Abstract

Background

Maleic anhydride (MAN) copolymers with methyl methacrylate, ethyl methacrylate, methyl acrylate, ethyl acrylate, and butyl acrylate monomers at 1:1 mole ratios were synthesized by free radical polymerization in the presence of α,α′-azobis(isobutyronitrile) as initiator and dry ethyl acetate as solvent.

Results

Copolymer compositions were obtained using related proton nuclear magnetic resonance (1HNMR) spectra, and the polydispersity of the copolymers was determined by gel permeation chromatography. Then, a solution of phthalimide salt as a nucleophilic reagent reacted through the ring opening of anhydride groups in copolymers resulting to modified copolymers IPht to VPht. All the prepared polymers were characterized by Fourier transform infrared and 1H NMR spectroscopic techniques. The glass transition temperature (Tg) of all copolymers before and after modification was determined by dynamic mechanical thermal analysis (DMTA).

Conclusions

It was shown that chemical modification of MAN copolymers with phthalimide substituents as side chains decreased the free volume of the polymers, and therefore, the rigidity and Tg are increased. Solubility of the copolymer products was tested in some organic solvents.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Maleic anhydride (MAN) is an excellent monomer which can provide reactive anhydride or carboxylic groups with nucleophilic molecules, as discussed by Zhou et al. [1]. MAN has an extremely low tendency to homopolymerize in a radical polymerization condition; on the contrary, it copolymerizes with a variety of donor monomers, as discussed by Nieuwhof et al. [2]. The anhydride groups, in the polymer chain, make the MAN polymer very reactive, and therefore, it is commonly used in various fields, as discussed elsewhere [3, 4]. The anhydride moiety constitutes a nice handle to modify the polymer [5]. One can modify the polymer via addition of low molecular weight compounds such as water, alcohols, or amines because of the high reactivity of the anhydride group, as discussed by Bruch et al. [6]. The chemical modification of synthetic polymers allows the control of their mechanical and thermal properties [7] and expands their applicabilities, as discussed elsewhere [8–10].

Polymers containing phthalimide groups are found to possess excellent heat resistance and transparency. Copolymers containing phthalimide derivatives have been used as optical brightening agents, as discussed by Jayakumar et al. [11]. The incorporation of the phthalimide group remarkably enhanced the thermal stability of polymers. Polymers bearing the phthalimide group as a pendant group will exhibit relatively high thermal stability and good solubility [12, 13]. Recently, we reported the synthesis and properties of MAN polymers modified with carbazole groups [14]. In this research work, we report the synthesis and properties of MAN copolymers modified with highly sterically hindered phthalimide groups. Firstly, copolymers of MAN with different methacrylate and acrylate monomers were synthesized by the free radical polymerization method. Then, phthalimide groups were linked to the resulting copolymers by the ring-opening reaction of the anhydride groups with sodium phthalimide salt. Dynamic mechanical thermal analysis (DMTA) showed that the incorporation of phthalimide groups as side chains decreased the free volume of the polymers, and therefore, the rigidity and the glass transition temperature (Tg) are increased.

Methods

Materials

Phthalimide, methyl methacrylate (MMA), ethyl methacrylate (EMA), methyl acrylate (MA), ethyl acrylate (EA), and butyl acrylate (BA) (Merck, Whitehouse Station, NJ, USA) were distilled under reduced pressure to remove inhibitors before use. Maleic anhydride (Aldrich, St. Louis, MO, USA) was recrystallized from chloroform. Ethyl acetate was stirred over calcium hydride for 24 h and distilled in argon atmosphere. The radical initiator of α,α′-azobis(isobutyronitrile) (AIBN; Merck) was purified by crystallization from methanol. Sodium hydride (60%) was obtained from Aldrich. N,N-Dimethylformamide (DMF) was dried over anhydrous MgSO4 for 2 days and later with phosphine anhydride overnight. After drying, DMF was distilled under reduced pressure.

General procedure for solubility

The polymer (0.1 g) and solvent (10 ml) were placed in an airtight vial and agitated about 25°C for 1 h. The samples were considered to be soluble if a single-phase, clear, gel-free solution was observed. This procedure was carried out again with the same condition as mentioned but for a much longer time (overnight) using a shaker.

Instruments

Infrared spectra were recorded using a Bruker-IR Scientific spectrophotometer as KBr pellets (Madison, WI, USA). 1H NMR spectra were run on a Bruker 250 MHz spectrometer at room temperature using deuterated dimethyl sulfoxide (DMSO-d6) as solvent. The molecular weights (Mw and Mn) were determined using a Waters 501 gel permeation chromatograph fitted with 103-nm Waters Styragel columns (Milford, MA, USA). Tg was determined using Tritec 2000 DMA (Triton Technology, Ltd., Keyworth, UK) at a heating rate of 5°C/min in air.

For I: 1H NMR (DMSO-d6, 250 MHz) ppm: 0.76 to 1.29 (3H, in CH3-C), 1.89 to 2.28 (2H, in -CH2-C-), 3.70 (2H, in -CH-CH-), 3.50 (3H, in -OCH3); FT-IR (KBr, cm−1): 2,999, 2,959 (aliphatic C-H); 1,854, 1,781 (C=O stretching of anhydride unit); 1,726 (C=O ester); 1,240, 1,148 (C-O ester); 1,061, 1,022 (C-O-C).

For II: 1H NMR (DMSO-d6, 250 MHz) ppm: 0.80 to 1.20 (3H, in CH3-C), 1.70 to 2.80 (2H, in -CH2-C-), 4.05 (2H, in -CH-CH-), 3.66 (2H, in -OCH2); FT-IR (KBr, cm−1): 2,988, 2,956 (aliphatic C-H); 1,857, 1,784 (C=O of anhydride unit); 1,726 (C=O ester); 1,240, 1,148 (C-O ester); 1,020 (C-O-C).

For III: 1H NMR (DMSO-d6, 250 MHz) ppm: 1.58 to 2.85 (3H, in -CH2-CH-), 3.84 (2H, in -CH-CH-), 3.63 (3H, in -OCH3); FT-IR (KBr, cm−1): 3,005, 2,957 (aliphatic C-H); 1,849, 1,781 (C=O of anhydride unit); 1,733 (C=O ester); 1,169, 1,223 (C-O ester); 1,101, 1,059 (C-O-C).

For IV: 1H NMR (DMSO-d6, 250 MHz) ppm: 1.70 to 2.84 (3H, in -CH2-C-), 4.20 (2H, in -CH-CH-), 4.00 (2H, in -OCH2); FT-IR (KBr, cm−1): 2,965, 2,876 (aliphatic C-H); 1,843, 1,770 (C=O of anhydride unit); 1,732 (C=O ester); 1,148, 1,223 (C-O ester); 1,097, 1,022 (C-O-C).

For V: 1H NMR (DMSO-d6, 250 MHz) ppm: 1.29 to 1.50, 1.5 to 1.80 (4H, in -CH2-CH2-), 2.21 to 2.86 (3H, in -CH2-C-), 3.94 (2H, in -CH-CH-), 3.64 (2H, in -OCH2); FT-IR (KBr, cm−1): 2,957, 2,989 (aliphatic C-H); 1,854, 1,781 (C=O of anhydride unit), 1,728 (C=O ester); 1,148, 1,240 (C-O ester); 1,087, 1,020 (C-O-C).

For IPht: 1H NMR (DMSO-d6, 250 MHz) ppm: 0.77 to 1.163 (3H, in CH3-C-), 2.49 to 2.86 (2H, in CH2-CH), 7.44 to 8.11 (Ar-H of phthalimide); 11.31 (1H, in O-H); FT-IR (KBr, cm−1): 3,059 (Ar-H of phthalimide); 2,400 to 3,400 (OH acid); 1,774, 1,750 (carbonyls of phthalimide).

For IIPht: 1H NMR (DMSO-d6, 250 MHz) ppm: 0.76 to 1.15 (3H, in CH3-C-), 2.03 to 2.85 (CH2-C-), 7.47 to 7.91 (4H, in Ar-H of phthalimide), 11.31 (1H, in O-H); FT-IR (KBr, cm−1): 3,058 (Ar-H of phthalimide); 2,400 to 3,400 (OH acid), 1,771, 1,748 (carbonyls of phthalimide).

For IIIPht: 1H NMR (DMSO-d6, 250 MHz) ppm: 0.74 to 2.83 (3H, in CH2-CH), 7.5 to 7.83 (4H, in Ar-H of phthalimide), 11.28 (1H, in O-H); FT-IR (KBr, cm−1): 3,061 (Ar-H of phthalimide), 2,400 to 3,400 (OH acid); 1,770, 1,733 (carbonyls of phthalimide).

For IVPht: 1H NMR (DMSO-d6, 250 MHz) ppm: 0.84 to 1.49 (3H, in CH2-CH), 7.44 to 8.10 (4H, in Ar-H of phthalimide), 11.30 (1H, in O-H); FT-IR (KBr, cm−1): 3,060 (Ar-H of phthalimide); 2,400 to 3,400 (OH acid), 1,770, 1,750 (carbonyls of phthalimide).

For VPht: 1H NMR (DMSO-d6, 250 MHz) ppm: 7.45 to 8.11 (4H, in Ar-H of phthalimide), 11.31 (1H, in O-H); FT-IR (KBr, cm−1): 3,060 (Ar-H of phthalimide); 2,400 to 3,400 (OH acid); 1,772, 1,720 (carbonyls of phthalimide).

Results and discussion

Preparation of MAN copolymers

The MAN monomer was copolymerized with methyl methacrylate, ethyl methacrylate, methyl acrylate, ethyl acrylate, and butyl acrylate monomers in ethyl acetate at 70°C ± 1°C using AIBN as the radical polymerization initiator.

Solubility

The resulting copolymers I to V were soluble in ethyl acetate, N,N-dimethylformamide, and dimethylsulfoxide and insoluble in n-hexane, chloroform, tetrahydrofuran, and hydroxyl group-containing solvents such as methanol, ethanol, or water.

Molecular weights

The number and weight average molecular weights (Mn and Mw, respectively) and polydispersity index of copolymer samples were determined by gel permeation chromatography and are presented in Table 1.

Copolymer composition

In the past few decades, 1H NMR spectroscopic analysis has been established as a powerful tool for the determination of copolymer compositions because of its simplicity, rapidity, and sensitivity [15–17]. The copolymer compositions were calculated by the 1H NMR spectral data (Table 2).

The compositions of copolymers synthesized using various monomer feed ratios were determined by the 1H NMR method and were achieved by comparing the integrals of the maleic anhydride, methyne, and methoxy group regions in the spectra of the comonomer units (m1 and m2) in copolymers using 1HNMR analysis data that were calculated according to the following equations:

where Am1 and Am2 are the normalized areas per H from the corresponding functional groups of the monomer unit regions in 1H NMR spectra, Atotal is the total area of protons in the copolymer, n1 and n2 are the integers of proton(s) in the functional group of the monomers, and a and b are integers of protons in the monomer units (m1 and m2). Monomer unit ratios can be calculated from Equations 1 and 2 using the following simplified formula:

Glass transition temperature analysis

The thermal behavior of all the copolymers was investigated by DMTA. The glass transition temperature of MAN copolymers with methacrylate monomers is higher than that of MAN copolymers with acrylate monomers since the α-methyl group in the main chain of methacrylate copolymers has reduced the flexibility of the polymer chains and increased Tg.

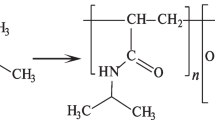

The modification of copolymers with phthalimide

The maleic anhydride functional group which grafts on the copolymers' backbone acts as the chemical link between the anhydride group and the sodium phthalimide in a nucleophilic substitution reaction. Copolymers of MAN are receiving great attention due to the presence of a reactive anhydride ring, which offers it an opportunity to enter into a wide range of chemical reactions. The anhydride group possesses a higher reactivity for phthalimide even though this coupling reaction is very rapid at −5°C. A solution of phthalimide salt as a nucleophilic reagent reacted with anhydride groups in copolymers I to V with a ring opening of all anhydride groups to give new modified copolymers. These new modified copolymers IPht to VPht were isolated in high yields at distilled HCl (0.2 N) as a non-solvent. Compared to the previous coupling methods for the preparation of modified copolymers of maleic anhydride in the literature [16], the present method is simple - the coupling reaction is fast.

Although the methods of phthalimide connection to initial copolymers and their modification has been carried out using similar methods that we have worked previously [14], phthalimide connection has been done in the present paper for the first time. The ring-opening reaction of maleic anhydride copolymer at low temperature (−5°C) is attempted for the first time in our research group.

Solubility

Copolymers IPht to VPht were soluble in solvents the same as those in which copolymers I to V are dissolved. The solubility of copolymers before and after modification with phthalimide salt was tested with polar and non-polar solvents, and it was observed that the resulting polymers are soluble in polar aprotic solvents and insoluble in polar protic and non-polar solvents. The results showed that the solubility of the modified copolymers with phthalimide has not changed compared to the initial polymers. The results of the solubility test for the longer time (overnight) were similar to those for the short time (1 h).

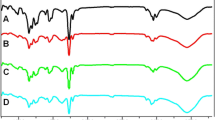

Infrared spectra

In the IR spectra of the copolymers (I to V), asymmetrical and symmetrical stretching due to the methyl and methylene groups are observed at 3,005 and 2,957 cm−1, respectively. The two bands at 1,849 and 1,781 cm−1 are attributed to symmetric and asymmetric stretching of anhydride carbonyl of copolymers, respectively. The band at 1,733 cm−1 is attributed to the ester carbonyl stretching of methacrylate and acrylate monomer units. The two bands at 1,059 and 1,101 cm−1 are attributed to the asymmetrical stretching of the C-O-C anhydride ring. The bands at 1,223 and 1,169 cm−1 are due to C-O stretching. The FT-IR spectra of copolymer II is shown in Figure 1a.

Modification of poly(MAN-co-EMA) is confirmed by the infrared spectrum in Figure 1b. The absorbance intensity is substantially diminished at 1,857 and 1,784 cm−1, whereas a broad band arises between 2,400 and 3,400 cm−1 of O-H acid, indicating that the ring-opening reaction of the maleic anhydride unit with phthalimide was completed. The band at 3,058 cm−1 is due to C-H stretching of the aromatic ring. The ring stretching vibration of the aromatic nuclei was observed at 1,600 and 1,491 cm−1.

1H NMR spectra

1H NMR spectra of the compounds (I to V) show that the proton resonances of C-H in anhydride groups in copolymers I, II, III, IV, and V are located at 3.70, 4.05, 3.84, 4.20, and 3.94 ppm, respectively. Aliphatic protons of CH3 and CH2 in copolymers I and II are located at 0.80 to 1.20 and 1.70 to 2.85 ppm, respectively, and aliphatic protons of CH and CH2 in copolymers III to V are located at 1.53 to 2.85 ppm. The resonance signal at 3.66 ppm was attributed to two methylene protons of COOCH2 in copolymers II, IV, and V, and three methoxy protons of COOCH3 in copolymers I and III appeared at 3.60 ppm. In the 1H NMR spectrum of the copolymers (I to V) modified by phthalimide groups, the aromatic resonances between 7.50 and 7.90 ppm are due to the phthalimide protons. The peaks at 11.28 ppm are due to the hydrogen of the acidic group. A typical 1H NMR spectrum of copolymer III is given in Figure 2.

Glass transition temperature

The thermal behavior of all the copolymers was investigated by DMTA. DMTA analysis showed that the presence of phthalimide groups led to an increase in Tg from 92°C for copolymer I to 120°C for copolymer IPht, from 94°C for copolymer II to 133°C for copolymer IIPht, from 36°C for copolymer III to 85°C for copolymer IIIPht, from 39°C for copolymer IV to 96°C for copolymer IVPht, and from 52°C for copolymer V to 102°C for copolymer VPht (Table 3, Figure 3a,b). Incorporation of phthalimide substituents into the polymer increased Tg as expected because it reduces the free volume of macromolecules; in addition, the π-stacking and ring structure of the aromatic groups increased the rigidity of the polymer. This reduced the flexibility of polymer chains, and hence, more energy has to be induced in order to overcome the interactions. The presence of a number of carbonyl groups also adds to the rigidity of the polymer. Because the bulky group is pendant and not a part of the polymer backbone, the rise in Tg was slight; however, it withstands semiconductor processing [7]. Therefore, novel polymer systems with new physical and chemical properties and new applications can be obtained.

Experimental

Copolymerization of maleic anhydride with methacrylate and acrylate monomers

Poly(MAN-co-MMA) (I), poly(MAN-co-EMA) (II), poly(MAN-co-MA) (III), poly(MAN-co-EA) (IV), and poly(MAN-co-BA) (V) were synthesized based on the following general procedure: In five different Pyrex glass ampoules, a mixture of 1.96 g (20 mmol) of MAN, 0.065 g (0.4 mmol) of AIBN, and 2.00 g (20 mmol) of methyl methacrylate, 2.28 g (20 mmol) of ethyl methacrylate, 1.73 g (20 mmol) of methyl acrylate, 2.00 g (20 mmol) of ethyl acrylate, or 2.56 g (20 mmol) of butyl acrylate was dissolved in 15 ml of dry ethyl acetate, respectively. Then, the ampoules were degassed, sealed under vacuum condition, and maintained at 70°C ± 1°C in a water bath and shaken using a shaker for about 24 h. Then, the viscous solutions were poured from the ampoules into 150 ml of cooled methanol separately. The precipitates were collected and washed with methanol for several times and dried under vacuum at room temperature to give 3.1 g of copolymer I, 3.39 g of copolymer II, 3.07 g of copolymer III, 3.1 g of copolymer IV, and 3.38 g of copolymer V (Table 4, Figure 4a).

Preparation of sodium phthalimide salt

For preparing sodium phthalimide, sodium hydride (4 mmol, 0.096 g) was slowly added to phthalimide (4 mmol, 1 g) dissolved in 15 ml of DMF at room temperature. Then, the mixture was stirred under nitrogen atmosphere for 30 min (Figure 4b).

Attaching phthalimide groups to copolymers (I to V)

Poly(MAN-co-MMA), poly(MAN-co-EMA), poly(MAN-co-MA), poly(MAN-co-EA), and poly(MAN-co-BA) containing phthalimide groups were prepared as follows: In a 100-ml two-necked round-bottom flask equipped with a dropping funnel, a solution of sodium phthalimide in DMF (15 ml) was prepared. After this time, the mixture was cooled to −5°C in an ice-salt mixture under vigorous stirring. A solution of copolymer I (0.198 g, 2 mmol), copolymer II (0.230 g, 2 mmol), copolymer III (0.200 g, 2 mmol), copolymer IV (0.230 g, 2 mmol), or copolymer V (0.226 g, 2mmol) in DMF (15 ml) was prepared and transferred into the dropping funnel under argon atmosphere. Then, a solution of copolymers (I to V) was added dropwise with stirring to the solution of sodium phthalimide into the flask at −5°C within 1 h. The reaction mixture was kept at −5°C temperature for another 3 h under stirring. Then, the solution was poured into an excess cold HCl (0.2 N), and the white precipitate was filtered and washed with HCl (0.2 N). The resulting polymer was washed sequentially with NaOH (0.2 N) and water (50 ml). Finally, the obtained white polymers containing phthalimide substituents in the side chains were collected and dried under vacuum at room temperature (Figure 4c). The yields of modified copolymers are presented in Table 3.

Conclusions

We have detailed the preparation and characterization of novel MAN copolymers bearing phthalimide groups of side chain substituents. The work described in this paper deals with the nucleophilic ring opening of anhydrides by Pht− Na+. The copolymers of MAN with different methacrylate and acrylate monomers were synthesized by free radical solution polymerization. The molar compositions of the obtained copolymers were calculated by the corresponding 1H NMR analysis. The anhydride group possessed a higher reactivity for the phthalimide in the modification process. Comparison of the 1H NMR and IR spectra of copolymers before and after modification showed disappearance of the peaks assigned to the anhydride ring and appearance of a new peak characteristic of phthalimide moieties, thus proving the modification of MAN copolymers. The MAN copolymers prepared here should be useful for the construction of well-defined functional polymers. DMTA indicated that the Tg of copolymers increases with incorporation of bulky phthalimide groups in side chains of MAN units. The presence of the phthalimide groups in the polymer structure reduces the free volume of macromolecules with modification of their properties and applications.

References

Zhou J, Wang LI, Wang CH, Chen T, Yu H, Yang Q: Synthesis and self-assembly of amphiphilic maleic anhydride–stearyl methacrylate copolymer. J Polymer 2005, 46: 1157–1164. 10.1016/j.polymer.2004.11.058

Nieuwhof R, Marcelis A, Sudholter E: Side-chain liquid-crystalline polymers from the alternating copolymerization of maleic anhydride and 1-olefins carrying biphenyl mesogens. J Macromol 1999, 32: 1398–1406. 10.1021/ma981393d

Al-Sabagh A, Noor MR, Din EL, Morsi RE, Elsabee MZ: Styrene-maleic anhydride copolymers esters as flow improvers of waxy crude oil. J Pet Sci Eng 2009, 62: 139–146.

Zhu LP, Yi Z, Liu F, Wei XZ, Zhu BK, Xu YY: Amphiphilic graft copolymers based on ultrahigh molecular weight poly(styrene-alt-maleic anhydride) with poly(ethylene glycol) side chain for surface modification of polyethersulfone membranes. Eur Polym J 2008, 44: 1907–1914. 10.1016/j.eurpolymj.2008.03.015

Nieuwhof R, Koudijs A, Marcelis A, Sudholter E: Modification of side-chain liquid-crystalline poly(maleic anhydride-co-alt-1-alkene)s with mesogen-containing alcohols. Macromol 1999, 32: 6499–6506. 10.1021/ma9903310

Bruch M, Mader D, Bauers F, Loontjens T, Mulhaupt R: Melt modification of poly(styrene-co-maleic anhydride) with alcohols in the presence of 1,3-oxazolines. J Polym Sci Part A: Polym Chem 2000, 38: 1222–1231.

Safa KD, Babazadeh M: Glass transition temperature modification of acrylic and dienic type copolymers of 4-chloromethyl styrene with incorporation of (Me3Si)3C– groups. Eur Polym J 2004, 40: 1659–1669. 10.1016/j.eurpolymj.2004.04.005

Boztug A, Basan S: The modification and characterization of maleic anhydride-styrene-methyl methacrylate terpolymer by poly(ethylene adipate). J Mol Struct 2007, 830: 126–130. 10.1016/j.molstruc.2006.07.005

Wang K, Huang W, Xia P, Gao C, Yan D: Fluorescent polymer made from chemical modification of poly(styrene-co-maleic anhydride). React Funct Polym 2002, 52: 143–148. 10.1016/S1381-5148(02)00088-3

Safa KD, Eram HA, Nasirtabrizi MH: Chemical modification of some 4-chloromethylstyrene polymers with highly sterically hindered tris(trimethylsilyl)methyl groups. Iran Polym J 2006, 15: 1249–1257.

Jayakumar R, Balaji R, Nanjundan S: Studies on coplymers of 2-(N-phthalimido) ethyl methacrylated with methyl methacrylate. Eur Polym J 2009, 36: 1659–1666.

Liaw DJ, Hung CC, Wu PL: Synthesis and characterization of novel diblock copolymers of 5-(N-carbazoyl methyl)bicycle [2.2.1] hept-2-ene and 5-(phthalimide methyl)bicyclo [2.2.1] hept-2-ene via living ring-opening metathesis polymerization. Polymer 2001, 42: 9371–9377. 10.1016/S0032-3861(01)00461-X

Liaw DJ, Tsai CH: Synthesis and characterization of poly(norbornene) substituted with phthalimide and ammonium groups via living ring-opening metathesis polymerization. J Mol Cat A: Chem 1999, 147: 23–31. 10.1016/S1381-1169(99)00123-5

Nasirtabrizi MH, Ziaie ZM, Parchehbaf Jadid A: The modification and characterization of maleic anhydride copolymers by carbazole groups. J Iran Chem Res 2011, 4: 59–68.

Dincer S, Koseli V, Kesim H, Rzeav Z, Piskin E: Radical copolymerization of N-isopropylacrylamide with anhydrides of maleic and citraconic acids. Eur Polym J 2002, 38: 2143–2152. 10.1016/S0014-3057(02)00127-1

Kesim H, Rzeav Z, Pincer S, Piskin E: Functional bioengineering copolymers. II. Synthesis and characterization of amphiphilic poly(N-isopropylacrylamide-co-maleic anhydride) and its macrobranched derivatives. Polymer 2003, 44: 2897–2909. 10.1016/S0032-3861(03)00177-0

Nicolescu FA, Jerca VV, Albu AM, Vuluga DM, Vasilescu DS: Poly(maleic-amic) structures for potential nonlinear optical applications. U P B Sci Bull 2009, 71: 1454–2331.

Acknowledgements

The authors are thankful to Islamic Azad University, Ardabil Branch, for the technical support during this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

MHN developed the concept. ZMZ drafted the manuscript. APJ advised on the methods of tests. LZF analyzed the data. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Nasirtabrizi, M.H., Ziaei, Z.M., Jadid, A.P. et al. Synthesis and chemical modification of maleic anhydride copolymers with phthalimide groups. Int J Ind Chem 4, 11 (2013). https://doi.org/10.1186/2228-5547-4-11

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2228-5547-4-11