Abstract

The addition of the second phase into tungsten can significantly refine the grain size of tungsten alloys, and also play a role in dispersion strengthening, thus improving the properties of tungsten alloy. As a preparation method of tungsten alloy powder, liquid-phase method avoids the disadvantage of mechanical alloying, and the obtained powder composition is accurate and controllable, with high purity and excellent uniformity. At present, the second phase particles used for dispersion strengthening tungsten alloys are mainly composed of oxides. Oxide particles can be synthesized and precipitated in nitrate solution through in situ chemical reaction, and are uniformly distributed in composite powder by mixing and stirring. Finally, the oxide dispersion strengthened tungsten alloy (ODS-W) was obtained by reduction and sintering. Liquid-phase methods for preparing ODS-W alloys include azeotropic distillation, sol–gel methods, freeze-drying, hydrothermal synthesis, spray-drying, etc. In this paper, several liquid-phase methods for preparing tungsten alloy composite powder precursors are reviewed, and their latest research progresses are discussed. In addition, the morphologies and properties of tungsten alloys prepared by different methods are compared, which provides guidance for preparing high-performance tungsten alloys.

Reproduced with permission from Ref. [32] Copyright 2021 Elsevier

Reproduced with permission from Ref. [36] Copyright 2013 Elsevier

Reproduced with permission from Ref. [38]. Copyright 2018 Elsevier

Reproduced with permission from Ref. [38] Copyright 2018 Elsevier

Reproduced with permission from Ref. [39] Copyright 2020 Elsevier

Reproduced with permission from Ref. [40] Copyright 2020 Elsevier

Reproduced with permission from Ref. [43] Copyright 2020 Royal Society of Chemistry

Reproduced with permission from Ref. [44] Copyright 2019 Elsevier

Reproduced with permission from Ref. [45] Copyright 2021 Elsevier

Reproduced with permission from Ref. [48] Copyright 2015 Rare Metals Cemented Carbides

Reproduced with permission from Ref. [52] Copyright 2017 Elsevier

Reproduced with permission from Ref. [53] Copyright 2020 Elsevier

Reproduced with permission from Ref. [60] Copyright 2016 Elsevier

Reproduced with permission from Ref. [61] Copyright 2014 Elsevier

Reproduced with permission from Ref. [67] Copyright 2018 Elsevier

Reproduced with permission from Ref. [70] Copyright 2019 Elsevier

Reproduced with permission from Ref. [71] Copyright 2020 Elsevier

Reproduced with permission from Ref. [76] Copyright 2020 Elsevier

Reproduced with permission from Ref. [71] Copyright 2020 Elsevier

Reproduced with permission from Ref. [30] Copyright 2012 Elsevier

Reproduced with permission from Ref. [84] Copyright 2006 Springer Nature

Reproduced with permission from Ref. [59] Copyright 2014 Elsevier

Reproduced with permission from Ref. [85] Copyright 2014 Elsevier

Reproduced with permission from Ref. [60] Copyright 2016 Elsevier

Reproduced with permission from Ref. [86] Copyright 2018 Elsevier

Reproduced with permission from Ref. [83] Copyright 2019 Elsevier

Reproduced with permission from Ref. [89] Copyright 2020 Elsevier

Reproduced with permission from Ref. [76] Copyright 2020 Elsevier

Similar content being viewed by others

References

Kurishita H, Amano Y, Kobayashi S, Nakai K, Arakawa H, Hiraoka Y, Takida T, Takebe K, Matsui H. Development of ultra-fine grained W-TiC and their mechanical properties for fusion applications. J Nucl Mater. 2007;367–370(part-PB):1453.

Antusch S, Armstrong D, Britton T, Commin L, Gibson J, Greuner H, Hoffmann J, Knabl W, Pintsuk G, Rieth M, Roberts S, Weingaertner T. Mechanical and microstructural investigations of tungsten and doped tungsten materials produced via powder injection molding. Nucl Mater Energy. 2015;3–4:22.

Hou L, Wang S, Chen G, He Y, Xie Y. Mechanical properties of tungsten nano whiskers characterized by nanoindentation. Trans Nonferr Metal Soc. 2013;23:2323.

Wurster S, Baluc N, Battabyal M, Crosby T, Pippan R. Recent progress in R&D on tungsten alloys for divertor structural and plasma facing materials. J Nucl Mater. 2013;442:S181.

Wang K, Zhang G. Synthesis of high-purity ultrafine tungsten and tungsten carbide powders. Trans Nonferr Metal Soc. 2020;30:1697.

Vieider G, Merola M, Bonal J. European development of the ITER divertor target. Fusion Eng Des. 1999;46:221.

Zhuge F, Ye Z, Wang F, Wang Y, Zhang H, Ding B. Nanocomposite W-4.5%ThO2 thermionic cathode. Mater Lett. 2003;57:2776.

Yoshizawa Y, Sakuma T. Evolution of microstructure and grain growth in ZrO2-Y2O3 alloys. Isij Int. 1989;29:746.

Sun J, Huang C, Liu H, Wang S, Zou B, Ai X. A review on the stabilized zirconia ceramics doped with stabilizers. Mater Mech Eng. 2005;29:1.

Ghamsari M, Abdul-hamid M, Radiman S, Ghamsari A, Rahmani S. Carbonation effect on the synthesis of highly crystalline γ-alumina nanopowders. Mater Lett. 2013;106:439.

Wang C, Huang H, Wei S, Zhang L, Pan K, Dong X, Xu L, Chen C, Mao F, Zhang C, Dong Z. Strengthening mechanism and effect of Al2O3 particle on high-temperature tensile properties and microstructure evolution of W-Al2O3 alloys. Mat Sci Eng A. 2022;835: 142678.

Wang C, Dong X, Wei S, Yu H, Pan K, Chen C, Xiong M, Mao F, Cui H, Xiao L, Dong Z, Wang S. Effect of hot-working process on interface structure and ductile-to-brittle transition temperature of tungsten alloy reinforced by Al2O3 particles. Int J Refract Met H. 2022;108: 105945.

Alizadeh M, Aliabadi M. Synthesis behavior of nanocrystalline Al-Al2O3 composite during low time mechanical milling process. J Alloy Compd. 2011;509(15):4978.

Nian H, Xia J, Feng T. Corrosion behavior of ZrO2-Mo composite in Na2SO4 solution. Key Eng Mater. 2013;544:351.

Zhou Y, Wei S, Xu L, Li X. Research on high-temperature properties of the molybdenum sheet doped with 1.0 wt%Al2O3 particles. J Alloy Compd. 2018;769:340.

Wang C, Zhang L, Wei S, Pan K, Wu X, Li Q. Effect of ZrO2 content on microstructure and mechanical properties of W alloys fabricated by spark plasma sintering. Int J Refract Met H. 2019;79:79.

Asachi M, Nourafkan E, Hassanpour A. A review of current techniques for the evaluation of powder mixing. Adv Powder Technol. 2018;29(7):1525.

Xiao F, Xu L, Zhou Y, Pan K, Li J, Liu W, Wei S. A hybrid microstructure design strategy achieving W-ZrO2(Y) alloy with high compressive strength and critical failure strain. J Alloy Compd. 2017;708:202.

Xiao F, Barriere T, Cheng G, Miao Q, Wei S, Zuo S, Huang Z, Xu L. Research on preparation process for the in situ nanosized Zr(Y)O2 particles dispersion-strengthened tungsten alloy through synthesizing doped hexagonal (NH4)0.33·WO3. J Alloy Compd. 2020;843:156059.

Xia M, Yan Q, Xu L, Guo H, Zhu L, Ge C. Bulk tungsten with uniformly dispersed La2O3 nanoparticles sintered from co-precipitated La2O3/W nanoparticles. J Nucl Mater. 2013;434:85.

Wang J, Lai C, Liu W, Yang F, Zhang X, Cui Y, Zhou M. Effect of scandia doping method on the emission uniformity of scandate cathode with Sc2O3-W matrix. Mater Res Bull. 2013;48:3594.

Waahlberg S, Yar M, Abuelnaga M, Salem H, Johnsson M, Muhammed M. Fabrication of nanostructured W-Y2O3 materials by chemical methods. J Mater Chem. 2012;22:12622.

Zhang G, Sun Y, Niu R, Sun J, Wei J, Zhao B, Yang L. Microstructure and strengthening mechanism of oxide lanthanum dispersion strengthened molybdenum alloy. Adv Eng Mater. 2004;6:943.

Hua Y, Wang J, Ma J, Chen S, Chen L, Englsen D. Effect of yttrium doping on the formation and stability of β-tungsten powder. Int J Refract Met H. 2018;72:71.

Lai C, Wang J, Zhou F, Liu W, Miao N. Reduction, sintering and mechanical properties of rhenium-tungsten compounds. J Alloy Compd. 2018;735:2685.

Han Y, Fan J, Liu T, Cheng H, Tian J. The effect of trace nickel additive and ball milling treatment on the near-full densification behavior of ultrafine tungsten powder. Int J Refract Met H. 2012;34:18.

Dong Z, Liu N, Ma Z, Guo Q, Yamauchi Y, Alamri H, Alothman Z, Hossain M, Liu Y. Synthesis of nanosized composite powders via a wet chemical process for sintering high performance W-Y2O3 alloy. Int J Refract Met H. 2017;69:266.

Zhao M, Luo L, Lin J, Zan X, Zhu X, Luo G, Wu Y. Thermal shock behavior of W-0.5wt% Y2O3 alloy prepared via a novel chemical method. J Nucl Mater. 2016;479:616.

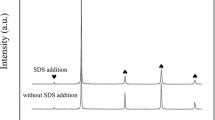

Dong Z, Liu N, Ma Z, Liu C, Guo Q, Alothman Z, Yamauchi Y, Hossain M, Liu Y. Microstructure refinement in W-Y2O3 alloy fabricated by wet chemical method with surfactant addition and subsequent spark plasma sintering. Sci Rep. 2017;7(1):6051.

Battabyal M, Schäubli R, Spaetig P, Baluc N. W-2wt%Y2O3 composite: microstructure and mechanical properties. Mater Sci Eng A. 2012;538:53.

Ding X, Luo L, Huang L, Luo G, Zhu X, Cheng J, Wu Y. Preparation of TiC/W core–shell structured powders by one-step activation and chemical reduction process. J Alloy Compd. 2015;619:704.

Xiao F, Barriere T, Cheng G, Miao Q, Zuo S, Wei S, Xu L. Extremely uniform nanosized oxide particles dispersion strengthened tungsten alloy with high tensile and compressive strengths fabricated involving liquid-liquid method. J Alloy Compd. 2021;878: 160335.

Yang J, Chen G, Chen Z, Mu X, Yu Y, Zhang L, Li X, Qu X, Qin M. Effects of doping route on microstructure and mechanical properties of W−1.0wt%La2O3 alloys. Trans Nonferr Metal Soc. 2020;30:3296.

Rao P, Cai L, Liu C, Cho I, Lee C, Weisse J, Yang P, Zheng X. Simultaneously efficient light absorption and charge separation in WO3/BiVO4 core/shell nanowire photoanode for photoelectrochemical water oxidation. Nano Lett. 2014;14:1099.

Wang X, Meng X, Zhong M, Wu F, Li J. Hydrothermal synthesis of WO3 center dot 0.5H2O microtubes with excellent photocatalytic properties. Appl Surf Sci. 2013;282:826.

Xu L, Yan Q, Xia M, Zhu L. Preparation of La2O3 doped ultra-fine W powders by hydrothermal-hydrogen reduction process. Int J Refract Met H. 2013;36:239.

Wu C. Preparation of ultrafine tungsten powders by in-situ hydrogen reduction of nano-needle violet tungsten oxide. Int J Refract Met Hard Mater. 2011;29:686.

Xiao F, Miao Q, Wei S, Liang W, Fan X, Pan K, Xu L. Hydrothermal synthesis of nanoplates assembled hierarchical h-WO3 microspheres and phase evolution in preparing cubic Zr(Y)O2-doped tungsten powders. Adv Powder Technol. 2018;29:2633.

Dong Z, Ma Z, Dong J, Li C, Yu L, Liu C, Liu Y. The simultaneous improvements of strength and ductility in W-Y2O3 alloy obtained via an alkaline hydrothermal method and subsequent low temperature sintering. Mater Sci Eng A. 2020;784: 139329.

Hu W, Dong Z, Ma Z, Liu Y. W-Y2O3 composite nano-powders prepared by hydrothermal synthesis method: co-deposition mechanism and low temperature sintering characteristics. J Alloy Compd. 2020;821: 153461.

Patil V, Adhyapak P, Suryavanshi S, Mulla I. Oxalic acid induced hydrothermal synthesis of single crystalline tungsten oxide nanorods. J Alloy Compd. 2014;590:283.

Yayapao O, Thongtem T, Phuruangrat A, Thongtem S. CTAB-assisted hydrothermal synthesis of tungsten oxide micro flowers. J Alloy Compd. 2011;509:2294.

Hu W, Dong Z, Ma Z, Liu Y. Microstructure refinement in W-Y2O3 alloys via an improved hydrothermal synthesis method and low temperature sintering. Inorg Chem Front. 2020;7:659.

Xiao F, Miao Q, Wei S, Li Z, Sun T, Xu L. Microstructure and mechanical properties of W-ZrO2 alloys by different preparation techniques. J Alloy Compd. 2019;774:210.

Xiao F, Thierry B, Cheng G, Miao Q, Wei S, Zuo S, Yang Y, Xu L. Research on the effect of liquid-liquid doping processes on the doped powders and microstructures of W-ZrO2(Y) alloys. J Alloy Compd. 2021;855: 157335.

Macinnis M, Kim T. The impact of solvent extraction and ion exchange onthe hydrometallurgy of tungsten and molybdenum. J Chem Technol Biotechnol. 1979;29:225.

Zha S, Fu Q, Lang Y, Xia C, Meng G. Novel azeotropic distillationprocess for synthesizing nanoscale powders of yttria doped ceria electrolyte. Mater Lett. 2001;47:351.

Xiao F, Xu L, Zhou Y, Pan K, Wei S. Phase transformation and microstructure characterization of W-ZrO2 composite powder prepared by azeotropic distillation. Rare Metal Cement Carbides. 2015;43(6):39.

Song X, Qu P, He X, Yang H, Qiu G. Synthesis of ZnO-doped CeO2 nanoparticles by azeotropic distillation processing. Rare Metal Mat Eng. 2006;35(S2):303.

Qiu H, Gao L, Feng C, Guo J, Yan D. Preparation of nanoscale zirconia powder by heterogeneous azeotropic distillation processing. J Inorg Mater. 1994;9:365.

Xu L, Xiao F, Wei S, Zhou Y, Pan K, Li X, Li J, Liu W. Development of tungsten heavy alloy reinforced by cubic zirconia through liquid-liquid doping and mechanical alloying methods. Int J Refract Met H. 2019;78:1.

Dong Z, Liu N, Ma Z, Liu C, Guo Q, Liu Y. Preparation of ultra-fine grain W-Y2O3 alloy by an improved wet chemical method and two-step spark plasma sintering. J Alloy Compd. 2017;695:2969.

Dong Z, Liu N, Hu W, Ma Z, Li C, Liu C, Guo Q, Liu Y. Controlled synthesis of high-quality W-Y2O3 composite powder precursor by ascertaining the synthesis mechanism behind the wet chemical method. J Mater Sci Technol. 2020;36:118.

Kalyan K, Sahoo P, Vimala J, Shanker B, Ghosal P, Durai L. Synthesis of high purity tungsten nanoparticles from tungsten heavy alloy scrap by selective precipitation and reduction route. J Alloy Compd. 2016;678:403.

Gustafsson J. Modelling molybdate and tungstate adsorption to ferrihydrite. Chem Geol. 2003;200:105.

Brinker C. Sol-gel science: the physics and chemistry of sol-gel processing. Boston: Academic Press; 1990. p. 164.

Latthe S, Imai H, Ganesan V, Rao A. Superhydrophobic silica films by sol-gel co-precursor method. Appl Surf Sci. 2009;256(1):217.

Schubert W, Lassner E. Production and characterization of hydrogen reduced submicron tungsten powders. Part II: controlled decomposition of APT and hydrogen reduction of the oxides. Int J Refract Met H. 1991;10:171.

Liu R, Wang X, Hao T, Liu C, Fang Q. Characterization of ODS-tungsten microwave-sintered from sol-gel prepared nano-powders. J Nucl Mater. 2014;450(1):69.

Liu R, Xie Z, Fang Q, Zhang T, Wang X, Hao T, Liu C, Dai Y. Nanostructured yttria dispersion-strengthened tungsten synthesized by sol-gel method. J Alloy Compd. 2016;657:73.

Fan J, Han Y, Li P, Sun Z, Zhou Q. Micro/nano composited tungsten materials and its high thermal loading behavior. J Nucl Mater. 2014;455:717.

Mecandlish L, Kera B, Kim B. Processing and properties of nanostructure WC-Co. Nanostruct Mater. 1992;1(2):119.

Shi X, Yang H, Wan G. Spark sintering of W-15Cu alloy from ultra composite powder prepared by spray drying and calcining-continuous reduction technology. Mater Characte. 2009;60(2):133.

Cui Y, Wang J, Liu W, Wang Y, Zhou M. Characterization of scandia doped pressed cathode fabricated by spray drying method. Appl Surf Sci. 2011;258:327.

Cui Y, Wang J, Liu W, Wang X. Effect of scandia on tungsten oxide powder reduction process. J Rare Earth. 2010;28:202.

Shu J, Shi X, Wang S, Yang X, Zhang Q, Wang Y. Microwave sintering of W-15Cu ultrafine composite powder prepared by spray drying & calcining continuous reduction technology. J Wuhan Univ Technol Mater Sci Edit. 2011;26(2):280.

Lv Y, Fan J, Han Y, Liu T, Li P, Yan H. The influence of modification route on the properties of W-0.3wt%Y2O3 powder and alloy prepared by nano-in-situ composite method. J Alloy Compd. 2018;774:1140.

Xi X, Chen G, Nie Z, He S, Pi X, Zhu X, Zhu J, Zuo T. Preparation and performance of LiFePO4 and LiFePO4/C cathodes by freeze-drying. J Alloy Compd. 2010;497:377.

Dong Z, Ma Z, Yu L, Liu Y. Achieving high strength and ductility in ODS-W alloy by employing oxide@W core-shell nano powder as precursor. Nat Commun. 2021;12:5052.

Hu W, Yu L, Ma Z, Liu Y. W-Y2O3 composite nano powders prepared by freeze-drying method and its sintering characteristic. J Alloy Compd. 2019;806:127.

Hu W, Dong Z, Yu L, Ma Z, Liu Y. Synthesis of W- Y2O3 alloys by freeze-drying and subsequent low temperature sintering: microstructure refinement and second phase particles regulation. J Mater Sci Technol. 2020;36:84.

Dong Z, Hu W, Ma Z, Li C, Liu Y. The synthesis of composite powder precursors via chemical processes for the sintering of oxide dispersion-strengthened alloys. Mater Chem Front. 2019;3(10):1952.

Zawrah M, Zayed H, Essawy R, Nassar A, Taha M. Preparation by mechanical alloying, characterization and sintering of Cu-20 wt% Al2O3 nanocomposites. Mater Des. 2013;46:485.

Hasany S, Rehman A, Jose R, Ahmed I. Iron oxide magnetic nanoparticles: a short review. J Appl Phys. 2012;1:298.

Yar M, Wahlberg S, Bergqvist H, Salem H, Johnsson M, Muhammed M. Chemically produced nanostructured ODS-lanthanum oxide-tungsten composites sintered by spark plasma. J Nucl Mater. 2011;408:129.

Xiao F, Miao Q, Wei S, Thierry B, Cheng G, Zuo S, Xu L. Uniform nanosized oxide particles dispersion strengthened tungsten alloy fabricated involving hydrothermal method and hot isostatic pressing. J Alloy Compd. 2020;824: 153894.

Kim Y, Lee K, Kim E, Cheong D, Hong S. Fabrication of high temperature oxides dispersion strengthened tungsten composites by spark plasma sintering process. Int J Refract Met H. 2009;27(5):842.

Battabyal M, Spaetig P, Baluc N. Effect of ion-irradiation on the microstructure and microhardness of the W-2Y2O3 composite materials fabricated by sintering and hot forging. Fusion Eng Des. 2013;88(9):1668.

Battabyal M, Veleva L, Schaeublin R, Plociski T, Baluc N. Investigation of microstructure and mechanical properties of W-Y and W-Y2O3 materials fabricated by powder metallurgy method. Int J Refract Met H. 2015;50:210.

Liu R, Zhou Y, Hao T, Zhang T, Wang X, Liu C, Fang Q. Microwave synthesis and properties of fine-grained oxides dispersion strengthened tungsten. J Nucl Mater. 2012;424(1):171.

Zhao M, Zhou Z, Ding Q, Zhong M, Kameel A. Effect of rare earth elements on the consolidation behavior and microstructure of tungsten alloys. Int J Refract Met H. 2015;48:19.

Zhao M, Zhou Z, Ding Q, Zhong M, Tan J. The investigation of Y doping content effect on the micro structure and microhardness of tungsten materials. Mater Sci Eng A. 2014;618:572.

Wang C, Zhang L, Wei S, Wu X, Li Q. Preparation, microstructure, and constitutive equation of W-0.25wt% Al2O3 alloy. Mater Sci Eng A. 2019;744:79.

Kim Y, Hong M, Lee S, Kim E, Lee S, Nohl J. The effect of yttrium oxide on the sintering behavior and hardness of tungsten. Metals Mater Int. 2006;12(3):245.

Ding X, Luo L, Lu Z, Luo G, Zhu X, Zan X, Cheng J, Wu Y. Chemically produced tungsten-praseodymium oxide composite sintered by spark plasma sintering. J Nucl Mater. 2014;454:200.

Li Z, Xu L, Wei S, Chen C, Xiao F. Fabrication and mechanical properties of tungsten alloys reinforced with c-ZrO2 particles. J Alloy Compd. 2018;769:694.

Li Z, Chen Y, Wei S, Xiao F, Hussain S, Xu L. Flow behavior and processing map for hot deformation of W-1.5ZrO2 alloy. J Alloy Compd. 2019;802:118.

Wang C, Zhang L, Wei S, Pan K, Mark A, Yang Y. Microstructure and preparation of an ultra-fine-grained W-Al2O3 composite via hydrothermal synthesis and spark plasma sintering. Int J Refract Met H. 2018;72:149.

Wang C, Zhang L, Wei S, Li X, Wu X, Li Q, Pan K. Establishment of processing map, microstructure and high-temperature tensile properties of W-0.25wt% Al2O3 alloys. J Alloy Compd. 2020;831:154751.

Tan X, Luo L, Chen H, Zhu X, Zan X, Luo G, Chen J, Li P, Cheng J, Liu D, Wu Y. Mechanical properties and microstructural change of W-Y2O3 alloy under helium irradiation. Sci Rep. 2015;5(1):12755.

Ding X, Luo L, Chen H, Zhu X, Zan X, Cheng J, Wu Y. Chemical synthesis and oxide dispersion properties of strengthened tungsten via spark plasma sintering. Materials. 2016;9(11):879.

Zhao M, Zhou Z, Zhong M, Lian Y, Tan J, Liu X. Thermal shock behavior of fine-grained W-Y2O3 materials fabricated via two different manufacturing technologies. J Nucl Mater. 2016;470:236.

Xiao F, Miao Q, Barriere T, Cheng G, Zuo S, Xu L. A study on the effect of solution acidity on the microstructure, mechanical, and wear properties of tungsten alloys reinforced by yttria-stabilised zirconia particles. Mater Today Commun. 2021;27: 102223.

Xiao F, Barriere T, Cheng G, Miao Q, Zuo S, Xu L. Investigation of solution acidity influence on the morphological structure and physical and mechanical properties of particle-reinforced tungsten alloys. Int J Adv Manuf Technol. 2021;116:439.

Li Z, Chen Y, Wei S, Pan K, Shen H, Xu L. Effect of rotary swaging and subsequent annealing on microstructure and mechanical properties of W-1.5ZrO2 alloys. J Alloy Compd. 2021;875:160041.

Yao G, Liu X, Zhao Z, Luo L, Cheng J, Zan X, Wang Z, Xu Q, Wu Y. Excellent performance of W-Y2O3 composite via powder process improvement and Y2O3 refinement. Mater Des. 2021;212: 110249.

Yao G, Chen H, Zhao Z, Luo L, Ma Y, Cheng J, Zan X, Xu Q, Wu Y. The superior thermal stability and irradiation resistance capacities of tungsten composites synthesized by simple second-phase particle component modulation. J Nucl Mater. 2022;561: 153522.

Acknowledgements

This work is supported by National Natural Science Foundation of China (no. U2004180).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, LJ., Li, Z., Xiao, FN. et al. Properties and microstructure of oxide dispersion strengthened tungsten alloy prepared by liquid-phase method: a review. Tungsten 5, 481–502 (2023). https://doi.org/10.1007/s42864-022-00180-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-022-00180-3