Abstract

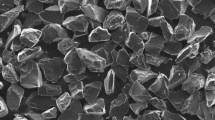

The present work shows the mechanical behavior of as-cast A356 alloy and A356-4 wt% graphite (Gr)-12 wt% boron carbide (B4C) hybrid composites. The hybrid composite samples were developed by two stage stir casting technique. The developed hybrid composites were subjected to scanning electron microscope (SEM) and energy dispersive spectroscope to analyze its microstructure followed by physical and mechanical tests like density, hardness, and tensile tests. The SEM analysis showed almost uniform distribution of particulates; also, hardness and tensile properties improved upon addition of reinforcement viz., graphite and B4C. The density of hybrid composite decreased upon addition of reinforcement when compared with base A356 alloy. Fractography of tensile specimens were carried out for analysis of fractured surfaces.

The A356-B4C-graphite hybrid composites were developed by two stage stir casting technique. The developed hybrid composites were subjected to SEM to analyze its microstructure followed by physical and mechanical properties like density, hardness, and tensile tests.

Similar content being viewed by others

References

Soundararajan R, Ramesh A, Sivasankaran S, Vignesh M (2017) Modeling and analysis of mechanical properties of aluminium alloy (A413) reinforced with boron carbide (B4C) processed through squeeze casting process using artificial neural network model and statistical technique. Mater Today: Proceedings 4:2008–2030

Nagaral M, Kalgudi S, Auradi V, Kori S (2018) Mechanical characterization of ceramic nano B4C-Al2618 alloy composites synthesized by semi solid processing. Trans Indian Ceram Soc 77(3):1–4

Lara RD, Soltani N, Bahrami A, Castaneda EG, Sanchez EG, Rodriguez MALH (2015) Tribological characterization of Al7075–graphite composites fabricated by mechanical alloying and hot extrusion. Mater Des 67:224–231

Liu H, Hu Y, Zhao Y, Fujii H (2015) Microstructure and mechanical properties of friction stir welded AC4A + 30 vol.%SiCp composite. Mater Des 65:395–400

Shoba C, Ramanaiah N, Nageswara Rao D (2015) Effect of reinforcement on the cutting forces while machining metal matrix composites – an experimental approach. Eng Sci Technol Int J 18:658–663

Shen Q, Wu C, Luo G, Fang P, Li C, Wang Y, Zhang L (2014) Microstructure and mechanical properties of Al-7075/B4C composites fabricated by plasma activated sintering. J Alloys Compd 588:265–270

Pio LY (2011) Effect of T6 heat treatment on the mechanical properties of gravity die cast A356 aluminium alloy. J Appl Sci 1812-5654:1–5

Chen HS, Wang WX, Li YL, Zhang P, Nie HH, Wu QC (2015) The design, microstructure and tensile properties of B4C particulatereinforced 6061Al neutron absorber composites. J Alloys Compd 632:23–29

Nagaral M, Auradi V, Kori SA, Hiremath V (2019) Investigations on mechanical and wear behavior of nano Al2O3 particulates reinforced AA7475 alloy composites. J Mech Eng Sci 13(1):4623–4635

Keshavsingh, Rana RS, Pandey A (2017) Fabrication and mechanical properties characterization of aluminium alloy LM24/B4C composites. Mater Today: Proceedings 4:701–708

Baradeswaran A, Vettivel SC, ElayaPerumal A, Selvakumar N, Franklin Issac R (2014) Experimental investigation on mechanical behaviour, modeling and optimization of wear parameters of B4C and graphite reinforced aluminium hybrid composites. Mater Des 63:620–632

Padmavathi KR, Ramkrishanan R, Palanikumar K (2015) Aluminium metal matrix composite an insight into solid state and liquid state processes. Appl Mech Mater 766-767:234–239

Rohatgi PK, Daoud A, Schultz BF, Puri T (2009) Microstructure and mechanical behaviour of die casting AZ91D fly ash cenosphere composites. Composites Part A 40:883–896

Zhang Y, Ma N, Wang H (2014) Improvement of yield strength of LM24 alloy. Mater Des 54:14–17

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jadhav, P.R., Sridhar, B.R., Nagaral, M. et al. Mechanical behavior and fractography of graphite and boron carbide particulates reinforced A356 alloy hybrid metal matrix composites. Adv Compos Hybrid Mater 3, 114–119 (2020). https://doi.org/10.1007/s42114-020-00143-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-020-00143-7