Abstract

Background

Removal of mercury from aqueous environment has been highly regarded in recent years and different methods have been tested for this purpose. One of the most effective ways for mercury ions (Hg+2) removal is the use of modified nano porous compounds. Hence, in this work a new physical modification of mesoporous silica (SBA-15) with 1, 3, 5 (Trithiane) as modifier ligand and its application for the removal of Hg+2 from aqueous environment has been investigated. SBA-15 and Trithiane were synthesized and the presence of ligand in the silica framework was demonstrated by FTIR spectrum. The amounts of Hg+2 in the samples were determined by cold vapor generation high resolution continuum source atomic absorption spectroscopy. Also, the effects of pH, stirring time and weight of modified SBA-15 as three major parameters for effective adsorption of Hg+2 were studied.

Results

The important parameter for the modification of the adsorbent was Modification ratio between ligand and adsorbent in solution which was 1.5. The results showed that the best Hg+2 removal condition was achieved at pH = 5.0, stirring time 15 min and 15.0 mg of modified adsorbent. Moreover, the maximum percentage removal of Hg+2 and the capacity of adsorbent were 85% and 10.6 mg of Hg+2/g modified SBA-15, respectively.

Conclusions

To sum up, the present investigation introduced a new modified nano porous compound as an efficient adsorbent for removal of Hg+2 from aqueous environment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

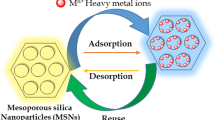

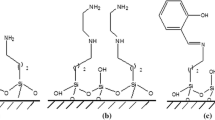

Mercury as a kind of heavy metal is present in industrial wastewater such as chemical industry, mining, refining petrochemical and a wide variety of industrial activities[1, 2]. This toxic and hazardous chemical compound has harmful effects on the environment and human health. In fact, mercury due to its bioaccumulation property the same as other heavy metals[3], has damaging effects on vital organs such as heart, brain, liver and fatty texture and will result in different cancers. Therefore, this compound is considered as one of the most toxic metals found in the environment and a main source of pollution[4, 5]. Hence, nowadays mercury ions removal from aqueous environment (water & wastewater) as one of the major challenges for hygienic management of societies has been the subject of extensive technological research[6]. Several methods including solvent extraction chemical precipitation, vacuum evaporation, membrane technologies, ion exchange, adsorption and membrane separation have been developed and used to remove Hg+2 from environment[1, 7–10], but some of these methods such as adsorption owing to different problems like low mechanical and thermal stability and a weak chemical union with the Hg+2, are often costly or inefficient for removing Hg+2 from dilute solutions[1, 10, 11]. Thus, the scientific community has felt obliged to look for a new method to remove Hg+2 from the environment[10]. Hence, synthesis and modification of adsorbents for the removal Hg+2 and other heavy metals ions from water and wastewater is a continuing research objective for the control of environmental pollution[12–17]. In this regard, the development of modified mesoporous materials based on MCM-41 and SBA-15[18] because of their great advantages among large surface area, uniform pore size and controlled surface chemistry for adsorption applications including removal and determination of metal ions[19–24], radio nuclides[25], dyes[26], organics[27], and anionic complexes[28, 29], has generated considerable interest[30]. According to the abovementioned, SBA-15 as one of the main types of mesoporous silica materials[31] is a highly common material possessing a regular two dimensional hexagonal array of channels[30]. This material is prepared with non-ionic amphiphilic triblock copolymer micelles as the template under acidic reaction conditions[10]. The pore size of this material typically can be varied between 7–10 nm[30], by varying the synthesis temperature (between 30 and 90°C) and the template[10]. Furthermore, a variety of functional groups such as organic ligands can be grafted or incorporated chemically or physically on the surface of mesoporous channels and prepare highly effective and selective adsorbents[32, 33]. Therefore, in this research, 1, 3, 5 Trithiane due to its ability to adsorb Hg+2 has been chosen as the ligand for the modification of SBA-15 resulting in a new adsorbent for removing Hg+2 from aqueous environment and the Batch method was applied in order to examine the capability of this new adsorbent.

Materials and methods

Reagents and chemicals

All chemicals and reagents used in this research were of analytical grade purchased from Merck Company (Darmstadt, Germany). Also, doubly distilled deionized water was used throughout for preparing all solutions. A stock solution (1000 mg L-1) of Hg+2 was prepared by dissolving the appropriate amounts of Hg (NO3)2 in doubly distilled deionized water and also a stock standard acetate buffer solution with pH 5.0 was prepared by mixing 14.8 mL 0.2 M acetic acid with 35.2 mL 0.2 M sodium acetate trihydrate and volume with doubly distilled deionized water to 100 mL.

Apparatus

An Analytik Jena cold vapor generation high resolution continuum source atomic absorption spectroscopy (model: contrAA 700) was used for the determination of Hg+2 in the samples. The optimized default conditions of this instrument conformed to Aspect CS 1.5.6 software released by the company. FTIR analyses of the modified and non-modified SBA-15 were performed in a Fourier transform infrared spectroscopy (Bruker-Tensor 27). The samples pH values were measured by a Metrohm pH-meter (model: 713, Herisau, Switzerland) equipped with a glass-combined electrode.

Synthesis of SBA-15

SBA-15 preparation was based on the procedure in the literature[34]. 2.0 g of triblock copolymer P123 (EO20PO70EO20) was dissolved in 60.0 g of 2 M Hydrochloric acid (HCl) aqueous solution stirred at 40°C. Then 4.3 g of Tetraethylorthosilicate (TEOS) was added to the homogeneous solution and stirred at this temperature for 24 h. Finally, it was heated to 100°C and held at this temperature for 24 h under static conditions. The prepared sample was filtered, and then washed with water and air-dried at room temperature. The removal of the template was carried out at 550°C in air for 5 h.

Synthesis of 1, 3, 5 Trithiane as Modifier

Since SBA-15 as the base adsorbent is not efficient for metal ions removal from aqueous environment, it needs modifying. One organic ligand that has the ability to form complex with Hg+2 is 1, 3, 5 Trithiane which was previously reported by research in literature[35]. This organic compound (Figure 1) as modifier ligand was prepared based on the procedure in literature[36]. A mixture of 32.6 g of Formaldehyde solution %36 (w/w) and 70 cc of concentrated Hydrochloric acid were used and then Hydrogen sulfide passed through the solution until no more precipitate was formed. In order to facilitate the process, the accumulated mass of crystals was removed by filtration from time to time. Afterward, the product was purified by the inverted filtration method.

Modification of SBA -15

Modification of the prepared SBA-15 was performed by dissolving 60 mg of Trithiane in adequate amount of Acetonitrile and adding 40 mg of SBA-15 and mixing for 15 min. Next, the solution was filtered and the solid phase as the functionalized product was exposed to atmosphere and used as a new sorbent for this research.

Metal adsorption experiments

The general procedure for removal of Hg+2 by the modified SBA-15 was as follows: A batch system was employed for the removal of Hg+2 and removing was performed in a beaker containing 10 mL (10 mg L-1) Hg+2 solutions. About 10 mg modified SBA-15 was added to the solution. Then the mixture was stirred for 10 min to remove Hg+2 from the solution. Finally, filtration was performed and Hg+2 concentrations were determined by cold vapor generation high resolution continuum source atomic absorption spectroscopy (model: contrAA 700).

Results and discussion

SBA-15 modification seems essential through suitable ligand because this mesoporous adsorbent has a major problem removing Hg+2 from aqueous environment selectively and efficiently. Previous studies[35] indicated that 1, 3, 5 Trithiane as organic ligand has an efficient interaction with Hg+2. Hence, it was used in the modification of SBA-15 for the removal of Hg+2. The preliminary experiments showed that the removal of Hg+2 ions by non-modified and modified SBA-15 was obviously different and the former cannot remove Hg+2 quantitatively.

FTIR analysis

For the characterization of the modified SBA-15, infrared spectrum was recorded on Bruker-Tensor 27 spectrophotometer in the region 400 – 4000 cm-1 using spectra quality KBr powder. According to Figure 2 the distinguished band at 1508 cm-1 can be assigned to Trithiane.

Effect of Modified Ratio (Ligand / SBA)

Modification ratio between ligand and adsorbent shown in this research as (Ligand / SBA-15) is one of the parameters affecting the prepared efficient modified adsorbent. In this study, mesoporous silica has been modified by Trithiane ligand by 3 modification ratios as 0.5, 1 and 1.5 (w/w). Then all the modified adsorbents were tested for removing Hg+2 from the samples. The results showed that the adsorbent modified by 1.5 (Ligand/SBA-15 w/w) has the maximum percentage of Hg+2 removal from the samples compared to the other two modification ratios. According to the obtained results, higher modification ratios were not studied in this research because the modified adsorbent has to be economical. On the other hand, the Hg+2 removal process revealed that by raising the modification ratio from 0.5 to 1 and 1 to 1.5, the percentage of removal increased slightly. Therefore, in the subsequent experiments we used 1.5 (Ligand / SBA-15 w/w) modification ratio.

Effect of pH

The aqueous samples pH adjustment is one of the major parameters in order to obtain efficient removal of toxic metal ions by specific adsorbents such as modified mesoporous silica. Hence, in this research the effect of pH on the removal of Hg+2 ions with modified adsorbent was studied at different pH values ranging from 4.0 to 8.0. As shown in Figure 3, the percentage of Hg+2 ions adsorption increased significantly between pH 4.0 – 5.0 and then at pH higher than 5.0 decreased extremely. In pH values higher than 8.0, modified mesoporous silica may be hydrolyzed in alkali solutions due to the breaking of the Si-O-Si bonds by hydroxide ions attack so this range of pH was not studied. Also, pH values lower than 4.0, were not studied in this research because this range due to decreasing pH value causes the ligand to be surrounded by H+ ions and prevents Hg+2 from reaching the ligand to form complexes for its removal from the environment. Therefore, pH value of the sample solutions was adjusted at 5.0 in the subsequent experiments.

Effect of Weight of Adsorbent

The optimum amount of the modified SBA-15 for maximum removal of Hg+2 was investigated by testing different amounts of modified sorbent (1, 2, 5, 10, 15, 30 and 45 mg) for Hg+2 uptake from the samples. As can be seen from Figure 4 in which the results are given, by raising the sorbent amount from 1 to 15 mg the percentage of Hg+2 removal increased significantly and in the range of 15 to 45 mg the percentage of removal was almost constant. Hence, in the experiments 15.0 mg of modified SBA-15 was used thereafter.

Effect of the stirring time on removal yield

The effect of stirring time on Hg+2 ions removal was investigated by performing a series of removal experiments with the same conditions and at several times (1, 3, 5, 10, 15 and 20 min). According to the results shown in Figure 5, Hg+2 removal up to 15 min increased and then was nearly constant. Therefore, the 15-min stirring time was used afterward.

Capacity of the modified SBA-15

The adsorbent capacity is an important parameter in adsorption processes because it determines how much adsorbent is required to quantitatively remove a specific amount of metal ions from the solutions[37]. Thus, the adsorption capacity of Hg+2 per unit weight of the modified adsorbent at time t, q t (mg g-1), was calculated from the mass balance:

Where C 0 (mg L-1) is the initial concentration of Hg+2 and C t (mg L-1) is Hg+2 concentration at time t. V is the volume of Hg+2 solutions and m is the mass of the modified mesoporous. The capacity of the modified adsorbent was found to be 10.6 mg of Hg+2/g modified SBA-15.

Conclusion

In the present research, new and effective modified mesoporous silica was prepared and tested in batch mode for Hg+2 removal from the aqueous samples. The results demonstrated a successful application of modified SBA-15 for the effective removal of Hg+2 as a rapid and easy method. Maximum percentage of removal happened at pH equal to 5.0, 15-min stirring time and using 15 mg of modified adsorbent. As adsorbents are used in wastewater treatment plants, the preparation of an applicable form of adsorbent such as an adsorption column and the determination of its effective parameters proves necessary so the authors will focus on this target in the future.

References

Rostamian R, Najafi M, Rafati AA: Synthesis and characterization of thiol-functionalized silica nano hollow sphere as a novel adsorbent for removal of poisonous heavy metal ions from water: Kinetics, isotherms and error analysis. Chem Eng J 2011, 171: 1004–1011. 10.1016/j.cej.2011.04.051

Aguado J, Arsuaga JM, Arencibia A, Lindo M, Gascon V: Aqueous heavy metals removal by adsorption on amine-functionalized mesoporous silica. J Hazard Mater 2009, 163: 213–221. 10.1016/j.jhazmat.2008.06.080

Boening DW: Ecological effects, transport, and fate of mercury: a general review. Chemosphere 2000, 40(12):1335–1351. 10.1016/S0045-6535(99)00283-0

Evangelista SM, Deoliveira E, Castro GR, Zara LF, Prado AGS: Hexagonal mesoporous silica modified with 2-mercaptothiazoline for removing mercury from water solution. Surf Sci 2007, 601: 2194–2202. 10.1016/j.susc.2007.03.020

Esmaeili Bidhendi M, Karbassi AR, Baghvand A, Saeedi M, Pejman AH: Potential of natural bed soil in adsorption of heavy metals in industrial waste landfill. Int J Environ Sci Tech 2010, 7(3):545–552. 10.1007/BF03326163

Lee B, Kim Y, Lee H, Yi J: Synthesis of functionalized porous via templating method as heavy metal ion adsorbents: the introduction of surface hydrophilicity onto the surface of adsorbents. Micropor Mesopor Mater 2001, 50: 77–90. 10.1016/S1387-1811(01)00437-1

Nabi SA, Shahadat M, Bushra R, Shalla AH, Ahmed F: Development of composite ion-exchange adsorbent for pollutants removal from environmental wastes. Chem Eng J 2010, 165: 405–412. 10.1016/j.cej.2010.08.068

Najafi M, Rostamian R, Rafati AA: Chemically modified silica gel with thiol group as an adsorbent for retention of some toxic soft metal ions from water and industrial effluent. Chem Eng J 2011, 168: 426–432. 10.1016/j.cej.2010.12.064

Huuha TS, Kurniawan TA, Sillanpaa MET: Removal of silicon from pulping whitewater using integrated treatment of chemical precipitation and evaporation. Chem Eng J 2010, 158: 584–592. 10.1016/j.cej.2010.01.058

Quintanilla DP, Hierro ID, Fajardo M, Sierra I: 2-Mercaptothiazoline modified mesoporous silica for mercury removal from aqueous media. J Hazard Mater 2006, B134: 245–256.

Babel S, Kurniawan TA: Low-cost adsorbents for heavy metals uptake from contaminated water: a review. J Hazard Mater 2003, 97: 219–243. 10.1016/S0304-3894(02)00263-7

Mahmoud ME, Osman MM, Hafez OF, Hegazi AH, Elmelegy E: Removal and preconcentration of lead (II) and other heavy metals from water by alumina adsorbents developed by surface-adsorbed-dithizone. Desalination 2010, 251: 123–130. 10.1016/j.desal.2009.08.008

Mahmoud ME, Hafez OF, Alrefaay A, Osman MM: Performance evaluation of hybrid inorganic/organic adsorbents in removal and preconcentration of heavy metals from drinking and industrial waste water. Desalination 2010, 253: 9–15. 10.1016/j.desal.2009.11.044

Mahmoud ME, Kenawy IMM, Hafez MAH, Lashein RR: Removal, preconcentration and determination of trace heavy metal ions in water samples by AAS via chemically modified silica gel N-(1-carboxy-6-hydroxy) benzylidenepropylamine ion exchanger. Desalination 2010, 250: 62–70. 10.1016/j.desal.2009.09.009

Burham N: Separation and pre concentration system for lead and cadmium determination in natural samples using 2-aminoacetylthiophenol modified polyurethane foam. Desalination 2009, 249: 1199–1205. 10.1016/j.desal.2009.04.009

Ciftci H, Yalcin H, Eren E, Olcucu A, Sekerci M: Enrichment and determination of Ni2+ ions in water samples with a diamino-4-(4-nitro-phenylazo)-1H-pyrazole (PDANP) by using FAAS. Desalination 2010, 256: 48–53. 10.1016/j.desal.2010.02.018

Chakravarty P, Sen Sarma N, Sarma HP: Removal of lead (II) from aqueous solution using heartwood of Areca catechu powder. Desalination 2010, 256: 16–21. 10.1016/j.desal.2010.02.029

Lei B, Li B, Zhang HR, Lu SZ, Zheng ZH, Li WL, Wang Y: Mesostructured Silica Chemically Doped with RuII as a Superior Optical Oxygen Sensor. Adv Funct Mater 2006, 16(14):1883–1891. 10.1002/adfm.200500737

Perez-Quintanilla D, Sanchez A, Del Hierro I, Fajardo M, Sierra I: Preparation of 2-mercaptobenzenothiazole-derivatived mesoporous silica and of Hg (II) from aqueous solution. J Environ Monit 2006, 8: 214–222. 10.1039/b507983g

Perez-Quintanilla D, Sanchez A, Del Hierro I, Fajardo M, Sierra I: Preconcentration of Zn (II) in water samples using a new hybrid SBA-15-based material. J Hazard Mater 2009, 166: 1449–1458. 10.1016/j.jhazmat.2008.12.065

Perez-Quintanilla D, Sanchez A, Del Hierro I, Fajardo M, Sierra I: Solid phase extraction of Pb(II) in water samples using a new hybrid inorganic–organic mesoporous silica prior to its determination by FAAS. Microchim Acta 2009, 165: 291–298. 10.1007/s00604-008-0132-0

Kang T, Park Y, Choi K, Sang Leec J, Yi J: Ordered mesoporous silica (SBA-15) derivatized with imidazole-containing functionalities as a selective adsorbent of precious metal ions. J Mater Chem 2004, 14: 1043–1049. 10.1039/b315829b

Ganjali MR, Hajiaghababaei L, Badiei AR, Saberyan K, Salavati-Niasari M, Ziarani GM, Behbahani SMR: A novel method for fast enrichment and monitoring of hexavalent and trivalent chromium at the PPT level with modified silica MCM-41 and its determination by inductively coupled plasm optical emission spectrometry. Quim Nova 2006, 29: 440–443. 10.1590/S0100-40422006000300007

Ganjali MR, Hajiaghababaei L, Badiei AR, Ziarani GM, Tarlani A: Novel method for the fast preconcentration and monitoring of a ppt level of lead and copper with a modified hexagonal mesoporous silica compound and inductively coupled plasma atomic emission spectrometry. Anal Sci 2004, 20: 725–729. 10.2116/analsci.20.725

Ju YH, Webb OF, Dai S, Lin JS, Barnes CE: Synthesis and characterization of ordered mesoporous anion-exchange inorganic hybrid resins for radionuclide separation. Ind Eng Chem Res 2000, 39: 550–553. 10.1021/ie990597v

Ho KY, Mckay G, Yeung KL: Selective adsorbents from ordered mesoporous silica. Langmuir 2003, 19: 3019–3024. 10.1021/la0267084

Lim MH, Stein A: Comparative studies of grafting and direct syntheses of inorganic–organic hybrid mesoporous materials. Chem Mater 1999, 11: 3285–3295. 10.1021/cm990369r

Lee B, Bao LL, Im HJ, Dai S, Hagaman EW, Lin JS: Synthesis and characterization of organic–inorganic hybrid mesoporous anion-exchange resin for perrhenate (ReO4 -) anion adsorption. Langmuir 2003, 19: 4246–4252. 10.1021/la026960b

Fryxell GE, Liu J, Hauser TA, Nie Z, Ferris KF, Mattigod S, Gong M, Hallen RT: Design and synthesis of selective mesoporous anion traps. Chem Mater 1999, 11: 2148–2154. 10.1021/cm990104c

Hajiaghababaei L, Badiei A, Ganjali MR, Heydari S, Khaniani Y, Mohammadi Ziarani G: Highly efficient removal and preconcentration of lead and cadmium cations from water and wastewater samples using ethylenediamine functionalized SBA-15. Desalination 2011, 266: 182–187. 10.1016/j.desal.2010.08.024

Zhao D, Huo Q, Feng J, Chmelka BF, Stucky GD: Nonionic triblock and star diblock copolymer and ologomeric surfactant syntheses of highly ordered, hydrothermally stable, mesoporous silica structures. J Am Chem Soc 1998, 120: 6024–6037. 10.1021/ja974025i

Badiei A, Norouzi P, Tousi F: Study of electrochemical behavior and adsorption mechanism of [Co(en) 2 C l2 ] + on mesoporous modified carbon paste electrode. Eur J Sci Res 2005, 12: 39–45.

Badiei A, Bonneviot L, Crowther N, Mohammadi Ziarani G: Surface tailoring control in micelle templated silica. J Organomet Chem 2006, 691: 5923–5931.

Murty DSR, Chakrapani G: Preconcentration of rare earth elements on activated carbon and its application to groundwater and sea-water analysis. J Anal At Spectrom 1996, 11: 815–820. 10.1039/ja9961100815

Ercan Ö, Aydınb A: Removal of Mercury, Antimony, Cadmium and Lead from Aqueous Solution using 1,3,5-Trithiane as an Adsorbent. J Braz Chem Soc 2013, 24(5):865–872.

Organic Syntheses Coll. Vol. 2, p.610 (1943); Vol. 16, p.81 (1936) [http://www.orgsyn.org/Content/pdfs/procedures/CV2P0610.pdf]

Dev K, Rao GN: Preparation and analytical properties of a chelating resin containing bicine groups. Talanta 1995, 42: 591–596. 10.1016/0039-9140(95)01452-H

Acknowledgment

The authors acknowledge the financial and scientific support provided by the Center of excellence in electrochemistry and Graduate faculty of Environment at the University of Tehran.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

This research is a part of the thesis by MEB who prepared the literature survey and performed the experiments. NM and HR participated in the design of the study, data analysis, and manuscript preparation. GRNB was the advisor. All the authors have read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Esmaeili Bidhendi, M., Nabi Bidhendi, G.R., Mehrdadi, N. et al. Modified Mesoporous Silica (SBA–15) with Trithiane as a new effective adsorbent for mercury ions removal from aqueous environment. J Environ Health Sci Engineer 12, 100 (2014). https://doi.org/10.1186/2052-336X-12-100

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2052-336X-12-100