Abstract

The paper predicts the shear strength of high-strength steel fiber-reinforced concrete deep beams. It studies the effect of clear span-to-overall depth ratio on shear capacity of steel fiber high-strength deep beams using artificial neural network (ANN8). The three-layered model has eight input nodes which represent width, effective depth, volume fraction, fiber aspect ratio and shear span-to-depth ratio, longitudinal steel, compressive strength of concrete, and clear span-to-overall depth ratio. The model predicts the shear strength of high-strength steel fiber deep beams to be reasonably good when compared with the results of proposed equations by researchers as well as the results obtained by neural network (ANN7) which is developed for seven inputs excluding span-to-depth ratio. The developed neural network ANN8 proves the versatility of artificial neural networks to establish the relations between various parameters affecting complex behavior of steel fiber-reinforced concrete deep beams and costly experimental processes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The deep beams differ from ordinary beams in their geometrical proportions and nowadays are widely used as transfer girders in multistory buildings to avoid columns for providing free space at different floor levels for parking. The ACI Committee 318 (2002), section 11.7.1 defines the deep beam based on two criteria: as clear span-to-depth ratio (L/D < 4) and shear span-to-depth ratio (a/d < 2). The IS: 456 (2000) describes deep beam having clear span-to-depth ratio less than 2. ACI-ASCE Committee 426 classifies a beam with shear span-to-depth ratio (a/d) less than 1.0 as deep beam and a beam with a/d exceeding 2.5 as an ordinary shallow beam. Any beam in between these two limits is categorized as a moderate deep beam. The concrete has inherent microcracks present in it which turns into macrocracks as the members are subjected to loading. The cracks are formed within the shear span when the principal tensile stress exceeds the tensile strength of concrete. The addition of randomly dispersed discrete steel fibers into concrete mix improves the post-cracking tensile strength of RC beams. The addition of fibers in concrete results in the reduction of crack formation and propagation (Anant and Modhera 2008). The high-strength concrete has relatively more brittleness and lack of ductility than normal strength concrete. This can be overcome by additions of fibers in high-strength concrete (HSC). It is important to understand better and predict the shear behavior of steel fiber-reinforced concrete (SFRC) deep beam for its wider applications. The lack of rational design equations in various building codes, shear failure modes, and various parameters affecting the load-carrying mechanism makes the shear behavior of steel fiber-reinforced concrete beams more complex, particularly in deep beams, and a topic for research (Roberts and Ho 1982). Many researchers in the past have studied the addition of steel fibers in concrete to improve the flexural as well as shear capacity of normal and deep beams. The studies support the use of steel fibers as shear reinforcement of reinforced concrete (RC) beam. The previous research is mainly carried on SFRC shallow beams (a/d > 2.5). The proposed equations are also generally based on tests carried on a certain type of fibers. The behavior of SFRC deep beam in shear needs to be investigated for different parameters for generalized shear strength equation if steel fibers are to be used in actual structural members (Al Ta’an and Al-Feel 1990; Mau and Hsu 1987; Kotsovos 1987; Lim 1987; Narayanan and Darwish 1987, 1988; Manicka Selvem and Kuruvilla 1988; Kwak 2002; Misrayah and Banthia 2002; Shah and Mishra 2004; Gohnert 2006; Gustavo 2006). The present study aims at proving the effectiveness of artificial neural network to study the effect of clear span-to-overall depth ratio on shear capacity of steel fiber in high-strength deep beams for L/D limit as per IS: 456 (2000) and compare the results obtained with the equations suggested by previous researchers. It also highlights the importance of span-to-depth ratio (L/D) in predicting the shear strength of deep beams.

Methods

Artificial neural network

The neural networks comprise a large number of highly interconnected elements called 'neurons’. The neural network is configured for a specific application. The main advantage is that they can solve problems that do not have an algorithmic solution or for which the solution is too complex. In recent past, artificial neural network (ANN) has been successfully applied in various disciplines of engineering analysis including the field of civil engineering. Sanand and Saka (2001) predicted the ultimate shear strength of RC deep beams using the artificial network. The results developed from ANN are more accurate than by ACI code and strut and tie method. Adhikari and Mutsuyoshi (2006) developed ANN for shear strength of SFRC beams and found that the accuracy of the network result increases with increase in number of inputs. It was found that five-input network predicts shear strength more closely than four-input networks. The accuracy of the results is found not biased with concrete strength, shear span-to-depth ratio, and beam depth. Arafa et al. (2011) showed that the developed ANN model has higher potential in predicting the ultimate shear strength of both normal and high-strength deep beams when compared with calculated values using ACI code.

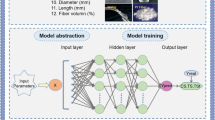

The major concerns of structural analysis problems like predicting different properties of concrete and load-carrying capacity have been solved mostly by using backpropagation neural network. The processing units are grouped into layers of input, hidden, and output processing units. The networks are trained so that a particular input leads a specific target output. The log-sigmoid transfer function is used in multilayer networks that are trained using the backpropagation algorithm because this function is differentiable. This transfer function takes the input and squashes the output into the range 0 to 1, according to the expression:

The networks are adjusted based on the comparison of output and target. The batch training of network proceeds by making weight and bias changes based on the entire set of input vectors. A stable set of weights adaptively evolves will produce good results.

Experimental data

The development of neural network requires reliable data which include input parameters affecting the system and corresponding output. These data can be experimental test results, reliable empirical data, or theoretical results.

The experimental test results of 118 tests on SFRC normal and high-strength concrete deep beams, carried by various researchers (Narayanan and Darwish 1987, 1988; Kwak et al. 2002; Shah and Mishra 2004; Gustavo 2006) have been used to develop the ANN8 model in the present study where the number stands for number of input parameters affecting the shear strength of SFRC deep beams. The data consists of 90 test results for normal strength concrete (NSC) and 28 test results for HSC steel fiber-reinforced beams for different values of span-to-overall depth ratio. The basic parameters that control the shear strength of SFRC beams, based on previous research works, are beam width (b), effective depth (d), fiber volume (Vf), fiber aspect ratio (lf/df), shear span ratio (a/d), compressive strength of concrete (fc) and longitudinal reinforcement area (Ast), and clear span-to-depth ratio (L/D). The shear span-to-depth ratio (a/d) of 45 beams, out of total data, has shear span-to-depth ratio equal to or less than 2. The total data base also includes 19 beams having clear span-to-depth ratio less than or equal to 2 to satisfy the condition for deep beam as per IS: 456 (2000). Table 1 shows the statistics for input parameters for SFRC beams as per Additional file 1.

Preprocessing of data

The learning rate of networks is significantly affected by the data presented to artificial neural networks. To ensure that all variables receive equal attention during training, the data scaling is important. Hence, the data needs preprocessing before presented for training. The scaling of the inputs is done in the range of [-1, +1] to improve the speed of learning process as these values fall in the region of sigmoid. The normalization of input and output data before presenting them to network is done by linear normalization function within the values of 0 and 1 and given by

Training of ANN

The MATLAB (R2009a) package is used for the development of present ANN8 model. The backpropagation is most successful and widely used in civil engineering. The collected data is divided into three units, i.e., training, validation, and testing. In the present case, training set comprises 80% of data base and remaining data base is equally divided into validation (10%) and testing sets (10%).

The values of network parameters considered in this approach are as follows: number of hidden layers = 1, number of hidden units = 20, learning rate = 0.5, momentum factor = 0.5, and learning cycles = 1,000. The root mean square error (R2) was 0.924. The coefficient indicates a significant correlation.

Topology of network

The topology or architecture is obtained using trial and error method. The architecture of the network ANN8 is as shown in Figure 1.

Performance of the proposed model

The network is trained for 80% of data collected by gradually increasing the number of neurons in the hidden layer. The performance was monitored during training process as sum squared error over all the training data. The training process stops when the maximum number of epochs is reached.

A comparison between experimental shear strength and corresponding values obtained by ANN8 model for 118 normal and high-strength SFRC ordinary and deep beams is shown in Figure 2. It shows that predicted shear strength is in good agreement with the experimental results.

Parametric study

The parametric study is carried out with the developed artificial neural network to evaluate the influence of parameters like b, d, Vf, lf/df, a/d, Ast, fc, and clear L/D. The effect was studied by varying one of the input parameters with respect to varying span-to-depth ratio mainly and all other parameters are set to constant values. The values of L/D ratio and a/d ratio are assumed less than 2 to fit the beam in deep beam category.

The model is fed with some assumed data and the resulting output values of shear strength are studied. The range of parameters used in parametric study is shown in Table 2.

Results and discussion

The effect of each parameter on the shear strength of SFRC deep beam is studied by varying influencing parameters. The model is fed with the values of influencing parameters and resulting output values of shear strength are studied. The range of parameters used in parametric study is shown in Table 2. The results obtained by developed ANN are plotted against respective parameters.

Effect of effective depth

Figure 3 shows the effect of increase in span-to-depth ratio on shear strength with increase in effective depth. It is found that for a constant volume fraction of 1% and fiber aspect ratio of 50, the shear strength of deep beam decreases as the depth of beam goes on increasing except at d = 350 mm (d/b = 2.33). The decrease in the shear strength varies from 18% to 26% for variation of depth from 300 to 500 mm. Similarly, it is noted that the shear strength decreases with increase in span-to-depth ratio (L/D) at different depths of high-strength SFRC deep beam shown in Figure 3. It resembles with the findings of Appa Rao (2007).

Effect of fiber volume fraction

The effect of fiber content on shear strength is observed from Figure 4. It shows the variation of shear strength with increase in fiber volume fraction for different values of L/D ratios. As the fiber volume increases, the shear strength is enhanced at all considered span-to-depth ratio. It is also noted that the shear strength decreases with the increase in L/D ratio for a volume fraction. For the assumed parameters shown in Figure 4, the decrease in shear strength with increase in L/D ratio at Vf = 0.5% is 25% and with the increase in volume fraction at Vf = 2%, the decrease in shear strength is 6%. This predicts the effectiveness of steel fiber in enhancing the shear strength of high-strength deep beam. It can be seen that there is an almost linear increase in the shear strength of deep beams with increase in fiber contents as predicted by Remigijus and Gediminas (2007).

Effect of fiber aspect ratio

The fiber aspect ratio is related with the geometry of the fibers. The influence of fiber aspect ratio on shear strength for different volume fraction and L/D ratio (less than 2) is represented in Figure 5. Many researchers like Narayan and Darwish (1987, 1988), Manicka Selvem and Kuruvilla (1988), Remigijus S (2007), Khuntia et al. (1999) have combined the effect of fiber aspect ratio and volume fraction in their formulations.

Figure 5 represents the effect of fiber aspect ratio with varying L/D ratio from 1 to 2 and fiber volume fraction from 0.5% to 1.5% at the interval of 0.25. It predicts that for L/D ratio <1.25, the effect of fiber aspect ratio is negligible for considered values of parameters. However, the shear strength goes on decreasing with increase in fiber aspect ratio though the volume fraction of fibers and L/D ratio is increased. The decrease in the shear strength by 0.8%, 1.6%, and 2.3% at L/D = 1.5, 1.75, and 2, respectively, is observed for change in fiber aspect ratio from 40 to 80 from Figure 5.

Effect of longitudinal steel

Figures 6 and 7 show the variation of shear strength with increase in longitudinal steel percentage. The relation is studied for the increase in fiber content as well as L/D ratio, respectively. Figure 6 obtained for variation of longitudinal steel along with volume fraction represents increase in shear capacity of up to Ast =1.5% by 140%, 94%, and 48% for the range of Vf = 0.5%, 1%, and 1.5%, respectively. However, the shear strength decreases even with the increase in fiber dosage at Ast = 2%, 2.5%, and 3% at constant fiber aspect ratio of 50. The percentage of decrease in the shear strength at Vf = 0.5%, 1%, and 1.5% is found to be 57%, 50%, and 37%, respectively. It indicates that for lower values of longitudinal steel percentage, the addition of steel fibers contributes to the shear strength of high-strength deep beams Lee and Kim (2008), and longitudinal steel with 1.5% is the optimum value for the considered parameters in Figure 6. For further increase in Ast from 2% to 3%, the decrease in shear strength percentage at lower than that of longitudinal steel and for the same fiber volume fraction is observed. This helps the optimum combination of longitudinal steel and volume fraction for high-strength SFRC deep beams.

The Figure 7 shows variation of the shear strength with increase in percentage of longitudinal steel at constant volume fraction (1%) for different L/D < 2. The increase in shear capacity is noted at Ast = 1.5% for all L/D ratios mentioned in Figure 7. The increase in strength by 82% and 91% is observed at L/D = 1 and 1.75, respectively.

It is observed that with the increase in span-to-depth ratio, the shear strength decreases at all values of longitudinal steel. The minimum decrease by 19% at Ast = 0.5% and maximum decrease by 39% at Ast = 2.5% is found for L/D = 1 to 1.75, respectively, as shown in Figure 7. The decrease in shear strength is enhanced with increase in the percentage in longitudinal steel and span-to-depth ratio.

Effect of compressive strength

The effect of compressive strength of concrete is plotted in Figure 8 for different L/D ratios; while other parameters are Vf = 1%, a/d = 1, lf/df = 50, d = 300 mm, and b = 150 mm.

It is found from Figure 8 that the shear strength of deep beam is enhanced by increase in compressive strength from 50 to 70 MPa for all L/D ratios but decreases with increase in L/D ratio at all considered compressive strengths. The depth of beam is constant. The result fairly agrees with the prediction of Appa Rao et al. (2007). The decrease in shear strength for variation in L/D from 1 to 2 is found to be 19% and 17% for compressive strength of concrete at 50 and 70 MPa, respectively, for other parameters shown in Figure 8.

Effect of shear span-to-depth ratio

The positions of load from support (shear span) affect the load-carrying mechanism of the flexure member. It is now well established that the point loads are directly transferred to the support through a strut, converting arch action into truss mechanism with increase in depth.

The shear span-to-depth ratio effect on deep beam for different L/D ratios is observed from Figure 9. The shear strength increases by 5%, 7%, 11%, 16%, and 12% at L/D = 1.25, 1.5, 1.75, 1.8, and 2, respectively, for variation in a/d = 0.5 to 1.5. The further increase in a/d decreases the shear strength. It is observed from Figure 9 that the shear strength is maximum at a/d = 1.5 for all L/D ratios considered. It also indicates that the shear strength decreases with the increase in L/D at a particular a/d ratio. The average decrease in the shear strength by 16% is found with increase in L/D ratio from 1.25 to 2 at each a/d ratio.

Figure 10 indicates the shear strength variation with fiber volume content at different shear span ratios. It represents that at a volume fraction Vf = 1.5% and a/d = 1.5, there is 1% increase and at Vf = 2% and a/d = 1.5, the shear capacity decreases by 2%. This indicates that addition of fiber volume fraction does not affect the load-carrying mechanism.

The results obtained from ANN8 are also compared with the results obtained from the equations (Slater et al. 2012) proposed by previous researchers Narayanan and Darwish (1988), Khuntia et al. (1999), Ashour et al. (1992), and the results of ANN7 model developed using same data with the same input parameters except L/D ratio. The equations proposed by Narayanan and Darwish (1988) and Ashour et al. (1992) do not include the effect of L/D ratio but consider the contribution of longitudinal steel to shear strength in their formulations. Khuntia et al. (1999) proposes equation based on contribution of concrete strength (fc) and steel fiber content (Vf%) to the shear strength. The constant parameters assumed are b = 150 mm, d = 300 mm, fc = 70 MPa, a/d = 1, L/D = 1.9 and crimped-type fibers. The comparison is made for variation in fiber volume as a key factor controlling the properties of SFRC concrete. Tables 3 and 4 show the results obtained for Ast = 0% and 1.5% at different volume fractions, respectively.

It can be observed from Table 3 that the shear strength at different Vf percentages by ANN7 is in good agreement with the results by other researchers where parameter L/D ratio is not considered. The results by ANN8 shows greater shear strength when the effect of L/D ratio is incorporated in the analysis for conditions without longitudinal steel. The increase in shear strength for variation in fiber volume fraction from 0.5% to 2% is observed 28%, 33%, 58%, and 86% from the comparison of ANN8 and ANN7.

Table 4 for 1.5% longitudinal steel indicates good agreement between ANN7 and Narayanan and Darwish (1988) while there is also very good agreement between ANN8 and Ashour et al. (1992). The comparison of the results in Tables 3 and 4 shows that the equation proposed by Ashour et al. (1992) is more accurate to predict the results of high-strength SFRC deep beams for effect of L/D ratio.

The results are also plotted in Figures 11 and 12 which indicate that the variation in shear strength is linear for increase in fiber volume fraction as observed by ANN8. The equations of Narayanan and Darwish (1988) and Khuntia et al. (1999) do not consider the effect of L/D ratio (size effect) in their formulation and underestimate the shear strength of high-strength SFRC deep beams at various fiber volume fractions. The results by Ashour et al. (1992) show overestimation of the strength as fiber volume fraction increases for L/D < 2.

Conclusions

The artificial neural network (ANN8) is developed and utilized to predict the shear strength of steel fiber-reinforced deep beams which consists of input layer with eight neurons, hidden layer with twenty neurons, and output layer with one neuron.

The comparison between results of ANN8 with results of ANN7 and proposed equations by previous researchers reveals the reliability of neural network developed for prediction of shear strength of high-strength steel fiber-reinforced concrete deep beams.

The parametric study of variables affecting shear strength using the developed network shows identical variation of shear strength for a/d and L/D ratios of less than 2 as observed by various researchers through experimental research. The results of variation in span-to-depth ratio show decrease in shear strength for different influencing factors like fiber content, fiber aspect ratio, longitudinal steel, depth of beam, and shear span. This also shows that the size effect is predominant in decreasing the shear strength and must be taken into consideration as an important factor in analysis and design of high-strength SFRC deep beams. The result predicted by developed ANN8 resembles with the findings of previous researchers. This shows the validity and versatility of developed neural network for predicting the shear strength of high-strength SFRC deep beam using artificial neural network model.

The various parameters affecting the shear strength of SFRC deep beams make the analysis more complex and there is need to study the behavior of high-strength SFRC deep beams by suitable combinations of the parameters. The ANN proves to be the most powerful technique to analyze the complex behavior.

Abbreviations

- a/d:

-

shear span-to-effective depth ratio

- ANN:

-

artificial neural network

- Ast:

-

longitudinal steel area, mm()

- B:

-

width of the beam, mm

- fc:

-

compressive strength of concrete

- HSC:

-

high-strength concrete

- L/D:

-

clear span-to-overall depth ratio

- lf:

-

fiber length, mm

- lf/df:

-

fiber aspect ratio; MPa

- d:

-

effective depth of beam

- NSC:

-

normal strength concrete

- SFRC:

-

steel fiber-reinforced concrete

- Vf:

-

fiber volume fraction, %.

References

ACI committee 318: Building code requirements for structural concrete and commentary. American Concrete Institute, Detroit, USA; 2002.

Adhikari BB, Mutsuyoshi H: Prediction of shear strength of steel fiber RC beams using neural networks. Constr Build Mater 2006, 20: 801–811. 10.1016/j.conbuildmat.2005.01.047

Al Ta’an SA, Al-Feel JR: Evaluation of shear strength of fiber reinforced concrete beams. Cement and Conc Composites 1990, 12: 87–94. 10.1016/0958-9465(90)90045-Y

Anant P, Modhera CD: Micro mechanical crack and deformations study of SFRC deep beams. In 33rd Conference on our world in concrete and structures. August 2008, Singapore; 2008:25–27. August 2008 August 2008

Appa Rao G, Injaganeri SS, Suresh P: Investigation of size effect on shear strength of reinforced concrete beams. J of Struct Engg 2007,33(06):499–504.

Arafa M, Alquedra M, An-Najjar H: Neural network models for predicting shear strength of reinforced normal and high strength concrete deep beams. J Appl Sci 2011,11(2):266–274.

Ashour SA, Hasanain GS, Wafa FF: Shear behavior of high strength fiber reinforced beams. ACI Struct J 1992,89(2):176–184.

Aurello M, Ruig MF: Shear strength of members without transverse reinforcement as a function of critical shear crack width. ACI Struct J 2008, 105: 163–172.

Choi K-K, Park H-G, Wight J: Shear strength of steel fiber reinforced concrete without web reinforcement. ACI Structural J 2007,104(S 58):12–20.

Gohnert M: Postulate on shear in reinforced concrete. J South African Inst Civil Engg 2006,48(4):9–13.

Gustavo J: Shear strength of beams with deformed steel fibers. Concrete International, November; 2006:57–66.

IS: 456: Plain and reinforced concrete- code of practice. Bureau of Indian Standards, Manak Bhavan, New Delhi, India; 2000.

Khuntia M, Stojadinovic B, Goel SC: Shear strength of normal and high strength fiber reinforced concrete beams without stirrups. ACI Structural J 1999,96(2):282–289.

Kotsovos MD: Shear failure of reinforced concrete beams. Engg Struct 1987, 9: 32–38. 10.1016/0141-0296(87)90038-1

Kumar S, Birari SV: Neural Network modeling of shear strength of SFRC corbels without stirrups. App Soft Computing 2010, 10: 135–148. 10.1016/j.asoc.2009.06.012

Kwak Y-K: Shear strength of steel fiber reinforced concrete beams without stirrups. ACI Struct J 2007,104-S(58):420–429.

Kwak Y, Eberhard MO, Kim W, KIM J: Shear strength of steel fiber reinforced concrete beams without stirrups. ACI. Struct J 2002,99(4):530–538.

Lee J-Y, Kim U-Y: Effect of longitudinal tensile reinforcement ratio and shear span-depth ratio on minimum shear reinforcement in beams. ACI Struct J 2008, 105: 134–144.

Lim TY: Bending behavior of steel fibre concrete beams. ACI Struct J 1987, 84: 524–536.

Madan SK, Rajesh K, Singh SP: Steel fibers replacement of web reinforcement for RCC deep beams in shear. Asian J of Civil Engg (Building and Housing) 2007,8(5):479–489.

Manicka Selvem VK, Kuruvilla T: An application of shear strength theories of concrete deep beams. J Struct Engg 1988,15(2):69–75.

Mau ST, Hsu TTC: Shear strength prediction of deep beams with web reinforcement. ACI Struct J 1987, 84: 513–523.

Misrayah A, Banthia N: Shear strength of steel fiber reinforced concrete. ACI Mater J 2002,99(M (40)):473–479.

Narayanan R, Darwish IYS: Use of steel fibers as shear reinforcement. ACI Struct J 1987, 84: 216–227.

Narayanan R, Darwish IYS: Fiber concrete deep beams in shear. ACI Struct J 1988, 85: 141–149.

Noghabhai K: Beams of fibrous concrete in shear and bending: experimental and model. J Struct Engg-ASCE 2000,126(2):243–251. 10.1061/(ASCE)0733-9445(2000)126:2(243)

Remigijus S, Gediminas M: The influence of shear span ratio on load capacity of fiber reinforced concrete elements with various steel fiber volumes. Civil Engg and Manag XIII 2007, (3):209–215.

Roberts TM, Ho NL: Shear failure of deep fiber reinforced concrete beams. Int J Cement Conc Lightweight Conc 1982,4(3):145–152. 10.1016/0262-5075(82)90040-9

Sanand A, Saka MP: Prediction of ultimate shear strength of reinforced concrete deep beams using neural networks. J Struct Engg 2001, 127: 818–828. 10.1061/(ASCE)0733-9445(2001)127:7(818)

Shah RH, Mishra SV: Crack and deformation characteristics of SFRC deep beam. Inst of Engg J CV (I) 2004, 85: 44–48.

Slater E, Moni M, Shahria Alam M: Predicting the shear strength of steel fiber reinforced concrete beams. Const Build Mat 2012, 26: 423–436. 10.1016/j.conbuildmat.2011.06.042

Acknowledgements

The authors acknowledge the help provided by Department of Library of K.K. Wagh Institute of Engineering and Research Centre, Nasik and MCERC, Nashik for acquisition of data.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declared that they have no competing interests.

Authors' contributions

UN carried acquisition of the relevant data of results of experiments carried by various researchers from literatures, developed the neural network, analyzed and interpreted the results, and also drafted the manuscript. SK have critically revised the draft for intellectual contents and participated in interpreting the results. Both the authors read and approved the final manuscript.

Electronic supplementary material

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Naik, U., Kute, S. Span-to-depth ratio effect on shear strength of steel fiber-reinforced high-strength concrete deep beams using ANN model. Int J Adv Struct Eng 5, 29 (2013). https://doi.org/10.1186/2008-6695-5-29

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2008-6695-5-29