Abstract

The purpose of the current investigation was to ascertain the efficacy of cellulose and gellan gum in removing pomegranate stains and dirt from a historic printed manuscript from the year 1888 AD. To confirm the efficacy of these compresses before and after treatment, as well as after exposing treated samples to artificial aging, numerous studies including a digital microscope, scanning electron microscope (SEM), fourier transform infrared (FTIR), color change (ΔE), and pH were carried out. After cleaning and aging, promising results were obtained. p-Hydroxy benzoic acid, gallic acid, salicylic acid, benzoic acid, quercetin, catechol, and rutin were the most prevalent phytochemicals in the pomegranate stain, which was analyzed using high-performance liquid chromatography (HPLC). The digital microscope and scanning microscope demonstrated that the gellan gum compress was successful in removing stains but severely weakened the paper, resulting in a clear cut of the fibers and substantially removing the inks. In contrast, the cellulose compress effectively removed stains without harming the paper fibers. Both compresses revealed a substantial rise in ΔE in the treated sample. These alterations were connected to a rise in the paper samples' Lightness (L), which was measured after surface debris was removed. As groups remained unaffected after the cleaning procedure, infrared spectrum analysis proved that the chemical structure of the paper had not been altered. However, after cleaning, both compresses, particularly gellan gum, showed an increase in the intensity of peaks at 3400 cm−1 (OH stretching). Additionally, a significant change was seen following treatment, with pH values rising. Gellan gum and cellulose compresses were shown to be quite good at removing acidity, and since pH levels rose after treatment, this suggests that the stain was cleaned up and removed. Based on these findings, we suggest cleaning cellulosic supports with a cellulose compress.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The Chinese invented paper in the second century AD, which is made comprised of a mesh of randomly organized plant fibers [1]. Ts'ai Lun, a Chinese court official, created a paper web by slurring paper mulberry (Broussonetia papyrifera) fibers in the water [2]. Chinese papermakers discovered that employing different plants as fiber sources allowed them to modify the properties of the paper they created [3]. An Arab army captured a Chinese paper-making facility in Samarkand over 600 years later [4]. Hemp, flax, and linen rags were used as raw materials for paper manufacturing [5, 6]. The first paper mill in the United Kingdom was established in Hertfordshire in 1488, and it was mentioned in a book printed by Caxton in 1490 [3].

The paper lists numerous elements that can cause deterioration, including extremes in temperature and humidity, light, airborne pollutants, mold, and pests. Deterioration is usually gradual and cumulative, and it is never completely reversible [7, 8]. Because some library materials are made of naturally unstable materials, like acidic paper, they deteriorate more quickly than others [9]. Two primary types of deterioration can affect the materials found in the libraries and archives, which primarily consist of paper, palm leaves, textiles, parchment, birch bark, leather, albumen silver prints and adhesives used in bookbinding [10,11,12,13,14,15]. There are two types of biological deterioration: the first is brought on by insect attack and/or fungal growth, while the second type is caused by unfavorable environmental factors like excessive moisture or wide variations in relative humidity that are linked to significant variations in day and nighttime temperatures, light and air pollutants [16, 17].

These two forms of deterioration are interconnected because dust and dirt accumulations attract insects and humid conditions encourage the growth of fungi, these two types of deterioration are related [18, 19]. Moreover, dust stains are regarded as a possible risk factor, as is the presence of silicon, acidic gases, and metallic ions—particles that are sharp and react chemically with writing materials to discolor and dissolve manuscripts [20]. Alum or rosin sizing agents, high lignin pulp material, coatings, and some inks, like iron gall ink, are examples of acidic substances that attack the long cellulose chains in paper, resulting in brittleness [18, 21,22,23].

One of the most important treatments for paper manuscripts is cleaning. However, a number of widely used techniques, like chemical bleaching and solvents used to remove some stains, cause the treated paper's fibers to break down [9, 24]. Additionally, the majority of organic solvents (such as acetone or toluene) that were used to treat paper manuscripts sped up the process of paper oxidation and hydrolysis, which is how the treated manuscripts degraded. In addition, several publications recommended using ethylenediamine tetraacetic acid (EDTA) to remove iron stains [25].

Numerous studies attempted to enhance the use of gel in cleaning treatments using various techniques, such as chemical or mechanical cleaning, which resulted in uncontrollably high residues [26,27,28]. These led to fabricate novel nanogels to clean paper manuscript from undesirable and contaminated materials such as hybrid nanogels from ZnO, TiO2 and Fe3O4/Carbopol for dust stains and soil remains [29], toluene and isopropyl alcohol gel in cleaning wax stains from paper supports [30], cleaning fungal stains on paper with hydrogels with controlling the pH [31], and cleaning paper from fungal and bacterial contaminations using carboxymethyl cellulose (CMC) and Phytagel plant cell (PGP) loaded with TiO2NPs [32].

Cellulose, or 100 percent vegetable products, is the greatest material for cleaning because it is environmentally benign and does not contain any contaminants [33, 34]. Cellulose is resistant to most chemicals and liquids, which may explain why it is used to remove stains and dirt from paper [35] and its nanostructure has a potential effects in strengths of paper manuscripts [36]. Gellan gum is a high molecular weight polysaccharide (complex sugar) generated by the bacterium Sphingomonas paucimobilis or S. elodea during the fermentation process [37,38,39,40,41]. It is used as a thickening or emulsifier [42] by creating hard gel that is compatible with impregnating acidic and basic solutions once they have been produced. It performs best when applied warm [43]. In the biomedical, pharmacological, and food industries, a gelling agent is used [44]. It is biodegradable and non-hazardous, and utilized in a variety of sectors [45, 46]. When hot liquids are cooled in the presence of cations that promote gel formation, gellan gum generates gels at low concentrations [47]. Modified gellan gum hydrogels can be used as materials for applications in tissue engineering [48, 49]. Gellan gum may be used to reduce stains or tidelines in a paper [50]. Microgel gellan compared to commonly used hydrogels and water bath treatments, ancient samples perform better in the removal of cellulose degradation byproducts [51].

The choice of both mud and pomegranate stains is one of the common stains on paper manuscripts. Mud stains are known for spreading quickly because of dust particles dissolving in water. During the winter, when temperatures drop, cellulose manuscripts with hygroscopic properties start to absorb water from the surrounding atmosphere, which further contributes to the formation of mud stains. Since numerous studies have tracked the occurrence of stains with an organic origin—such as fruit stains, sweat stains, and stains—due to the handling of manuscripts, the concept of using pomegranate stains as a simulation of the organic stains present on historical manuscripts.

Thus, the objective of this research was to ascertain how well mud and pomegranate stains could be removed from printed historical documents using cellulose and gellan gum. These were obtained through the application of several analytical methods.

2 Materials and methods

2.1 Preparation of pomegranate juice and HPLC analysis

Pomegranate (Punica granatum L.) fruits were manually peeled, and then the juice was extracted by pressing the arils with a pedal, leaving the seeds and pulp behind on the plate [52]. The phenolic components from the juice of P. granatum were categorized by HPLC 1260 Infinity Agilent System (Agilent Technologies, Santa Clara, CA, USA) equipped with a Quaternary pump and a Zorbax Eclipse Plus C18 column (100 mm × 4.6 mm i.d.) (Agilent Technologies, Santa Clara, CA, USA). The instrument was operated at 30 °C and the injection volume was 20 µL with the following ternary linear elution gradient; (A) HPLC grade water 0.2% H3PO4 (v/v), (B) methanol, and (C) acetonitrile [53, 54].

The HPLC analysis involved the use of standard HPLC-grade phenolic and flavonoid compounds, including caffeine, pyrogallol, quinol, gallic acid, catechol, p-hydroxy benzoic acid, chlorogenic acid, vanillic acid, caffeic acid, syringic acid, vanillin, p-coumaric acid, ferulic acid, benzoic acid, rutin, ellagic acid, o-coumaric acid, salicylic acid, resveratrol, cinnamic acid, myricetin, quercetin, rosmarinic acid, naringenin, and kaempferol. To detect the phenolic compounds, the detection wavelength was set to 284 nm.

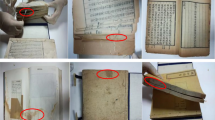

2.2 Description of the printed samples

For the experimental part of the current investigation, a satirical novel by author Gustave Flaubert (Bouvard et Pécuchet) (Fig. 1) was used. It is discovered in Cairo, Egypt, in private collections, and it was created in the year 1888 AD. All of the information regarding Gustave Flaubert's incomplete satirical novel Bouvard et Pécuchet is listed in Table 1. The novel was published in France in 1881 following Flaubert's death in 1880.

2.3 Preparation of compresses

In order to avoid the micro-emulsion's direct contact with the cellulose structure, the current study focuses on cleaning paper prints contaminated with pomegranate juice and clay stains using a micro-emulsion loaded on compresses of pure cellulose (Sigma-Aldrich Chemie GmbH, Eschenstrasse 5, D-82024 Taufkirchen, Germany) and another gellan gum (Otto Chemie pvt. Ltd., Mumbai, India). This is to protect the paper's surface from any potential damage. Deep cleaning with the least amount of cleaning agent intervention is the aim. As a result, the polysaccharide compounds are only a carrier for the potent cleaning ingredients; the micro-emulsion is the actual cleaning agent that effectively removes stains. They have been employed because of their chemical makeup, which is comparable to that of paper since both paper and carriers are composed of carbohydrates.

The composition (% w/w) of the compresses employed in the cleaning process is shown in Table 2. Oil in water micro-emulsion made with sodium dodecyl sulfate, 1-pentanol as a co-surfactant, and a small amount of a mixture of p-xylene, propylene carbonate, and nitro diluent (a mixture of 62% toluene, 15% butyl acetate, 15% ethyl acetate, 6% n-butyl alcohol). The mixture was sonicated for 20 min at room temperature using a 400-W ultrasonic, but because the ultrasonic waves cause the mixture to heat up during the sonication process, the sonication process must take place in an ice bath to keep the temperature constant.

The produced micro-emulsion was mixed in the ratio 1:0.75 (v/v) [55] with cellulose powder or gellan gum at the Polymer Department National Research Centre in Dokki, Giza, Egypt.

2.4 Accelerated aging of paper after cleaning

The accelerated artificial aging after cleaning is done to ascertain the long-term effects of the compress on the chemical composition of the paper. The treated and untreated samples that underwent thermal and light aging are shown in Table 1. In accordance with ISO guidelines, the samples were heated for 72 h at 80 °C and 65% relative humidity at the Polymer Department National Research Centre in Dokki, Giza, Egypt. The samples were then exposed to 150 lx of UV light for aging them (Fig. 2) [56].

2.5 Examinations and analyses

2.5.1 Universal Serial Bus (USB) digital microscope

A USB digital microscope (1600 ×) was used for the visual assessment of the experimental samples before and after treatment and ageing.

2.5.2 Scanning electron microscope

The paper samples were examined using SEM order to identify the internal changes of the paper during the cleaning process. Specimens from paper with size of 10 mm in diameter circular shape were used for SEM examinations. These samples subjected to sputter coating (Edwards’s model S 140A) of gold ions to have a conducting medium. Sputter coated samples were scanned with JEOL Model JSM-T20 SEM, 1550VP. with energy dispersive X-ray spectroscopy (EDS) detector.

2.6 Color change using the CIELAB system

The colors of the samples were measured with an Optimatch 3100 (CE 3100, SDL, United Kingdom). All samples were measured in the visible region, i.e., in a wavelength range of 400 to 700 nm, with an interval of 10 nm, using a D65 light source and an observed angle of 10°. The colorimetric coordinates L, a, and b of the CIELAB color space were used to express color change. The CIELAB color space is organized in a cubic form. The L axis runs from top to bottom. The maximum for L is 100, which represents white, while the minimum for L is zero, which represents black. The a and b axes have no specific numerical limits; positive a is red, negative a is green, positive b is yellow, and negative b is blue [57]. The total color change of all the treated paper samples was expressed as AE, which was calculated according to the following equation [7].

where (\(\Delta L)\) 2, (\(\Delta a)\) 2,(\(\Delta b)\) 2 are the differences between the values of the respective color indices before and after treatment.

2.6.1 Fourier transform infrared (FIR) analysis

Fourier transform infrared analysis was used to monitor the chemical composition and changes that occurred in the paper due to treatment. The samples were analyzed with an FTIR spectrometer (Model 6100, Jasco, Tokyo, Japan). The spectra were obtained in transmission mode with a triglycine sulfate (TGS) detector via the KBr method and represent 2 mm/s co-added scans in the spectral region from 4000 to 400 cm−1, with a resolution of 4 cm [28].

2.6.2 pH measurement

The PH meter, made in Romania, is a waterproof temp pocket tester with a replaceable probe. It is located in the lab of manuscripts, Faculty of Archaeology, Cairo University. The samples were cut into 400 mg pieces for each treatment and placed into 50 mL of distilled water (a pH of 7) for 6 h to measure the paper acidity using the hot extraction method. The temperature of the solution during the measurement was 19: 20 °C.

2.6.3 Statistical analysis

The measured values of pH were statistically analyzed using one-way ANOVA and the comparison between means were done using LSD at 0.05 level of probability.

3 Results and discussion

3.1 Application of compresses

In the initial attempt, a polyester sheet was placed between the pages to stop any cellulose leakage, and the compresses of microemulsion to cellulose or Gellan gum (1:0.75 v/v) were applied to the mud stain for 20 min. After 15 min, they returned, and the best results were obtained at the 5-min mark. This was because an initial experimental study on some paper samples had shown that the optimal result was at 5 min.

On the initial attempt, the compress was left for 15 min in order to try and remove a pomegranate stain; this resulted in the paper becoming brittle due to its absorption of moisture from the compress. An initial experimental investigation on some paper samples revealed that the second attempt as the compress was left for 10 min, yielded the best results in terms of the pomegranate stain being removed with no detrimental effects on the paper itself (Fig. 3).

Shows the cleaning of mud stain using compress of cellulose. The mud stain before cleaning (a), the mud stain during cleaning (b), the final result of cleaning of mud stain using cellulose compress (c), the pomegranate stain (d), the pomegranate stain during cleaning (b, e), the final result of cleaning forthermore as the cleaning of pomegranate stain using compress of gellan gum (f), the accumulation of mud particles on the surface (g), the role of gellan gum compress in removing mud stain (h), and the mud stain after cleaning, where the paper became more fragile (i)

3.2 Visual assessment by digital microscope

Using a USB Digital Microscope to compare the standard samples before and after aging, it was found that there was some erosion in the inks following cleaning with gellan gum compress and that the paper surface weakened with time. The following is an explanation of the outcomes:

Before cleaning, the pomegranate stain was purple, and after cleaning, it returned to its original color. However, at some point, the gellan gum compress affected the fibers and inks as shown in Fig. 4, and aging made the color more yellow and more into the fibers, letting us know how much the cellulose compress affected at cleaning the surface as it made the pomegranate stain disappear while also demonstrating the detrimental effect of gellan gum compress as shown in Fig. 5.

Cleaned pomegranate stain with cellulose and gellan gum compresses. The red color appeard on the paper surface and inkdue to the paper absorption of pomegranate stain (a and b), the good effect of surface cleaning with cellulose (c), the minimal impact of cleaning cellulose compress on ink (d), the surface's brittleness following gellan gum compress cleaning and any residual compress residue (e), and the breakdown of fibers on the surface and ink damage (f)

Cleaned pomegranate stains on paper samples with cellulose and gellan gum compresses after aging the penetration effect of pomegranate stain after aging with changing stain color to yellowish (a and b), the cleaning of pomegranate stain with cellulose compress after aging and the paper returned to its original color without any effects on inks (c and d), the cleaning with gellan gum compress after aging and the weakness of fibers (e), and the erosion of inks and fibers due to the cleaning with gellan gum compress after aging (f)

Cleaning with cellulose helped us remove the mud stain and had a minor negative impact on the inks, but gellan gum compress had a significant negative impact on the inks as seen in the Figs. 6 and 7. As the mud stain grew more ingrained in the fibers, it became more difficult to remove; nevertheless, cellulose compress removed it. Cellulose compress offers a better cleaning performance as compared to the compress of gellan gum because it does not have as much of an impact on the paper's surface or fibers.

Cleaned mud stain samples with cellulose and gellan gum compresses. The penetration of mud stain on the surface of the paper (a and b), the mud stain was removed by cleaning with cellulose compress and the paper became more bright and with little effect on inks (c and d), the cleaning of mud stain after treating with gellan gum compress, where the surface was good cleaned but the fibers become weaker (e), and the deformation of inks as the result of cleaning with gellan gum compress (f)

The paper appears darker due to the calcination of mud stain on its surface, possibly as a result of aging (a, b), the mud stain was removed after cleaning with cellulose compress (c), the elimination of mud stains with minimal impact on inks (d), the paper surface after using gellan gum compress to clean it, where 85% of it was removed (e), and as the carbon is a chemically stable material, it shown that carbon ink can fade and smear in moist environments (f) [58]. It is evident that there is a small change in inks following aging and cleaning with gellan gum compress. Additionally, we observed that the gellan gum compress affected the fibers and did not entirely remove the mud stain..

3.3 Scanning electron microscope

A scanning electron microscope (SEM) was used to observe the original paper fibers' shape, the impact of artificial aging on the fibers, and the impact of the treatment materials. Paper is a hygroscopic material because it is composed of organic fibers. Due to their multiple thin paper layers, books, magazines, and newspapers in a room may have a great potential for acting as a moisture buffer. Between the sheets, tiny air layers may form that enhance moisture buffering capacity and facilitate the transport of water vapor [59]. Due to the paper's high porosity, where the fibers were covered and impregnated with stains (Fig. 8a-c), the pomegranate stains completely enter the paper. It can be shown that cellulose compress has a better cleaning effect than gellan gum compress after pomegranate stains from printed ancient paper have been removed, as shown in Fig. 9a-d after cleaning with gellan gum compress and Fig. 10a-d after cleaning with.

Pomegranate stain on paper samples before cleaning with cellulose compress. The pomegranate's ability to absorb into paper, creating an isolation layer that causes the fiber’s surface to vanish because of the pomegranate's high penetration (a), the breakdown of the connection between the fiber chains (b), and the fibers’ swelling as a result of the high pomegranate juice absorption at the fibers (c)

The effect of cleaning with cellulose and the breaking down of the isolation layer from the fiber surface (a and b), and the fiber returned to its normal size and the stain was removed (85%) with very little pomegranate residue on the surface following cleaning with cellulose and its effect on removing the pomegranate stain (c and d)

Figure 11c, d demonstrate the total removal of mud stains after cleaning with cellulose compress, however, Figs. 12 and 13 show that washing mud with gellan gum compress did not completely remove the mud stains and that the gellan gum also left crystals on the fiber.

Cleaned pomegranate stain samples with cellulose and gellan gum compresses after aging. he pomegranate stain deeply penetrated the surface, causing the surface to become dehydrated due to exposure to heat and relative humidity (a), the aging of the drought fibers and the appearance of fiber cracks (b), the result of using cellulose compress to clean the surface after it had aged and dried completely caused the fibers to break down and crack (c), the splitting of fibers due to the drought of the surface (d), and the cleaning of pomegranate stain with gellan gum compress after aging (e)

Mud stain samples before and after cleaning with cellulose and gellan gum compresses. The mud crystals and their high penetration on the paper and its total interlinked between fibers (a and b), the good effect of cleaning mud with cellulose compress, where the fibers in a good condition after cleaning and its returned to its original color (c and d), and the cleaning of mud stain with gellan gum compress with a medium effect in removing stains but the gellan gum compress under SEM does not remove and it can be seen crystals of gellan gum covered some fibers (e and f)

Cleaned mud stain samples with cellulose and gellan gum compresses after aging. The fibers became wicking and fragile after exposing the mud stain sample to oven heat and relative humidity (a and b), the mud stains cleaned with gellan gum after aging, where the fibers twisted and the gellan gum crystals remained on its surface and the fibers became visible (c and d), and the mud stains cleaned with gellan gum compress after aging, where the fibers twisted and the gellan gum crystals remained on the surface, leaving a black stain, possibly a burnt gellan gum stain (e and f)

Thus, when working with priceless cultural heritage objects, researchers are constrained in their ability to select the best cleaning solution in order to have good results in eliminating the filth and generating no chemical or mechanical damage to the surface. Additionally, they should not leave residues on the surface after removing the cleaning agent [60]. As a consequence, we can suggest that cellulose compress is an effective substance for removing stains from antique paper. Sodium dodecyl sulfate micro-emulsion, according to a different theory, was employed as a clever cleaning solution for manuscripts found in ancient sites and was successful in removing many types of stains without harming the manuscripts' structural integrity [7].

But when we apply it to our samples and compare the results, we discover that this opinion is false because the appearance of gellan gum crystals, the breaking and twisting of individual fibers, and the degradation of the fibers and gaps between them were not eliminated.

SEM photos show that the cellulose compress was superior to the artificial gellan gum compress in removing both the mud stain and the pomegranate stain from the paper surface. When the gellan gum compress is removed, however, there are still crystals visible between the fibers, which leads to a burnt mark on the paper surface after aging.

3.4 Color change using the CIELAB system

The use of cleaning agents and artificially accelerated aging tests on paper samples resulted in color change (∆E), which were investigated using colorimetric testing. The ∆E values were computed using the color parameter data and are displayed in Table 3. According to the values of ∆E in the mud stain treated with cellulose compress, we can observe that after cleaning the mud stain with cellulose, the stain became brighter after cleaning as shown in Table 3, where the value of ∆E before aging was 8.98 and after aging 8.41. The value of ∆E was compared between the standard samples and samples treated with both cellulose and gellan gum compresses.

However, while lightness (L) was also present in the treated samples of the mud stain following treatment with the gellan gum compress after aging the difference was evident in the lamination as it increased and it can be brought on by any remaining of compress in the fibers.

It was discovered that there is a noticeable variation in brightness for the pomegranate stain treated with cellulose compress, especially in the aging samples, where ∆E was 9.47. Additionally, based on the L values for standard samples and samples that have been compresses-treated before and after age they are displayed in Table 3.

Although the gellan gum compress's brightness increased and it left residues on the fiber surface, the cellulose compress outperformed the other in cleaning both stains. The removal of redness was evident in pomegranate samples treated with gellan gum and natural cellulose compresses, both before and after aging, as determined by the Δa values. This suggests that both compresses were effective in removing stains.

The gellan gum compress left residues on the fiber surface even as its brightness increased. The cellulose compress worked the best, even though both cleaned the two stains. Based on the values of Δa in pomegranate samples treated with gellan gum and natural cellulose compresses before and after aging, it was clear that the redness was eliminated, demonstrating the efficacy of both compresses in removing the stains..

According to the Δb values of the mud stain sample treated with cellulose compress prior to aging, the Δb was 0.03 and in the samples following aging, it was 0.05. For the mud stain sample treated with gellan gum, the amount of change is − 18.0 for the non-aging sample and − 1.34 for the aging sample.

The ∆b for the pomegranate stain treated with cellulose compress was 4.92 prior to aging and 9.85 subsequent to aging. Old historical paper needs to be preserved and treated with extreme effectiveness, but the most important aspect of these procedures is that they must preserve the paper's microscopic shape. Due to cellulose oxidation, old historical paper is more likely to deteriorate. This is especially true if the paper was made using rough materials, such as wood pulp, and is affected by the manufacturing process, the environment, and other factors from that era [61].

The absence of unfavorable changes on the paper after treatment with both compresses indicates the success of the treatment, and some studies' findings indicate that agar-gellan treatments are the most effective in terms of having little to no negative effects on this kind of paper's surface [62, 63]. It was discovered that the compress had a very straightforward effect on the paper after the aging process; a comparison of the samples before and after aging revealed a value of 0.6, indicating the compress's efficacy and efficiency. Regarding the mud stain treated with cellulose, the total change value revealed that it significantly increases the stain's cleaning efficiency. The overall value of the mud stain was 11.07 more expensive after being treated with gellan gum compress than it was before, while the effect of this compress on the paper was just marginal, totaling 2.32. When treating with gellan gum compress, the difference between the samples before and after aging was also evident, but the effect of the compress on the paper after aging was not significantly impacted, valued at 2.35. As for the pomegranate treated with cellulose compress, the value of ∆E after aging was higher than its value before aging, and this is a clear change, as it reached 14.46 after aging (Table 3).

When all of these factors were taken into account, both compresses were successful in removing the two stains; however, the cellulose compress was the most efficient and effective because, unlike the gellan gum compress, it left no residue behind after cleaning. According to reports, using a gel cleaning product like Phytagel can effectively remove debris that has built up on paper due to cellulose's degradation. One of its downsides is the deposition of gel residues on the surface, as shown by microscopic analysis. Its efficiency rises when the gel is the size of a micro and its efficacy increases when it is a material [51].

3.5 Fourier transform infrared (FIR) analysis

Figures 14, 15, 16 and 17 show the comparison between the standard sample and the sample treated with cellulose and gellan gum compresses. As the spectra after ageing (Fig. 14), it can be observed the typically functional groups of paper after treatment and after aging. But with slight differences where OH starching, which occurs at 3339 cm−1, was found to decrease, indicating a drop in humidity in control sample. After he treatment and even after aging, the OH vibration increased, indicating an increase in the moisture content [64].

It was also observed (Fig. 14) that the stretching of the CH group at 2901 cm−1 decreased after treatment with cellulose compress. This indicates a decrease in fatty substances that may be related to the clay particles, as clay granules usually contain a number of organic fatty suspensions [65]. No observed change was detected in C-H bond stretching vibration at 1426 cm−1 and this indicates that aliphatic methylene groups of cellulose is not affected, but after ageing. After the treatment with gellan gum compress (Fig. 15), it was noticed an increase in the CH group, Which indicates the success of the cleaning process in strengthening the cellulose structure by increasing the intensity of C-H bond stretching vibration under accelerated industrial aging. The stretching of the C-O group at 1607 cm−1 had increased during treatment and also after aging, which indicates an increase in ether [65]. No harm effect was detected in treated paper after treatment the mud stains by cellulose compress, beside that polymerization of treated paper did not decline, also no significant effect was observed after aging [64]. Furthermore after treatment, the C-O, which is connected to the absorption of OH at 1029 cm−1, reduced, and aging increased [66]. Additionality, a very slight change in the stretching of O-C-O at 800 and 950 cm−1, related to the amount of cellulose was observed.

Although we cannot determine the treatment of the mud spots from the FTIR analysis because the mud functional groups are located in the areas of the cellulose functional groups, where the mud functional groups are in the wavelength range between 1000 and 1100 cm−1, we can confirm the other analyses that were carried out [67].

In pomegranate samples treated with gellan gum compress (Fig. 16), FTIR analysis reveals a drop in the OH group, which is visible at wavelength 3339 cm−1 and denotes a decrease in moisture content. Additionally, a drop was seen after aging, showing that the compress has an impact on the paper's moisture content [64], as well as a decrease in the stretching of the CH group, which is seen at wavelength 2091 cm−1 and is lessened after treatment and aging. This implies that the compress has an impact on the cellulose's organic matter, causing a shortfall [65], and the bending of the CH group can be seen at 1426 cm−1.

The fact that a significant change occurred, whether during treatment or after aging and that this had no significant impact on cellulose, as well as the stretching of the O-C-O group, suggests that cellulose polymerization had not changed [64]. The C-O group, which is linked to OH absorption, was shown to decrease after treatment and after aging; this demonstrates how the compress affects the paper's moisture content [66].

Regarding the stretching of the O-C-O group, which is related to the amount of cellulose and appears at a wavelength of 800–950 cm−1, it was discovered that when treated, a slight change occurred during treatment, which indicates a slight decrease in the amount of cellulose, but after aging, a noticeable decrease occurred, which indicates a decrease in the amount of cellulose after aging. From this, it can be inferred that the gellan gum compress influences the paper's moisture content, which may be attributed to the compress's high concentration. This has little effect on cellulose, and its effectiveness has not been shown to last over time.

The functional stretching group (OH), which shows at wavelength 3334 cm−1 and indicates a rise in the moisture content of the paper, was significantly increased in the FTIR examination of a sample of a pomegranate stain that had been treated with a cellulose compress. Even after age, it has little impact on the paper's moisture [64]. There was an increase in the treated sample compared to the standard sample at the bend of the NH group, which shows at 1642 cm−1 for pomegranates. However, when aging took place, we detected a little rise from the standard sample, which indicates an increase in amino acids [68].

The stretching of (C–C), which appears at wavelength 1426 cm−1, shows a small increase when treated and no change after aging, indicating a slight increase in the treated sample and no increase after aging. The stretching of C = O, which appears at wavelength 1611 cm−1, shows a noticeable increase when treated and also when aging occurs, which is related to the increase in ketones [68].

It was observed that the functional group (O-C-O) related to the polymerization of cellulose, which shows at wavelength 1160 cm−1, did not alter, indicating that the compress did not affect the polymerization of cellulose paper [64]. The stretching of the (O-C-O) group, which is related to the amount of cellulose at wavelength 910 cm−1, and an increase were observed, indicating that the compress improved the cellulosic fiber of the paper. The functional group (C-O) linked to (OH), which is found at the wavelength 1029 cm−1, increased upon treatment and upon aging.

It was observed from Fig. 16 that the gellan gum was effected to the OH functional group at 3334 cm−1 in the pomegranate stain sample. The standard sample saw an increase following treatment and after age, which denotes an increase in moisture content [64]. When it comes to the CH group, we observe a substantial difference between the treated sample and the standard sample, but after age, we observe a drop in the standard sample, which shows that the gellan gum loses its effectiveness [65]. After aging (Fig. 17) we observed a modest increase from the standard sample, which indicates an increase in cinnamic acid of pomegranate. The bending of the (N–H) group, which shows at wavelength 1642 cm−1 for pomegranate, increased in the treated sample relative to the standard sample [68]. After treatment and aging (Fig. 17), it was seen that the stretching of the (C–C) group, which shows at wavelength 1426 cm−1, increased, which suggests an increase in aromatic acids [68]. In contrast, the functional group C-O associated with OH, which appears at wavelength 1029 cm−1, increases after treatment and after aging. The stretching of the O-C-O group is related to the amount of cellulose at wavelength 910 cm−1, and an increase was observed in the treated and aging samples. Additionally, the functional group O-C-O associated with cellulose polymerization, which appears at wavelength 1160 cm−1, does not show a significant change, indicating any change.

3.6 HPLC of pomegranate juice

The phenolic compounds of pomegranate juice are presented in Table 4 and Fig. 18. The highest percentages phenolic of compounds (mg/kg) observed were for p-hydroxy benzoic acid (1174.37), gallic acid (1105.84), salicylic acid (678.18), benzoic acid (248.68), quercetin (214.11), catechol (126.56) and rutin (115.15).

Pomegranate phenolic components give the juice color, astringency, and bitterness [69]. The levels of ellagic acid in the juice of several pomegranate cultivars ranged from 160 to 7 mg/L [52]. Gallic, chlorogenic, caffeic, ferulic, ellagic acids, catechin, epicatechin, phloridzin, quercetin, and rutin were the phenolic components of 18 pomegranate juices produced in Morocco [70]. The pomegranate juices contained anthocyanins, derivatives of ellagic acid, and hydrolyzable tannins that were identified and measured [71]. Ellagic acid, one of the identified phenolic chemicals in pomegranate juice, was discovered in concentrations between 17.4 and 928 mg/L [72].

3.7 pH measurements

Table 5 presents the results of pH values. According to the findings, the historical sample’s (unstained zone) pH value was 6.5. While the pH of the pomegranate spot sample was 3.7 and was generated by the acids naturally present in the pomegranate, the pomegranate stain on the paper caused an increase in the acidity of the paper [73].

Since the stain is acidic, as we previously mentioned, there was a dramatic change after treatment, where the pH values increased. We noticed the effectiveness of gellan gum and cellulose compresses in removing acidity, and this indicates cleaning and removal of the stain. The Table 4 shows that the pH value in the cellulose-treated sample reached 5.6 and the pH value in the gellan gum-treated sample reached 5.9.

The pH level rising means that the stain has been eliminated. It can be seen that the pH value increased higher than it had before the treated samples were exposed to age; the pH value in both samples increased to 6.1. While most soils have a pH in the range of 2.0–11.0, soils with sulfuric elements may oxidize to have a pH below 2.0, as we observed in the sample of the mud stain before cleaning when the pH value was equal to 5.6 [74].

After washing, the pH values of the gellan and cellulose samples both increased to 6.1 and 6, respectively. The high pH values show that the stain was eliminated and the cleaning was successful.

According to the PH measurement and the consensus that cleaning materials shouldn't leave residues on the surface after the cleaning agent removal and shouldn't affect the historical artifact, the pH value increased after aging, reaching 6.5. This may be due to the compress residues, which are very evident in the SEM images showing the crystals of compress covering the fibers [60]. Consequently, it is possible to suggest that the cellulose compress is a promising material in the field of conservation.

4 Conclusion

In the current experimental work, dirt and pomegranate stains were removed from printed cellulosic support using two types of compresses: microemulsion mixed with cellulose or gellan gum in the ratio of 1:0.75 v/v. The following findings and conclusions were drawn:

-

1.

Images from SEM and digital microscopes show that using cellulose compress to remove stains does not harm the paper's structure, but using gellan gum compress to do so weakens the paper's fibers and also causes the compress to leave fewer crystals on the fibers.

-

2.

Although the values of gellan gum compress were better in some samples, they left a residue on the surface, so we advised that the cellulosic material be used instead. According to the values of color changes, it was noticed that an observed color change occurred when using the two compresses to clean the two types of stains. This suggests that while both compresses cleaned effectively, the cellulose compress was more successful and efficient.

-

3.

According to the FTIR analysis, cellulose compress does not affect cellulosic paper, however, gellan gum compresses have a small impact on the printed paper's cellulosic fibers and raise the acidity of the paper.

-

4.

When the pH of the samples treated with the two compresses was measured, it was possible to determine the effects of the compresses on eliminating the acidity that the paper had. We observe the stability of the treated samples, the efficacy of the cellulose substance in eliminating both stains without damaging the cellulose fibers, and the composition of cellulose even after aging. Both the mud and the pomegranate stains were successfully removed by compresses, though in varying amounts. Furthermore, the gellan gum compress had a negative impact on the paper fibers and its effectiveness had not been demonstrated after aging, whereas the cellulose compress was more successful in eliminating both stains.

-

5.

We recommended using cellulose compress for use in all tests and analyses, as well as to show that it is effective at cleaning cellulose paper without causing damage.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Griffin RC (2012) Principles of package development. Springer Science & Business Media, Cham

Leland J. Aliens in the backyard: Plant and animal imports into America. Columbia: University of South Carolina Press; 2012.

Otieno JO, Okumu TN, Adalla M, Ogutu F, Oure B. Agricultural residues as an alternative source of fibre for the production of paper in Kenya-a review. Asian Journal of Chemical Sciences. 2021;10(1):22–37. https://doi.org/10.9734/ajocs/2021/v10i119084.

Abel EL (2013) Marihuana: the first twelve thousand years. Springer Science & Business Media, Cham

Clark TF. Plant fibers in the paper industry. Econ Bot. 1965;19(4):394–405. https://doi.org/10.1007/BF02904811.

Abd El-Sayed ES, El-Sakhawy M, El-Sakhawy MA-M. Non-wood fibers as raw material for pulp and paper industry. Nord Pulp Pap Res J. 2020;35(2):215–30. https://doi.org/10.1515/npprj-2019-0064.

Hassan RRA, Mahmoud SMA, Karam YA, Salah SM, Ebrahim SY, Abdelwahab MA, Ahmed A-HMH, Ali HM, Böhm M, Salem MZM (2021) Application of Frankincense and Rice Starch as Eco-Friendly Substances for the Resizing of Paper as a Conservation Practice. BioResources 16 (4):7180–7204. https://doi.org/10.15376/biores.16.4.7180-7204

Mohamed HM, Ahmed NM, Mohamed WS, Mohamed MG. Advanced coatings for consolidation of pottery artifacts against deterioration. J Cult Herit. 2023;64:63–72. https://doi.org/10.1016/j.culher.2023.08.014.

Zervos S, Alexopoulou I. Paper conservation methods: a literature review. Cellulose. 2015;22(5):2859–97. https://doi.org/10.1007/s10570-015-0699-7.

Roberts MT, Etherington D (1982) Bookbinding and the Conservation of Books. A Dictionary of Descriptive Terminology. ERIC,

Ahmed Eldeeb HM, Ali MF, Mansour MMA, Ali Ahmed MA, Salem MZM. Monitoring the effects of fungi isolated from archival document on model albumen silver prints. Microb Pathog. 2022;169: 105632. https://doi.org/10.1016/j.micpath.2022.105632.

Taha AS, Abo-Elgat WAA, Fares YGD, Salem MZM. Isolated essential oils as antifungal compounds for organic materials. Biomass Conversion and Biorefinery. 2022. https://doi.org/10.1007/s13399-022-02815-4.

Mansour MMA, Zidan YE, El Fettouh A, Abd El Hakim A, Allam MM, Ali HM, Akrami M, Salem MZM. Characterization of two historical postage stamps made from cotton fibers and their restoration trials based on the experimental studies. J Chem. 2021;2021:4162311. https://doi.org/10.1155/2021/4162311.

Querner P, Beenk J, Linke R. The analysis of red lead endsheets in rare books from the fung ping shan library at the University of Hong Kong. Heritage. 2022;5(3):2408–21. https://doi.org/10.3390/heritage5030125.

Taha AS, Ibrahim IHM, Abo-Elgat WAA, Abdel-Megeed A, Salem MZM, El-Kareem MSMA. GC–MS, quantum mechanics calculation and the antifungal activity of river red gum essential oil when applied to four natural textiles. Sci Rep. 2023;13(1):18214. https://doi.org/10.1038/s41598-023-45480-x.

Sanchez-Silva M, Rosowsky David V. Biodeterioration of construction materials: state of the art and future challenges. J Mater Civ Eng. 2008;20(5):352–65. https://doi.org/10.1061/(ASCE)0899-1561(2008)20:5(352).

Ayoade F, Amona S. Deterioration and microbiological evaluation of information bearing paper in a Nigerian University. Annual Research & Review in Biology. 2018;26(2):1–9. https://doi.org/10.9734/ARRB/2018/39280.

Mahmood ZU, Mari HM. Deterioration of library resources and its causes: theoretical review. International journal of basic and Applied Science. 2013;1(4):773–8.

Afifi HAM, Mansour MMA, Hassan AGAI, Salem MZM. Biodeterioration effects of three Aspergillus species on stucco supported on a wooden panel modeled from Sultan al-Ashraf Qaytbay Mausoleum, Egypt. Sci Rep 2023;13(1):15241. https://doi.org/10.1038/s41598-023-42028-x.

Abdel-Maksoud G, Emam H, Ragab NM (2020) From traditional to laser cleaning techniques of parchment manuscripts: a review. Advanced Research in Conservation Science 1 (1):52–76. https://doi.org/10.21608/arcs.2020.111216

Area M, Cheradame H. Paper aging and degradation: recent findings and research methods. BioResources. 2011;6(4):5307–37.

Baglioni P, Chelazzi D, Giorgi R (2015) Deacidification of Paper, Canvas and Wood. In: Baglioni P, Chelazzi D, Giorgi R (eds) Nanotechnologies in the Conservation of Cultural Heritage: A compendium of materials and techniques. Springer Netherlands, Dordrecht, pp 117–144. https://doi.org/10.1007/978-94-017-9303-2_5

Hubbe MA, Smith RD, Zou X, Katuscak S, Potthast A, Ahn K. Deacidification of acidic books and paper by means of non-aqueous dispersions of alkaline particles: a review focusing on completeness of the reaction. BioResources. 2017;12(2):4410–77.

Hage R, Lienke A. Applications of transition-metal catalysts to textile and wood-pulp bleaching. Angew Chem Int Ed. 2006;45(2):206–22. https://doi.org/10.1002/anie.200500525.

Hur DH, Choi MS, Chung HS, Kim UC. Optimum EDTA solvent chemistry for iron oxide removal at 150 °C. J Nucl Mater. 2002;305(2):220–3. https://doi.org/10.1016/S0022-3115(02)00912-1.

Devanathan R. Conservation of manuscripts–the natural way. International Journal of Current Pharmaceutical Review and Research. 2012;3(4):99–104.

Maravelaki PN (2022) Surface cleaning: implications from choices & future perspectives. In: Gherardi F, Maravelaki PN (eds) Conserving stone heritage: traditional and innovative materials and techniques. Springer International Publishing, Cham, pp 37–74. https://doi.org/10.1007/978-3-030-82942-1_2

Salim E, Abdel-Hamied M, Salim S, Gamal S, Mohamed S, Galal FE-Z, Tarek F, Hassan RRA, Ali HM, Salem MZM (2020) Reduction of borax/agar-based gel residues used to neutralize acidity of a historical manuscript with use of different paper barriers: artificial ageing results. BioResources 15 (3):6576–6599. https://doi.org/10.15376/biores.15.3.6576-6599

Hassan R, Hassan HM, Mohamed YA, Ismail M, Farid Y, Mohamed H, et al. TiO2 and Fe3O4/ Carbopol hybrid nanogels for the cleaner process of paper manuscripts from dust stains and soil remains. Herit Sci. 2023;11(1):221. https://doi.org/10.1186/s40494-023-01063-7.

Salim E (2022) A comparative experimental study of the use of toluene and isopropyl alcohol gel in cleaning wax stains from paper supports. Pigment & Resin Technology ahead-of-print (ahead-of-print). https://doi.org/10.1108/PRT-10-2021-0122

Barrulas RV, Nunes AD, Sequeira SO, Casimiro MH, Corvo MC. Cleaning fungal stains on paper with hydrogels: the effect of pH control. Int Biodeterior Biodegradation. 2020;152: 104996. https://doi.org/10.1016/j.ibiod.2020.104996.

Mansour MMA, Salem MZM. Poultices as biofilms of titanium dioxide nanoparticles/carboxymethyl cellulose/Phytagel for cleaning of infected cotton paper by Aspergillus sydowii and Nevskia terrae.Environ Sci Pollut Res. 2023. https://doi.org/10.1007/s11356-023-30353-7.

Sb H, Chen Z, An C, Lee K. Recent advances in developing cellulosic sorbent materials for oil spill cleanup: A state-of-the-art review. J Clean Prod. 2021;311: 127630. https://doi.org/10.1016/j.jclepro.2021.127630.

R R, Philip E, Madhavan A, K.B A, Binod P, Pugazhendhi A, Awasthi MK, Gnansounou E, Pandey A, Sindhu R,. Promising eco-friendly biomaterials for future biomedicine: Cleaner production and applications of Nanocellulose. Environ Technol Innov. 2021;24: 101855. https://doi.org/10.1016/j.eti.2021.101855.

Ontario (2013) Provincial Infectious Diseases Advisory Committee. Best practices for cleaning, disinfection and sterilization of medical equipment/devices in all health care settings. Public Health Ontario,

Abdel-Hamied M, Hassan RRA, Salem MZM, Ashraf T, Mohammed M, Mahmoud N, El-din YS, Ismail SH. Potential effects of nano-cellulose and nano-silica/polyvinyl alcohol nanocomposites in the strengthening of dyed paper manuscripts with madder: an experimental study. Sci Rep. 2022;12(1):19617. https://doi.org/10.1038/s41598-022-23907-1.

Bajaj IB, Survase SA, Saudagar PS, Singhal RS. Gellan gum: fermentative production, downstream processing and applications. Food Technology and Biotechnology. 2007;45(4):341–54.

Prajapati VD, Jani GK, Zala BS, Khutliwala TA. An insight into the emerging exopolysaccharide gellan gum as a novel polymer. Carbohyd Polym. 2013;93(2):670–8. https://doi.org/10.1016/j.carbpol.2013.01.030.

Bajaj IB, Saudagar PS, Singhal RS, Pandey A. Statistical approach to optimization of fermentative production of gellan gum from Sphingomonas paucimobilis ATCC 31461. J Biosci Bioeng. 2006;102(3):150–6. https://doi.org/10.1263/jbb.102.150.

Banik RM, Kanari B, Upadhyay SN. Exopolysaccharide of the gellan family: prospects and potential. World J Microbiol Biotechnol. 2000;16(5):407–14. https://doi.org/10.1023/A:1008951706621.

Huang H, Lin J, Wang W, Li S. Biopolymers produced by Sphingomonas strains and their potential applications in petroleum production. Polymers. 2022;14(9):1920. https://doi.org/10.3390/polym14091920.

Jindal N, Singh Khattar J (2018) Chapter 4 - Microbial polysaccharides in food industry. In: Grumezescu AM, Holban AM (eds) Biopolymers for food design. Academic Press, New York, pp 95–123. https://doi.org/10.1016/B978-0-12-811449-0.00004-9

Guilminot E, Gomez A, Raimon A, Leroux M (2019) Use of gels for the treatment of metals. In: Proceedings of the Metal 2019 Proceedings of the interim meeting of the ICOM-CC Metals Working Group; Chemello, C., Brambilla, L., Joseph, E., Eds.; International Councils of Museums—Committee for Conservation: Paris, France, 2019; p. 473. ISBN 9789290124573.

Zia KM, Tabasum S, Khan MF, Akram N, Akhter N, Noreen A, Zuber M. Recent trends on gellan gum blends with natural and synthetic polymers: a review. Int J Biol Macromol. 2018;109:1068–87. https://doi.org/10.1016/j.ijbiomac.2017.11.099.

Maheux AF. Cross-disciplinary uses for gellan gum in conservation. Book and Paper Group Annual. 2015;34(2016):69–79.

Agarwal N, Jyoti TM, Mishra BB, Singh SP. Preparation and characterization of biodegradable films based on levan polysaccharide blended with gellan gum. Environ Technol Innov. 2023;31: 103231. https://doi.org/10.1016/j.eti.2023.103231.

Sworn G, Stouby L (2021) Chapter 28 - Gellan gum. In: Phillips GO, Williams PA (eds) Handbook of Hydrocolloids (Third Edition). Woodhead Publishing, UK, pp 855–885. https://doi.org/10.1016/B978-0-12-820104-6.00009-7

Ferris CJ, Gilmore KJ, Wallace GG, Mih P. Modified gellan gum hydrogels for tissue engineering applications. Soft Matter. 2013;9(14):3705–11. https://doi.org/10.1039/C3SM27389J.

Oliveira JT, Martins L, Picciochi R, Malafaya PB, Sousa RA, Neves NM, Mano JF, Reis RL. Gellan gum: a new biomaterial for cartilage tissue engineering applications. J Biomed Mater Res, Part A. 2010;93A(3):852–63. https://doi.org/10.1002/jbm.a.32574.

Hughes A, Sullivan M. Targeted cleaning of works on paper: rigid polysaccharide gels and conductivity in aqueous solutions. The Book and Paper Group Annual. 2016;25:30–41.

Di Napoli B, Franco S, Severini L, Tumiati M, Buratti E, Titubante M, Nigro V, Gnan N, Micheli L, Ruzicka B, Mazzuca C, Angelini R, Missori M, Zaccarelli E. Gellan gum microgels as effective agents for a rapid cleaning of paper. ACS Applied Polymer Materials. 2020;2(7):2791–801. https://doi.org/10.1021/acsapm.0c00342.

Mousavinejad G, Emam-Djomeh Z, Rezaei K, Khodaparast MHH. Identification and quantification of phenolic compounds and their effects on antioxidant activity in pomegranate juices of eight Iranian cultivars. Food Chem. 2009;115(4):1274–8. https://doi.org/10.1016/j.foodchem.2009.01.044.

Salem MZ, Mohamed AA, Ali HM, Al Farraj DA. Characterization of phytoconstituents from alcoholic extracts of four woody species and their potential uses for management of six Fusarium oxysporum isolates identified from some plant hosts. Plants. 2021;10(7):1325. https://doi.org/10.3390/plants10071325.

Elbanoby NE, El-Settawy AAA, Mohamed AA, Salem MZM. Phytochemicals derived from Leucaena leucocephala (Lam.) de Wit (Fabaceae) biomass and their antimicrobial and antioxidant activities: HPLC analysis of extracts. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-03420-1

Brajer IE, Fossé-Le Rouzic M, Shashoua Y, Taube M, Chelazzi D, Baglioni M, Giorgi R, Baglioni P The removal of aged acrylic coatings from wall paintings using microemulsions. In: ICOM-CC 17th Triennial Conference Preprints-2014 Melbourne, 2014. International Council of Museums, p 1103

Elmetwaly TE, Darwish SS, Attia NF, Hassan RRA, El Ebissy AA, Eltaweil AS, Omer AM, El-Seedi HR, Elashery SEA. Cellulose nanocrystals and its hybrid composite with inorganic nanotubes as green tool for historical paper conservation. Prog Org Coat. 2022;168: 106890. https://doi.org/10.1016/j.porgcoat.2022.106890.

Sehlstedt-Persson M (2008) Impact of drying and heat treatment on physical properties and durability of solid wood. Doctoral thesis, comprehensive summary, Luleå tekniska universitet, Luleå

Mazen BSM, Ismail BM, Ali Hassan RR, Ali M. Damage caused by black inks to the chemical properties of archaeological papyrus - analytical study. Pigm Resin Technol. 2023;52(1):73–81. https://doi.org/10.1108/PRT-08-2021-0088.

Derluyn H, Janssen H, Diepens J, Derome D, Carmeliet J. Hygroscopic behavior of paper and books. J Building Phys. 2007;31(1):9–34. https://doi.org/10.1177/1744259107079143.

Hassan RRA. Behavior of archaeological paper after cleaning by organic solvents under heat accelerated aging. Mediter Archaeol Archaeom. 2015;15(3):141–50. https://doi.org/10.5281/zenodo.18365.

Casoli A, Cremonesi P, Isca C, Groppetti R, Pini S, Senin N. Evaluation of the effect of cleaning on the morphological properties of ancient paper surface. Cellulose. 2013;20(4):2027–43. https://doi.org/10.1007/s10570-013-9975-6.

Zhao J, Liu T, Xia K, Liu X, Zhang X. Preparation and application of edible agar-based composite films modified by cellulose nanocrystals. Food Packag Shelf Life. 2022;34: 100936. https://doi.org/10.1016/j.fpsl.2022.100936.

Ishii T, Matsumiya K, Aoshima M, Matsumura Y. Microgelation imparts emulsifying ability to surface-inactive polysaccharides—bottom-up vs top-down approaches. NPJ Science of Food. 2018;2(1):15. https://doi.org/10.1038/s41538-018-0023-7.

Chen W, He H, Zhu H, Cheng M, Li Y, Wang S. Thermo-responsive cellulose-based material with switchable wettability for controllable oil/water separation. Polymers. 2018;10(6):592.

Abderrahim B, Abderrahman E, Mohamed A, Fatima T, Abdesselam T, Krim O (2015) Kinetic thermal degradation of cellulose, polybutylene succinate and a green composite: comparative study. World J Environ Eng 3 (4):95–110. https://doi.org/10.12691/wjee-3-4-1

Jiang X, Wang S, Ge L, Lin F, Lu Q, Wang T, Huang B, Lu B. Development of organic–inorganic hybrid beads from sepiolite and cellulose for effective adsorption of malachite green. RSC Adv. 2017;7(62):38965–72. https://doi.org/10.1039/c7ra06351b.

Derrick MR, Stulik D, Landry JM (1999) Scientific tools for conservation: infrared spectroscopy in conservation science. Los Angeles: The Getty Conservation Institute 158

Nisha MH, Tamileaswari R. Analysis of anti-bacterial activity of silver nanoparticles from pomegranate (Punica granatum) seed and peel extracts. International Journal of Engineering Research & Technology. 2015;4(4):1044–8.

Fernandez de Simon B, Perez-Ilzarbe J, Hernandez T, Gomez-Cordoves C, Estrella I. Importance of phenolic compounds for the characterization of fruit juices. J Agric Food Chem. 1992;40(9):1531–5. https://doi.org/10.1021/jf00021a012.

Hmid I, Elothmani D, Hanine H, Oukabli A, Mehinagic E. Comparative study of phenolic compounds and their antioxidant attributes of eighteen pomegranate (Punica granatum L.) cultivars grown in Morocco. Arab J Chem. 2017;10:S2675–84. https://doi.org/10.1016/j.arabjc.2013.10.011.

Gil MI, Tomás-Barberán FA, Hess-Pierce B, Holcroft DM, Kader AA. Antioxidant activity of pomegranate juice and its relationship with phenolic composition and processing. J Agric Food Chem. 2000;48(10):4581–9. https://doi.org/10.1021/jf000404a.

Akhavan H, Barzegar M, Weidlich H, Zimmermann BF. Phenolic compounds and antioxidant activity of juices from ten iranian pomegranate cultivars depend on extraction. J Chem. 2015;2015: 907101. https://doi.org/10.1155/2015/907101.

Ragab M, El-Nemr SE. Chemical composition and volatile constituents of canned mango juice. Food Nahrung. 1990;34(7):591–9. https://doi.org/10.1002/food.19900340703.

Ditzler C, Scheffe K, Monger H (2017) Soil survey manual: soil science division staff. Goverment Printing Office: Washington, DC, USA

Acknowledgements

The authors are grateful appreciation the cooperation between Restoration and Conservation Department, Faculty of Archaeology, Cairo University, Egypt, Polymer Department National Research Centre, Dokki, Giza, Egypt and Forestry and Wood Technology Department, Faculty of Agriculture (El-Shatby), Alexandria University, Alexandria, Egypt.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

RRAH, WSM, and ZMMS designed the experiment, and methodology, and wrote the manuscript; AMOAE, EEME, EMAN, EGA-EE, and RAAH contributed in rewriting, design the figures and interpretation the results. All authors investigated the results and reviewed the manuscript.

Corresponding authors

Ethics declarations

Ethical approval and consent to participate

This study is complied with relevant institutional, national, and international guidelines and legislation. This study does not contain any studies with human participants or animals performed by any of the authors.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hassan, R.R.A., Mohamed, W.S., Salem, M.Z.M. et al. Cellulose and gellan gum compresses for cleaning mud and pomegranate stains from a historical printed paper. Discov Appl Sci 6, 43 (2024). https://doi.org/10.1007/s42452-024-05658-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-024-05658-y