Abstract

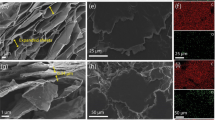

Paraffin, as a low-cost organic phase change material (PCM), has the advantage of large latent heat in a phase change but suffers from the disadvantage of poor thermal conductivity and easy leakage. Improving the thermal conductivity and enhancing the leakage-proof of paraffin are significantly important for its large-scale application. In this work, we adopt the convenient melt blending method to prepare the paraffin/high-density polyethylene (HDPE)/expandable graphite (EG) composite PCMs. The results show that HDPE as a packaging medium can restrict the leakage of paraffin efficiently, and the introduction of EG can significantly improve the heat transfer rate of the PCM. By optimizing the ratio of each component, the sample PCM10-5 (HDPE 10 wt%, EG 5 wt%) exhibits the best performance and its thermal conductivity is 0.641 W/(m · K), which is 2.7 times than that of paraffin, and the speed of response to temperature is increased by about 25.9%. It is noted that the paraffin would be leaked completely at 70 °C, while the leakage of PCM10-5 is only 30% owing to the HDPE packaging. The 120 thermal cycles show that the heat loss of PCM10-5 is within 5%, suggesting its high thermal storage stability. The excellent properties of composite PCMs render it broad application potentials in low-temperature thermal management devices.

Graphical abstract

The paraffin/HDPE/EG composite phase change materials exhibits enhanced thermal conductivity and leakage-proof properties compared to the matrix, which is attributed to the addition of HDPE as packaging materials and the introduction of EG as conductive fillers.

Similar content being viewed by others

References

Luo Z, Huang Z, Xie N, Gao X, Xu T, Fang Y, Zhang Z (2017) Numerical and experimental study on temperature control of solar panels with form-stable paraffin/expanded graphite composite PCM. Energy Convers Manage 149:416–423

Liu L, Su D, Tang Y, Fang G (2016) Thermal conductivity enhancement of phase change materials for thermal energy storage: a review. Renew Sustain Energy Rev 62:305–317

Zhou Z, Liu J, Wang C, Huang X, Gao F, Zhang S, Yu B (2018) Research on the application of phase-change heat storage in centralized solar hot water system. J Clean Prod 198:1262–1275

Lin Y, Jia Y, Alva G, Fang G (2018) Review on thermal conductivity enhancement, thermal properties and applications of phase change materials in thermal energy storage. Renew Sustain Energy Rev 82:2730–2742

Lu X, Liu H, Murugadoss V, Seok I, Guo Z (2020) Polyethylene glycol/carbon black shape-stable phase change composites for peak load regulating of electric power system and corresponding thermal energy storage. Engineered Science 9:24–35

Zhou Y, Wu S, Ma Y, Zhang H, Guo Z (2020) Recent advances in organic/composite phase change materials for energy storage. ES Energy & Environment 9:28–40

Chen Y-J, Nguyen D-D, Shen M-Y, Yip M-C, Tai N-H (2013) Thermal characterizations of the graphite nanosheets reinforced paraffin phase-change composites. Compos A Appl Sci Manuf 44:40–46

Mehrali M, Latibari ST, Mehrali M, Indra Mahlia TM, Cornelis Metselaar HS, Naghavi MS, Sadeghinezhad E, Akhiani AR (2013) Preparation and characterization of palmitic acid/graphene nanoplatelets composite with remarkable thermal conductivity as a novel shape-stabilized phase change material. Appl Therm Eng 61(2):633–640

Qian T, Li J, Deng Y (2016) Pore structure modified diatomite-supported PEG composites for thermal energy storage. Sci Rep 6(1):1–14

Sarier N, Onder E (2012) Organic phase change materials and their textile applications: an overview. Thermochim Acta 540:7–60

Kibria MA, Anisur MR, Mahfuz MH, Saidur R, Metselaar IHSC (2015) A review on thermophysical properties of nanoparticle dispersed phase change materials. Energy Convers Manage 95:69–89

Latibari ST, Sadrameli SM (2018) Carbon based material included-shaped stabilized phase change materials for sunlight-driven energy conversion and storage: an extensive review. Sol Energy 170:1130–1161

Zhang Y, Zheng S, Zhu S, Ma J, Sun Z, Farid M (2018) Evaluation of paraffin infiltrated in various porous silica matrices as shape-stabilized phase change materials for thermal energy storage. Energy Convers Manage 171:361–370

Belessiotis GV, Papadokostaki KG, Favvas EP, Efthimiadou EK, Karellas S (2018) Preparation and investigation of distinct and shape stable paraffin/SiO2 composite PCM nanospheres. Energy Convers Manage 168:382–394

Yang J, Tang L-S, Bao R-Y, Bai L, Liu Z-Y, Yang W, Xie B-H, Yang M-B (2016) An ice-templated assembly strategy to construct graphene oxide/boron nitride hybrid porous scaffolds in phase change materials with enhanced thermal conductivity and shape stability for light–thermal–electric energy conversion. J Mater Chem A 4(48):18841–18851

Wang Z, Zhang Z, Jia L, Yang L (2015) Paraffin and paraffin/aluminum foam composite phase change material heat storage experimental study based on thermal management of Li-ion battery. Appl Therm Eng 78:428–436

Xiao X, Zhang P, Li M (2014) Effective thermal conductivity of open-cell metal foams impregnated with pure paraffin for latent heat storage. Int J Therm Sci 81:94–105

Xia L, Zhang P, Wang RZ (2010) Preparation and thermal characterization of expanded graphite/paraffin composite phase change material. Carbon 48(9):2538–2548

Su W, Darkwa J, Kokogiannakis G (2017) Development of microencapsulated phase change material for solar thermal energy storage. Appl Therm Eng 112:1205–1212

Fang Y, Qu ZG, Zhang JF, Xu HT, Qi GL (2020) Charging performance of latent thermal energy storage system with microencapsulated phase-change material for domestic hot water. Energy Build 224:110237

Zheng Z, Chang Z, Xu G-K, McBride F, Ho A, Zhuola Z, Michailidis M, Li W, Raval R, Akhtar R, Shchukin D (2016) Microencapsulated phase change materials in solar-thermal conversion systems: understanding geometry-dependent heating efficiency and system reliability. ACS Nano 11(1):721–729

Atinafu DG, Dong W, Wang C, Wang G (2018) Synthesis of porous carbon from cotton using an Mg(OH)2 template for form-stabilized phase change materials with high encapsulation capacity, transition enthalpy and reliability. J Mater Chem A 6(19):8969–8977

Lu Y, Xiao X, Zhan Y, Huan C, Qi S, Cheng H, Xu G (2018) Core-sheath paraffin-wax-loaded nanofibers by electrospinning for heat storage. ACS Appl Mater Interfaces 10(15):12759–12767

Li L, Wang G, Guo C (2016) Influence of intumescent flame retardant on thermal and flame retardancy of eutectic mixed paraffin/polypropylene form-stable phase change materials. Appl Energy 162:428–434

Chen Y, Wu X, Situ Y, Liu J, Huang H (2018) Ethylene-propylene terpolymer-modified polyethylene-based phase change material with enhanced mechanical and thermal properties for building application. Ind Eng Chem Res 58(1):179–186

AlMaadeed MA, Labidi S, Krupa I, Karkri M (2015) Effect of expanded graphite on the phase change materials of high density polyethylene/wax blends. Thermochim Acta 600:35–44

Chen F, Wolcott M (2015) Polyethylene/paraffin binary composites for phase change material energy storage in building: a morphology, thermal properties, and paraffin leakage study. Sol Energy Mater Sol Cells 137:79–85

Lin Y, Zhu C, Alva G, Fang G (2018) Palmitic acid/polyvinyl butyral/expanded graphite composites as form-stable phase change materials for solar thermal energy storage. Appl Energy 228:1801–1809

Chen F, Wolcott MP (2014) Miscibility studies of paraffin/polyethylene blends as form-stable phase change materials. Eur Polymer J 52:44–52

Xu L, Zhang J, Liu C, Li N, Chen L, Zhang S, Wang Z (2020) Fast Thermal response of shape-stabilized thermal storage materials: the case of interconnected netlike graphene/hexadecane/HDPE composites. ACS Omega 5(21):12415–12420

Sahan N, Fois M, Paksoy H (2015) Improving thermal conductivity phase change materials—a study of paraffin nanomagnetite composites. Sol Energy Mater Sol Cells 137:61–67

Xiao X, Zhang P, Li M (2013) Preparation and thermal characterization of paraffin/metal foam composite phase change material. Appl Energy 112:1357–1366

Zhang LB, Li RY, Tang B, Wang P (2016) Solar-thermal conversion and thermal energy storage of graphene foam-based composites. Nanoscale 8(30):14600–14607

Xie B, Cheng W-L, Xu Z-M (2015) Studies on the effect of shape-stabilized PCM filled aluminum honeycomb composite material on thermal control. Int J Heat Mass Transf 91:135–143

Zhong Y, Li S, Wei X, Liu Z, Guo Q, Shi J, Liu L (2010) Heat transfer enhancement of paraffin wax using compressed expanded natural graphite for thermal energy storage. Carbon 48(1):300–304

Mu M, Basheer PAM, Sha W, Bai Y, McNally T (2016) Shape stabilised phase change materials based on a high melt viscosity HDPE and paraffin waxes. Appl Energy 162:68–82

Funding

This work is supported by National Key Research and Development Project from MOST (2018YFD0700200) and the fund from BUCT.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xie, Y., Yang, Y., Liu, Y. et al. Paraffin/polyethylene/graphite composite phase change materials with enhanced thermal conductivity and leakage-proof. Adv Compos Hybrid Mater 4, 543–551 (2021). https://doi.org/10.1007/s42114-021-00249-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00249-6