMO, whereas the Freundlich model fitted best the adsorption on TP-214. The maximum adsorption capacities were 66 and 456 mg/g for SH-ePMO and TP-214, respectively, indicating a 1:1 stoichiometry of the mercury towards the functional groups of both adsorbents. TP-214 has a much larger adsorption capacity than SH-ePMO and is capable of purifying water to parts per trillion (ppt) levels. The lower capacity of SH-ePMO is attributed to its small amount of thiol groups.

Modelling of the adsorption kinetics of both adsorbents showed good agreement of the experimental data with the Lagergren's pseudo-first-order kinetic model. The equilibrium time was low and comparable for both adsorbents.

This study clearly shows the potential of the ultra stable, regenerable SH-ePMO for removing mercury from aqueous solutions. Future work will concentrate on optimisation of SH-ePMO to get the same performance of TP-214 (high adsorption capacity + purification of water to ppt levels).

References

Ghodbane I, Hamdaoui O: Removal of mercury(II) from aqueous media using eucalyptus bark: Kinetic and equilibrium studies. J Hazard Mater 2008, 160: 301. 10.1016/j.jhazmat.2008.02.116

Anirudhan TS, Divya L, Ramachandran M: Mercury(II) removal from aqueous solutions and wastewaters using a novel cation exchanger derived from coconut coir pith and its recovery. J Hazard Mater 2008, 157: 620. 10.1016/j.jhazmat.2008.01.030

Puanngam M, Unob F: Preparation and use of chemically modified MCM-41 and silica gel as selective adsorbents for Hg(II) ions. J Hazard Mater 2008, 154: 578. 10.1016/j.jhazmat.2007.10.090

De Canck E, Lapeire L, De Clercq J, Verpoort F, Van Der Voort P: A new Ultra Stable Mesoporous Adsorbent for the Removal of Mercury. Langmuir 2010, 26: 10076. 10.1021/la100204d

Van Der Voort P, Vercaemst C, Schaubroeck D, Verpoort F: Ordered mesoporous materials at the beginning of the third millennium: new strategies to create hybrid and non-siliceous variants. Phys Chem Chem Phys 2008, 10: 347.

Vercaemst C, Ide M, Allaert B, Ledoux N, Verpoort F, Van Der Voort P: Ultra-fast hydrothermal synthesis of diastereoselective pure ethenylene-bridged periodic mesoporous organosilica. Chem Commun 2007, 22: 2261.

Vercaemst C, Ide M, Wiper PV, Jones JTA, Khimyak YZ, Verpoort F, Van Der Voort P: Ethenylene-bridged periodic mesoporous organosilicas: From E to Z. Chem Mater 2009, 21: 5792. 10.1021/cm902164t

Chiarle S, Ratto M, Rovatti M: Mercury Removal from Water by Ion Exchange Resins Adsorption. Water Res 2000, 34: 2971. 10.1016/S0043-1354(00)00044-0

Walcarius A, Etienne M, Bessiere J: Rate of Access to the Binding Sites in Organically Modified Silicates. 1. Amorphous Silica Gels Grafted with Amine or Thiol Groups. Chem Mater 2002, 14: 2757. 10.1021/cm021117k

Mercier L, Pinnavaia TJ: Heavy metal ion adsorbents formed by the grafting of thiol functionality to mesoporous silica molecular sieves: factors affecting Hg2+ uptake. J Environ Sci Te 1998, 32: 2749. 10.1021/es970622t

Wu HY, Liao CH, Pan YC, Yeh CL, Kao HM: Synthesis and characterization of cubic thiol-functionalized periodic mesoporous organosilicas as effective mercury ion adsorbents. Microporous and Mesoporous Mater 2009, 119: 109. 10.1016/j.micromeso.2008.10.005

Walcarius A, Delacôte C: Mercury(II) binding to thiol-functionalized mesoporous silicas: critical effect of pH and sorbent properties on capacity and selectivity. Anal Chim Acta 2005, 547: 3. 10.1016/j.aca.2004.11.047

Olkhovyk O, Jaroniec M: Polymer-Templated Mesoporous Organosilicas with Two Types of Multifunctional Organic Groups. Ind Eng Chem Res 2007, 46: 1745. 10.1021/ie061244g

Ho Y: Review of second-order models for adsorption systems. J Hazard Mater 2006, B136: 681.

Hameeda BH, El-Khaiary MI: Batch removal of malachite green from aqueous solutions by adsorption on oil palm trunk fibre: Equilibrium isotherms and kinetic studies. J Hazard Mater 2008, 154: 237. 10.1016/j.jhazmat.2007.10.017

Acknowledgements

The author thanks Professor Pascal Van der Voort and Els De Canck (Ghent University) for the supply of the SH-ePMO adsorbent. The author thanks Karolien De Doncker and Elena Soler from the Faculty of Applied Engineering Sciences (University College Ghent) for their help with the CV-AAS measurements and adsorption experiments, respectively. The author acknowledges Jean Moriau of LANXESS for the supply of the ion exchange resin.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that she has no competing interests.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

De Clercq, J. Removal of mercury from aqueous solutions by adsorption on a new ultra stable mesoporous adsorbent and on a commercial ion exchange resin. Int J Ind Chem 3, 1 (2012). https://doi.org/10.1186/2228-5547-3-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2228-5547-3-1