Abstract

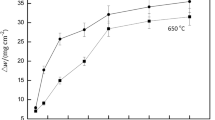

High-nitrogen (N) austenitic stainless steel (Cr–Mn–N series) is commonly used for non-magnetic drill collars, which exhibits excellent mechanical properties and corrosion resistance. The effects of N content (0.63 to 0.86 wt.%) on the pitting corrosion behavior of the experimental non-magnetic drill collar steel were investigated using the electrochemical tests and immersion tests. Besides, X-ray photoelectron spectroscopy was used to analyze the constitution of the passive film. The results show that with the enhancement of N content from 0.63 to 0.86 wt.%, the metastable pitting corrosion sensitivity of the tested materials in 3.5 wt.% NaCl solution decreased and the pitting corrosion resistance increased. Meanwhile, the corrosion rate in 6 wt.% FeCl3 solution at 30 °C decreased from 10.40 to 4.93 mm/a. On the other hand, nitrogen was concentrated in the form of ammonia (NH4+ and NH3) on the outermost surface of the passive films. The contents of Cr2O3 and Fe2O3 raised in the passive films, together with the content of CrN, at metal/film interface increased as N content increased from 0.63 to 0.86 wt.%, which facilitated protective ability of the passive films, thus contributing to higher pitting corrosion resistance.

Similar content being viewed by others

References

M.J. Knight, F.P. Brennan, Eng. Fail. Anal. 6 (1999) 301–319.

J. Edwards, F. Pernet, S.V.J. Jakeman, Geoexploration 17 (1979) 229–241.

Z. Zhong, Y. Li, Y. Liu, L. Bao, Z. Tian, Eng. Fail. Anal. 105 (2019) 727–735.

N.A. Mariano, D. Spinelli, Mater. Sci. Eng. A 385 (2004) 212–219.

Y.P. Lang, H.P. Qu, H.T. Chen, Y.Q. Weng, J. Iron Steel Res. Int. 22 (2015) 91–98.

H.C. Zhu, Z.H. Jiang, H.B. Li, H. Feng, S.C. Zhang, G.H. Liu, J.H. Zhu, P.B. Wang, B.B. Zhang, G.W. Fan, G.P. Li, Metall. Mater. Trans. B 48 (2017) 2493–2503.

S. Zhang, H. Li, Z. Jiang, B. Zhang, Z. Li, J. Wu, S. Fan, H. Feng, H. Zhu, Mater. Charact. 152 (2019) 141–150.

G. Saller, H. Aigner, Mater. Manuf. Process. 14 (2004) 41–49.

Y. Fu, X. Wu, E. Han, W. Ke, K. Yang, Z. Jiang, Electrochim. Acta 54 (2009) 4005–4014.

H.B. Li, Z.H. Jiang, H. Feng, S.C. Zhang, L. Li, P.D. Han, R.D.K. Misra, J.Z. Li, Mater. Des. 84 (2015) 291–299.

Z. Jiang, H. Feng, H. Li, H. Zhu, S. Zhang, B. Zhang, Y. Han, T. Zhang, D. Xu, Materials 10 (2017) 861.

H. Li, E. Zhou, Y. Ren, D. Zhang, D. Xu, C. Yang, H. Feng, Z. Jiang, X. Li, T. Gu, K. Yang, Corros. Sci. 111 (2016) 811–821.

G. Lothongkum, P. Wongpanya, S. Morito, T. Furuhara, T. Maki, Corros. Sci. 48 (2006) 137–153.

W.C. Jiao, H.B. Li, J. Dai, H. Feng, Z.H. Jiang, T. Zhang, D.K. Xu, H.C. Zhu, S.C. Zhang, J. Mater. Sci. Technol. 35 (2019) 2357–2364.

S.L. Lv, Z.M. Yang, B. Zhang, J. Chen, Y. Chen, X.B. Li, J. Iron Steel Res. Int. 25 (2018) 943–953.

H.F. Xu, G.L. Wu, C. Wang, J. Li, W.Q. Cao, J. Iron Steel Res. Int. 25 (2018) 954–967.

J.B. Lee, S.I. Yoon, Mater. Chem. Phys. 122 (2010) 194–199.

S. Ningshen, U. Kamachi Mudali, V.K. Mittal, H.S. Khatak, Corros. Sci. 49 (2007) 481–496.

H. Feng, Z. Jiang, H. Li, P. Lu, S. Zhang, H. Zhu, B. Zhang, T. Zhang, D. Xu, Z. Chen, Corros. Sci. 144 (2018) 288–300.

R.F.A. Jargelius-Pettersson, Corros. Sci. 41 (1999) 1639–1664.

H. Feng, H. Li, X. Wu, Z. Jiang, S. Zhao, T. Zhang, D. Xu, S. Zhang, H. Zhu, B. Zhang, M. Yang, J. Mater. Sci. Technol. 34 (2018) 1781–1790.

Y. Zhao, X. Li, C. Zhang, T. Zhang, J. Xie, G. Zeng, D. Xu, F. Wang, Corros. Sci. 145 (2018) 307–319.

Database for surface spectroscopies as XPS, AES and UPS, 2017. http://www.lasurface.com. (Accessed: 2017-10-10).

D. Kong, C. Dong, X. Ni, L. Zhang, J. Yao, C. Man, X. Cheng, K. Xiao, X. Li, J. Mater. Sci. Technol. 35 (2019) 1499–1507.

X.Y. Li, C.H. Fan, Q.L. Wu, L.H. Dong, Y.S. Yin, C.J. Wang, J.X. Liang, J. Iron Steel Res. Int. 24 (2017) 1238–1247.

G.S. Frankel, J. Electrochem. Soc. 145 (1998) 2186–2198.

M. Tang, J. Wang, Z. Feng, G. Li, Z. Yan, R. Zhang, Ceram. Int. 45 (2019) 16918–16926.

S. Fajardo, I. Llorente, J. JimÉNez, J.M. Bastidas, D.M. Bastidas, Corros. Sci. 154 (2019) 246–253.

H. Li, Z. Jiang, H. Feng, Q. Wang, W. Zhang, G. Fan, G. Li, L. Wang, Int. J. Electrochem. Sci. 10 (2015) 1616–1631.

Y.X. Qiao, Y.G. Zheng, W. Ke, P.C. Okafor, Corros. Sci. 51 (2009) 979–986.

G. Tranchida, M. Clesi, F. Di Franco, F. Di Quarto, M. Santamaria, Electrochim. Acta 273 (2018) 412–423.

C.R. Clayton, G.P. Halada, J.R. Kearns, Mater. Sci. Eng. A 198 (1995) 135–144.

Y. Yang, X. Ning, H. Tang, L. Guo, H. Liu, Appl. Surf. Sci. 320 (2014) 274–280.

H. Feng, H.B. Li, Z.H. Jiang, T. Zhang, N. Dong, S.C. Zhang, P.D. Han, S. Zhao, Z.G. Chen, Corros. Sci. 158 (2019) 108081.

H.B. Li, Z.H. Jiang, Y. Cao, Z.R. Zhang, Int. J. Miner. Metall. Mater. 16 (2009) 387–392.

C.O.A. Olsson, Corros. Sci. 37 (1995) 467–479.

H.J. Grabke, ISIJ Int. 36 (1996) 777–786.

R.D. Willenbruch, C.R. Clayton, M. Oversluizen, D. Kim, Y. Lu, Corros. Sci. 31 (1990) 179–190.

C.R. Clayton, Y.C. Lu, J. Electrochem. Soc. 133 (1986) 2465–2473.

Acknowledgements

This research was sponsored by the National Natural Science Foundation of China (Grant Nos. U1960203, 51774074 and 51434004), Shanxi Municipal Major Science and Technology Project (Grant No. 20181101014), Fundamental Research Funds for the Central Universities (Grant Nos. N172512033 and N2024005-4), Talent Project of Revitalizing Liaoning (XLYC1902046) and State Key Laboratory of Metal Material for Marine Equipment and Application (Grant No. HG-SKL (2019) 13).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, Lw., Li, Hb., Zheng, Hb. et al. Effects of nitrogen content on pitting corrosion resistance of non-magnetic drill collar steel. J. Iron Steel Res. Int. 27, 1466–1475 (2020). https://doi.org/10.1007/s42243-020-00428-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00428-7