Abstract

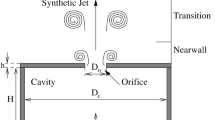

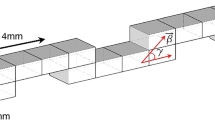

The purpose of this study is to evaluate cavitation behavior in orifice flow geometries. The influence of operating conditions (ten inlet pressures ranging from 50 to 730 kPa) and orifice designs (three orifice thicknesses ranging from 2 to 16 mm) are studied. Computational fluid dynamics (CFD) were used to evaluate cavitational flow in single- and two-phase models. These models were compared with experimental data. The results showed that the single-phase model cannot represent well the hydrodynamic cavitation (HC) behavior, since relative errors were close to 20%. In contrast, the two-phase model presented relative errors less than 10%, which indicates that the HC must be working in the two-phase model. The highest cavitational intensity was observed for an inlet pressure of 730 kPa compared to other pressures, and the 6 mm thickness plate presented optimal cavitational activity among the tested scenarios.

Similar content being viewed by others

References

Adhikari R, Vaz J, Wood D (2016) Cavitation Inception in Crossflow Hydro Turbines. Energies 9:237–249

Alves PHL, Silva PSL, Ferreira DC, Gonçalves JCSI (2019) COD removal from sucrose solution using hydrodynamic cavitation and hydrogen peroxide: a comparison between Venturi device and orifice plate. Braz J Water Resour 24:e12

Ansys Inc. (2015) Ansys fluent theory guide. ANSYS Inc, Canonsburg

Arrojo S, Benito Y (2007) A theoretical study of hydrodynamic cavitation. Ultrason Sonochem 15:203–211

Arrojo S, Benito Y, Tarifa AM (2008) A parametrical study of disinfection with hydrodynamic cavitation. Ultrason Sonochem 15:903–908

Bashir TA, Soni AG, Mahulkar AV, Pandit AB (2011) The CFD driven optimisation of a modified venturi for cavitational activity. Can J Chem Eng 89:1366–1375

Batista MD, Anhê ACBM, Gonçalves JCSI (2017) Use of hydrodynamic cavitation for algae removal: effect on the inactivation of microalgae belonging to genus Scenedesmus. Water Air Soil Pollut 228:1–8

Bhandari VM, Sorokhaibam LG, Ranade VV (2016) Industrial wastewater treatment for fertilizer industry: a case study. Desalination Water Treat 1:1–11

Biçer B, Sou A (2014) Numerical simulation of turbulent cavitating flow in diesel fuel injector. In: 3rd international symposium of maritime sciences. Kobe

Cai J, Li X, Liu B, Huai X (2014) Effect of cavitating flow on forced convective heat transfer: a modeling study. Chin Sci Bull 59:1580–1590

Capocelli M, Musmarra D, Prisciandaro M, Lancia A (2014a) Chemical effect of hydrodynamic cavitation: simulation and experimental comparison. AIChE J 60(7):2566–2572

Capocelli M, Prisciandaro M, Lancia A, Musmarra D (2014b) Hydrodynamic cavitation of p-nitrophenol: a theoretical and experimental insight. Chem Eng J 254:1–8

Carpenter J, George S, Saharan VK (2017) Low pressure hydrodynamic cavitating device for producing highly stable oil in water emulsion: effect of geometry and cavitation number. Chem Eng Process 116:97–104

Chuah LF, Yusup S, Aziz ARA, Bokhari A, Abdllah MZ (2016) Cleaner production of methyl ester using waste cooking oil derived from palm olein using a hydrodynamic cavitation reactor. J Clean Prod 112:4505–4514

Concli F (2016) Pressure distribution in small hydrodynamic journal bearings considering cavitation: a numerical approach based on the open-source CFD code OpenFOAM. Lubr Sci 28:329–347

Dhande DY, Pande DW (2016) Multiphase flow analysis of hydrodynamic journal bearing using CFD coupled Fluid Structure Interaction considering cavitation. J Kind Saud Univ Eng Sci 30(4):345–354

Dular M, Griessler-Bulc T, Gutierrez-Aguirre I, Heath E, Kosjek T, Klemenc AK, Oder M, Petkovšek M, Racki N, Ravnikar M, Šarc A, Širok B, Zupanc M, Zitnik M, Kompare B (2016) Ultrasonics sonochemistry use of hydrodynamic cavitation in (waste) water treatment. Ultrason Sonochem 29:577–588

Echouchene F, Belmabrouk HLL, Buffat M (2011) Numerical simulation of wall roughness effects in cavitation flow. Int J Heat Fluid Flow 32:1068–1075

Erfanian M, Anbarsooz M (2018) Numerical investigation of body and hole effects on the cavitating flow behind a disk cavitator at extremely low cavitation numbers. Appl Math Model 62:163–180

Fard MB, Nikseresht AH (2012) Numerical simulation of unsteady 3D cavitating flows over axisymmetric cavitators. Sci Iran 19:1258–1264

Ghayal D, Pandit AB, Rathod VK (2013) Optimization of biodiesel production in a hydrodynamic cavitation reactor using used frying oil. Ultrason Sonochem 20:322–328

Gogate PR (2007) Application of cavitational reactors for water disinfection: current status and path forward. J Environ Manage 85(4):801–815

Gogate PR, Kabadi AM (2009) A review of applications of cavitation in biochemical engineering/biotechnology. Biochem Eng J 44:60–72

Hilares RT, Almeida GF, Ahmed MA, Antunes FAF, da Silva SS, Han J, dos Santos JC (2017) Hydrodynamic cavitation as an efficient pretreatment method for lignocellulosic biomass: a parametric study. Bioresour Technol 235:301–308

Huang Y, Wu Y, Huang W, Yang F, Ren X (2013) Degradation of chitosan by hydrodynamic cavitation. Polym Degrad Stab 98:37–43

Kuldeep, Saharan VK (2016) Computational study of different venturi and orifice type hydrodynamic cavitating devices. J Hydrodyn 28:293–305

Kumar PS, Kumar MS, Pandit AB (2000) Experimental quantification of chemical effects of hydrodynamic cavitation. Chem Eng Sci 55:1633–1639

Kummitha OR (2017) Numerical analysis of hydrogen fuel scramjet combustor with turbulence development inserts and with different turbulence models. Int J Hydrogen Energy 42:6360–6368

Lam WH, Robinson DJ, Hamill GA, Johnston HT (2012) An effective method for comparing the turbulence intensity from LDA Measurements and CFD predictions within a ship propeller jet. Ocean Eng 52:105–124

Li X, Huang B, Chen T, Liu Y, Qiu S, Zhao J (2017) Combined experimental and computational investigation of the cavitating flow in an orifice plate with special emphasis on surrogate-based optimization method. J Mech Sci Technol 31:269–279

Mancuso G, Langone M, Andreottola G (2017) A swirling jet-induced cavitation to increase activated sludge solubilization and aerobic sludge biodegradability. Ultrason Sonochem 35:498–501

Menter FR (1994) Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J 32:1598–1605

Mezule L, Tsyfansky S, Yakushevich V, Juhna T (2009) A simple technique for water disinfection with hydrodynamic cavitation: effect on survival of Escherichia coli. Desalination 248:152–159

Moholkar VS, Pandit AB (2001) Modeling of hydrodynamic cavitation reactors: a unified approach. Chem Eng Sci 56:6295–6302

Montusiewicz A, Pasieczna-Patkowska S, Lebiocka M, Szaja A, Szymanska-Chargot M (2017) Hydrodynamic cavitation of brewery spent grain diluted by wastewater. Chem Eng J 313:946–956

Nada SA, Fouda A, Elattar HF (2016) Parametric study of flow field and mixing characteristics of outwardly injected jets into a crossflow in a cylindrical chamber. Int J Therm Sci 102:185–201

Pawar SK, Mahulkar AV, Pandit AB, Roy K, Moholkar VS (2017) Sonochemical effect induced by hydrodynamic cavitation: comparison of venturi/orifice flow geometries. AIChE J 63:4705–4716

Pendar M, Roohi E (2016) Investigation of cavitation around 3D hemispherical head-form body and conical cavitators using different turbulence and cavitation models. Ocean Eng 112:287–306

Rajoriya S, Bargole S, George S, Saharan VK (2018) Treatment of textile dyeing industry effluent using hydrodynamic cavitation in combination with advanced oxidation reagents. J Hazard Mater 344:1109–1115

Raut-Jadhav S, Badve MP, Pinjari DV, Saini DR, Sonawane SH, Pandit AB (2016) Treatment of the pesticide industry effluent using hydrodynamic cavitation and its combination with process intensifying additives (H2O2 and ozone). Chem Eng J 112:4505–4514

Schnerr GH, Sauer J (2001) Physical and numerical modeling of unsteady cavitation dynamics. In: 4th international conference on multiphase flow. New Orleans

Shang Z (2013) Numerical investigations of supercavitation around blunt bodies of submarine shape. Appl Math Model 37(20–21):8836–8845

Sivakumar M, Pandit AB (2002) Wastewater treatment: a novel energy efficient hydrodynamic cavitational technique. Ultrason Sonochem 9:123–131

Tao Y, Cai J, Huai X, Liu B, Guo Z (2016) Application of hydrodynamic cavitation to wastewater treatment. Chem Eng Technol J 39:1363–1376

Wang Y, Sun XJ, Dai YJ, Wu GQ, Cao Y, Huang DG (2015) Numerical investigation of drag reduction by heat-enhanced cavitation. Appl Therm Eng 75:193–202

Acknowledgements

The authors are grateful to Fundação de Amparo à Pesquisa do Estado de Minas Gerais—FAPEMIG, to Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—CAPES (finance code 001) and to Conselho Nacional de Desenvolvimento Científico e Tecnológico—CNPq, for their support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cappa, O.A.P., Soeira, T.V.R., Simões, A.L.A. et al. Experimental and computational analyses for induced cavitating flows in orifice plates. Braz. J. Chem. Eng. 37, 89–99 (2020). https://doi.org/10.1007/s43153-019-00007-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43153-019-00007-8