Abstract

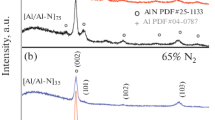

In this research, an Al–Mg–Si–Ag multilayered coating with different amounts of silver additive was deposited on the AA2024 substrate using the friction surfacing process to investigate the microstructure, corrosion, and wear characteristics of the structure. The results showed that the silver-containing coating layer had a lower deposition rate and efficiency than coating without the silver additive. Owing to the lower temperature than silver-free coating and the presence of silver-rich particles acting as a barrier to grain boundary movement, no significant difference was found in grain size of different layers of the silver-containing coating. After aging heat treatment of the silver-containing coating, the Q (Al4(Cu, Ag) Mg4Si4) precipitates were formed as part of the silver-rich particles began to dissolve. After aging heat treatment, the top layer of the silver-containing coating showed 16% higher hardness than the AA2024 substrate. The wear rate of coating containing 13 wt% silver was 37% lower than the AA2024 substrate. The corrosion current density was reduced by approximately 97% and 99% in the silver-containing sample as compared to the sample devoid of silver and AA2024 substrate. With increasing silver content in the coated layer, the wear mechanism transitions from a combination of abrasive and adhesive wear mechanisms to an abrasive wear mechanism.

Similar content being viewed by others

References

Silvério S, Krohn H, Fitseva V, Alcântara NGD, Santos JFD. Deposition of AA5083-H112 over AA2024-T3 by friction surfacing. Soldagem Inspeção. 2018;23:225–34.

Vilaça P. Friction surfacing. Surface modification by solid state processing. New York: Elsevier; 2014. p. 25–72.

Mostafavi M, Taghiabadi R, Jafarzadegan M. Optimizing the mechanical properties of Al-4.5 Cu-xSi alloys through multi-pass friction stir processing and post-process aging. Arch Civ Mech Eng. 2022;22(1):1–15.

Farajollahi R, Jamshidi Aval H, Jamaati R. Effect of friction surfacing parameters on the microstructural, mechanical properties, and wear characteristic of Al–Cu–Mg alloy coating reinforced by nickel aluminide. Arch Civ Mech Eng. 2022;22(2):75.

Bhat KU, Panemangalore DB, Kuruveri SB, John M, Menezes PL. Surface modification of 6xxx Series aluminum alloys. Coatings. 2022;12(2):180.

Seidi E, Miller SF, Carlson BE. Friction surfacing deposition by consumable tools. J Manuf Sci Eng Trans ASME. 2021;143(12):120801–26.

Yu M, Zhang Z, Zhao H, Zhou L, Song X. Microstructure and corrosion behavior of the ultra-fine grained aluminum coating fabricated by friction surfacing. Mater Lett. 2019;250:174–7.

Liu S, Bor T, Van der Stelt A, Geijselaers H, Kwakernaak C, Kooijman A, et al. Friction surface cladding: an exploratory study of a new solid state cladding process. J Mater Process Technol. 2016;229:769–84.

Gnanasekaran M, Mohan K, Kumaravel A, Magibalan S. Characterization, corrosion behavior, effect of temperature and inhibition studies on AA6351 frictional surfaced mild steel. J Mater Res Technol. 2020;9(6):16080–92.

Guo D, Kwok C, Chan S. Fabrication of stainless steel 316L/TiB2 composite coating via friction surfacing. Surf Coat Technol. 2018;350:936–48.

Sharma A, Sagar S, Mahto RP, Sahoo B, Pal SK, Paul J. Surface modification of Al6061 by graphene impregnation through a powder metallurgy assisted friction surfacing. Surf Coat Technol. 2018;337:12–23.

Belei C, Fitseva V, Dos Santos J, Alcântara N, Hanke S. TiC particle reinforced Ti-6Al-4V friction surfacing coatings. Surf Coat Technol. 2017;329:163–73.

Khodabakhshi F, Gerlich A. Potentials and strategies of solid-state additive friction-stir manufacturing technology: a critical review. J Manuf Process. 2018;36:77–92.

Dilip JJS, Babu S, Rajan SV, Rafi KH, Ram GDJ, Stucker BE. Use of friction surfacing for additive manufacturing. Mater Manuf Processes. 2013;28(2):189–94.

Dilip JJS, Janaki Ram GD. Microstructure evolution in aluminum alloy AA 2014 during multi-layer friction deposition. Mater Charact. 2013;86:146–51.

Gandra J, Vigarinho P, Pereira D, Miranda R, Velhinho A, Vilaça P. Wear characterization of functionally graded Al–SiC composite coatings produced by friction surfacing. Mater Des. 2013;52:373–83.

Pirhayati P, Jamshidi AH. Effect of silver on non-isothermal aging of friction surfaced AA2024-16 wt% Ag composites. Surf Coat Technol. 2019;379: 125059.

Gandra J, Miranda R, Vilaça P. Performance analysis of friction surfacing. Mater Process Technol. 2012;212(8):1676–86.

Gandra J, Krohn H, Miranda R, Vilaça P, Quintino L, dos Santos JF. Friction surfacing—a review. J Mater Process Technol. 2014;214(5):1062–93.

Pirhayati P, Jamshidi AH. Microstructural characterization and mechanical properties of friction surfaced AA2024−Ag composites. Trans Nonferr Met Soc China. 2020;30(7):1756–70.

Humphreys FJ, Hatherly M. Recrystallization and related annealing phenomena. New York: Elsevier; 2012.

Ehrich J, Roos A, Klusemann B, Hanke S. Influence of Mg content in Al alloys on processing characteristics and dynamically recrystallized microstructure of friction surfacing deposits. Mater Sci Eng A. 2021;819: 141407.

Weng Y, Ding L, Zhang Z, Jia Z, Wen B, Liu Y, et al. Effect of Ag addition on the precipitation evolution and interfacial segregation for Al–Mg–Si alloy. Acta Mater. 2019;180:301–16.

Jha SC, Sanders TH, Dayananda MA. Grain boundary precipitate free zones in Al–Li alloys. Acta Metall. 1987;35(2):473–82.

Archard J. Contact and rubbing of flat surfaces. J Appl Phys. 1953;24(8):981–8.

Nakamura J, Matsuda K, Kawabata T, Sato T, Nakamura Y, Ikeno S. Effect of silver addition on the β′-phase in Al–Mg–Si–Ag alloy. Mater Trans. 2010;51(2):310–6.

Yu M, Zhao H, Zhang Z, Zhou L, Song X, Ma N. Texture evolution and corrosion behavior of the AA6061 coating deposited by friction surfacing. J Mater Process Technol. 2021;291: 117005.

Kairy SK, Birbilis N. Clarifying the role of Mg2Si and Si in localized corrosion of aluminum alloys by quasi in situ transmission electron microscopy. Corrosion. 2020;76(5):464–75.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflicts of interest.

Ethical statement

Authors state that the research was conducted according to ethical standards.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pirhayati, P., Jamshidi Aval, H. & Loureiro, A. Characterization of microstructure, corrosion, and tribological properties of a multilayered friction surfaced Al–Mg–Si–Ag alloy. Archiv.Civ.Mech.Eng 22, 176 (2022). https://doi.org/10.1007/s43452-022-00497-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-022-00497-3