Abstract

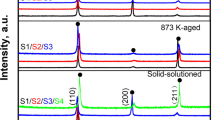

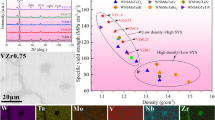

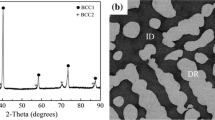

The refractory high entropy alloys (RHEAs) containing disordered body-centered cubic (BCC) and ordered BCC (B2) structures often exhibit high strength but low ductility at room temperature, even in the compressive tests. In this study, (Ta25-xNb25Zr25Ti25+x)95Al5 (x = 0, 5, 10) RHEAs are fabricated to investigate the compositional dependence of the microstructures and mechanical properties. All the three alloys exhibit a single BCC structure at the as-cast and solution-treated states, while the basket weave-like microstructures consisting of cuboidal and strip-like phases are formed after aging at 600 °C. The microstructure of the aged alloys is sensitive to the compositions: only disordered BCC1 + BCC2 dual phases are observed in the (Ta25Nb25Zr25Ti25)95Al5 alloy; additional B2 phases are formed by replacing 5 at% Ta with Ti; a complex microstructure containing BCC1 + BCC2 + B2 + Omega phases are identified in the (Ta15Nb25Zr25Ti35)95Al5 alloy. Although replacing Ta with Ti results in a reduction of compressive yield strength from 1762 to 1243 MPa, the fracture strain is greatly enhanced from 7.3 to 44.3%, indicating that the strength-ductility balance can be tuned to a large extent in this RHEA system.

Similar content being viewed by others

References

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT, Tsau CH, Chang SY. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater. 2004;6(5):299.

Cantor B, Chang I, Knight P, Vincent A. Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng A. 2004;375:213.

Wu Z, Bei H, Pharr GM, George EP. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014;81:428.

Shi P, Ren W, Zheng T, Ren Z, Hou X, Peng J, Hu P, Gao Y, Zhong Y, Liaw PK. Enhanced strength-ductility synergy in ultrafine-grained eutectic high-entropy alloys by inheriting microstructural lamellae. Nat Commun. 2019;10(1):489.

Xu Z, Li Z, Tong Y, Zhang W, Wu Z. Microstructural and mechanical behavior of a CoCrFeNiCu4 non-equiatomic high entropy alloy. J Mater Sci Technol. 2021;60:35.

Jiang H, Han K, Gao X, Lu Y, Cao Z, Gao MC, Hawk JA, Li T. A new strategy to design eutectic high-entropy alloys using simple mixture method. Mater Des. 2018;142:101.

Lu Y, Gao X, Jiang L, Chen Z, Wang T, Jie J, Kang H, Zhang Y, Guo S, Ruan H. Directly cast bulk eutectic and near-eutectic high entropy alloys with balanced strength and ductility in a wide temperature range. Acta Mater. 2017;124:143.

Jin K, Sales BC, Stocks GM, Samolyuk GD, Daene M, Weber WJ, Zhang Y, Bei H. Tailoring the physical properties of Ni-based single-phase equiatomic alloys by modifying the chemical complexity. Sci Rep. 2016;6:20159.

Mu S, Pei Z, Liu X, Stocks GM. Electronic transport and phonon properties of maximally disordered alloys: from binaries to high-entropy alloys. J Mater Res. 2018;33(19):2857.

Senkov ON, Wilks GB, Scott JM, Miracle DB. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics. 2011;19(5):698.

Senkov ON, Scott JM, Senkova SV, Meisenkothen F, Miracle DB, Woodward CF. Microstructure and elevated temperature properties of a refractory TaNbHfZrTi alloy. J Mater Sci. 2012;47(9):4062.

Zou Y, Maiti S, Steurer W, Spolenak R. Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy. Acta Mater. 2014;65:85.

Yao HW, Qiao JW, Gao MC, Hawk JA, Ma SG, Zhou HF, Zhang Y. NbTaV-(Ti, W) refractory high-entropy alloys: experiments and modeling. Mater Sci Eng, A. 2016;674:203.

Feuerbacher M, Lienig T, Thomas C. A single-phase bcc high-entropy alloy in the refractory Zr-Nb-Ti-V-Hf system. Scripta Mater. 2018;152:40.

An Z, Mao S, Liu Y, Wang L, Zhou H, Gan B, Zhang Z, Han X. A novel HfNbTaTiV high-entropy alloy of superior mechanical properties designed on the principle of maximum lattice distortion. J Mater Sci Technol. 2021;79:109.

Li Z, Wang Z, Wu Z, Xu B, Zhao S, Zhang W, Lin N. Phase, microstructure and related mechanical properties of a series of (NbTaZr)C-Based high entropy ceramics. Ceram Int. 2021;47(10):14341.

He JY, Wang H, Huang HL, Xu XD, Chen MW, Wu Y, Liu XJ, Nieh TG, An K, Lu ZP. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016;102:187.

He JY, Wang H, Wu Y, Liu XJ, Mao HH, Nieh TG, Lu ZP. Precipitation behavior and its effects on tensile properties of FeCoNiCr high-entropy alloys. Intermetallics. 2016;79:41.

Peng H, Hu L, Li L, Zhang W. Ripening of L12 nanoparticles and their effects on mechanical properties of Ni28Co28Fe21Cr15Al4Ti4 high-entropy alloys. Mater Sci Eng A. 2020;772:138803.

Jensen JK, Welk BA, Williams REA, Sosa JM, Huber DE, Senkov ON, Viswanathan GB, Fraser HL. Characterization of the microstructure of the compositionally complex alloy Al1Mo0.5Nb1Ta0.5Ti1Zr1. Scripta Mater. 2016;121:1.

Senkov ON, Jensen JK, Pilchak AL, Miracle DB, Fraser HL. Compositional variation effects on the microstructure and properties of a refractory high-entropy superalloy AlMo0.5NbTa0.5TiZr. Mater Des. 2018;139:498.

Whitfield TE, Pickering EJ, Owen LR, Jones CN, Stone HJ, Jones NG. The effect of Al on the formation and stability of a BCC–B2 microstructure in a refractory metal high entropy superalloy system. Materialia. 2020;13:100858.

Whitfield TE, Pickering EJ, Christofidou KA, Jones CN, Stone HJ, Jones NG. Elucidating the microstructural development of refractory metal high entropy superalloys via the Ti–Ta–Zr constituent system. J Alloys Compd. 2020;818:152935.

Zhang JX, Wang JC, Harada H, Koizumi Y. The effect of lattice misfit on the dislocation motion in superalloys during high-temperature low-stress creep. Acta Mater. 2005;53(17):4623.

Van Sluytman JS, Pollock TM. Optimal precipitate shapes in nickel-base γ–γ′ alloys. Acta Mater. 2012;60(4):1771.

Zhang J, Huang T, Cao K, Chen J, Zong H, Wang D, Zhang J, Zhang J, Liu L. A correlative multidimensional study of γ′ precipitates with Ta addition in Re-containing Ni-based single crystal superalloys. J Mater Sci Technol. 2021;75:68.

Chen W, Tang QH, Wang H, Xie YC, Yan XH, Dai PQ. Microstructure and mechanical properties of a novel refractory AlNbTiZr high-entropy alloy. Mater Sci Technol. 2018;34(11):1309.

Soni V, Senkov ON, Gwalani B, Miracle DB, Banerjee R. Microstructural design for improving ductility of an initially brittle refractory high entropy alloy. Sci Rep. 2018;8(1):8816.

Soni V, Gwalani B, Alam T, Dasari S, Zheng Y, Senkov ON, Miracle D, Banerjee R. Phase inversion in a two-phase, BCC+B2, refractory high entropy alloy. Acta Mater. 2020;185:89.

Wang Q, Han J, Liu Y, Zhang Z, Dong C, Liaw PK. Coherent precipitation and stability of cuboidal nanoparticles in body-centered-cubic Al0.4Nb0.5Ta0.5TiZr0.8 refractory high entropy alloy. Scripta Mater. 2021;190:40ss.

Nguyen VT, Qian M, Shi Z, Song T, Huang L, Zou J. Compositional design of strong and ductile (tensile) Ti-Zr-Nb-Ta medium entropy alloys (MEAs) using the atomic mismatch approach. Mater Sci Eng A. 2019;742:762.

Nguyen VT. Equiatomic and non-equiatomic Ti-Zr-Nb-Ta refractory medium entropy alloys. PhD Thesis, Queenslan: The University of Queensland, 2020.

Nguyen VT, Qian M, Shi Z, Tran XQ, Fabijanic DM, Joseph J, Qu DD, Matsumura S, Zhang C, Zhang F, Zou J. Cuboid-like nanostructure strengthened equiatomic Ti–Zr–Nb–Ta medium entropy alloy. Mater Sci Eng A. 2020;798:140169.

Yang M, Shao L, Duan JM, Chen XT, Tang BY. Temperature dependence of mechanical and thermodynamic properties of Ti(25+x)Zr25Nb25Ta(25–x) (x ≤ 20) refractory high entropy alloys: influences of substitution of Ti for Ta. Phys B. 2021;606:412851.

Wang W, Zhang Z, Niu J, Wu H, Zhai S, Wang Y. Effect of Al addition on structural evolution and mechanical properties of the AlxHfNbTiZr high-entropy alloys. Mater Today Communs. 2018;16:242.

Xu ZQ, Ma ZL, Wang M, Chen YW, Tan YD, Cheng XW. Design of novel low-density refractory high entropy alloys for high-temperature applications. Mater Sci Eng A. 2019;755:318.

Maiti S, Steurer W. Structural-disorder and its effect on mechanical properties in single-phase TaNbHfZr high-entropy alloy. Acta Mater. 2016;106:87.

Ng HP, Devaraj A, Nag S, Bettles CJ, Gibson M, Fraser HL, Muddle BC, Banerjee R. Phase separation and formation of omega phase in the beta matrix of a Ti–V–Cu alloy. Acta Mater. 2011;59(8):2981.

De Fontaine D. Mechanical instabilities in the bcc lattice and the beta to omega phase transformation. Acta Metall. 1970;18(2):275.

Bendersky L, Boettinger W, Burton B, Biancaniello F, Shoemaker C. The formation of ordered ω-related phases in alloys of composition Ti4Al3Nb. Acta Metall Mater. 1990;38(6):931.

Wang X, Yang J, Song L, Kou H, Li J, Fu H. Evolution of B2 (ω) region in high-Nb containing TiAl alloy in intermediate temperature range. Intermetallics. 2017;82:32.

Soni V, Senkov O, Couzinie JP, Zheng Y, Gwalani B, Banerjee R. Phase stability and microstructure evolution in a ductile refractory high entropy alloy Al10Nb15Ta5Ti30Zr40. Materialia. 2020;9:100569.

Soni V, Gwalani B, Senkov ON, Viswanathan B, Alam T, Miracle DB, Banerjee R. Phase stability as a function of temperature in a refractory high-entropy alloy. J Mater Res. 2018;33(19):3235.

Senkov ON, Woodward C, Miracle DB. Microstructure and Properties of Aluminum-containing refractory high-entropy alloys. Jom. 2014;66(10):2030.

Zhang Y, Zhou YJ, Lin JP, Chen GL, Liaw PK. Solid-solution phase formation rules for multi-component alloys. Adv Eng Mater. 2008;10(6):534.

Senkov ON, Miracle DB, Rao SI. Correlations to improve room temperature ductility of refractory complex concentrated alloys. Mater Sci Eng A. 2021;820:141512.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 11905008).

Author information

Authors and Affiliations

Contributions

Ya-Guang Dong wrote the draft; Ya-Guang Dong, Shang Chen, Nan-Nan Jia, and Qiu-Hong Zhang collected the data; Liang Wang, Yun-Fei Xue, and Ke Jin contributed to conceive the idea of the study. All authors contributed to the writing the revisions.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dong, YG., Chen, S., Jia, NN. et al. Microstructures and mechanical properties of Ta–Nb–Zr–Ti–Al refractory high entropy alloys with varying Ta/Ti ratios. Tungsten 3, 406–414 (2021). https://doi.org/10.1007/s42864-021-00111-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-021-00111-8