Abstract

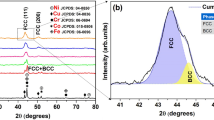

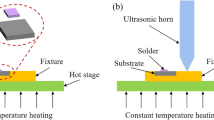

Graphite film (GF) is considered as an unrivaled candidate of heat sink in thermal management applications. The inappropriate thermal interface material (TIM), however, could severely restrain the application of GF as heat sink. In this study, GF heat sink was assembled with SAC305 (Sn-3.0Ag-0.5Cu, wt. %) solder through ultrasonic-assisted soldering approach. Due to ultrasonic effects, the soldered interface for heat transfer exhibited compact structure. The forming of Ag3Sn and Cu6Sn5 nanoparticles at interface could improve the interfacial coefficient gradient of thermal expansion. Comparing to traditional thermally conducted packaging method, soldering-assembled GF heat sinks exhibited excellent cooling efficiency, which could be maintained after more than 50 thermal cycles from 0 to 100 °C, and after thermal aging treatments for over 48 h under 150 °C in air. In the mechanical performance tests, the ultrasonic-assisted soldered GF joints showed high structural stability. These findings reinforce the significant potential of ultrasonic-assisted soldered GFs in thermal management.

Graphical abstract

Assembly of graphite film (GF) heat sink was realized by employing SAC305 solders as TIMs with ultrasonic-assisted soldering approach. The high thermal conductivity of GF and SAC305, compact thermal conduction interface and improved interfacial coefficient gradient of thermal expansion, endowed GF heat sink with durably excellent heat dissipating efficiency, high structural stability, indicating its significant potential in thermal management applications.

Similar content being viewed by others

Availability of data and material

All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

Song H, Liu J, Liu B, Wu J, Cheng HM, Kang F (2018) Two-dimensional materials for thermal management applications. Joule 2:442–463. https://doi.org/10.1016/j.joule.2018.01.006

Moore AL, Li S (2014) Emerging challenges and materials for thermal management of electronics. Mater Today 17:163–174. https://doi.org/10.1016/j.mattod.2014.04.003

Deng Y, Liu J (2010) A liquid metal cooling system for the thermal management of high power LEDs. Int Commun Heat Mass Transf 37:788–791. https://doi.org/10.1016/j.icheatmasstransfer.2010.04.011

Razeeb KM, Dalton E, Cross GLW, Robinson AJ (2018) Present and future thermal interface materials for electronic devices. Int Mater Rev 63:1–21. https://doi.org/10.1080/09506608.2017.1296605

Liu Y, Chen HF, Zhang HW, Li YX (2015) Heat transfer performance of lotus-type porous copper heat sink with liquid GaInSn coolant. Int J Heat Mass Transf 80:605–613. https://doi.org/10.1016/j.ijheatmasstransfer.2014.09.058

Peng L, Xu Z, Liu Z, Guo Y, Li P, Gao C (2017) Ultrahigh thermal conductive yet superflexible graphene films. Adv Mater 29:1700589. https://doi.org/10.1002/adma.201700589

Akbari A, Cunning BV, Joshi SR, Wang C, Camacho-Mojica DC, Chatterjee S, Modepalli V, Cahoon C, Bielawski CW, Bakharev P, Kim GH, Ruoff RS (2020) Highly ordered and dense thermally conductive graphitic films from a graphene oxide/reduced graphene oxide mixture. Matter 2:1198–1206. https://doi.org/10.1016/j.matt.2020.02.014

Xin G, Sun H, Hu T, Fard HR, Sun X, Koratkar N, Borca-Tasciuc T, Lian J (2014) Large-area freestanding graphene paper for superior thermal management. Adv Mater 26:4521–4526. https://doi.org/10.1002/adma.201400951

Liou B-H, Chen C-M, Horng R-H, Chiang Y-C, Wuu D-S (2012) Improvement of thermal management of high-power GaN-based light-emitting diodes. Microelectron Reliab 52:861–865. https://doi.org/10.1016/j.microrel.2011.04.002

Prasher RS, Koning P, Shipley J, Devpura A (2003) Dependence of thermal conductivity and mechanical rigidity of particle-laden polymeric thermal interface material on particle volume fraction. J Electron Packag Trans ASME 125:386–391. https://doi.org/10.1115/1.1602703

Xu J, Munari A, Dalton E, Mathewson A, Razeeb KM (2009) Silver nanowire array-polymer composite as thermal interface material. J Appl Phys 106:1–8. https://doi.org/10.1063/1.3271149

Bockenheimer C, Fata D, Possart W (2004) New aspects of aging in epoxy networks. I. Thermal aging. J Appl Polym Sci 91:361–368. https://doi.org/10.1002/app.13092

Zahra Y, Djouani F, Fayolle B, Kuntz M, Verdu J (2014) Thermo-oxidative aging of epoxy coating systems. Prog Org Coatings 77:380–387. https://doi.org/10.1016/j.porgcoat.2013.10.011

Hsu CY, Lin YL (2013) Thermal characteristics of high-power LED packages with dissipation film. Appl Mech Mater 397–400:1767–1771. https://doi.org/10.4028/www.scientific.net/AMM.397-400.1767

Ganguli S, Roy AK, Wheeler R, Varshney V, Du F, Dai L (2013) Superior thermal interface via vertically aligned carbon nanotubes grown on graphite foils. J Mater Res 28:933–939. https://doi.org/10.1557/jmr.2012.401

Xu S, Wang S, Chen Z, Sun Y, Gao Z, Zhang H, Zhang J (2020) Electric-field-assisted growth of vertical graphene arrays and the application in thermal interface materials. Adv Funct Mater 2003302:1–7. https://doi.org/10.1002/adfm.202003302

Barako MT, Gao Y, Marconnet AM, Asheghi M, Goodson KE (2012) Solder-bonded carbon nanotube thermal interface materials. In: 13th InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems. IEEE, pp 1225–1233

Tuan WH, Chou TT, Kao CT, Wang SY, Weng BJ (2018) Thermal diffusivity of graphite paper and its joint with alumina substrate. J Eur Ceram Soc 38:187–191. https://doi.org/10.1016/j.jeurceramsoc.2017.07.029

Sánchez SA, Narciso J, Louis E, Rodríguez-Reinoso F, Saiz E, Tomsia A (2008) Wetting and capillarity in the Sn/graphite system. Mater Sci Eng A 495:187–191. https://doi.org/10.1016/j.msea.2007.09.090

Wang Z, Li P, Song R, Qian W, Zhou H, Wang Q, Wang Y, Zeng X, Ren L, Yan S, Mu S, He D (2020) High conductive graphene assembled films with porous micro-structure for freestanding and ultra-low power strain sensors. Sci Bull 65:1363–1370. https://doi.org/10.1016/j.scib.2020.05.002

Peacock MA, Roy CK, Hamilton MC, Wayne Johnson R, Knight RW, Harris DK (2016) Characterization of transferred vertically aligned carbon nanotubes arrays as thermal interface materials. Int J Heat Mass Transf 97:94–100. https://doi.org/10.1016/j.ijheatmasstransfer.2016.01.071

Moutis NV, Jimenez C, Azpiroz X, Speliotis T, Wilhelmi C, Messoloras S, Mergia K (2010) Brazing of carbon-carbon composites to Nimonic alloys. J Mater Sci 45:74–81. https://doi.org/10.1007/s10853-009-3893-x

Chang J, Zhang Q, Lin Y, Shao P, Pei Y, Zhong S, Wu G (2019) Thermal management applied laminar composites with SiC nanowires enhanced interface bonding strength and thermal conductivity. Nanoscale 11:15836–15845. https://doi.org/10.1039/c9nr04644e

Zhao S, Zheng Z, Huang Z, Dong S, Luo P, Zhang Z, Wang Y (2016) Cu matrix composites reinforced with aligned carbon nanotubes: mechanical, electrical and thermal properties. Mater Sci Eng A 675:82–91. https://doi.org/10.1016/j.msea.2016.08.044

Fu W, Hu SP, Song XG, Li JX, Cao J, Feng JC, Wang GD (2017) Wettability and bonding of graphite by Sn0.3Ag0.7Cu-Ti alloys. Carbon 121:536–543. https://doi.org/10.1016/j.carbon.2017.06.030

Amaratunga GAJ, Andrienko I, Anguita JV, Aono M, Arnold W, Barklie RC, Beghi MG, Bilek MM, Bottani CE (2003) Properties of Amorphous Carbon, 29th edn. The Institution of Electrical Engineers, London

Tollefsen TA, Larsson A, Løvvik OM, Aasmundtveit K (2012) Au-Sn SLID bonding—properties and possibilities. Metall Mater Trans B 43:397–405. https://doi.org/10.1007/s11663-011-9609-z

Fu H, Xiao Y, Song R, Wang Z, Ji H, He D (2020) Rapid soldering of flexible graphene assembled films at low temperature in air with ultrasonic assistance. Carbon 158:55–62. https://doi.org/10.1016/j.carbon.2019.11.089

Caņado LG, Takai K, Enoki T, Endo M, Kim YA, Mizusaki H, Jorio A, Coelho LN, Magalhães-Paniago R, Pimenta MA (2006) General equation for the determination of the crystallite size la of nanographite by Raman spectroscopy. Appl Phys Lett 88:1–4. https://doi.org/10.1063/1.2196057

Reich S, Thomsen C (2004) Raman spectroscopy of graphite. Philos Trans R Soc London Ser A Math Phys Eng Sci 362:2271–2288

Mukhtar MFM, Abas A, Haslinda M, Ani FC, Abdullah MZ, Jalar A, Ismail R (2018) Discrete Phase Model (DPM) study of nano-reinforced Lead Free Solder Sn-3.0Ag-0.5Cu (SAC305). IOP Conf Ser Mater Sci Eng 370:012067. https://doi.org/10.1088/1757-899X/370/1/012067

Suslick KS (1989) The chemical effects of ultrasound. Sci Am 80–86. https://www.jstor.org/stable/24987145

Shchukin DG, Skorb E, Belova V, Möhwald H (2011) Ultrasonic cavitation at solid surfaces. Adv Mater 23:1922–1934. https://doi.org/10.1002/adma.201004494

Eskin DG (2015) Ultrasonic degassing of liquids. In: Power Ultrasonics. Elsevier, pp 611–631

Eskin G (1995) Cavitation mechanism of ultrasonic melt degassing. Ultrason Sonochem 2:S137–S141. https://doi.org/10.1016/1350-4177(95)00020-7

Yu WY, Liu SH, Liu XY, Shao JL, Liu MP (2015) Wetting behavior in ultrasonic vibration-assisted brazing of aluminum to graphite using Sn-Ag-Ti active solder. Surf Rev Lett 22:1–9. https://doi.org/10.1142/S0218625X15500353

Yu W, Liu Y, Liu X (2018) Spreading of Sn-Ag-Ti and Sn-Ag-Ti(-Al) solder droplets on the surface of porous graphite through ultrasonic vibration. Mater Des 150:9–16. https://doi.org/10.1016/j.matdes.2018.04.028

Li JF, Agyakwa PA, Johnson CM (2010) Kinetics of Ag3Sn growth in Ag–Sn–Ag system during transient liquid phase soldering process. Acta Mater 58:3429–3443. https://doi.org/10.1016/j.actamat.2010.02.018

Li JF, Agyakwa PA, Johnson CM (2011) Interfacial reaction in Cu/Sn/Cu system during the transient liquid phase soldering process. Acta Mater 59:1198–1211. https://doi.org/10.1016/j.actamat.2010.10.053

Ma Y, Li X, Zhou W, Yang L, Wu P (2017) Reinforcement of graphene nanosheets on the microstructure and properties of Sn58Bi lead-free solder. Mater Des 113:264–272. https://doi.org/10.1016/j.matdes.2016.10.034

Liang J, Yamajo S, Kuball M, Shigekawa N (2019) Room-temperature direct bonding of diamond and Al. Scr Mater 159:58–61. https://doi.org/10.1016/j.scriptamat.2018.09.016

Huang Y, Ouyang Q, Guo Q, Guo X, Zhang G, Zhang D (2016) Graphite film/aluminum laminate composites with ultrahigh thermal conductivity for thermal management applications. Mater Des 90:508–515. https://doi.org/10.1016/j.matdes.2015.10.146

Billah MM, Siddiquee RI, Motalab M (2019) Temperature dependent mechanical properties of inter-metallic compounds in nano-solder joints. In: AIP Conference Proceedings, p 140014

Yoon D, Son Y-W, Cheong H (2011) Negative thermal expansion coefficient of graphene measured by Raman spectroscopy. Nano Lett 11:3227–3231. https://doi.org/10.1021/nl201488g

Wang MS, Wang JY, Chen Q, Peng L-M (2005) Fabrication and electrical and mechanical properties of carbon nanotube interconnections. Adv Funct Mater 15:1825–1831. https://doi.org/10.1002/adfm.200500215

Lindsay AL, Bromley LA (1950) Thermal conductivity of gas mixtures. Ind Eng Chem 42:1508–1511. https://doi.org/10.1021/ie50488a017

Suh D, Moon CM, Kim D, Baik S (2016) Ultrahigh thermal conductivity of interface materials by silver-functionalized carbon nanotube phonon conduits. Adv Mater 28:7220–7227. https://doi.org/10.1002/adma.201600642

Wang G, Dai Z, Wang Y, Tan P, Liu L, Xu Z, Wei Y, Huang R, Zhang Z (2017) Measuring interlayer shear stress in bilayer graphene. Phys Rev Lett 119:036101. https://doi.org/10.1103/physrevlett.119.036101

Acknowledgements

The authors thank Prof. Zhi Zhang from Huazhong University of Science and Technology for the TEM characterization of interface structure. The authors thank Dr. Xiaoqing Liu from Center for Materials Research and Analysis of Wuhan University of Technology for the data analysis of TEM.

Funding

This study was funded by National Natural Science Foundation of China (No. 51605357) and 2018 National Key R&D Program of China 257.

Author information

Authors and Affiliations

Contributions

Y. X. and D. H. conceived the project. H. F., Y. X., and D. L. designed and performed the ultrasonic-assisted soldering of graphite films. H. F., P. L., and W. Q. performed the characterizations and carried out the mechanical performance test. H. F. carried out the test on thermal dissipating performance of GF heat sink using different TIMs. H. F. wrote the paper. Y. X., X. Z., and D. H. revised the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Fu, H., Xiao, Y., Li, P. et al. Ultrasonic-assisted soldering for graphite films as heat sinks with durably superior heat dissipating efficiency. Adv Compos Hybrid Mater 5, 2154–2162 (2022). https://doi.org/10.1007/s42114-021-00255-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00255-8