Abstract

The electronic properties and thermal stabilities of MAlO2 and M5AlO4 (M = Li, Na, K) are investigated by density functional theory and lattice phonon dynamics. Based on the calculated electronic and lattice thermodynamic properties, their abilities to capture CO2 as solid sorbents are analyzed. The calculated electronic structural properties of MAlO2 and M5AlO4 indicate that all these alkali aluminates are semiconductors with a bandgap range of 2.4 ~ 6.4 eV. The 1st valence bands of these alkali aluminates are located 0 ~ − 6 eV under Fermi levels and are mainly contributed by p orbitals of O, s and p orbitals of Al and M. The phonon vibrational frequencies of M5AlO4 spread at a lower frequency range compared to their MAlO2 phases. With increasing temperature, the calculated phonon free energies of M5AlO4 decrease faster than their corresponding MAlO2 while their entropies have opposite trends. The reaction 2MAlO2 + CO2 = M2CO3 + Al2O3 has higher reaction heat and Gibbs free energy change than those of corresponding reaction 2/5M5AlO4 + CO2 = M2CO3 + 1/5Al2O3, which shows the former reaction possesses lower turnover temperature. Among the alkali aluminates studied, the β-NaAlO2, lt-KAlO2, and γ-LiAlO2 are better candidates that could be applied for CO2 capture technologies.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Currently, over 85% of the global energy demand is still being met by burning fossil fuels, which release large quantities of carbon dioxide (CO2) into the atmosphere to cause the climate change we are facing today [1,2,3]. To mitigate such problems, CO2 emissions into the atmosphere must be reduced by being captured and stored. Thus, intensive research on CO2 capture and storage has been conducted to mitigate CO2 emissions, which are found to be a major contributor to global climate change [4,5,6,7]. Although significant progress has been made, few current carbon capture and sequestration methodologies can meet the overall fossil energy performance goals set by the U.S. Department of Energy of a 90% CO2 capture rate with 95% CO2 purity at a cost of electricity 30% less than baseline capture approaches [8]. Current technologies for capturing CO2, including solvent-based (amines) and CaO-based materials, are still too energy intensive [9,10,11,12]. Hence, development of new materials that can capture and release CO2 reversibly with acceptable energy costs is critical. In particular, solid oxide sorbent materials have been proposed for capturing CO2 through a reversible chemical transformation leading primarily to the formation of carbonate products. In previous studies, solid sorbents containing alkali and alkaline earth metals have been reported as promising candidates for CO2 sorbent applications due to their high CO2 chemical absorption capacity at moderate working temperatures [13,14,15,16].

Solid materials could be good sorbents for CO2 capture. Except for alkali- and alkaline-oxides and hydroxides capturing CO2, solid salts and their doped systems express very good CO2 capture performance [13, 14, 17, 18]. Nakagawa and Ohashi [19, 20] reported a novel method to capture CO2 from high-temperature gases though the reversible reaction Li4SiO4 + CO2 ↔ Li2SiO3 + Li2CO3 where Li4SiO4 as a CO2 absorbent maintains its absorption effectiveness during the cycle between absorption at 973 K and emission at 1123 K, following pure CO2 at a total pressure of 1.0 × 105 Pa [21, 22]. Gauer and Heschel [23] revealed that doping vacancy or hetero elements in Li4SiO4 can enhance its CO2 absorption at moderate temperature. Wang et al. [24] found that sodium-doping could improve the CO2 absorption ability of lithium silicates; a similar conclusion was also made for potassium-doped lithium zirconates [25]. Li2ZrO3 and Na2ZrO3 and their doped sorbents have been extensively investigated for CO2 capture applications [15, 26,27,28,29,30,31,32]. Obviously, these salts can be formed by a mixture of oxides; for example, Li4SiO4 is the mixture of Li2O and SiO2 and Li2ZrO3 is the mixture of Li2O and ZrO2, etc. We have investigated that changing the mixing ratio of oxides can form different salts that express different CO2 capture properties, particularly, the turnover temperature can be shifted to fit the needs of different CO2 capture technologies [33,34,35]. Our results showed that by increasing the ratio of Li2O and SiO2, a series of lithium silicates can be formed and their corresponding turn-over temperatures are increased [34]. Additionally, by doping Li or K into NaZrO3 the turn-over temperature can be increased or decreased depending on the doping levels and doped element [33].

Besides the solid sorbents mentioned above, alkali-aluminates have been also found useful in CO2 capture technologies. Avalos-Renson et al. compared thermochemical capture of CO2 by LiAlO2 and Li5AlO4 [36]. Their CO2 capture experimental results showed that, due to its thermal stability, LiAlO2 only has a 0.13 w.t.% increase between 540 and 830 °C while Li5AlO4 has a 55.5 w.t.% increase up to 780 °C. Korake and Gaikwad also found that by increasing the Li/Al ratio in lithium aluminates can also increase the corresponding CO2 capture capacity [37]. In these applications, CO2 capture by LiAlO2 takes place according to the reaction 2LiAlO2 + CO2 = Li2CO3 + Al2O3, with a theoretical CO2 capture capacity of 33.37 w.t.%. As this value is much higher than the practical capacity reported by Avalos-Renson et al. [36], it is also important to understand the CO2 capture mechanism by LiAlO2 and to identify new ways to improve its overall CO2 capacity. Figure S1 in the supplementary information (SI) shows the phase diagram of Al2O3-Li2O optimized by Kulkarni and Besmann [38]. As one can see, these lithium aluminates are stable at a wide range of temperatures, although by increasing the ratio of Li2O:Al2O3, the melting temperature is decreased. In addition, Al2O3-Na2O and Al2O3-K2O have similar phase diagrams [39].

Solid sorbents are still promising for developing CO2 capture technologies. Theoretical modeling can play a role in identifying optimal sorbents. By combining thermodynamic database mining with first principles density functional theory and phonon lattice dynamics calculations, we have established a theoretical screening methodology to identify the most promising CO2 sorbent candidates from the vast array of possible solid materials [13, 18, 33, 40]. The advantage of this method is that it identifies the thermodynamic properties of the CO2 capture reaction as a function of temperature and pressure without any experimental input beyond crystallographic structural information of the solid phases involved. The calculated thermodynamic properties of different classes of solid materials versus temperature and pressure changes were further used to evaluate the equilibrium properties for the CO2 adsorption/desorption cycles. Only the selected CO2 sorbent candidates are further considered for experimental validations. [33, 40]

In our previous study, we investigated the electronic and phonon properties of γ-LiAlO2 and α-Li5AlO4 and their capability for CO2 capture [41, 42]. In this study, to fully describe the application of alkali-aluminate salts in CO2 capture technologies by calculating the electronic structure, lattice thermodynamic, and thermodynamics properties of MAlO2 and M5AlO4 (M = Li, Na, K) materials, we fully analyze their CO2 capture behaviors and compare with available experimental data.

This paper is organized as follows: in the second section, we briefly describe the theoretical method we employed; in the third section, we first demonstrate the electronical structures and lattice phonon dynamics of MAlO2 and M5AlO4, then show the results of these alkali aluminates capturing CO2 and compare with other available reports; and in the last section, we summarize our conclusions.

2 Theoretical methods

The calculation performed in this work was based on first-principles density-functional theory (DFT) with plane-wave basis set and the pseudopotential to describe the electron–ion interactions. The Vienna ab-initio simulation package(VASP)[43,44,45] was employed to calculate the electronic structures of these alkali aluminate and carbonate materials. Based on our previous tests on properly choosing the pseudo-potential and exchange–correlation functions for tin oxides [46], we employed the projector augmented wave (PAW) pseudo-potential and PW91 exchange–correlation functions in all the calculations, which are in accordance with our previous studies on other CO2 sorbent materials [13, 18, 33, 34]. As tested in our previous study on γ-LiAlO2 and α-Li5AlO4 systems [41, 42], the Perdew-Burke-Ernzerhof (PBE) exchange–correlation functions resulted in slightly better predictions for total energy but didn’t change any conclusions. Since we are calculating thermodynamical properties of CO2 capture reactions and need to use our previous data, which were generated with PW91 exchange–correlation functions, for consistency we continue to use PW91 exchange–correlation functions for this study. Plane wave basis sets are used with a kinetic energy cutoff of 520 eV and an augmentation charge cutoff of 605.4 eV. The k-point sampling grids of m × n × l, obtained using the Monkhorst–Pack method [47], are used for the these bulk calculations respectively, where m, n, and l are determined by the spacing of around 0.028 Å−1 along the a, b, and c axes of their unit cells. The valence electrons contain s and p orbitals for Li, Na, K, C, O and Al atoms. During calculations, we relax lattice parameters and all atoms in the cell to find the optimized structure until the total energy is changed within 10−5 eV per atom, and the Hellmann–Feynman force on each atomic site is less than 0.01 eV/Å. For band structure and phonon dispersion calculations, the symbols and coordinates of the high symmetrical points in the crystals are taken from Bradley and Cracknell’s definitions [48].

For MAlO2 and M5AlO4 (M = Li, Na, K) capture CO2 reactions:

Their Gibbs free energies (∆G) versus CO2 pressure (PCO2) and temperature (T) can be written as [13, 18, 33]:

where

Here, ∆EDFT is the DFT energy difference between the reactants (MAlO2/M5AlO4, CO2) and products (M2CO3, Al2O3) of reactions (a) and (b), ∆EZP is the zero-point energy difference between the reactants and products and can be obtained directly from phonon calculations. ∆FPH is the phonon free energy change excluding zero-point energy (which is already counted into the ∆EZP term) between the solids of products and reactants. PCO2 is the partial pressure of CO2 in the gas phase and P0 is the standard state reference pressure taken to be 1 bar. The heat of reaction, ∆H(T), can be evaluated through the following equation:

where ∆SPH(T) is the difference of entropies between product solids and reactant solids. The free energy of CO2 (G0CO2) can be obtained from standard statistical mechanics, [13, 18] and its entropy (SCO2) can be found in the empirical thermodynamic databases [49]. Equation (1) provides the relationships of Gibbs free energy change of reactions (a) and (b) versus temperature and CO2 pressure. Obviously, when set ∆G = 0, the P–T relationship (van’t Hoff plot) is obtained to determine the turnover temperature Tt:

Based on Eq. (4), at a given CO2 pressure PCO2, the turnover temperature Tt can be determined for each CO2 capture reaction.

To calculate the phonon free energies and entropies of solids involved, in this study, we employed the PHONON software package [50] in which the direct method is applied following the formula derived by Parlinski et al. [51] to combine ab initio DFT with phonon calculations. More details on how to perform such phonon calculations can be found in our previous studies [13, 18, 32, 33].

3 Results and discussion

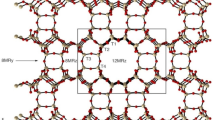

3.1 Electronic properties

The crystal structures of MAlO2, M5AlO4 (M = Li, Na, K), and Al2O3 are taken from the ICSD database [52]. Although LiAlO2 has six polymorphs reported to date [53, 54], the most stable forms under ambient conditions are a hexagonal α- (R3̅m, NaCrS2 type) [55] and a tetragonal γ- (P41212/P43212, γ-LiAlO2 type) [56]. Penta-lithium aluminate (Li5AlO4) has two main orthorhombic phases: α-phase in Pbca (#61) [57] and β-phase in PmmnZ (#59) space groups [58]. Similarly, NaAlO2 and KAlO2 also have two main phases: α- and β-phases in R \(\overline{3 }\) mH (#166) [59] and Pna21 (No.33) [60], low-temperature (lt) and high-temperature (ht) phases of KAlO2 in Pbca (#61) [61] and P41212 (No.92) [61], respectively. Although Na5AlO4 has the same space group (Pbca [#61]) as α-Li5AlO4, its lattice dimension and atomic coordinates are quite different [62]. In the literature, since we didn’t find the crystal structure of K5AlO4, we assume it has the same structure as Na5AlO4. Although Al2O3 possesses many phases under different conditions, the most stable phase is α-Al2O3 (R \(\overline{3 }\) cH [#167]) [63] and the most practically used phase is γ-Al2O3. The γ-Al2O3 has several settings; here, we adopted the well-constructed model in P21/m (#11) by the first ab initio calculations [64]. Figure 1 shows the structures of these crystals. Table 1 lists the experimental structural constants of crystals studied and our optimized results. Space groups and the formula unit (f.u.) (Z) in their unit cells are also listed in Table 1. The calculated DFT total energies of these crystals are listed in Table 2. Overall, as one can see, the optimized structures are close to their experimental measurements. In the case of Al2O3, although the calculated total energy of α-Al2O3 is -37.74677 eV/f.u., which is 0.1357 eV/f.u. (3.13 kcal/mol) lower than that of γ-Al2O3, the γ-phase is commonly used for general applications. Hence, we use γ-Al2O3 for the following study.

As an example, the calculated band structures of β-NaAlO2 (SG#33) and lt-KAlO2 (SG#61) are shown in Fig. 2. The electronic band structures of other MAlO2 and M5AlO4 are demonstrated in Figs. S2(a)-S7(a) of SI. The calculated band gaps and valence band widths are summarized in Table 2. As shown, all these alkali aluminates are semiconductors/insulators with various band gaps from 2.48 eV to 6.21 eV. Most of them have direct bandgaps at the Γ high symmetry point except for the α phases of LiAlO2 and NaAlO2, which have indirect band gaps located between the Γ and F high symmetry points. From the calculated DFT energies listed in Table 2, it can be seen that the γ phase of LiAlO2 and α phase of Li5AlO4 have slightly lower energies than α-LiAlO2 and β-Li5AlO4 (−0.069 eV, − 0.041 eV, respectively). The energy difference between the α and β phases of NaAlO2 is 0.241 eV, while in the lt- and ht- phases of KAlO2 the difference is only − 0.016 eV, which means their structures are closer to each other. Actually, the crystal structure of lt-KAlO2 is similar to a 1 × 2 × 2 supercell of ht-KAlO2, which leads to similar properties.

The calculated total and partial density of states (TDOS, PDOS) of β-NaAlO2 (SG#33) and lt-KAlO2 (SG#61) are shown in Fig. 3. The TDOS and PDOS of other MAlO2 and M5AlO4 are demonstrated in Figs. S2(b)-S7(b) of SI. The 1st valence bands (VB1) of these alkali aluminates are located 0 ~ − 6 eV under Fermi levels. In M5AlO4, small gaps can be clearly seen within the VB1. There are large gaps between VB1 and VB2, which is located bellow − 15 eV. For K5AlO4 and KAlO2, an additional band (VB2’) is located between the − 12 ~ − 13 eV energy range. From their PDOS, as shown in Figs.3(b), S6(b), S7(b), the VB2’ is mainly formed by p orbitals of K. In all cases, the VB1 are mainly contributed by p orbitals of O, s and p orbitals of Al and M. The p orbitals of Al have a greater contribution to the upper portion of VB1 while its s orbital has a larger contribution to the lower portion of VB1.

3.2 Phonon dynamic properties

As described in our previous study [13, 18, 33], the phonon calculations were performed on primitive cells of solids, that may be different from the conventional cells used in the above electronic structure calculations. As listed in Table 1, the f.u. in these primitive cells (Zph) may be smaller than those in their corresponding conventional cells (Z). The number of the solid’s phonon modes is the product of three times Zph and the number of atoms in each f.u: 3 × Zph × 4 for MAlO2, 3 × Zph × 10 for M5AlO4. Hence, as shown in Fig. 4 phonon dispersions, β-Li5AlO4, α-LiAlO2, β-NaAlO2, and lt-KAlO2 have 60, 12, 48, and 192 phonon vibrational modes respectively. The calculated phonon dispersions of other alkali aluminates are given in Figure S8 of SI. From these phonon dispersions, one can see two noticeable soft modes (negative frequency) in ht-KAlO2 (Figure S8c) around the Г point, one negligible soft mode in Na5AlO4 (Figure S8b) around the Y point, and one negligible soft point in lt-KAlO2 (Fig. 4d) between the S and X wavevector points. Such soft modes indicate the structure may not be in its global minimum state. During the following free energy calculations, we ignore these soft modes. As one can see from Fig. 8d, no soft mode was found in the case of K5AlO4, which indicates the crystal structure of K5AlO4 in orthorhombic phase Pbca (#61) could stably exist. Hence, further experimental synthesis is needed to verify this prediction because we didn’t find any report on its crystal structure in the literature.

The calculated total phonon density of states (TPDOS) of α-LiAlO2, γ-LiAlO2, α-Li5AlO4, and β-Li5AlO4 are shown in Fig. 5. The TPDOS of other alkali aluminates are shown in Figure S9 of SI. From Figs. 4, 5, S8 and S9, one can see that the vibrational frequencies of M5AlO4 spread at a lower frequency range in comparison with their MAlO2 phases. These TPDOS are used to calculate the thermodynamic properties.

Based on the phonon density of states, the phonon free energy and entropy versus temperature can be evaluated [13, 18, 32, 33]. Figure 6 shows the calculated results of these alkali aluminates. Obviously, the zero-point energy (Ezp) of a solid can be obtained from Fig. 6(a) by setting T = 0 K. The obtained EZP as well as the phonon entropy at 300 K of alkali aluminates are listed in Table 2. As one can see from Fig. 6, with increasing temperature the phonon free energies of these alkali aluminates decrease while their entropies increase. Compared to Li5AlO4 and Na5AlO4, K5AlO4 has a higher entropy as demonstrated in Fig. 6b and will exhibit different thermodynamic properties. From Fig. 6, one can see an obvious difference between α-Li5AlO4 and β-Li5AlO4, but such differences become smaller among different phases of MAlO2. To analyze the thermodynamic properties of these alkali aluminates capturing CO2, the most stable phases with lower energies in Table 2 will be used for further investigations.

3.3 CO2 capture properties

By combining DFT energies and the phonon free energy and entropy data, we can further evaluate the thermodynamic properties of these alkali aluminates capturing CO2 reactions. According to Eqs. (1)–(3), the calculated thermodynamic properties [∆H(T), ∆G(T)] of reactions (a) and (b) versus temperatures are plotted in Fig. 7 and summarized in Table 3. For MAlO2, only the most stable phases γ-LiAlO2, β-NaAlO2 and lt-KAlO2 were used to calculate their CO2 capturing properties.

As shown in Fig. 7, overall, MAlO2 solids have higher ∆H(T) and ∆G(T) than M5AlO4 solids. Among MAlO2, γ-LiAlO2 has lowest ∆H(T) and ∆G(T) values while β-NaAlO2 has higher ∆H(T) and ∆G(T) value than lt-KAlO2. However, among M5AlO4, one can see that at low temperature ranges the ∆H(T) of α-Li5AlO4 is higher than those of Na5AlO4 and K5AlO4. When the temperature is increased above 750 K, Na5AlO4 has a higher ∆H(T). With increasing temperature, the ∆G(T) of α-Li5AlO4 is always higher than those of Na5AlO4 and K5AlO4. Obviously, different from other alkali aluminates, with increasing temperature the ∆G(T) of Na5AlO4 and K5AlO4 first increase slightly at a low temperature range (< 650 K) and then decrease at high temperatures. Such behaviors have a strong impact on their CO2 capture performance as demonstrated in the following Fig. 8.

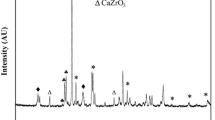

The calculated van’t Hoff plot of CO2 pressures versus temperatures for MAlO2 and M5AlO4 (M = Li, Na, K) capturing CO2 reactions. Y-axis plotted in logarithm scale. Only the ΔG = 0 curve is shown explicitly. For each reaction, above its ΔG = 0 curve, their ΔG < 0, which means the solids absorb CO2 and the reaction goes forward, whereas below the ΔG = 0 curve, their ΔG > 0, which means the CO2 starts to release and the reaction goes backward to regenerate the sorbents

Figure 8 shows the dependence of CO2 pressure on temperature (also known as the van’t Huff plot, Figure S10), which was obtained by setting ΔG(T,P) = 0 in Eq. (1). Under certain CO2 capture conditions (e.g., under post-combustion PCO2 ≈ 0.15 atm, under pre-combustion PCO2 ≈ 15–25 atm), according to Eq. (4) the calculated turnover temperatures (Tt) of these alkali aluminates capturing CO2 reactions (a), (b) are listed in Table 3 corresponding to post- and pre-combustions respectively. As demonstrated in our previous study, [14] the Tt of M2O + CO2 ⇄ M2CO3 reactions are much higher (most of them > 1500 K) and are out of the desired operating conditions of practical CO2 capture technology development. Hence, we use CaO + CO2 ⇌ CaCO3 reaction as our baseline for comparison. The corresponding calculated data of CaO capturing CO2 are also listed in Table 3 [18].

From Fig. 8 and Table 3, one can see that compared to γ-LiAlO2, both β-NaAlO2 and lt-KAlO2 have lower turnover temperatures (T1, T2) with (565 K, 485 K) and (715 K, 615 K), respectively, under pre- and post-combustion conditions, indicating both β-NaAlO2 and lt-KAlO2 can capture CO2 at low temperature and hence require less energy input. In the case of M5AlO4, all the Tt were much higher, indicating they can easily capture CO2 to form carbonates and Al2O3, as observed in the literature [36], but their regeneration reactions only can happen at very high temperature (> 1000 K). Therefore, M5AlO4, particularly Na5AlO4 and K5AlO4, are not good candidates for CO2 sorbents because they are hardly regenerated at a moderate temperature range. By comparing these alkaline aluminates with CaO baseline in Table 3, one can see that the Tt of MAlO2 (M = Li, Na, K) capturing CO2 reactions are much lower than that of CaO reaction with CO2. Therefore, in comparison with CaO, the MAlO2 capturing CO2 can operate at lower temperature and hence consume less energy.

From Fig. 8, we can see that during the 1st capture cycle, the M5AlO4 can react with CO2 to form M2CO3 and Al2O3 in a wide range of temperatures. However, during the regenerating cycle to release CO2, the M2CO3 and Al2O3 will be first regenerated to MAlO2 by following the reverse reaction (a), not reverse reaction (b) to M5AlO4. Hence, even though initially we started with M5AlO4, during the following cycles, the effective sorbents became MAlO2. In conclusion, among MAlO2 and M5AlO4 solids, the β-NaAlO2, lt-KAlO2, and γ-LiAlO2 are better candidates for capturing CO2. Here, it should be pointed out that an experimental work by Avalos-Rendon et al. [36] found that in the temperature range of 200–800 ºC, LiAlO2 only absorbed 0.13 w.t.% CO2, which is far below the theoretical value of 33.37 w.t.%. The reason for such low practical capacity is the slow kinetics. Our calculated results only show favorable thermodynamics of MAlO2 capturing CO2. To increase their practical CO2 capacities, the reaction kinetics need to be improved by lowering the reaction barriers, and the active surface areas should be increased by reducing the particle size. For example, the porous form of LiAlO2 can increase its CO2 capacity to 7 w.t.%. mixing other oxides (such as MgO, CaO, etc.) can also improve the CO2 capture capacity of MAlO2 [37]. Obviously, further experimental and theoretical investigations are needed to improve the capture reaction kinetics.

4 Summary and conclusions

CO2 is one of the major combustion products that, once released into the air, can contribute to global climate change. There is a critical need for development of new materials that can capture CO2 reversibly with acceptable energy cost and performance for such applications. Accordingly, solid sorbents have been reported to be promising candidates for CO2 sorbent applications through a reversible chemical transformation due to their high CO2 absorption capacities at moderate operating temperatures. In this study, by combining DFT and lattice phonon dynamics approaches, the electronic and thermodynamic properties of different phases of MAlO2 and M5AlO4 (M = Li, Na, K) and their capturing CO2 behaviors have been investigated.

The calculated electronic structure properties of MAlO2 and M5AlO4 indicate that all these alkali aluminates are semiconductors or insulators with a bandgap range of 2.4 ~ 6.4 eV. The low-temperature phase (#61) of KAlO2 has similar electronic properties as its high-temperature phase (#92). The VB1 of these alkali aluminates are located 0 ~ -6 eV under Fermi levels and are mainly contributed by p orbitals of O, s and p orbitals of Al and M. The p orbitals of Al have a greater contribution to the upper portion of VB1 while its s orbital has a larger contribution to the lower portion of VB1. Some of these alkali aluminates have small gaps within their VB1. There are large gaps (5.9 ~ 12 eV) between VB1 and VB2. For K5AlO4 and KAlO2, between the − 12 ~ − 13 eV energy range, an additional band (VB2’) is mainly formed by p orbitals of K.

From the calculated phonon dispersions of MAlO2 and M5AlO4, only one or two noticeable soft modes were found in lt-KAlO2 and ht-KAlO2, which indicate these alkali aluminates are stable. Overall, the vibrational frequencies of M5AlO4 spread at a lower frequency range compared to their MAlO2 phases. With increasing temperature, the calculated phonon free energies of M5AlO4 decrease faster than their corresponding MAlO2 while their entropy trends are opposite. Obviously, from Li to K, our results showed that the MAlO2 and M5AlO4 exhibit different electronic structures and phonon dynamic properties, resulting in different CO2 capture properties and capabilities.

From the calculated thermodynamic properties of MAlO2 and M5AlO4 capturing CO2 reactions, we found that reaction 2MAlO2 + CO2 = M2CO3 + Al2O3 has a higher reaction heat [∆H(T)] and Gibbs free energy [∆G(T)] than those of corresponding reaction 2/5M5AlO4 + CO2 = M2CO3 + 1/5Al2O3, which shows the former reaction possesses lower turnover temperature. Overall, MAlO2 can be used to capture CO2 at medium temperature ranges, while M5AlO4 can capture CO2 easily but can hardly be regenerated below 1000 K, indicating M5AlO4 are not good for CO2 sorbents. Among the alkali aluminates studied, the β-NaAlO2, lt-KAlO2, and γ-LiAlO2 are thermodynamically better candidates that could be applied to CO2 capture technologies. In comparison with CaO baseline, these alkali aluminates can capture CO2 at lower temperature and hence need less energy inputs. To further understand the kinetics of these thermodynamically feasible solid materials capturing CO2 and to improve their practical CO2 capacities, further simulations and experiments on the CO2 reacting with the sorbent and the diffusing barriers through the formed carbonate shell, as well as on the formation of products, are highly demanded.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

D’Alessandro DM, Smit B, Long JR. Carbon dioxide capture: prospects for new materials. Angew Chem-Int Edn. 2010;49(35):6058–82.

Figueroa JD, Fout T, Plasynski S, McIlvried H, Srivastava RD. Advancesn in CO2 capture technology—the US Department of Energy’s Carbon Sequestration Program. Int J Greenhouse Gas Control. 2008;2(1):9–20.

Li BY, Duan Y, Luebke D, Morreale B. Advances in CO2 capture technology: a patent review. Appl Energy. 2013;102:1439–47.

Rochelle GT. Amine scrubbing for CO2 capture. Science. 2009;325(5948):1652–4.

Blanchard LA, Hancu D, Beckman EJ, Brennecke JF. Green processing using ionic liquids and CO2. Nature. 1999;399(6731):28–9.

Lin LC, Berger AH, Martin RL, Kim J, Swisher JA, Jariwala K, Rycroft CH, Bhown AS, Deem MW, Haranczyk M, et al. In silico screening of carbon-capture materials. Nat Mater. 2012;11(7):633–41.

Markewitz P, Kuckshinrichs W, Leitner W, Linssen J, Zapp P, Bongartz R, Schreiber A, Muller TE. Worldwide innovations in the development of carbon capture technologies and the utilization of CO2. Energy Environ Sci. 2012;5(6):7281–305.

Liu J, Thallapally PK, McGrail BP, Brown DR, Liu J. Progress in adsorption-based CO2 capture by metal-organic frameworks. Chem Soc Rev. 2012;41(6):2308–22.

Liu WQ, An H, Qin CL, Yin JJ, Wang GX, Feng B, Xu MH. Performance enhancement of calcium oxide sorbents for cyclic CO2 capture-a review. Energy Fuels. 2012;26(5):2751–67.

Chen J, Duan LB, Sun ZK. Review on the development of sorbents for calcium looping. Energy Fuels. 2020;34(7):7806–36.

Naeem MA, Armutlulu A, Imtiaz Q, Donat F, Schäublin R, Kierzkowska A, Müller CR. Optimization of the structural characteristics of CaO and its effective stabilization yield high-capacity CO2 sorbents. Nat Commun. 2018;9(1):2408.

Supap T, Saiwan C, Idem R, Tontiwachwuthikul PPT. Part 2: Solvent management: solvent stability and amine degradation in CO2 capture processes. Carbon Manage. 2011;2(5):551–66.

Duan Y, Sorescu DC. Density functional theory studies of the structural, electronic, and phonon properties of Li2O and Li2CO3: application to CO2 capture reaction. Phys Rev B. 2009;79(1): 014301.

Duan Y, Zhang B, Sorescu DC, Johnson JK. CO2 capture properties of M–C–O–H (M=Li, Na, K) systems: a combined density functional theory and lattice phonon dynamics study. J Solid State Chem. 2011;184(2):304–11.

Duan Y. A first-principles density functional theory study of the electronic structural and thermodynamic properties of M2ZrO3 and M2CO3 (M=Na, K) and their capabilities for CO2 capture. J Renew Sustain Energy. 2012;4(1): 013109.

Osman AI, Hefny M, Maksoud M, Elgarahy AM, Rooney DW. Recent advances in carbon capture storage and utilisation technologies: a review. Environ Chem Lett. 2021;19(2):797–849.

Wang J, Huang L, Yang R, Zhang Z, Wu J, Gao Y, Wang Q, O’Hare D, Zhong Z. Recent advances in solid sorbents for CO2 capture and new development trends. Energy Environ Sci. 2014;7(11):3478–518.

Duan Y, Sorescu DC. CO2 capture properties of alkaline earth metal oxides and hydroxides: a combined density functional theory and lattice phonon dynamics study. J Chem Phys. 2010;133(7): 074508.

Nakagawa K, Ohashi T. A novel method of CO2 capture from high temperature gases. J Electrochem Soc. 1998;145(4):1344–6.

Nakagawa K, Ohashi T. A reversible change between lithium zirconate and zirconia in molten carbonate. Electrochemistry. 1999;67(6):618–21.

Kato M, Nakagawa K. New series of lithium containing complex oxides, lithium silicates, for application as a high temperature CO2 absorbent. J Ceram Soc Jpn. 2001;109(11):911–4.

Essaki K, Nakagawa K, Kato M, Uemoto H. CO2 absorption by lithium silicate at room temperature. J Chem Eng Jpn. 2004;37(6):772–7.

Gauer C, Heschel W. Doped lithium orthosilicate for absorption of carbon dioxide. J Mater Sci. 2006;41(8):2405–9.

Wang YJ, Qi L, Dai KH. Effect of Na-doping on CO2 absorption of Li4SiO4. Acta Phys Chim Sin. 2006;22(7):860–3.

Xiong R, Ida J, Lin YS. Kinetics of carbon dioxide sorption on potassium-doped lithium zirconate. Chem Eng Sci. 2003;58:4377–85.

Dunstan MT, Schlogelhofer HL, Griffin JM, Dyer MS, Gaultois MW, Lau CY, Scott SA, Grey CP. Ion Dynamics and CO2 absorption properties of Nb-, Ta-, and Y-Doped Li2ZrO3 studied by solid-state NMR, thermogravimetry, and first-principles calculations. J Phys Chem C. 2017;121(40):21877–86.

Hernandez LOG, Gutierrez DL, Collins-Martinez V, Ortiz AL. Synthesis, characterization and high temperature CO2 capture evaluation of Li2ZrO3-Na2ZrO3 mixtures. J New Mater Electrochem Syst. 2008;11(2):137–42.

Ochoa-Fernandez E, Rusten HK, Jakobsen HA, Ronning M, Holmen A, Chen D. Sorption enhanced hydrogen production by steam methane reforming using Li2ZrO3 as sorbent: sorption kinetics and reactor simulation. Catal Today. 2005;106(1–4):41–6.

Alcerreca-Corte I, Fregoso-Israel E, Pfeiffer H. CO2 absorption on Na2ZrO3: a kinetic analysis of the chemisorption and diffusion processes. J Phys Chem C. 2008;112(16):6520–5.

Zhao TJ, Ochoa-Fernandez E, Ronning M, Chen D. Preparation and high-temperature CO2 capture properties of nanocrystalline Na2ZrO3. Chem Mater. 2007;19(13):3294–301.

Duan Y. Electronic structural and phonon properties of lithium zirconates and their capabilities of CO2 capture: a first-principle density functional approach. J Renew Sustain Energy. 2011;3(1): 013102.

Duan Y, Lekse J, Wang XF, Li BY, Alcantar-Vazquez B, Pfeiffer H, Halley JW. Electronic structural, phonon dynamic properties, and CO2 capture capabilities of Na2-xMxZrO3 (M=Li, K): density functional theory calculations and experimental validations. Phys Rev Appl. 2015;3(4): 044013.

Duan Y. ab initio thermodynamic approach to identify mixed solid sorbents for CO2 capture technology. Front Environ Sci. 2015;3:69.

Duan Y, Pfeiffer H, Li BY, Romero-Ibarra IC, Sorescu DC, Luebke DR, Halley JW. CO2 capture properties of lithium silicates with different ratios of Li2O/SiO2: an ab initio thermodynamic and experimental approach. Phys Chem Chem Phys. 2013;15(32):13538–58.

Duan Y, Parlinski K. Density functional theory study of the structural, electronic, lattice dynamical, and thermodynamic properties of Li4SiO4 and its capability for CO2 capture. Phys Rev B. 2011;84(10): 104113.

Avalos-Rendon T, Casa-Madrid J, Pfeiffer H. Thermochemical capture of carbon dioxide on lithium aluminates (LiAlO2 and Li5AlO4): a new option for the CO2 absorption. J Phys Chem A. 2009;113(25):6919–23.

Korake PV, Gaikwad AG. Capture of carbon dioxide over porous solid adsorbents lithium silicate, lithium aluminate and magnesium aluminate at pre-combustion temperatures. Front Chem Sci Eng. 2011;5(2):215–26.

Kulkarni NS, Besmann TM, Spear KE. Thermodynamic optimization of lithia-alumina. J Am Ceram Soc. 2008;91(12):4074–83.

Eriksson G, Wu P, Pelton AD. Critical-evaluation and optimization of the thermodynamic properties and phase-diagrams of the MgO-Al2O3, MnO-Al2O3, FeO-Al2O3, Na2O-Al2O3 and K2O-Al2O3 systems. Calphad-Comput Coupling Phase Diagr Thermochem. 1993;17(2):189–205.

Duan Y, Luebke D, Pennline HW. Efficient theoretical screening of solid sorbents for CO2 capture applications. Int J Clean Coal Energy. 2012;1(1):1–11.

Duan Y. Theoretical investigations of the CO2 capture properties of r-LiAlO2 and a-Li5AlO4. Micro Nanosyst. 2021;13:32–41.

Duan Y, Sorescu DC, Jiang WL, Senor DJ. Theoretical study of the electronic, thermodynamic, and thermo-conductive properties of r-LiAlO2 with 6Li isotope substitutions for tritium production. J Nucl Mater. 2020;530: 152963.

Kresse G, Hafner J. Abinitio molecular-dynamics for liquid-metals. Phys Rev B. 1993;47(1):558–61.

Kresse G, Furthmuller J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B. 1996;54(16):11169–86.

Kresse G, Furthmuller J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comp Mater Sci. 1996;6(1):15–50.

Duan Y. Electronic properties and stabilities of bulk and low-index surfaces of SnO in comparison with SnO2: a first-principles density functional approach with an empirical correction of van der Waals interactions. Phys Rev B. 2008;77(4): 045332.

Monkhorst HJ, Pack JD. Special points for Brillouin-zone integrations. Phys Rev B. 1976;13(12):5188–92.

Bradley CJ, Cracknell AP. The mathematical theory of symmetry in solids. Oxford: Clarendon press; 1972.

Chase MWJ. NIST-JANAF themochemical tables 4th edition. J Phys Chem Ref Data. 1998;Monograph 9:1–1951.

Parlinski K. Software PHONON 2010.

Parlinski K, Li ZQ, Kawazoe Y. First-principles determination of the soft mode in cubic ZrO2. Phys Rev Lett. 1997;78(21):4063–6.

ICSD Database. http://www2.fiz-karlsruhe.de/icsd_home.html

Wiedemann D, Nakhal S, Rahn J, Witt E, Islam MM, Zander S, Heitjans P, Schmidt H, Bredow T, Wilkening M, et al. Unravelling ultraslow lithium-ion diffusion in gamma-LiAlO2: experiments with tracers, neutrons, and charge carriers. Chem Mater. 2016;28(3):915–24.

Bianchini F, Fjellvag H, Vajeeston P. A first principle comparative study of the ionic diffusivity in LiAlO2 and NaAlO2 polymorphs for solid-state battery applications. Phys Chem Chem Phys. 2018;20(15):9824–32.

Marezio M, Remeika JP. High-pressure synthesis and crystal structure of alpha-LiAlO2. J Chem Phys. 1966;44(8):3143–5.

Wiedemann D, Indris S, Meven M, Pedersen B, Boysen H, Uecker R, Heitjans P, Lerch M: Single-crystal neutron diffraction on gamma-LiAlO2: structure determination and estimation of lithium diffusion pathway. Zeitschrift Fur Kristallographie-Crystalline Materials 2016; 231(3):189–193.

Stewner F, Hoppe R. Crystal structure of alpha Li5AlO4. Z Anorg Allg Chem. 1971;380(3):241–3.

Hoppe R, Konig H. Crystal-structure of beta-Li5AlO4. Z Anorg Allg Chem. 1977;430(3):211–7.

Reid AF, Ringwood AE. High-pressure NaAlO2 an alpha-NaFeO2 isotype. Inorg Chem. 1968;7(3):443–5.

Kaduk JA, Pei SY. The crystal-structure of hydrated sodium aluminate, NaAlO2-center-dot-5/4H2O, and its dehydration product. J Solid State Chem. 1995;115(1):126–39.

Burmakin EI, Voronin VI, Akhtyamova LZ, Berger IF, Shekhtman GS. Potassium aluminate crystalline structure and electroconduction. Russ J Electrochem. 2004;40(6):619–25.

Barker MG, Gadd PG, Begley MJ. Preparation and crystal-structures of the 1st alkali-rich sodium aluminates Na7Al3O8 and Na5AlO4. J Chem Soc-Chem Commun. 1981;8:379–81.

Kondo S, Tateishi K, Ishizawa N. Structural evolution of corundum at high temperatures. Jpn J Appl Phys. 2008;47(1):616–9.

Digne M, Sautet P, Raybaud P, Euzen P, Toulhoat H. Use of DFT to achieve a rational understanding of acid-basic properties of gamma-alumina surfaces. J Catal. 2004;226(1):54–68.

Acknowledgements

This project was funded by the United States Department of Energy, National Energy Technology Laboratory Transform Carbon capture FWP #1022402. The author wishes to express his gratitude to Jenny Bowman (technical writer) for critical reading of the manuscript. This report was prepared as an account of work sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

Author information

Authors and Affiliations

Contributions

YD: Conceptualization, Resources, Investigation, Formal analysis, Writing.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Duan, Y. Electronic structural and lattice thermodynamic properties of MAlO2 and M5AlO4 (M = Li, Na, K) sorbents for CO2 capture applications. Discov Chem Eng 3, 6 (2023). https://doi.org/10.1007/s43938-023-00022-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43938-023-00022-9