Abstract

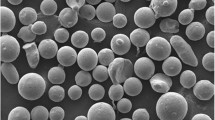

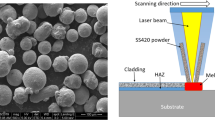

Stainless steel (SS) 410 is widely used in many components of nuclear reactors due to its good corrosion resistance and high strength. However, wear is a major issue of these components due to its continuous sliding. SS 420 and Colmonoy 5 particles were deposited over SS 410 substrate by laser cladding process. Then, X-ray diffraction was used to find the phases present after cladding process. Further, coating morphologies were analysed by scanning electron microscopy (SEM) twinned with energy-dispersive spectroscopy. The obtained morphology indicates the hard laves phase present in the Colmonoy 5 cladding surface and needle-like structure in SS 420 cladding surface. Then, Vickers microhardness test was carried out in order to study the hardness and load-carrying capacity of the cladding specimen. Among those, Colmonoy 5 cladding specimen provide higher hardness due to the presence of laves phase formation. Then, the dry sliding wear study was conducted to calculate the mass loss after 2500 m of sliding. The combined effect of hardness and laves phase formation were reflected in dry sliding wear study analysis of the specimens. Then, to study the wear mechanism and roughness, worn surface morphologies were captured using SEM and white light interferometer, respectively.

Similar content being viewed by others

References

K.R. Ramkumar, S. Sivasankaran, F.A. Al-Mufadi, S. Siddharth, R. Raghu, Arch. Civ. Mech. Eng. 19 (2019) 428–438.

Š. Houdková, Z. Pala, E. Smazalová, M. Vostřák, Z. Česánek, Surf. Coat. Technol. 318 (2017) 129–141.

A.P. Wu, J.L. Ren, Z.S. Peng, H. Murakawa, Y. Ueda, J. Mater. Process. Technol. 101 (2000) 70–75.

V.D. Botch, Y.H. Hong, Z.H. Huang, Z.W. Li, Q. Liu, J. Wu, Y.M. Lu, X.K. Liu, J. Alloy. Compd. 773 (2019) 698–705.

W. Ya, B. Pathiraj, D.T.A. Matthews, M. Bright, S. Melzer, Surf. Coat. Technol. 350 (2018) 323–333.

D.Y. Lin, N.N. Zhang, B. He, G.W. Zhang, Y. Zhang, D.Y. Li, J. Iron Steel Res. Int. 24 (2017) 184–189.

S. Atamert, H.K.D.H. Bhadeshia, Metall. Trans. A 20 (1989) 1037–1054.

Y. Wang, D.O. Northwood, Int. J. Hydrogen Energy 32 (2007) 895–902.

Z. Zhang, P. Farahmand, R. Kovacevic, Mater. Des. 109 (2016) 686–699.

L.J. da Silva, A.S.C.M. D’Oliveira, Weld. Int. 31 (2017) 1–8

M. Benkahoul, P. Robin, L. Martinu, J.E. Klemberg-Sapieha, Surf. Coat. Technol. 203 (2009) 934–940.

S. Hassani, J.E. Klemberg-Sapieha, L. Martinu, Surf. Coat. Technol. 205 (2010) 1426–1430.

F.A. España, V.K. Balla, A. Bandyopadhyay, Surf. Coat. Technol. 204 (2010) 2510–2517.

X.T Liu, W.B. Lei, Q.J. Wang, W.P. Tong, C.S. Liu, J.Z. Cui, J. Iron Steel Res. Int. 23 (2016) 1195–1199.

N. Jeyaprakash, C.H. Yang, S.P. Tseng, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00526-6.

S. Gnanasekaran, G. Padmanaban, V. Balasubramanian, H. Kumar, S.K. Albert, High Temp. Mater. Processes 38 (2019) 16–29.

R.K. Rajan, H. Kumar, S.K. Albert, T.R. Vijayaram, Appl. Mech. Mater. 592–594 (2014) 1346–1351.

F. Gao, R. Liu, X.J. Wu, Thin Solid Films 519 (2011) 4809–4817.

N. Jeyaprakash, M. Duraiselvam, R. Raju, Arch. Metall. Mater. 63 (2018) 1303–1315.

J.B. Lin, C.J. Chen, M. Zhang, S.Q. Wang, J. Mater. Eng. Perform. 27 (2018) 6339–6348.

R. Liu, J.H. Yao, Q.L. Zhang, M.X. Yao, R. Collier, J. Eng. Mater. Technol. 138 (2016) 041001–041007.

S. Kumar, D.P. Mondal, A.K. Jha, H.K. Khaira, J. Mater. Eng. Perform. 8 (1999) 711–715.

N. Jeyaprakash, C.H. Yang, M. Duraiselvam, G. Prabu, Results Phys. 12 (2019) 1610–1620.

A. Vencl, B. Katavić, D. Marković, M. Ristić, B. Gligorijević, Tribol. Ind. 37 (2015) 320–329.

N. Jeyaprakash, C.H. Yang, M. Duraiselvam, G. Prabu, S.P. Tseng, D. Raj Kumar, Results Phys. 15 (2019) 102585.

E. Rodriguez, M.A. González, H.R. Monjardín, O. Jimenez, M. Flores, J. Ibarra, Met. Mater. Int. 23 (2017) 1121–1132.

J.D. Gates, Wear 214 (1998) 139–147.

N. Jeyaprakash, M. Duraiselvam, S.V. Aditya, Surf. Rev. Lett. 26 (2019) 1950009.

J.R. Davis, ASM Int. Met. Park 6 (1993) 789–829.

Ö.N. Doǧan, J.A. Hawk, Wear 189 (1995) 136–142.

A.P. Umanskii, M.S. Storozhenko, I.V. Hussainova, A.E. Terentiev, A.M. Kovalchenko, M.M. Antonov, Powder Metall. Met. Ceram. 53 (2015) 663–671.

Acknowledgements

Authors wish to thank Ministry of Science and Technology (MOST), Taiwan, China, for providing financial support to carry out this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jeyaprakash, N., Yang, Ch., Ramkumar, K. et al. Comparison of microstructure, mechanical and wear behaviour of laser cladded stainless steel 410 substrate using stainless steel 420 and Colmonoy 5 particles. J. Iron Steel Res. Int. 27, 1446–1455 (2020). https://doi.org/10.1007/s42243-020-00447-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00447-4