Abstract

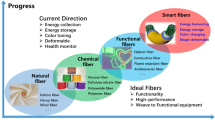

Conventional electronic devices with bulky and rigid features cannot fully meet the requirements of flexibility and wearability in wearable applications. Fiber-shaped electronic devices have been intensively pursued in the past decade attributed to their excellent flexibility, weavability and wearability. The innovation of novel functions has been widely recognized as an emerging direction of fiber-shaped electronic devices, pursuing a better adaptability and longer lifetime in practical applications. In this Review, we summarize the recent advances of functional fiber devices, focusing on the preparation of functional fiber electrodes and electrolytes, as well as the formed interfaces. Fiber devices with a variety of novel functions are systematically introduced, including but not limited to stretchability, healability, shape memory and electrochromism. The remaining challenges and opportunities are also discussed to propose future directions for functionalization of fiber electronics.

Copyright 2013, Wiley–VCH. b The pre-strain process for production of a stretchable fiber electrode [53]. Reproduced with permission. Copyright 2015, Wiley–VCH. c Functional guests and aligned MWCNT sheets stacked together (scale bar: 250 μm). d The preparation of functional fiber electrode using a biscrolling method. The numbers at the left bottom corner represent the twisting turns [54]. Reproduced with permission. Copyright 2011, AAAS. e A continuous process for production of Fe3O4/MWCNT fibers with magnetic response (scale bar: 1 cm) [55]. Reproduced with permission. Copyright 2013, Wiley–VCH

Copyright 2011, Nature Publishing Group. d Stretchability demonstration of an rGO-based fiber spring [57]. Reproduced with permission. Copyright 2017, American Chemical Society. e CareGum fiber prepared via a wet-spinning method with self-healing ability [58]. Reproduced with permission. Copyright 2021, Wiley–VCH

Copyright 2013, Wiley–VCH. b The cross section of a self-healing fiber showing the interface between aligned MWCNT sheets and self-healing polymer (scale bar: 3 μm). c The “bridge” structure formed between the broken ends after healing (scale bar: 5 μm) [32]. Reproduced with permission. Copyright 2014, Wiley–VCH. d Cross-sectional SEM image of a 3D printing fiber electrode coated with a PVDF-co-HFP gel (scale bar: 25 μm) [59]. Reproduced with permission. Copyright 2017, Wiley–VCH. e SEM images of bare aligned MWCNTs (scale bar: 500 nm) and MWCNT/PANI composites (inset, scale bar: 100 nm) [60]. Reproduced with permission. Copyright 2013, The Royal Society of Chemistry. f The structure of fiber-shaped dye-sensitized solar cell and the chemical structure of the ionic liquid gel electrolyte [63]. Reproduced with permission. Copyright 2015, Wiley–VCH

Copyright 2013, Wiley–VCH. c Schematic illustration of the fiber device parallel-twisted around a spandex fiber to realize stretchability. d The stretchability demonstration of the fiber-shaped Zn-ion battery [64]. Reproduced with permission. Copyright 2021, American Chemical Society. e Schematic illustration of the stretchable Archimedean spiral-like Li metal electrode [67]. Reproduced with permission. Copyright 2018, Elsevier. f SEM images of a MWCNT fiber spring at different strains of 0%, 50% and 100% (scale bar: 40 μm) [70]. Reproduced with permission. Copyright 2014, Wiley–VCH

Copyright 2015, Wiley–VCH. c Schematic illustration to the self-healing process of a fiber-shaped supercapacitor [32]. Reproduced with permission. Copyright 2014, Wiley–VCH. d Cyclic voltammetry curves of self-healing supercapacitors with rGO fiber electrode [57]. Reproduced with permission. Copyright 2017, American Chemical Society. e The specific capacitance retention of a magnet-assistant self-healing supercapacitor at different healing cycles [78]. Reproduced with permission. Copyright 2015, American Chemical Society. f Schematic illustration of the self-healing mechanism of a fiber-shaped lithium-ion battery [80]. Reproduced with permission. Copyright 2018, Elsevier

Copyright 2014, Wiley–VCH. b Schematic illustration of an electrochromic fiber based on the parallel dual-counter-electrode structure. c Photograph of long electrochromic fibers with lengths of hundreds of meters (scale bar: 10 cm) [83]. Reproduced with permission. Copyright 2020, American Chemical Society. d TEM image of a MWCNTs (scale bar: 3 nm); SEM images of a single-ply fiber (scale bar: 6 μm) and multi-ply sensing fiber bundle (scale bar: 20 μm). e Injection of the fiber sensor into blood vessel [91]. Reproduced with permission. Copyright 2020, Nature Publishing Group. f Spherical load produced a synergistic response of the forward and backward movement with the stimulation of infrared radiation light and moisture [99]. Reproduced with permission. Copyright 2021, American Chemical Society

Copyright 2017, Nature Publishing Group. b Exploration of new functions such as anti-radiation, self-cleaning and thermal resistance. c Integration of multiple functions into one fiber device. d Large-scale fabrication of functional fiber devices based on a continuous production strategy [104]. Reproduced with permission. Copyright 2015, Wiley–VCH

Similar content being viewed by others

References

Lee GH, Moon H, Kim H, Lee GH, Kwon W, Yoo S, Myung D, Yun SH, Bao Z, Hahn SK. Multifunctional materials for implantable and wearable photonic healthcare devices. Nat Rev Mater 2020;5:149.

Zeng W, Shu L, Li Q, Chen S, Wang F, Tao XM. Fiber-based wearable electronics: a review of materials, fabrication, devices, and applications. Adv Mater 2014;26:5310.

Hashemi SA, Ramakrishna S, Aberle AG. Recent progress in flexible-wearable solar cells for self-powered electronic devices. Energ Environ Sci 2020;13:685.

Zhu S, Ni JF, Li Y. Carbon nanotube-based electrodes for flexible supercapacitors. Nano Res 1825;2020:13.

Sun H, Zhang Y, Zhang J, Sun XM, Peng HS. Energy harvesting and storage in 1D devices. Nat Rev Mater 2017;2:1.

Kang M, Kim TW. Recent advances in fiber-shaped electronic devices for wearable applications. Appl Sci 2021;11:6131.

Wang X, Jiang K, Shen G. Flexible fiber energy storage and integrated devices: recent progress and perspectives. Mater Today 2015;18:265.

Jin L, Xiao X, Deng W, Nashalian A, He D, Raveendran V, Yan C, Su H, Chu X, Yang T. Manipulating relative permittivity for high-performance wearable triboelectric nanogenerators. Nano Lett 2020;20:6404.

Chen G, Li Y, Bick M, Chen J. Smart textiles for electricity generation. Chem Rev 2020;120:3668.

Shen S, Xiao X, Chen J. Wearable triboelectric nanogenerators for heart rate monitoring. Chem Commun 2021;57:5871.

Zhang S, Bick M, Xiao X, Chen G, Nashalian A, Chen J. Leveraging triboelectric nanogenerators for bioengineering Matter 2021;4:845.

Xiao X, Chen GR, Libanori A, Chen J. Wearable Triboelectric nanogenerators for therapeutics. Trends Chem 2021;3:279.

Zou D, Wang D, Chu Z, Lv Z, Fan X. Fiber-shaped flexible solar cells. Coord Chem Rev 2010;254:1169.

Casadio S, Sangiorgi N, Sangiorgi A, Dessì A, Zani L, Calamante M, Reginato G, Mordini A, Sanson A. Highly efficient long thin-film fiber-shaped dye sensitized solar cells based on a fully organic sensitizer. Sol Energy Mater Sol Cells. 2021;224:110986.

Dong YH, Zou YS, Song JZ, Zhu ZF, Li JH, Zeng HB. Self-powered fiber-shaped wearable omnidirectional photodetectors. Nano Energy 2016;30:173.

Chu X, Chen GR, Xiao X, Wang ZX, Yang T, Xu Z, Huang HC, Wang YH, Yan C, Chen NJ, Zhang HT, Yang WQ, Chen J. Air-stable conductive polymer ink for printed wearable micro-supercapacitors. Small 2021;17:2100956.

Duan M, Ren Y, Sun X, Zhu X, Wang X, Sheng L, Liu J. EGaIn fiber enabled highly flexible supercapacitors. ACS Omega 2021;6:24444.

Mo F, Liang G, Huang Z, Li H, Wang D, Zhi C. An overview of fiber-shaped batteries with a focus on multifunctionality, scalability, and technical difficulties. Adv Mater 2020;32:1902151.

Shi FY, Chen CH, Xu ZL. Recent advances on electrospun nanofiber materials for post-lithium ion batteries. Adv Fiber Mater 2021;3:275.

Chong WG, Huang JQ, Xu ZL, Qin X, Wang X, Kim JK. Lithium–sulfur battery cable made from ultralight, flexible graphene/carbon nanotube/sulfur composite fibers. Adv Funct Mater 2017;27:1604815.

Ouyang Y, Zong W, Wang J, Xu Z, Mo L, Lai F, Xu Z-L, Miao Y-E, Liu T. Multi-scale uniform Li regulation triggered by tunable electric field distribution on oxygen-functionalized porous framework for flexible Li-S full batteries. Energy Stor Mater 2021;42:68.

Feng JY, Chen CR, Sun XM, Peng HS. Implantable fiber biosensors based on carbon nanotubes. Accounts Mater Res 2021;2:138.

Wang Y, Zhou Z, Qing X, Zhong W, Liu Q, Wang W, Li M, Liu K, Wang D. Ion sensors based on novel fiber organic electrochemical transistors for lead ion detection. Anal Bioanal Chem 2016;408:5779.

Wu R, Ma L, Hou C, Meng Z, Guo W, Yu W, Yu R, Hu F, Liu XY. Silk composite electronic textile sensor for high space precision 2D combo temperature–pressure sensing. Small 2019;15:1901558.

Leng XQ, Hu XY, Zhao WB, An BG, Zhou X, Liu ZF. Recent advances in twisted-fiber artificial muscles. Adv Intell Syst 2021;3:2000185.

He S, Chen P, Qiu L, Wang B, Sun X, Xu Y, Peng H. A mechanically actuating carbon-nanotube fiber in response to water and moisture. Angew Chem Int Ed 2015;54:14880.

Chen P, Xu Y, He S, Sun X, Pan S, Deng J, Chen D, Peng H. Hierarchically arranged helical fibre actuators driven by solvents and vapours. Nat Nanotechnol 2015;10:1077.

He J, Lu C, Jiang H, Han F, Shi X, Wu J, Wang L, Chen T, Wang J, Zhang Y, Yang H, Zhang G, Sun X, Wang B, Chen P, Wang Y, Xia Y, Peng H. Scalable production of high-performing woven lithium-ion fibre batteries. Nature 2021;597:57.

Deng J, Zhang Y, Zhao Y, Chen P, Cheng X, Peng H. A shape-memory supercapacitor fiber. Angew Chem Int Ed 2015;54:15419.

Chen X, Lin H, Deng J, Zhang Y, Sun X, Chen P, Fang X, Zhang Z, Guan G, Peng H. Electrochromic fiber-shaped supercapacitors. Adv Mater 2014;26:8126.

Yang Z, Deng J, Chen X, Ren J, Peng H. A highly stretchable, fiber-shaped supercapacitor. Angew Chem Int Ed 2013;52:13453.

Sun H, You X, Jiang Y, Guan G, Fang X, Deng J, Chen P, Luo Y, Peng H. Self-healable electrically conducting wires for wearable microelectronics. Angew Chem Int Ed 2014;53:9526.

Zhang X, Lin H, Shang H, Xu J, Zhu J, Huang W. Recent advances in functional fiber electronics. SusMat 2021;1:105.

Wang L, Fu X, He J, Shi X, Chen T, Chen P, Wang B, Peng H. Application challenges in fiber and textile electronics. Adv Mater. 2020;32:e1901971.

Fakharuddin A, Li HZ, Di Giacomo F, Zhang TY, Gasparini N, Elezzabi AY, Mohanty A, Ramadoss A, Ling J, Soultati A, Tountas M, Schmidt-Mende L, Argitis P, Jose R, Nazeeruddin MK, Yusoff AB, Vasilopoulou M. Fiber-Shaped Electron Devices Adv Energy Mater 2021;11:2101443.

Hou SC, Lv ZB, Wu HW, Cai X, Chu ZZ, Yiliguma, Zou DC. Flexible conductive threads for wearable dye-sensitized solar cells. J Mater Chem. 2012; 22:6549.

Kim B, Koncar V, Devaux E, Dufour C, Viallier P. Electrical and morphological properties of PP and PET conductive polymer fibers. Synth Met 2004;146:167.

Kaynak A, Najar SS, Foitzik RC. Conducting nylon, cotton and wool yarns by continuous vapor polymerization of pyrrole. Synth Met 2008;158:1.

Gasana E, Westbroek P, Hakuzimana J, De Clerck K, Priniotakis G, Kiekens P, Tseles D. Electroconductive textile structures through electroless deposition of polypyrrole and copper at polyaramide surfaces. Surf Coat Technol 2006;201:3547.

Abbasi AR, Akhbari K, Morsali A. Dense coating of surface mounted CuBTC metal–organic framework nanostructures on silk fibers, prepared by layer-by-layer method under ultrasound irradiation with antibacterial activity. Ultrason Sonochem 2012;19:846.

Zhao Y, Dong D, Wang Y, Gong S, An T, Yap LW, Cheng W. Highly stretchable fiber-shaped supercapacitors based on ultrathin gold nanowires with double-helix winding design. ACS Appl Mater Interfaces 2018;10:42612.

Tebyetekerwa M, Xu Z, Li W, Wang X, Marriam I, Peng S, Ramkrishna S, Yang S, Zhu M. Surface self-assembly of functional electroactive nanofibers on textile yarns as a facile approach toward super flexible energy storage. ACS Appl Energy Mater 2018;1:377.

Yin Z, Jian M, Wang C, Xia K, Liu Z, Wang Q, Zhang M, Wang H, Liang X, Liang X. Splash-resistant and light-weight silk-sheathed wires for textile electronics. Nano Lett 2018;18:7085.

Shao W, Tebyetekerwa M, Marriam I, Li W, Wu Y, Peng S, Ramakrishna S, Yang S, Zhu M. Polyester@ MXene nanofibers-based yarn electrodes. J Power Sources 2018;396:683.

Yang QY, Xu Z, Gao C. Graphene fiber based supercapacitors: strategies and perspective toward high performances. J Energy Chem 2018;27:6.

Wu JX, Hong Y, Wang BJ. The applications of carbon nanomaterials in fiber-shaped energy storage devices. J Semicond. 2018; 39:011004.

Jang Y, Kim SM, Spinks GM, Kim SJ. Carbon nanotube yarn for fiber-shaped electrical sensors, actuators, and energy storage for smart systems. Adv Mater 2020;32:1902670.

Benzigar MR, Dasireddy VDBC, Guan XW, Wu T, Liu GZ. Advances on emerging materials for flexible supercapacitors: current trends and beyond. Adv Funct Mater 2020;30:2002993.

Meng WS, Nie MY, Liu ZY, Zhou J. Buckled fiber conductors with resistance stability under strain. Adv Fiber Mater 2021;3:149.

Zhang T, Zong W, Ouyang Y, Wu Y, Miao Y-E, Liu T. Carbon fiber supported binary metal sulfide catalysts with multi-dimensional structures for electrocatalytic nitrogen reduction reactions over a wide pH range. Adv Fiber Mater 2021;3:229.

Wang JN, Luo XG, Wu T, Chen Y. High-strength carbon nanotube fibre-like ribbon with high ductility and high electrical conductivity. Nat Commun 2014;5:3848.

Oh E, Cho H, Kim J, Kim JE, Yi Y, Choi J, Lee H, Im YH, Lee KH, Lee WJ. Super-strong carbon nanotube fibers achieved by engineering gas flow and postsynthesis treatment. ACS Appl Mater Interfaces 2020;12:13107.

Zhang Z, Deng J, Li X, Yang Z, He S, Chen X, Guan G, Ren J, Peng H. Superelastic supercapacitors with high performances during stretching. Adv Mater 2015;27:356.

Lima MD, Fang SL, Lepro X, Lewis C, Ovalle-Robles R, Carretero-Gonzalez J, Castillo-Martinez E, Kozlov ME, Oh JY, Rawat N, Haines CS, Haque MH, Aare V, Stoughton S, Zakhidov AA, Baughman RH. Biscrolling nanotube sheets and functional guests into yarns. Science 2011;331:51.

Sun H, Yang Z, Chen X, Qiu L, You X, Chen P, Peng H. Photovoltaic wire with high efficiency attached onto and detached from a substrate using a magnetic field. Angew Chem Int Ed 2013;52:8276.

Xu Z, Gao C. Graphene chiral liquid crystals and macroscopic assembled fibres. Nat Commun 2011;2:571.

Wang S, Liu N, Su J, Li L, Long F, Zou Z, Jiang X, Gao Y. Highly stretchable and self-healable supercapacitor with reduced graphene oxide based fiber springs. ACS Nano 2017;11:2066.

Kadumudi FB, Hasany M, Pierchala MK, Jahanshahi M, Taebnia N, Mehrali M, Mitu CF, Shahbazi MA, Zsurzsan TG, Knott A, Andresen TL, Dolatshahi-Pirouz A. The manufacture of unbreakable bionics via multifunctional and self-healing silk-graphene hydrogels. Adv Mater. 2021;33:e2100047.

Wang YB, Chen CJ, Xie H, Gao TT, Yao YG, Pastel G, Han XG, Li YJ, Zhao JP, Fu K, Hu LB. 3D-printed all-fiber Li-Ion battery toward wearable energy storage. Adv Funct Mater 2017;27:1703140.

Cai ZB, Li L, Ren J, Qiu LB, Lin HJ, Peng HS. Flexible, weavable and efficient microsupercapacitor wires based on polyaniline composite fibers incorporated with aligned carbon nanotubes. J Mater Chem A 2013;1:258.

Li H, Liu Z, Liang G, Huang Y, Huang Y, Zhu M, Pei Z, Xue Q, Tang Z, Wang Y, Li B, Zhi C. Waterproof and tailorable elastic rechargeable yarn zinc ion batteries by a cross-linked polyacrylamide electrolyte. ACS Nano 2018;12:3140.

Yang Z, Sun H, Chen T, Qiu L, Luo Y, Peng H. Photovoltaic wire derived from a graphene composite fiber achieving an 8.45% energy conversion efficiency. Angew Chem. 2013;125:7693.

Li HP, Guo JJ, Sun H, Fang X, Wang DH, Peng HS. Stable hydrophobic ionic liquid gel electrolyte for stretchable fiber-shaped dye-sensitized solar cell. Chemnanomat 2015;1:399.

Li M, Li Z, Ye X, Zhang X, Qu L, Tian M. Tendril-inspired 900% ultrastretching fiber-based zn-ion batteries for wearable energy textiles. ACS Appl Mater Interfaces 2021;13:17110.

Guo K, Ma Y, Li H, Zhai T. Flexible wire-shaped supercapacitors in parallel double helix configuration with stable electrochemical properties under static/dynamic bending. Small 2016;12:1024.

Wu J, Wang Z, Liu W, Wang L, Xu F. Bioinspired superelastic electroconductive fiber for wearable electronics. ACS Appl Mater Interfaces 2019;11:44735.

Liu K, Kong B, Liu W, Sun YM, Song MS, Chen J, Liu YY, Lin DC, Pei A, Cui Y. Stretchable lithium metal anode with improved mechanical and electrochemical cycling stability. Joule 1857;2018:2.

Marriam I, Wang X, Tebyetekerwa M, Chen G, Zabihi F, Pionteck J, Peng S, Ramakrishna S, Yang S, Zhu M. A bottom-up approach to design wearable and stretchable smart fibers with organic vapor sensing behaviors and energy storage properties. J Mater Chem A 2018;6:13633.

Yu S, Wang X, Xiang H, Zhu L, Tebyetekerwa M, Zhu M. Superior piezoresistive strain sensing behaviors of carbon nanotubes in one-dimensional polymer fiber structure. Carbon 2018;140:1.

Zhang Y, Bai WY, Cheng XL, Ren J, Weng W, Chen PN, Fang X, Zhang ZT, Peng HS. Flexible and stretchable lithium-ion batteries and supercapacitors based on electrically conducting carbon nanotube fiber springs. Angew Chem Int Ed 2014;53:14564.

Lee JM, Chun S, Son W, Suh D, Kim SH, Kim H, Lee D, Kim Y, Kim YK, Lim SK, Choi C. DNA-inspired, highly packed supercoil battery for ultra-high stretchability and capacity. Nano Energy. 2021;85:106034.

Jahid MA, Hu J, Zhuo H. Stimuli-responsive polymers in coating and laminating for functional textile. Smart Textile Coat Lamin. 2019;155.

Brinson LC. One-dimensional constitutive behavior of shape memory alloys: thermomechanical derivation with non-constant material functions and redefined martensite internal variable. J Intell Mater Syst Struct 1993;4:229.

Song G, Ma N, Li HN. Applications of shape memory alloys in civil structures. Eng Struct 2006;28:1266.

Shi M, Yang C, Song X, Liu J, Zhao L, Zhang P, Gao L. Recoverable wire-shaped supercapacitors with ultrahigh volumetric energy density for multifunctional portable and wearable electronics. ACS Appl Mater Interfaces 2017;9:17051.

Berg GJ, McBride MK, Wang C, Bowman CN. New directions in the chemistry of shape memory polymers. Polymer 2014;55:5849.

Xia Y, He Y, Zhang F, Liu Y, Leng J. A review of shape memory polymers and composites: mechanisms, materials, and applications. Adv Mater. 2021;33:e2000713.

Huang Y, Huang Y, Zhu M, Meng W, Pei Z, Liu C, Hu H, Zhi C. Magnetic-assisted, self-healable, yarn-based supercapacitor. ACS Nano 2015;9:6242.

Wu XM, Meng L, Wang QG, Zhang WZ, Wang Y. A self-healable asymmetric fibered-supercapacitor integrated in self-supported inorganic nanosheets array and conducting polymer electrodes. Chem Eng J 2018;352:423.

Rao JY, Liu NS, Zhang Z, Su J, Li LY, Xiong L, Gao YH. All-fiber-based quasi-solid-state lithium-ion battery towards wearable electronic devices with outstanding flexibility and self-healing ability. Nano Energy 2018;51:425.

Chen K-C, Hsu C-Y, Hu C-W, Ho K-C. A complementary electrochromic device based on Prussian blue and poly (ProDOT-Et2) with high contrast and high coloration efficiency. Sol Energy Mater Sol Cells 2011;95:2238.

Zhou Y, Fang J, Wang HX, Zhou H, Yan GL, Zhao Y, Dai LM, Lin T. Multicolor electrochromic fibers with helix-patterned electrodes. Adv Electron Mater 2018;4:1800104.

Fan H, Li K, Liu X, Xu K, Su Y, Hou C, Zhang Q, Li Y, Wang H. Continuously processed, long electrochromic fibers with multi-environmental stability. ACS Appl Mater Interfaces 2020;12:28451.

Yang BG, Yang GJ, Zhang YM, Zhang SXA. Recent advances in poly(ionic liquid)s for electrochromic devices. J Mater Chem C 2021;9:4730.

Zhang Y, Wang H, Lu H, Li S, Zhang Y. Electronic fibers and textiles: recent progress and perspective. iScience. 2021;24:102716.

Zhao HX, Zhou YL, Cao ST, Wang YF, Zhang JX, Feng SX, Wang JC, Li DC, Kong DS. Ultrastretchable and washable conductive microtextiles by coassembly of silver nanowires and elastomeric microfibers for epidermal human-machine interfaces. ACS Mater Lett 2021;3:912.

Zhong W, Liu C, Xiang C, Jin Y, Li M, Liu K, Liu Q, Wang Y, Sun G, Wang D. Continuously producible ultrasensitive wearable strain sensor assembled with three-dimensional interpenetrating Ag nanowires/polyolefin elastomer nanofibrous composite yarn. ACS Appl Mater Interfaces 2017;9:42058.

Cheng B, Wu P. Scalable fabrication of kevlar/Ti3C2Tx MXene intelligent wearable fabrics with multiple sensory capabilities. ACS Nano 2021;15:8676.

Wang P, Li GX, Liu J, Hou ZR, Meng CZ, Guo SJ. Flexible, freestanding, ultrasensitive, and iontronic tactile sensing textile. ACS Appl Electron Mater 2021;3:2195.

Wang JJ, Wang LY, Feng JY, Tang CQ, Sun XM, Peng HS. Long-term in vivo monitoring of chemicals with fiber sensors. Adv Fiber Mater 2021;3:47.

Wang L, Xie S, Wang Z, Liu F, Yang Y, Tang C, Wu X, Liu P, Li Y, Saiyin H, Zheng S, Sun X, Xu F, Yu H, Peng H. Functionalized helical fibre bundles of carbon nanotubes as electrochemical sensors for long-term in vivo monitoring of multiple disease biomarkers. Nat Biomed Eng 2020;4:159.

Wu XY, Feng JY, Deng J, Cui ZC, Wang LY, Xie SL, Chen CR, Tang CQ, Han ZQ, Yu HB, Sun XM, Peng HS. Fiber-shaped organic electrochemical transistors for biochemical detections with high sensitivity and stability. Sci China Chem 2020;63:1281.

Yang Y, Wang H, Zhang S, Wei Y, He X, Wang J, Zhang Y, Ji Y. Vitrimer-based soft actuators with multiple responsiveness and self-healing ability triggered by multiple stimuli. Matter 2021;4:3354.

Naciri J, Srinivasan A, Jeon H, Nikolov N, Keller P, Ratna BR. Nematic elastomer fiber actuator. Macromolecules 2003;36:8499.

Song Y, Zhou S, Jin K, Qiao J, Li D, Xu C, Hu D, Di J, Li M, Zhang Z, Li Q. Hierarchical carbon nanotube composite yarn muscles. Nanoscale 2018;10:4077.

Wang Y, Miao MH. Helical shape linen artificial muscles responsive to water. Smart Mater Struct. 2021;30:075031.

Dong L, Qiao J, Wu Y, Ren M, Wang Y, Shen X, Wei X, Wang X, Di J, Li Q. Programmable contractile actuations of twisted spider dragline silk yarns. ACS Biomater Sci Eng 2021;7:482.

Wang Y, Wang Z, Lu Z, Jung de Andrade M, Fang S, Zhang Z, Wu J, Baughman RH. Humidity- and water-responsive torsional and contractile lotus fiber yarn artificial muscles. ACS Appl Mater Interfaces. 2021;13:6642.

Zheng QC, Jiang ZL, Xu XT, Xu CX, Zhu M, Chen C, Fu FF. Bio-inspired bicomponent fiber with multistimuli response to infrared light and humidity for smart actuators. ACS Appl Polym Mater 2021;3:3131.

Zhang Q, Huang JQ, Qian WZ, Zhang YY, Wei F. The road for nanomaterials industry: a review of carbon nanotube production, post-treatment, and bulk applications for composites and energy storage. Small 2013;9:1237.

Lin L, Peng H, Liu Z. Synthesis challenges for graphene industry. Nat Mater 2019;18:520.

Zhang D, Yang W, Gong W, Ma W, Hou C, Li Y, Zhang Q, Wang H. Abrasion resistant/waterproof stretchable triboelectric yarns based on fermat spirals. Adv Mater. 2021; 2100782.

Chen G, Wang H, Guo R, Duan M, Zhang Y, Liu J. Superelastic EGaIn composite fibers sustaining 500% tensile strain with superior electrical conductivity for wearable electronics. ACS Appl Mater Interfaces 2020;12:6112.

Wang B, Fang X, Sun H, He S, Ren J, Zhang Y, Peng H. Fabricating continuous supercapacitor fibers with high performances by integrating all building materials and steps into one process. Adv Mater 2015;27:7854.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, S., Xu, Q. & Sun, H. Functionalization of Fiber Devices: Materials, Preparations and Applications. Adv. Fiber Mater. 4, 324–341 (2022). https://doi.org/10.1007/s42765-021-00120-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-021-00120-9