Abstract

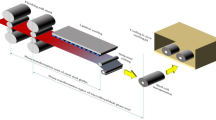

After cooling in the hot rolling process, the metallographic structure of microalloyed dual-phase steel is nonuniform along the rolling direction, while the thickness fluctuation of microalloyed dual-phase steel with a nonuniform metallographic structure will occur during cold rolling. The mechanism of nonuniform phase transformation of microalloyed dual-phase steels was studied during the cooling process after hot rolling, and the nonuniform phase transformation of microalloyed dual-phase steel was regulated during the cooling process after hot rolling through process optimization. First, the empirical equation of phase transformation temperature was measured by a dilatometer considering thermal expansion. Then, the phase field and temperature field of laminar cooling process were calculated to provide initial boundary conditions for the finite element model. After that, the coupling finite element model of the temperature phase transformation of the strip steel in coiling transportation process was established. The simulation results show that the different thermal contact conditions of the microalloyed dual-phase steel during coil transportation lead to uneven cooling of the coil, which leads to nonuniform transformation of the coil along the rolling direction. In addition, by prolonging the time interval from coiling to unloading, the phenomenon of nonuniform phase transformation of microalloyed dual-phase steel can be effectively controlled. The simulation results are applied to industrial production. The application results show that prolonging the time interval from coiling to unloading can effectively improve the nonuniform phase transformation of microalloyed dual-phase steel in the cooling process after hot rolling.

Access this article

We’re sorry, something doesn't seem to be working properly.

Please try refreshing the page. If that doesn't work, please contact support so we can address the problem.

Similar content being viewed by others

References

Z. Jiang, Z. Guan, J. Lian, Mater. Sci. Eng. A 190 (1995) 55–64.

J.Z. Xue, Z.Z. Zhao, D. Tang, H. Li, H.H. Wu, W.L. Xiong, L. Liang, Y. Huang, J. Iron Steel Res. Int. 28 (2021) 346–359.

C.P. Scott, F. Fazeli, B. Shalchi Amirkhiz, I. Pushkareva, S.Y.P. Allain, Mater. Sci. Eng. A 703 (2017) 293–303.

X. Wang, Q. Yang, A. He, J. Mater. Process. Technol. 207 (2008) 130–146.

B. Ning, H.B. Wu, G. Niu, X.P. Yu, J. Iron Steel Res. Int. 29 (2022) 503–511.

L.M. Kaputkina, A.V. Marmulev, E.I. Poliak, G. Herman, Met. Sci. Heat Treat. 54 (2013) 628–632.

E.I. Poliak, D. Bhattacharya, Mater. Sci. Forum 783–786 (2014) 3–8.

K. Prinz, A. Steinboeck, M. Muller, A. Ettl, A. Kugi, IEEE Trans. Ind. Applicat. 53 (2017) 2560–2568.

C. Song, J. Cao, L. Wang, J. Xiao, Q. Zhao, Int. J. Adv. Manuf. Technol. 121 (2022) 295–308.

Y.W. Wang, J.G. Cao, C.N. Song, L.L. Wang, L. Sun, D. Xie, Y.L. Lu, Steel Res. Int. 93 (2022) 2100514.

C. Park, J.W. Kim, B. Kim, J. Lee, IEEE Access 8 (2020) 60890–60905.

A. Milenin, R. Kuziak, M. Lech-Grega, A. Chochorowski, S. Witek, M. Pietrzyk, Arch. Civ. Mech. Eng. 16 (2016) 125–134.

M. Karlberg, ISIJ Int. 56 (2016) 1808–1814.

S. Witek, A. Milenin, Arch. Civ. Mech. Eng. 18 (2018) 659–668.

S.J. Park, B.H. Hong, S.C. Baik, K.H. Oh, ISIJ Int. 38 (1998) 1262–1269.

J. Ilmola, A. Pohjonen, O. Seppälä, J. Larkiola, Procedia Manuf. 50 (2020) 418–424.

J. Ilmola, A. Pohjonen, S. Koskenniska, O. Seppälä, O. Leinonen, J. Jokisaari, J. Pyykkönen, J. Larkiola, Mater. Today Commun. 26 (2021) 101973.

Y. Kaynak, E. Taşcıoğlu, S. Sharif, M.A. Suhaimi, O. Benefan, J. Manuf. Process. 75 (2022) 1144–1152.

M. Avrami, J. Chem. Phys. 8 (1940) 212–224.

E. Scheil, Arch. Für Das Eisenhüttenwesen 8 (1935) 565–567.

A.I. Zaky, A. El-Morsy, T. El-Bitar, J. Mater. Process. Technol. 209 (2009) 1565–1569.

M. Rahaman, W. Mu, J. Odqvist, P. Hedström, Metall. Mater. Trans. A 50 (2019) 2081–2091.

N. Peranio, Y.J. Li, F. Roters, D. Raabe, Mater. Sci. Eng. A 527 (2010) 4161–4168.

F. Hollander, Iron and Steel Institute 208 (1970) 46–74.

L.P. Yang, Y. Peng, H.M. Liu, J. Iron Steel Res. Int. 11 (2004) No. 4, 29–33.

E.Y. Liu, W. Peng, N. Cao, S.R. Yu, J. Xu, L.G. Peng, D.H. Zhang, Appl. Mech. Mater. 633–634 (2014) 679–683.

T. Yuan, W. Sun, A. He, L. Chen, C. Liu, S. Yong, Int. J. Adv. Manuf. Technol. 122 (2022) 3867–3880.

S.H. Zhang, L. Deng, L.Z. Che, J. Manuf. Process. 75 (2022) 100–109.

S.H. Zhang, L. Deng, W.H. Tian, L.Z. Che, Y. Li, Comput. Math. Appl. 109 (2022) 58–73.

W.W. Park, D.K. Kim, Y.T. Im, H.C. Kwon, M.S. Chun, Met. Mater. Int. 20 (2014) 719–726.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 52004029).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, Wq., Yong, Sy., Yuan, Th. et al. Mechanism and control of nonuniform phase transformation of microalloyed dual-phase steel during cooling process after hot rolling. J. Iron Steel Res. Int. 31, 428–441 (2024). https://doi.org/10.1007/s42243-023-00961-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-00961-1