Abstract

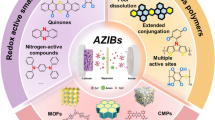

To realize a low-carbon economy and sustainable energy supply, the development of energy storage devices has aroused intensive attention. Lithium-sulfur (Li-S) batteries are regarded as one of the most promising next-generation battery devices because of their remarkable theoretical energy density, cost-effectiveness, and environmental benignity. However, the practical application of Li-S batteries is hindered by such challenges as low sulfur utilization (< 80%), fast capacity fade, short service life (< 200 redox cycles), and severe self-discharge. The reasons behind the challenges are: (1) low conductivity of the active materials, (2) large volume changes during redox cycling, (3) serious polysulfide shuttling and, (4) lithium-metal anode contamination/corrosion and dendrite formation. Significant achievements have been made to address these problems in the past decade. In this review, the recent advances in material synthesis and technology development are analysed in terms of the electrochemical performance of different Li-S battery components. The critical analysis was conducted based on the merits and shortcomings of the reported work on the issues facing the individual component. A versatile 3D-printing technique is also examined on its practicability for Li-S battery production. The insights on the rational structural design and reasonable parameters for Li-S batteries are highlighted along with the “five 5s” concept from a practical point of view. The remaining challenges are outlined for researchers to devote more efforts on the understanding and commercialization of the devices in terms of the material preparation, cell manufacturing, and characterization.

Graphical Abstract

Reproduced with permission from Ref. [42]. Copyright © 2018, Elsevier. b Synthesis scheme of α-CoS/Co architecture on N-doped carbon polyhedron. Reproduced with permission from Ref. [51]. Copyright © 2019, The Royal Society of Chemistry. c Fabrication strategy of graphene wrapped MIL-101(Cr). d Cycling performance of a cell with MIL-101(Cr)/S cathode. (c, d) Reproduced with permission from Ref. [52]. Copyright © 2014, The Royal Society of Chemistry. e Schematic representation of sulfur/carbon hybrid fabrication via electrolysis. Reproduced with permission from Ref. [53]. Copyright © 2016, American Chemical Society

Copyright © 2012, American Chemical Society. f XRD measurements of sulfur and porous carbon with different sulfur concentrations. Reproduced with permission from Ref. [83]. Copyright © 2015, WILEY-VCH. g Schematic illustration of mesoporous carbon electrode and cyclic performance of Li-S battery with various ratios of sulfur. Reproduced with permission from Ref. [84]. Copyright © 2011, The Royal Society of Chemistry. h Comparison of specific capacity of porous carbon according to surface area, pore volume and size for 100th discharge cycle. Reproduced with permission from Ref. [76]. Copyright © 2016, WILEY-VCH. i Representation of sulfur impregnation principle. Reproduced with permission from Ref. [85]. Copyright © 2015, WILEY-VCH. j Representation of polysulfide adsorption capability in porous carbon materials. Reproduced with permission from Ref. [86]. Copyright © 2016, WILEY-VCH

Reproduced with permission from Ref. [101]. Copyright © 2013, Macmillan Publisher Limited. d Synthesis and advantages of MnO2. Reproduced with permission from Ref. [24]. Copyright © 2015, WILEY-VCH. e Distribution of Mn4+, change(s) of structure after introducing polysulfides, and distribution of Mn2+ and Mn4+ at Mn3O4, shrinkage and expansion after exposed to polysulfides. Reproduced with permission from Ref. [103]. Copyright © 2017, The Royal Society of Chemistry. f, g DFT calculations of binding geometry and b-values obtained from the plots. Reproduced with permission from Ref. [104]. Copyright © 2016, The Royal Society of Chemistry

(a–c) Reproduced with permission from Ref. [111]. Copyright © 2015, The Royal Society of Chemistry. d Hydroxyl-MXene and polysulfide interaction. Reproduced with permission from Ref. [117]. Copyright © 2016, WILEY-VCH. e Step-by-step synthesis of Fe3C@N‐GE-CNTs composite. f Representation of conjunction of graphene/CNTs/Fe3C characterized by HRTEM. g Plot of Coulombic efficiency and cycling performance of the S@FexS@N‐GE-CNTs composite at 10 C. (e–g) Reproduced with permission from Ref. [118]. Copyright © 2016, WILEY-VCH

(a–f) Reproduced with permission from Ref. [123]. Copyright © 2019, American Chemical Society

Reproduced with permission from Ref. [127]. Copyright © 2017, WILEY-VCH. b Chemical interactions of Li-O and S-Ni. c CV curves of the HEMO-1 and KB cathodes at a scan rate of 0.1 mV s−1. d Rate capability of HEMO-1. e Discharge–charge profiles of HEMO-1 and KB at 0.1 C. f CV curves of symmetric cells of HEMO-1@KB carbon and KB carbon electrodes with and without Li2S6. g Cycling performance and CE of HEMO-1 and KB at 0.1 C. h Long-term cycling performance and CE of HEMO-1 and KB at 0.5 C. (b–h) Reproduced with permission from Ref. [128]. Copyright © 2019, Elsevier

Reproduced with permission from Ref. [204]. Copyright © 2019, Elsevier

(a, b) Reproduced with permission from Ref. [241]. Copyright © 2018, American Chemical Society. c Role of LiTFSI and LiDFTFSI in solid-state Li-S batteries. d Long term cycling stability of Li-S cells with LiDFTFSI/PEO electrolyte at 0.1 C. (c, d) Reproduced with permission from Ref. [242]. Copyright © 2019, Elsevier

(a–f) Reproduced with permission from Ref. [269]. Copyright © 2018, Elsevier

Reproduced with permission from Ref. [280]. Copyright © 2015, Elsevier. b Suppression mechanism of polysulfides with carbon fiber. Reproduced with permission from Ref. [290]. Copyright © 2016, Elsevier. c Insertion of CNF/PVDF composite member separator. Reproduced with permission from Ref. [292]. Copyright © 2016, Elsevier. d Schematic diagram of sulfur/nitrogen dually doped graphene interlayer. Reproduced with permission from Ref. [293]. Copyright © 2016, Royal Society of Chemistry. e RGO film as inhabitant of polysulfide shuttle. Reproduced with permission from Ref. [291]. Copyright © 2013, Elsevier. f Working mechanism of TiO2/graphene interlayer. Reproduced with permission from Ref. [100]. Copyright © 2015, WILEY-VCH. g Illustration of MWCNTs as efficient separator. Reproduced with permission from Ref. [292]. Copyright © 2015, American Chemical Society. h Encapsulation of polysulfide phenomenon. Reproduced with permission from Ref. [295]. Copyright © 2015, Elsevier. i Polysulfide reduction with CoS2/carbon paper interlayer. Reproduced with permission from Ref. [293]. Copyright © 2016, Elsevier

(a–d) Reproduced with permission from Ref. [317]. Copyright © 2016, Macmillan Publisher Limited. e Schematic illustration of the MOF-based separator and pristine separator in Li-S batteries. f Schematic diagram of a flexible Li-S pouch cell with an MOF@PVDF-HFP separator and its electrochemical performance at a high sulfur loading amount. (e, f) Reproduced with permission from Ref. [319]. Copyright © 2018, WILEY-VCH

(a, b) Reproduced with permission from Ref. [227]. Copyright © 2018, Elsevier. c Molecular structures of DME, MBE, DPE, DOL, MTBE, and DIPE, and photographs of concentrated solution of Li2S8 in DME:DOL = 1:1, MBE, MTBE, DPE and DIPE. d Initial discharge profiles and cycling performance comparison in different electrolytes. (c, d) Reproduced with permission from Ref. [342]. Copyright © 2018, American Chemical Society

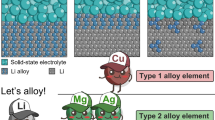

(a, b) Reproduced with permission from Ref. [380]. Copyright © 2020, Elsevier. c Cycling performances of Li-S batteries with pristine Li and Sb-Li anodes at 1.0 C and with high areal mass loadings of CNTs/S cathodes (2.8 and 4.8 mgsulfur cm−2) cycled at 0.1 C. Reproduced with permission from Ref. [381]. Copyright © 2019, American Chemical Society

Reproduced with permission from Ref. [411]. Copyright © 2020, Elsevier

(a–c) Reproduced with permission from Ref. [427]. Copyright © 2019, Elsevier. d A 3D-PC structure corresponding to the predesigned pattern and bracelet battery on wrist. e Thermogravimetric analysis curve of the 3D-PC and rate performance with a sulfur loading of 9.8 mg cm−2 at 0.1–2.0 C. f Cycling performance of Li-S cells assembled using 3D-PC with a sulfur loading of 10.2 mg cm−2 at 0.2 C. (d–f) Reproduced with permission from Ref. [428]. Copyright © 2020, WILEY-VCH

Reproduced with permission from Ref. [430]. Copyright © 2018, Royal Society of Chemistry. b Schematic diagram of the process of 3D-printing solid electrolyte structures. c Schematic diagram of Li-filled pores between 3D-printed LLZ grids in a stacked-array pattern on LLZ substrate. The cross-sectional SEM image of 3D-printed LLZ|Li metal interface (red line). DC cycling of a Li|3D-printed LLZ|Li metal cell at varying current densities. Each plating/stripping cycle was 1 h long. (b, c) Reproduced with permission from Ref. [431]. Copyright © 2018, WILEY-VCH

Copyright © 2020, Elsevier. c Schematic illustration of the fabrication process and Li plating process on the Cu foil and 3D carbon host. d Coulombic efficiency evaluation of 3DP-NC and bare Cu foil at different current densities and plating capacities. Galvanostatic cycling profiles of symmetric cells using the Li@3DP-NC, Li@Cu foil and bare Li foil electrodes at the current rate of 10 mA cm−2 and a limited capacity of 2 mAh cm−2. (c, d) Reproduced with permission from Ref. [434]. Copyright © 2020, Elsevier

Similar content being viewed by others

Abbreviations

- ABF-STEM:

-

Annular bright-field scanning transmission electron microscopy

- Al-TPA:

-

Aluminum terephthalic acid

- AM:

-

Additive manufacturing

- BPSO:

-

Bi-grafted polysiloxane

- BTFE:

-

Bis(2,2,2-trifluoroethyl) ether

- CA:

-

Cellulose acetate

- CE:

-

Coulombic efficiency

- CMC:

-

Carboxymethylcellulose

- CNF:

-

Carbon nanofiber

- CNS:

-

Carbon nanosphere

- CNT:

-

Carbon nanotube

- COSMO-RS:

-

Conductor like screening model for real solvents

- C-PDA:

-

Carbonized polydopamine

- CPE:

-

Composite polymer electrolyte

- CVD:

-

Chemical vapor deposition

- DFT:

-

Density functional theory

- DIPE:

-

Diisopropyl ether

- DIW:

-

Direct ink writing

- DME:

-

1,2-Dimethoxyethane

- DN:

-

Donor number

- DOL:

-

1,3-Dioxolane

- DPE:

-

Dipropyl ether

- EMITFSI:

-

1-Ethyl-3-methyl-imidazolium bis(trifluoromethanesulfonyl)-imide

- ETFE:

-

Ethyl 1,1,2,2-tetrafluoroethyl ether

- FDM:

-

Fused deposition molding

- FLG:

-

Few-layer graphene

- G4CMP:

-

4-Carbomethoxy pyrrolidone

- GDC:

-

Galvanostatic discharge/charge

- GG:

-

Guar gum

- GO:

-

Graphene oxide

- HC:

-

Hard carbon

- HCF:

-

Hollow carbon fiber

- HDI:

-

Hexamethylene diisocyanate

- HEMO:

-

High-entropy metal oxide

- HFE:

-

Hydrofluoroether

- HFP:

-

Hexafluoropropylene

- HRTEM:

-

High-resolution transmission electron microscopy

- IJP:

-

Inkjet printing

- IL:

-

Ionic liquid

- LAGP:

-

Lithium aluminum germanium phosphate, Li1.5Al0.5Ge1.5(PO4)3

- LATP:

-

Lithium aluminum titanium phosphate, Li1.5Al0.5Ti1.5(PO4)3

- LED:

-

Light-emitting diode

- LIB:

-

Lithium-ion battery

- LiDFTFSI:

-

Lithium (difluoromethanesulfonyl)-(trifluoro-methanesulfonyl) imide

- LiF:

-

Lithium fluoride

- LIFSI:

-

Lithium bis(fluorosulfonyl)imide

- LiFTFSI:

-

Lithium (fluorosulfonyl)-(trifluoromethanesulfonyl)imide

- Li(G4)-Ntf2:

-

Lithium tetraglyme bis(trifluoromethylsulfonyl)imide

- Li(G4)-TFSA:

-

Lithium tetraglyme bis(trifluoromethanesulfonyl)amide

- LiOH:

-

Lithium hydroxide

- LiOTf:

-

Lithium trifluoromethanesulfonate

- LiPAACA:

-

Lithium poly(acryloyl-6-aminocaproic acid)

- LiPS:

-

Lithium polysulfide

- Li-S:

-

Lithium-sulfur

- LISICON:

-

Lithium superionic conductor

- LiTFSA:

-

Lithium bis(trifluoromethanesulfonyl)amide

- LiTFSI:

-

Lithium bis(trifluoromethanesulfonyl)imide

- LLZO:

-

Lithium lanthanum zirconium oxide, Li7La3Zr2O12

- LLZTO:

-

Ta-doped lithium lanthanum zirconium oxide, Li6.4La3Zr1.4Ta0.6O12

- LOM:

-

Laminated object manufacturing

- LTO:

-

Lithium titanium oxide, Li4Ti5O12

- MBE:

-

Methyl butyl ether

- MOFs:

-

Metal-organic frameworks

- MoN:

-

Molybdenum nitride

- MoP:

-

Molybdenum phosphide

- MPC:

-

Microporous carbon

- MTBE:

-

Methyl tert-butyl ether

- MWCNT:

-

Multi-walled carbon nanotube

- NASICON:

-

Sodium superionic conductor

- NCA:

-

Layered lithium metal oxides (nickel, cobalt, aluminum)

- N-FLG:

-

Nitrogen-doped few-layer graphene

- OFE:

-

1H,1H,5H-octafluoropentyl-1,1,2,2-tetrafluoroethyl ether

- ONPCG:

-

Oxygen and nitrogen codoped porous carbon granules

- P13-TFSA:

-

N-methyl-N-propylpyrrolidinium bis(trifluoromethanesulfonyl)amide

- PAA:

-

Polyacrylic acid

- PAMAM:

-

Poly(amidoamine)

- PAN:

-

Polyacrylonitrile

- PANI:

-

Polyaniline

- PDMS:

-

Polydimethylsiloxane

- PEDOT:

-

Poly(3,4-ethylenedioxythiophene)

- PEI:

-

Polyethyleneimine

- PEGDME:

-

Poly(ethylene glycol) dimethyl ether

- PEO:

-

Poly(ethylene oxide)

- PFM:

-

Poly(9,9-dioctylfluorene-co-fluorenone-co-methylbenzoic ester)

- PMMA:

-

Poly(methyl methacrylate)

- PP:

-

Polypropylene

- PP13-TFSI:

-

N-methyl-N-propylpiperidinium bis(trifluoromethanesulfonyl) imide

- PPy:

-

Polypyrrole

- PQ:

-

Polyquaternium

- PTFE:

-

Polytetrafluoro ethylene

- PU:

-

Polyurethane

- PVB:

-

Polyvinyl butyral

- PVDF:

-

Polyvinylidene fluoride

- PVP:

-

Polyvinylpyrollidone

- Pyr1,201TFSI:

-

N-Methoxyethyl-N-methylpyrrolidinium bis(trifluoromethanesulfonyl)-imide

- RCF:

-

Rimous copper foam

- rGO:

-

Reduced graphene oxide

- RTIL:

-

Room temperature ionic liquid

- SBR:

-

Styrene and butadiene rubber

- SCG:

-

SEI-coated graphene

- SEI:

-

Solid electrolyte interphase

- SEM:

-

Scanning electron microscopy

- SLA:

-

Stereolithography

- SLM:

-

Selective laser melting

- SLMP:

-

Stabilized lithium metal powder

- SLS:

-

Selective laser sintering

- SPE:

-

Solid polymer electrolyte

- SP-PAA:

-

Soy protein and polyacrylic acid

- STEM:

-

Scanning transmission electron microscopy

- TAED:

-

Triethylene glycol dimethyl ether

- TEGDME:

-

Tetra(ethylene glycol)dimethyl ether

- TEM:

-

Transmission electron microscopy

- TFEE:

-

1,2-(1,1,2,2-Tetrafluoroethoxy) ethane

- TFEG:

-

2,2,2-Trifluoroethyl methyl ether ethylene glycol

- TFETFE:

-

1,1,2,2-Tetra-fluoro-1-(2,2,2-trifluoroethoxy) ethane

- THF:

-

Tetrahydrofuran

- TiN:

-

Titanium nitride

- TMS:

-

Tetra-methylene sulfone

- TTE:

-

1,1,2,2-Tetra-fluoroethyl 2,2,3,3-tetrafluoropropyl ether

- UGF:

-

Ultrathin graphite foam

- VN:

-

Vanadium nitride

- XANES:

-

X-ray absorption near-edge spectroscopy

- XG:

-

Xanthan gum

- XPS:

-

X-ray photoelectron spectroscopy

- XRD:

-

X-ray diffraction

References

Smalley, R.E.: Future global energy prosperity: the terawatt challenge. MRS Bull. 30, 412–417 (2005). https://doi.org/10.1557/mrs2005.124

Wang, Q.S., Ping, P., Zhao, X.J., et al.: Thermal runaway caused fire and explosion of lithium ion battery. J. Power Sources 208, 210–224 (2012). https://doi.org/10.1016/j.jpowsour.2012.02.038

Sun, C.L., Wang, Y.J., Gu, H., et al.: Interfacial coupled design of epitaxial graphene@SiC Schottky junction with built-in electric field for high-performance anodes of lithium ion batteries. Nano Energy 77, 105092 (2020). https://doi.org/10.1016/j.nanoen.2020.105092

Zhou, Z.F., Li, G.C., Zhang, J.J., et al.: Wide working temperature range rechargeable lithium-sulfur batteries: a critical review. Adv. Funct. Mater. 31, 2107136 (2021). https://doi.org/10.1002/adfm.202107136

Tarascon, J.M., Armand, M.: Issues and challenges facing rechargeable lithium batteries. Nature 414, 359–367 (2001). https://doi.org/10.1038/35104644

Song, M.K., Park, S., Alamgir, F.M., et al.: Nanostructured electrodes for lithium-ion and lithium-air batteries: the latest developments, challenges, and perspectives. Mater. Sci. Eng. R Rep. 72, 203–252 (2011). https://doi.org/10.1016/j.mser.2011.06.001

Zhao, B., Song, D.Y., Ding, Y.W., et al.: Size-tunable SnS2 nanoparticles assembled on graphene as anodes for high performance lithium/sodium-ion batteries. Electrochim. Acta 354, 136730 (2020). https://doi.org/10.1016/j.electacta.2020.136730

Chu, S., Majumdar, A.: Opportunities and challenges for a sustainable energy future. Nature 488, 294–303 (2012). https://doi.org/10.1038/nature11475

Bock, D.C., Marschilok, A.C., Takeuchi, K.J., et al.: Batteries used to power implantable biomedical devices. Electrochim. Acta 84, 155–164 (2012). https://doi.org/10.1016/j.electacta.2012.03.057

Nagata, M., Saraswat, A., Nakahara, H., et al.: Miniature pin-type lithium batteries for medical applications. J. Power Sources 146, 762–765 (2005). https://doi.org/10.1016/j.jpowsour.2005.03.156

Bruce, P.G., Freunberger, S.A., Hardwick, L.J., et al.: Li-O2 and Li-S batteries with high energy storage. Nat. Mater. 11, 19–29 (2011). https://doi.org/10.1038/nmat3191

Zhang, S.S.: Liquid electrolyte lithium/sulfur battery: fundamental chemistry, problems, and solutions. J. Power Sources 231, 153–162 (2013). https://doi.org/10.1016/j.jpowsour.2012.12.102

Xu, J.Q., Zhou, K., Chen, F., et al.: Natural integrated carbon architecture for rechargeable lithium-sulfur batteries. ACS Sustain. Chem. Eng. 4, 666–670 (2016). https://doi.org/10.1021/acssuschemeng.5b01258

Huang, J.Q., Zhuang, T.Z., Zhang, Q., et al.: Permselective graphene oxide membrane for highly stable and anti-self-discharge lithium-sulfur batteries. ACS Nano 9, 3002–3011 (2015). https://doi.org/10.1021/nn507178a

Yang, Y., Zheng, G.Y., Cui, Y.: Nanostructured sulfur cathodes. Chem. Soc. Rev. 42, 3018–3032 (2013). https://doi.org/10.1039/c2cs35256g

Feng, S., Fu, Z.H., Chen, X., et al.: A review on theoretical models for lithium-sulfur battery cathodes. InfoMat 4, e12304 (2022). https://doi.org/10.1002/inf2.12304

Mikhaylik, Y.V., Akridge, J.R.: Polysulfide shuttle study in the Li/S battery system. J. Electrochem. Soc. 151, A1969 (2004). https://doi.org/10.1149/1.1806394

Ma, G.Q., Wen, Z.Y., Wu, M.F., et al.: A lithium anode protection guided highly-stable lithium-sulfur battery. Chem. Commun. (Camb.) 50, 14209–14212 (2014). https://doi.org/10.1039/c4cc05535g

Zhang, X.Y., Chen, K., Sun, Z.H., et al.: Structure-related electrochemical performance of organosulfur compounds for lithium-sulfur batteries. Energy Environ. Sci. 13, 1076–1095 (2020). https://doi.org/10.1039/C9EE03848E

Fang, R.P., Zhao, S.Y., Sun, Z.H., et al.: More reliable lithium-sulfur batteries: status, solutions and prospects. Adv. Mater. 29, 1606823 (2017). https://doi.org/10.1002/adma.201606823

Fan, X.J., Sun, W.W., Meng, F.C., et al.: Advanced chemical strategies for lithium-sulfur batteries: a review. Green Energy Environ. 3, 2–19 (2018). https://doi.org/10.1016/j.gee.2017.08.002

Ji, X.L., Lee, K.T., Nazar, L.F.: A highly ordered nanostructured carbon-sulphur cathode for lithium-sulphur batteries. Nat. Mater. 8, 500–506 (2009). https://doi.org/10.1038/nmat2460

Song, X., Gao, T., Wang, S.Q., et al.: Free-standing sulfur host based on titanium-dioxide-modified porous-carbon nanofibers for lithium-sulfur batteries. J. Power Sources 356, 172–180 (2017). https://doi.org/10.1016/j.jpowsour.2017.04.093

Li, Z., Zhang, J.T., Lou, X.W.: Hollow carbon nanofibers filled with MnO2 nanosheets as efficient sulfur hosts for lithium-sulfur batteries. Angew. Chem. Int. Ed. 54, 12886–12890 (2015). https://doi.org/10.1002/anie.201506972

Chen, W., Lei, T.Y., Lv, W.Q., et al.: Atomic interlamellar ion path in high sulfur content lithium-montmorillonite host enables high-rate and stable lithium-sulfur battery. Adv. Mater. 30, 1804084 (2018). https://doi.org/10.1002/adma.201804084

Majumder, S., Shao, M.H., Deng, Y.F., et al.: Ultrathin sheets of MoS2/g-C3N4 composite as a good hosting material of sulfur for lithium-sulfur batteries. J. Power Sources 431, 93–104 (2019). https://doi.org/10.1016/j.jpowsour.2019.05.045

Majumder, S., Shao, M.H., Deng, Y.F., et al.: Two dimensional WS2/C nanosheets as a polysulfides immobilizer for high performance lithium-sulfur batteries. J. Electrochem. Soc. 166, A5386–A5395 (2019). https://doi.org/10.1149/2.0501903jes

Yan, R.Y., Oschatz, M., Wu, F.X.: Towards stable lithium-sulfur battery cathodes by combining physical and chemical confinement of polysulfides in core-shell structured nitrogen-doped carbons. Carbon 161, 162–168 (2020). https://doi.org/10.1016/j.carbon.2020.01.046

Ji, L.W., Rao, M.M., Zheng, H.M., et al.: Graphene oxide as a sulfur immobilizer in high performance lithium/sulfur cells. J. Am. Chem. Soc. 133, 18522–18525 (2011). https://doi.org/10.1021/ja206955k

Wang, L., Song, Y.H., Zhang, B.H., et al.: Spherical metal oxides with high tap density as sulfur host to enhance cathode volumetric capacity for lithium-sulfur battery. ACS Appl. Mater. Interfaces 12, 5909–5919 (2020). https://doi.org/10.1021/acsami.9b20111

Chang, C.H., Chung, S.H., Manthiram, A.: Transforming waste newspapers into nitrogen-doped conducting interlayers for advanced Li-S batteries. Sustain. Energy Fuels 1, 444–449 (2017). https://doi.org/10.1039/C7SE00014F

Lee, C.L., Kim, I.D.: A hierarchical carbon nanotube-loaded glass-filter composite paper interlayer with outstanding electrolyte uptake properties for high-performance lithium-sulphur batteries. Nanoscale 7, 10362–10367 (2015). https://doi.org/10.1039/c5nr02637g

Ren, W.C., Ma, W., Zhang, S.F., et al.: Recent advances in shuttle effect inhibition for lithium sulfur batteries. Energy Storage Mater. 23, 707–732 (2019). https://doi.org/10.1016/j.ensm.2019.02.022

Wang, L.L., Ye, Y.S., Chen, N., et al.: Development and challenges of functional electrolytes for high-performance lithium-sulfur batteries. Adv. Funct. Mater. 28, 1800919 (2018). https://doi.org/10.1002/adfm.201800919

Li, Z., Wu, H.B., Lou, X.W.: Rational designs and engineering of hollow micro-/nanostructures as sulfur hosts for advanced lithium-sulfur batteries. Energy Environ. Sci. 9, 3061–3070 (2016). https://doi.org/10.1039/C6EE02364A

Li, Y.Y., Li, X.F., Hao, Y.C., et al.: β-FeOOH interlayer with abundant oxygen vacancy toward boosting catalytic effect for lithium sulfur batteries. Front. Chem. 8, 309 (2020). https://doi.org/10.3389/fchem.2020.00309

Chen, Y., Wang, T.Y., Tian, H.J., et al.: Advances in lithium-sulfur batteries: from academic research to commercial viability. Adv. Mater. 33, 2003666 (2021). https://doi.org/10.1002/adma.202003666

Sun, J.G., Wang, T., Gao, Y.L., et al.: Will lithium-sulfur batteries be the next beyond-lithium ion batteries and even much better? InfoMat 4, e12359 (2022). https://doi.org/10.1002/inf2.12359

Pang, Q., Kwok, C.Y., Kundu, D.P., et al.: Lightweight metallic MgB2 mediates polysulfide redox and promises high-energy-density lithium-sulfur batteries. Joule 3, 136–148 (2019). https://doi.org/10.1016/j.joule.2018.09.024

Li, F., Liu, Q.H., Hu, J.W., et al.: Recent advances in cathode materials for rechargeable lithium-sulfur batteries. Nanoscale 11, 15418–15439 (2019). https://doi.org/10.1039/c9nr04415a

Xie, Y.P., Fang, L., Cheng, H.W., et al.: Biological cell derived N-doped hollow porous carbon microspheres for lithium-sulfur batteries. J. Mater. Chem. A 4, 15612–15620 (2016). https://doi.org/10.1039/C6TA06164H

Xu, Z.L., Kim, J.K., Kang, K.: Carbon nanomaterials for advanced lithium sulfur batteries. Nano Today 19, 84–107 (2018). https://doi.org/10.1016/j.nantod.2018.02.006

Xie, C., Shan, H., Song, X.X., et al.: Flexible S@C-CNTs cathodes with robust mechanical strength via blade-coating for lithium-sulfur batteries. J. Colloid Interface Sci. 592, 448–454 (2021). https://doi.org/10.1016/j.jcis.2021.02.065

Liang, J., Sun, Z.H., Li, F., et al.: Carbon materials for Li-S batteries: functional evolution and performance improvement. Energy Storage Mater. 2, 76–106 (2016). https://doi.org/10.1016/j.ensm.2015.09.007

Borchardt, L., Oschatz, M., Kaskel, S.: Carbon materials for lithium sulfur batteries: ten critical questions. Chem. A Eur. J. 22, 7324–7351 (2016). https://doi.org/10.1002/chem.201600040

Zhang, B., Kang, F.Y., Tarascon, J.M., et al.: Recent advances in electrospun carbon nanofibers and their application in electrochemical energy storage. Prog. Mater. Sci. 76, 319–380 (2016). https://doi.org/10.1016/j.pmatsci.2015.08.002

Xin, S., Gu, L., Zhao, N.H., et al.: Smaller sulfur molecules promise better lithium-sulfur batteries. J. Am. Chem. Soc. 134, 18510–18513 (2012). https://doi.org/10.1021/ja308170k

Guo, Z.J., Zhang, B., Li, D.J., et al.: A mixed microporous/low-range mesoporous composite with high sulfur loading from hierarchically-structured carbon for lithium sulfur batteries. Electrochim. Acta 230, 181–188 (2017). https://doi.org/10.1016/j.electacta.2017.01.174

Li, S.S., Jin, B., Zhai, X.J., et al.: Review of carbon materials for lithium-sulfur batteries. ChemistrySelect 3, 2245–2260 (2018). https://doi.org/10.1002/slct.201703112

Yang, K., Gao, Q., Tan, Y., et al.: Microporous carbon derived from Apricot shell as cathode material for lithium-sulfur battery. Microporous Mesoporous Mater. 204, 235–241 (2015). https://doi.org/10.1016/j.micromeso.2014.12.003

Gu, S.N., Bai, Z.W., Majumder, S., et al.: In situ grown α-CoS/Co heterostructures on nitrogen doped carbon polyhedra enabling the trapping and reaction-intensification of polysulfides towards high performance lithium sulfur batteries. Nanoscale 11, 20579–20588 (2019). https://doi.org/10.1039/c9nr07249g

Zhao, Z.X., Wang, S., Liang, R., et al.: Graphene-wrapped chromium-MOF(MIL-101)/sulfur composite for performance improvement of high-rate rechargeable Li-S batteries. J. Mater. Chem. A 2, 13509–13512 (2014). https://doi.org/10.1039/C4TA01241K

He, B., Li, W.C., Yang, C., et al.: Incorporating sulfur inside the pores of carbons for advanced lithium-sulfur batteries: an electrolysis approach. ACS Nano 10, 1633–1639 (2016). https://doi.org/10.1021/acsnano.5b07340

Niu, S.Z., Zhou, G.M., Lv, W., et al.: Sulfur confined in nitrogen-doped microporous carbon used in a carbonate-based electrolyte for long-life, safe lithium-sulfur batteries. Carbon 109, 1–6 (2016). https://doi.org/10.1016/j.carbon.2016.07.062

Yeon, J.S., Park, S.H., Suk, J., et al.: Confinement of sulfur in the micropores of honeycomb-like carbon derived from lignin for lithium-sulfur battery cathode. Chem. Eng. J. 382, 122946 (2020). https://doi.org/10.1016/j.cej.2019.122946

Tan, J.C., Li, D., Liu, Y.Q., et al.: A self-supported 3D aerogel network lithium-sulfur battery cathode: sulfur spheres wrapped with phosphorus doped graphene and bridged with carbon nanofibers. J. Mater. Chem. A 8, 7980–7990 (2020). https://doi.org/10.1039/D0TA00284D

Rehman, S., Gu, X.X., Khan, K., et al.: 3D vertically aligned and interconnected porous carbon nanosheets as sulfur immobilizers for high performance lithium-sulfur batteries. Adv. Energy Mater. 6, 1502518 (2016). https://doi.org/10.1002/aenm.201502518

Wang, S., Zhao, Z.X., Xu, H., et al.: Sulfur impregnated in tunable porous N-doped carbon as sulfur cathode: effect of pore size distribution. Electrochim. Acta 173, 282–289 (2015). https://doi.org/10.1016/j.electacta.2015.05.030

Sun, Z.J., Xiao, M., Wang, S.J., et al.: Specially designed carbon black nanoparticle-sulfur composite cathode materials with a novel structure for lithium-sulfur battery application. J. Power Sources 285, 478–484 (2015). https://doi.org/10.1016/j.jpowsour.2015.03.138

Wang, S.X., Liu, X.Y., Zou, K.X., et al.: Toward a practical Li-S battery enabled by synergistic confinement of a nitrogen-enriched porous carbon as a multifunctional interlayer and sulfur-host material. J. Electroanal. Chem. 858, 113797 (2020). https://doi.org/10.1016/j.jelechem.2019.113797

Zhou, G.M., Zhao, Y.B., Manthiram, A.: Dual-confined flexible sulfur cathodes encapsulated in nitrogen-doped double-shelled hollow carbon spheres and wrapped with graphene for Li-S batteries. Adv. Energy Mater. 5, 1402263 (2015). https://doi.org/10.1002/aenm.201402263

Nersisyan, H.H., Joo, S.H., Yoo, B.U., et al.: Combustion-mediated synthesis of hollow carbon nanospheres for high-performance cathode material in lithium-sulfur battery. Carbon 103, 255–262 (2016). https://doi.org/10.1016/j.carbon.2016.03.022

Wu, F., Li, J., Su, Y.F., et al.: Layer-by-layer assembled architecture of polyelectrolyte multilayers and graphene sheets on hollow carbon spheres/sulfur composite for high-performance lithium-sulfur batteries. Nano Lett. 16, 5488–5494 (2016). https://doi.org/10.1021/acs.nanolett.6b01981

Xu, C.M., Wu, Y.S., Zhao, X.Y., et al.: Sulfur/three-dimensional graphene composite for high performance lithium-sulfur batteries. J. Power Sources 275, 22–25 (2015). https://doi.org/10.1016/j.jpowsour.2014.11.007

Li, L., Zhou, G.M., Yin, L.C., et al.: Stabilizing sulfur cathodes using nitrogen-doped graphene as a chemical immobilizer for Li-S batteries. Carbon 108, 120–126 (2016). https://doi.org/10.1016/j.carbon.2016.07.008

Tang, C., Li, B.Q., Zhang, Q., et al.: CaO-templated growth of hierarchical porous graphene for high-power lithium-sulfur battery applications. Adv. Funct. Mater. 26, 577–585 (2016). https://doi.org/10.1002/adfm.201503726

Li, H., Wen, X.Z., Shao, F., et al.: Interface covalent bonding endowing high-sulfur-loading paper cathode with robustness for energy-dense, compact and foldable lithium-sulfur batteries. Chem. Eng. J. 412, 128562 (2021). https://doi.org/10.1016/j.cej.2021.128562

Zhang, X.Q., He, B., Li, W.C., et al.: Hollow carbon nanofibers with dynamic adjustable pore sizes and closed ends as hosts for high-rate lithium-sulfur battery cathodes. Nano Res. 11, 1238–1246 (2018)

Deng, W.N., Hu, A.P., Chen, X.H., et al.: Sulfur-impregnated 3D hierarchical porous nitrogen-doped aligned carbon nanotubes as high-performance cathode for lithium-sulfur batteries. J. Power Sources 322, 138–146 (2016). https://doi.org/10.1016/j.jpowsour.2016.05.024

Gulzar, U., Li, T., Bai, X., et al.: Nitrogen-doped single-walled carbon nanohorns as a cost-effective carbon host toward high-performance lithium-sulfur batteries. ACS Appl. Mater. Interfaces 10, 5551–5559 (2018). https://doi.org/10.1021/acsami.7b17602

Wang, H.Q., Zhang, C.F., Chen, Z.X., et al.: Large-scale synthesis of ordered mesoporous carbon fiber and its application as cathode material for lithium-sulfur batteries. Carbon 81, 782–787 (2015). https://doi.org/10.1016/j.carbon.2014.10.024

Wu, F., Shi, L.L., Mu, D.B., et al.: A hierarchical carbon fiber/sulfur composite as cathode material for Li-S batteries. Carbon 86, 146–155 (2015). https://doi.org/10.1016/j.carbon.2015.01.026

He, B., Li, W.C., Chen, Z.Y., et al.: Multilevel structured carbon film as cathode host for Li-S batteries with superhigh-areal-capacity. Nano Res. 14, 1273–1279 (2021)

Li, G.X., Sun, J.H., Hou, W.P., et al.: Three-dimensional porous carbon composites containing high sulfur nanoparticle content for high-performance lithium-sulfur batteries. Nat. Commun. 7, 10601 (2016). https://doi.org/10.1038/ncomms10601

Zhang, Y.Z., Zong, X.L., Zhan, L., et al.: Double-shelled hollow carbon sphere with microporous outer shell towards high performance lithium-sulfur battery. Electrochim. Acta 284, 89–97 (2018). https://doi.org/10.1016/j.electacta.2018.05.144

Sahore, R., Levin, B.D.A., Pan, M., et al.: Design principles for optimum performance of porous carbons in lithium-sulfur batteries. Adv. Energy Mater. 6, 1600134 (2016). https://doi.org/10.1002/aenm.201600134

Mi, K., Jiang, Y., Feng, J.K., et al.: Hierarchical carbon nanotubes with a thick microporous wall and inner channel as efficient scaffolds for lithium-sulfur batteries. Adv. Funct. Mater. 26, 1571–1579 (2016). https://doi.org/10.1002/adfm.201504835

Li, F.Q., Qin, F.R., Zhang, K., et al.: Hierarchically porous carbon derived from banana peel for lithium sulfur battery with high areal and gravimetric sulfur loading. J. Power Sources 362, 160–167 (2017). https://doi.org/10.1016/j.jpowsour.2017.07.038

Sevilla, M., Carro-Rodríguez, J., Díez, N., et al.: Straightforward synthesis of sulfur/N,S-codoped carbon cathodes for lithium-sulfur batteries. Sci. Rep. 10, 4866 (2020). https://doi.org/10.1038/s41598-020-61583-1

Ai, W., Zhou, W.W., Du, Z.Z., et al.: Nitrogen and phosphorus codoped hierarchically porous carbon as an efficient sulfur host for Li-S batteries. Energy Storage Mater. 6, 112–118 (2017). https://doi.org/10.1016/j.ensm.2016.10.008

Hu, Q.Q., Dong, H.Y., Wang, B., et al.: Constructing coral-like hierarchical porous carbon architectures with tailored pore size distribution as sulfur hosts for durable Li-S batteries. Electrochim. Acta 377, 138063 (2021). https://doi.org/10.1016/j.electacta.2021.138063

Helen, M., Reddy, M.A., Diemant, T., et al.: Single step transformation of sulphur to Li2S2/Li2S in Li-S batteries. Sci. Rep. 5, 12146 (2015). https://doi.org/10.1038/srep12146

Xu, Y.H., Wen, Y., Zhu, Y.J., et al.: Confined sulfur in microporous carbon renders superior cycling stability in Li/S batteries. Adv. Funct. Mater. 25, 4312–4320 (2015). https://doi.org/10.1002/adfm.201500983

Li, X.L., Cao, Y.L., Qi, W., et al.: Optimization of mesoporous carbon structures for lithium-sulfur battery applications. J. Mater. Chem. 21, 16603–16610 (2011). https://doi.org/10.1039/C1JM12979A

Zhou, W.D., Wang, C.M., Zhang, Q.L., et al.: Tailoring pore size of nitrogen-doped hollow carbon nanospheres for confining sulfur in lithium-sulfur batteries. Adv. Energy Mater. 5, 1401752 (2015). https://doi.org/10.1002/aenm.201401752

Hippauf, F., Nickel, W., Hao, G.P., et al.: The importance of pore size and surface polarity for polysulfide adsorption in lithium sulfur batteries. Adv. Mater. Interfaces 3, 1600508 (2016). https://doi.org/10.1002/admi.201600508

Wang, D.X., Fu, A.P., Li, H.L., et al.: Mesoporous carbon spheres with controlled porosity for high-performance lithium-sulfur batteries. J. Power Sources 285, 469–477 (2015). https://doi.org/10.1016/j.jpowsour.2015.03.135

Sun, L., Wang, D.T., Luo, Y.F., et al.: Sulfur embedded in a mesoporous carbon nanotube network as a binder-free electrode for high-performance lithium-sulfur batteries. ACS Nano 10, 1300–1308 (2016). https://doi.org/10.1021/acsnano.5b06675

Xin, S., You, Y., Li, H.Q., et al.: Graphene sandwiched by sulfur-confined mesoporous carbon nanosheets: a kinetically stable cathode for Li-S batteries. ACS Appl. Mater. Interfaces 8, 33704–33711 (2016). https://doi.org/10.1021/acsami.6b12142

Li, C.X., Xi, Z.C., Guo, D.X., et al.: Chemical immobilization effect on lithium polysulfides for lithium-sulfur batteries. Small 14, 1701986 (2018). https://doi.org/10.1002/smll.201701986

Hwang, J.Y., Kim, H.M., Lee, S.K., et al.: High-energy, high-rate, lithium-sulfur batteries: synergetic effect of hollow TiO2-webbed carbon nanotubes and a dual functional carbon-paper interlayer. Adv. Energy Mater. 6, 1501480 (2016). https://doi.org/10.1002/aenm.201501480

Ni, L.B., Wu, Z., Zhao, G.J., et al.: Core-shell structure and interaction mechanism of γ-MnO2 coated sulfur for improved lithium-sulfur batteries. Small 13, 1603466 (2017). https://doi.org/10.1002/smll.201603466

Liang, X., Hart, C., Pang, Q., et al.: A highly efficient polysulfide mediator for lithium-sulfur batteries. Nat. Commun. 6, 5682 (2015). https://doi.org/10.1038/ncomms6682

Fan, Q., Liu, W., Weng, Z., et al.: Ternary hybrid material for high-performance lithium-sulfur battery. J. Am. Chem. Soc. 137, 12946–12953 (2015). https://doi.org/10.1021/jacs.5b07071

Hu, N.N., Lv, X.S., Dai, Y., et al.: SnO2/reduced graphene oxide interlayer mitigating the shuttle effect of Li-S batteries. ACS Appl. Mater. Interfaces 10, 18665–18674 (2018). https://doi.org/10.1021/acsami.8b03255

Ponraj, R., Kannan, A.G., Ahn, J.H., et al.: Improvement of cycling performance of lithium-sulfur batteries by using magnesium oxide as a functional additive for trapping lithium polysulfide. ACS Appl. Mater. Interfaces 8, 4000–4006 (2016). https://doi.org/10.1021/acsami.5b11327

Gu, X.X., Tong, C.J., Wen, B., et al.: Ball-milling synthesis of ZnO@sulphur/carbon nanotubes and Ni(OH)2@sulphur/carbon nanotubes composites for high-performance lithium-sulphur batteries. Electrochim. Acta 196, 369–376 (2016). https://doi.org/10.1016/j.electacta.2016.03.018

Abualela, S., Lv, X.X., Hu, Y., et al.: NiO nanosheets grown on carbon cloth as mesoporous cathode for high-performance lithium-sulfur battery. Mater. Lett. 268, 127622 (2020). https://doi.org/10.1016/j.matlet.2020.127622

Liang, X., Nazar, L.F.: In situ reactive assembly of scalable core-shell sulfur-MnO2 composite cathodes. ACS Nano 10, 4192–4198 (2016). https://doi.org/10.1021/acsnano.5b07458

Xiao, Z.B., Yang, Z., Wang, L., et al.: A lightweight TiO2/graphene interlayer, applied as a highly effective polysulfide absorbent for fast, long-life lithium-sulfur batteries. Adv. Mater. 27, 2891–2898 (2015). https://doi.org/10.1002/adma.201405637

Wei Seh, Z., Li, W.Y., Cha, J.J., et al.: Sulphur-TiO2 yolk-shell nanoarchitecture with internal void space for long-cycle lithium-sulphur batteries. Nat. Commun. 4, 1–6 (2013). https://doi.org/10.1038/ncomms2327

Ghosh, A., Manjunatha, R., Kumar, R., et al.: A facile bottom-up approach to construct hybrid flexible cathode scaffold for high-performance lithium-sulfur batteries. ACS Appl. Mater. Interfaces 8, 33775–33785 (2016). https://doi.org/10.1021/acsami.6b11180

Guo, J.L., Zhang, X.L., Du, X.Y., et al.: A Mn3O4 nano-wall array based binder-free cathode for high performance lithium-sulfur batteries. J. Mater. Chem. A 5, 6447–6454 (2017). https://doi.org/10.1039/C7TA00475C

Tao, Y.Q., Wei, Y.J., Liu, Y., et al.: Kinetically-enhanced polysulfide redox reactions by Nb2O5 nanocrystals for high-rate lithium-sulfur battery. Energy Environ. Sci. 9, 3230–3239 (2016). https://doi.org/10.1039/C6EE01662F

Lee, J.S., Jun, J., Jang, J., et al.: Sulfur-immobilized, activated porous carbon nanotube composite based cathodes for lithium-sulfur batteries. Small 13, 1602984 (2017). https://doi.org/10.1002/smll.201602984

Zhang, D.A., Wang, Q., Wang, Q., et al.: High capacity and cyclability of hierarchical MoS2/SnO2 nanocomposites as the cathode of lithium-sulfur battery. Electrochim. Acta 173, 476–482 (2015). https://doi.org/10.1016/j.electacta.2015.05.086

Zhang, Q.F., Wang, Y.P., Seh, Z.W., et al.: Understanding the anchoring effect of two-dimensional layered materials for lithium-sulfur batteries. Nano Lett. 15, 3780–3786 (2015). https://doi.org/10.1021/acs.nanolett.5b00367

Dirlam, P.T., Park, J., Simmonds, A.G., et al.: Elemental sulfur and molybdenum disulfide composites for Li-S batteries with long cycle life and high-rate capability. ACS Appl. Mater. Interfaces 8, 13437–13448 (2016). https://doi.org/10.1021/acsami.6b03200

Zhang, S.S., Tran, D.T.: Pyrite FeS2 as an efficient adsorbent of lithium polysulphide for improved lithium-sulphur batteries. J. Mater. Chem. A 4, 4371–4374 (2016). https://doi.org/10.1039/C6TA01214K

Zhang, A.Y., Fang, X., Shen, C.F., et al.: A carbon nanofiber network for stable lithium metal anodes with high Coulombic efficiency and long cycle life. Nano Res. 9, 3428–3436 (2016)

Pang, Q., Kundu, D.P., Nazar, L.F.: A graphene-like metallic cathode host for long-life and high-loading lithium-sulfur batteries. Mater. Horiz. 3, 130–136 (2016). https://doi.org/10.1039/C5MH00246J

Yuan, Z., Peng, H.J., Hou, T.Z., et al.: Powering lithium-sulfur battery performance by propelling polysulfide redox at sulfiphilic hosts. Nano Lett. 16, 519–527 (2016). https://doi.org/10.1021/acs.nanolett.5b04166

Li, X.L., Chu, L.B., Wang, Y.Y., et al.: Anchoring function for polysulfide ions of ultrasmall SnS2 in hollow carbon nanospheres for high performance lithium-sulfur batteries. Mater. Sci. Eng. B 205, 46–54 (2016). https://doi.org/10.1016/j.mseb.2015.12.002

Lu, Y., Li, X.N., Liang, J.W., et al.: A simple melting-diffusing-reacting strategy to fabricate S/NiS2-C for lithium-sulfur batteries. Nanoscale 8, 17616–17622 (2016). https://doi.org/10.1039/c6nr05626a

Sun, K., Su, D., Zhang, Q., et al.: Interaction of CuS and sulfur in Li-S battery system. J. Electrochem. Soc. 162, A2834–A2839 (2015). https://doi.org/10.1149/2.1021514jes

Bugga, R.V., Jones, S.C., Pasalic, J., et al.: Metal sulfide-blended sulfur cathodes in high energy lithium-sulfur cells. J. Electrochem. Soc. 164, A265–A276 (2016). https://doi.org/10.1149/2.0941702jes

Liang, X., Rangom, Y., Kwok, C.Y., et al.: Interwoven MXene nanosheet/carbon-nanotube composites as Li-S cathode hosts. Adv. Mater. 29, 1603040 (2017). https://doi.org/10.1002/adma.201603040

Su, D.W., Cortie, M., Wang, G.X.: Fabrication of N-doped graphene-carbon nanotube hybrids from Prussian blue for lithium-sulfur batteries. Adv. Energy Mater. 7, 1602014 (2017). https://doi.org/10.1002/aenm.201602014

He, J.R., Hartmann, G., Lee, M., et al.: Freestanding 1T MoS2/graphene heterostructures as a highly efficient electrocatalyst for lithium polysulfides in Li-S batteries. Energy Environ. Sci. 12, 344–350 (2019). https://doi.org/10.1039/C8EE03252A

Liu, A.M., Liang, X.Y., Ren, X.F., et al.: Recent progress in MXene-based materials for metal-sulfur and metal-air batteries: potential high-performance electrodes. Electrochem. Energy Rev. 5, 112–144 (2022)

Wu, Y.L., Zhu, X.R., Li, P.R., et al.: Ultradispersed WxC nanoparticles enable fast polysulfide interconversion for high-performance Li-S batteries. Nano Energy 59, 636–643 (2019). https://doi.org/10.1016/j.nanoen.2019.03.015

Cui, Z.M., Zu, C.X., Zhou, W.D., et al.: Mesoporous titanium nitride-enabled highly stable lithium-sulfur batteries. Adv. Mater. 28, 6926–6931 (2016). https://doi.org/10.1002/adma.201601382

Chen, Y., Zhang, W.X., Zhou, D., et al.: Co-Fe mixed metal phosphide nanocubes with highly interconnected-pore architecture as an efficient polysulfide mediator for lithium-sulfur batteries. ACS Nano 13, 4731–4741 (2019). https://doi.org/10.1021/acsnano.9b01079

Rost, C.M., Sachet, E., Borman, T., et al.: Entropy-stabilized oxides. Nat. Commun. 6, 1–8 (2015). https://doi.org/10.1038/ncomms9485

Raza, H., Cheng, J.Y., Lin, C., et al.: High-entropy stabilized oxides derived via a low-temperature template route for high-performance lithium-sulfur batteries. EcoMat 5, e12324 (2023). https://doi.org/10.1002/eom2.12324

Raza, H., Cheng, J.Y., Chen, G.H., et al.: Low-temperature calcination of metal-organic frameworks (MOFs) to derive the high entropy stabilized oxide for high performance lithium-sulfur batteries. ECS Meet. Abstr. (2022). https://doi.org/10.1149/MA2022-0162432mtgabs

Kong, L., Chen, X., Li, B.Q., et al.: A bifunctional perovskite promoter for polysulfide regulation toward stable lithium-sulfur batteries. Adv. Mater. 30, 1705219 (2018). https://doi.org/10.1002/adma.201705219

Zheng, Y.N., Yi, Y.K., Fan, M.H., et al.: A high-entropy metal oxide as chemical anchor of polysulfide for lithium-sulfur batteries. Energy Storage Mater. 23, 678–683 (2019). https://doi.org/10.1016/j.ensm.2019.02.030

Liu, G., Zeng, Q., Fan, Z.Y., et al.: Boosting sulfur catalytic kinetics by defect engineering of vanadium disulfide for high-performance lithium-sulfur batteries. Chem. Eng. J. 448, 137683 (2022). https://doi.org/10.1016/j.cej.2022.137683

Jiao, L., Li, H., Zhang, C., et al.: Molecular engineering of sulfur-providing materials for optimized sulfur conversion in Li-S chemistry. EcoMat 4, e12262 (2022). https://doi.org/10.1002/eom2.12262

Wang, L., Hua, W.X., Wan, X., et al.: Design rules of a sulfur redox electrocatalyst for lithium-sulfur batteries. Adv. Mater. 34, 2110279 (2022). https://doi.org/10.1002/adma.202110279

Peng, H.J., Zhang, G., Chen, X., et al.: Enhanced electrochemical kinetics on conductive polar mediators for lithium-sulfur batteries. Angew. Chem. 128, 13184–13189 (2016). https://doi.org/10.1002/ange.201605676

Liu, D.H., Zhang, C., Zhou, G.M., et al.: Catalytic effects in lithium-sulfur batteries: promoted sulfur transformation and reduced shuttle effect. Adv. Sci. 5, 1700270 (2018). https://doi.org/10.1002/advs.433

Wang, L., Hu, Z.H., Wan, X., et al.: Li2S4 anchoring governs the catalytic sulfur reduction on defective SmMn2O5 in lithium-sulfur battery. Adv. Energy Mater. 12, 2200340 (2022). https://doi.org/10.1002/aenm.202200340

Zhou, J.B., Liu, X.J., Zhu, L.Q., et al.: Deciphering the modulation essence of p bands in Co-based compounds on Li-S chemistry. Joule 2, 2681–2693 (2018). https://doi.org/10.1016/j.joule.2018.08.010

Hua, W.X., Li, H., Pei, C., et al.: Selective catalysis remedies polysulfide shuttling in lithium-sulfur batteries. Adv. Mater. 33, 2101006 (2021). https://doi.org/10.1002/adma.202101006

Chen, Y., Gao, X.C., Su, D.W., et al.: Accelerating redox kinetics of lithium-sulfur batteries. Trends Chem. 2, 1020–1033 (2020). https://doi.org/10.1016/j.trechm.2020.09.001

Babu, G., Ababtain, K., Ng, K.Y., et al.: Electrocatalysis of lithium polysulfides: current collectors as electrodes in Li/S battery configuration. Sci. Rep. 5, 8763 (2015). https://doi.org/10.1038/srep08763

Wang, Z.S., Shen, J.D., Ji, S.M., et al.: B, N codoped graphitic nanotubes loaded with Co nanoparticles as superior sulfur host for advanced Li-S batteries. Small 16, 1906634 (2020). https://doi.org/10.1002/smll.201906634

Hu, S.Y., Yi, M.J., Wu, H., et al.: Ionic-liquid-assisted synthesis of N, F, and B co-doped CoFe2O4−x on multiwalled carbon nanotubes with enriched oxygen vacancies for Li-S batteries. Adv. Funct. Mater. 32, 2111084 (2022). https://doi.org/10.1002/adfm.202111084

Hou, W.S., Feng, P.L., Guo, X., et al.: Catalytic mechanism of oxygen vacancies in perovskite oxides for lithium-sulfur batteries. Adv. Mater. 34, 2202222 (2022). https://doi.org/10.1002/adma.202202222

He, J.R., Manthiram, A.: A review on the status and challenges of electrocatalysts in lithium-sulfur batteries. Energy Storage Mater. 20, 55–70 (2019). https://doi.org/10.1016/j.ensm.2019.04.038

Chen, J.J., Yuan, R.M., Feng, J.M., et al.: Conductive Lewis base matrix to recover the missing link of Li2S8 during the sulfur redox cycle in Li-S battery. Chem. Mater. 27, 2048–2055 (2015). https://doi.org/10.1021/cm5044667

Pang, Q., Tang, J.T., Huang, H., et al.: A nitrogen and sulfur dual-doped carbon derived from polyrhodanine@cellulose for advanced lithium-sulfur batteries. Adv. Mater. 27, 6021–6028 (2015). https://doi.org/10.1002/adma.201502467

Li, L., Chen, L., Mukherjee, S., et al.: Phosphorene as a polysulfide immobilizer and catalyst in high-performance lithium-sulfur batteries. Adv. Mater. 29, 1602734 (2017). https://doi.org/10.1002/adma.201602734

Wang, C.L., Sun, L.S., Li, K., et al.: Unravel the catalytic effect of two-dimensional metal sulfides on polysulfide conversions for lithium-sulfur batteries. ACS Appl. Mater. Interfaces 12, 43560–43567 (2020). https://doi.org/10.1021/acsami.0c09567

Zhang, G.D., Wang, S.S., Zeng, X.Q., et al.: Holey amorphous FeCoO-coated black phosphorus for robust polysulfide adsorption and catalytic conversion in lithium-sulfur batteries. J. Mater. Chem. A 10, 11676–11683 (2022). https://doi.org/10.1039/D2TA01215D

Xue, P., Zhu, K.P., Gong, W.B., et al.: “One stone two birds” design for dual-functional TiO2-TiN heterostructures enabled dendrite-free and kinetics-enhanced lithium-sulfur batteries. Adv. Energy Mater. 12, 2200308 (2022). https://doi.org/10.1002/aenm.202200308

Zhou, T.H., Lv, W., Li, J., et al.: Twinborn TiO2-TiN heterostructures enabling smooth trapping-diffusion-conversion of polysulfides towards ultralong life lithium-sulfur batteries. Energy Environ. Sci. 10, 1694–1703 (2017). https://doi.org/10.1039/C7EE01430A

Song, Y.Z., Zhao, W., Kong, L., et al.: Synchronous immobilization and conversion of polysulfides on a VO2-VN binary host targeting high sulfur load Li-S batteries. Energy Environ. Sci. 11, 2620–2630 (2018). https://doi.org/10.1039/C8EE01402G

Ye, C., Jiao, Y., Jin, H.Y., et al.: 2D MoN-VN heterostructure to regulate polysulfides for highly efficient lithium-sulfur batteries. Angew. Chem. 130, 16945–16949 (2018). https://doi.org/10.1002/ange.201810579

Zhang, L.L., Liu, D.B., Muhammad, Z., et al.: Single nickel atoms on nitrogen-doped graphene enabling enhanced kinetics of lithium-sulfur batteries. Adv. Mater. 31, e1903955 (2019). https://doi.org/10.1002/adma.201903955

Li, Y.J., Gao, T.T., Ni, D.Y., et al.: Two birds with one stone: interfacial engineering of multifunctional Janus separator for lithium-sulfur batteries. Adv. Mater. 34, 2107638 (2022). https://doi.org/10.1002/adma.202107638

Zhang, M., Chen, W., Xue, L.X., et al.: Adsorption-catalysis design in the lithium-sulfur battery. Adv. Energy Mater. 10, 1903008 (2020). https://doi.org/10.1002/aenm.201903008

Wang, P., Xi, B.J., Zhang, Z., et al.: Atomic tungsten on graphene with unique coordination enabling kinetically boosted lithium-sulfur batteries. Angew. Chem. Int. Ed. 60, 15563–15571 (2021). https://doi.org/10.1002/anie.202104053

Han, Z.Y., Zhao, S.Y., Xiao, J.W., et al.: Engineering d-p orbital hybridization in single-atom metal-embedded three-dimensional electrodes for Li-S batteries. Adv. Mater. 33, e2105947 (2021). https://doi.org/10.1002/adma.202105947

Liu, K.F., Zhao, H.B., Ye, D.X., et al.: Recent progress in organic polymers-composited sulfur materials as cathodes for lithium-sulfur battery. Chem. Eng. J. 417, 129309 (2021). https://doi.org/10.1016/j.cej.2021.129309

Xiang, J.W., Guo, Z.Z., Yi, Z.Q., et al.: Facile synthesis of sulfurized polyacrylonitrile composite as cathode for high-rate lithium-sulfur batteries. J. Energy Chem. 49, 161–165 (2020). https://doi.org/10.1016/j.jechem.2020.01.037

Wang, J., Yang, J., Xie, J., et al.: A novel conductive polymer-sulfur composite cathode material for rechargeable lithium batteries. Adv. Mater. 14, 963–965 (2002). https://doi.org/10.1002/1521-4095(20020705)14:13/14%3c963:AID-ADMA963%3e3.0.CO;2-P

Yu, X.G., Xie, J.Y., Yang, J., et al.: Lithium storage in conductive sulfur-containing polymers. J. Electroanal. Chem. 573, 121–128 (2004). https://doi.org/10.1016/j.jelechem.2004.07.004

Zhang, S.: Understanding of sulfurized polyacrylonitrile for superior performance lithium/sulfur battery. Energies 7, 4588–4600 (2014). https://doi.org/10.3390/en7074588

Wei, S.Y., Ma, L., Hendrickson, K.E., et al.: Metal-sulfur battery cathodes based on PAN-sulfur composites. J. Am. Chem. Soc. 137, 12143–12152 (2015). https://doi.org/10.1021/jacs.5b08113

Yang, H.J., Chen, J.H., Yang, J., et al.: Prospect of sulfurized pyrolyzed poly(acrylonitrile) (S@pPAN) cathode materials for rechargeable lithium batteries. Angew. Chem. Int. Ed. 59, 7306–7318 (2020). https://doi.org/10.1002/anie.201913540

Chen, X., Peng, L.F., Wang, L.H., et al.: Ether-compatible sulfurized polyacrylonitrile cathode with excellent performance enabled by fast kinetics via selenium doping. Nat. Commun. 10, 1021 (2019). https://doi.org/10.1038/s41467-019-08818-6

Yin, L.C., Wang, J.L., Yang, J., et al.: A novel pyrolyzed polyacrylonitrile-sulfur@MWCNT composite cathode material for high-rate rechargeable lithium/sulfur batteries. J. Mater. Chem. 21, 6807–6810 (2011). https://doi.org/10.1039/C1JM00047K

Mentbayeva, A., Belgibayeva, A., Umirov, N., et al.: High performance freestanding composite cathode for lithium-sulfur batteries. Electrochim. Acta 217, 242–248 (2016). https://doi.org/10.1016/j.electacta.2016.09.082

Yin, L.C., Wang, J.L., Lin, F.J., et al.: Polyacrylonitrile/graphene composite as a precursor to a sulfur-based cathode material for high-rate rechargeable Li-S batteries. Energy Environ. Sci. 5, 6966–6972 (2012). https://doi.org/10.1039/C2EE03495F

Li, J., Li, K., Li, M.Q., et al.: A sulfur-polyacrylonitrile/graphene composite cathode for lithium batteries with excellent cyclability. J. Power Sources 252, 107–112 (2014). https://doi.org/10.1016/j.jpowsour.2013.11.088

Liu, Y., Haridas, A.K., Lee, Y., et al.: Freestanding porous sulfurized polyacrylonitrile fiber as a cathode material for advanced lithium sulfur batteries. Appl. Surf. Sci. 472, 135–142 (2019). https://doi.org/10.1016/j.apsusc.2018.03.062

Sohn, H., Gordin, M.L., Regula, M., et al.: Porous spherical polyacrylonitrile-carbon nanocomposite with high loading of sulfur for lithium-sulfur batteries. J. Power Sources 302, 70–78 (2016). https://doi.org/10.1016/j.jpowsour.2015.10.013

Hu, C.J., Chen, H.W., Shen, Y.B., et al.: In situ wrapping of the cathode material in lithium-sulfur batteries. Nat. Commun. 8, 479 (2017). https://doi.org/10.1038/s41467-017-00656-8

Zhang, Y.G., Zhao, Y., Yermukhambetova, A., et al.: Ternary sulfur/polyacrylonitrile/Mg0.6Ni0.4O composite cathodes for high performance lithium/sulfur batteries. J. Mater. Chem. A 1, 295–301 (2013). https://doi.org/10.1039/C2TA00105E

Liu, Y.G., Wang, W.K., Wang, A.B., et al.: A polysulfide reduction accelerator-NiS2-modified sulfurized polyacrylonitrile as a high performance cathode material for lithium-sulfur batteries. J. Mater. Chem. A 5, 22120–22124 (2017). https://doi.org/10.1039/C7TA04279E

Haridas, A., Heo, J., Liu, Y., et al.: Boosting high energy density lithium-ion storage via the rational design of an FeS-incorporated sulfurized polyacrylonitrile fiber hybrid cathode. ACS Appl. Mater. Interfaces 11, 29924–29933 (2019). https://doi.org/10.1021/acsami.9b09026

Zhao, X.H., Wang, C.L., Li, Z.W., et al.: Sulfurized polyacrylonitrile for high-performance lithium sulfur batteries: advances and prospects. J. Mater. Chem. A 9, 19282–19297 (2021). https://doi.org/10.1039/d1ta03300j

Xu, Z.X., Wang, J.L., Yang, J., et al.: Enhanced performance of a lithium-sulfur battery using a carbonate-based electrolyte. Angew. Chem. Int. Ed. 55, 10372–10375 (2016). https://doi.org/10.1002/anie.201605931

Jin, F., Hu, C.J., Liu, C.H., et al.: Enhancing the performance of sulfurized polyacrylonitrile cathode by in-situ wrapping. J. Electroanal. Chem. 835, 156–160 (2019). https://doi.org/10.1016/j.jelechem.2019.01.032

Yang, H.J., Li, Q.Y., Guo, C., et al.: Safer lithium-sulfur battery based on nonflammable electrolyte with sulfur composite cathode. Chem. Commun. (Camb.) 54, 4132–4135 (2018). https://doi.org/10.1039/c7cc09942h

Chen, W.J., Li, B.Q., Zhao, C.X., et al.: Electrolyte regulation towards stable lithium-metal anodes in lithium-sulfur batteries with sulfurized polyacrylonitrile cathodes. Angew. Chem. Int. Ed. 59, 10732–10745 (2020). https://doi.org/10.1002/anie.201912701

Perez Beltran, S., Balbuena, P.B.: A solid electrolyte interphase to protect the sulfurized polyacrylonitrile (SPAN) composite for Li-S batteries: computational approach addressing the electrolyte/SPAN interfacial reactivity. J. Mater. Chem. A 9, 7888–7902 (2021). https://doi.org/10.1039/D1TA00110H

Yang, H.J., Naveed, A., Li, Q.Y., et al.: Lithium sulfur batteries with compatible electrolyte both for stable cathode and dendrite-free anode. Energy Storage Mater. 15, 299–307 (2018). https://doi.org/10.1016/j.ensm.2018.05.014

Bonino, F., Morzilli, S., Scrosati, B.: Electrochemical behaviour of metal sulphides as cathodes in primary lithium batteries. J. Power Sources 14, 65–69 (1985). https://doi.org/10.1016/0378-7753(85)88012-5

Kaiser, M.R., Han, Z.J., Liang, J., et al.: Lithium sulfide-based cathode for lithium-ion/sulfur battery: recent progress and challenges. Energy Storage Mater. 19, 1–15 (2019). https://doi.org/10.1016/j.ensm.2019.04.001

Zhang, K., Wang, L.J., Hu, Z., et al.: Ultrasmall Li2S nanoparticles anchored in graphene nanosheets for high-energy lithium-ion batteries. Sci. Rep. 4, 6467 (2014). https://doi.org/10.1038/srep06467

Wang, C., Wang, X.S., Yang, Y., et al.: Slurryless Li2S/reduced graphene oxide cathode paper for high-performance lithium sulfur battery. Nano Lett. 15, 1796–1802 (2015). https://doi.org/10.1021/acs.nanolett.5b00112

Tan, G.Q., Xu, R., Xing, Z.Y., et al.: Burning lithium in CS2 for high-performing compact Li2S-graphene nanocapsules for Li-S batteries. Nat. Energy 2, 1–10 (2017). https://doi.org/10.1038/nenergy.2017.90

Yang, Y., McDowell, M.T., Jackson, A., et al.: New nanostructured Li2S/silicon rechargeable battery with high specific energy. Nano Lett. 10, 1486–1491 (2010). https://doi.org/10.1021/nl100504q

Chen, Y., Lu, S.T., Zhou, J., et al.: Synergistically assembled Li2S/FWNTs@reduced graphene oxide nanobundle forest for free-standing high-performance Li2S cathodes. Adv. Funct. Mater. 27, 1700987 (2017). https://doi.org/10.1002/adfm.201700987

Seh, Z.W., Wang, H.T., Liu, N., et al.: High-capacity Li2S-graphene oxide composite cathodes with stable cycling performance. Chem. Sci. 5, 1396–1400 (2014). https://doi.org/10.1039/C3SC52789A

Wang, D.H., Xie, D., Xia, X.H., et al.: A 3D conductive network with high loading Li2S@C for high performance lithium-sulfur batteries. J. Mater. Chem. A 5, 19358–19363 (2017). https://doi.org/10.1039/C7TA06090D

Zhang, J., Shi, Y., Ding, Y., et al.: A conductive molecular framework derived Li2S/N,P-codoped carbon cathode for advanced lithium-sulfur batteries. Adv. Energy Mater. 7, 1602876 (2017). https://doi.org/10.1002/aenm.201602876

Wu, F.X., Pollard, T.P., Zhao, E.B., et al.: Layered LiTiO2 for the protection of Li2S cathodes against dissolution: mechanisms of the remarkable performance boost. Energy Environ. Sci. 11, 807–817 (2018). https://doi.org/10.1039/C8EE00419F

He, J.R., Chen, Y.F., Manthiram, A.: Metal sulfide-decorated carbon sponge as a highly efficient electrocatalyst and absorbant for polysulfide in high-loading Li2S batteries. Adv. Energy Mater. 9, 1900584 (2019). https://doi.org/10.1002/aenm.201900584

Zheng, S.Y., Chen, Y., Xu, Y.H., et al.: In situ formed lithium sulfide/microporous carbon cathodes for lithium-ion batteries. ACS Nano 7, 10995–11003 (2013). https://doi.org/10.1021/nn404601h

Zhang, S.G., Ueno, K., Dokko, K., et al.: Recent advances in electrolytes for lithium-sulfur batteries. Adv. Energy Mater. 5, 1500117 (2015). https://doi.org/10.1002/aenm.201500117

Ye, F.M., Liu, M.N., Yan, X., et al.: In situ electrochemically derived amorphous-Li2S for high performance Li2S/graphite full cell. Small 14, 1703871 (2018). https://doi.org/10.1002/smll.201703871

Balach, J., Jaumann, T., Giebeler, L.: Nanosized Li2S-based cathodes derived from MoS2 for high-energy density Li-S cells and Si-Li2S full cells in carbonate-based electrolyte. Energy Storage Mater. 8, 209–216 (2017). https://doi.org/10.1016/j.ensm.2017.03.013

Gu, S., Sun, C.Z., Xu, D., et al.: Recent progress in liquid electrolyte-based Li-S batteries: shuttle problem and solutions. Electrochem. Energy Rev. 1, 599–624 (2018)

Hou, L.P., Zhang, X.Q., Yao, N., et al.: An encapsulating lithium-polysulfide electrolyte for practical lithium-sulfur batteries. Chem 8, 1083–1098 (2022). https://doi.org/10.1016/j.chempr.2021.12.023

Tan, J., Matz, J., Dong, P., et al.: Appreciating the role of polysulfides in lithium-sulfur batteries and regulation strategies by electrolytes engineering. Energy Storage Mater. 42, 645–678 (2021). https://doi.org/10.1016/j.ensm.2021.08.012

Yang, H.J., Qiao, Y., Chang, Z., et al.: Designing cation-solvent fully coordinated electrolyte for high-energy-density lithium-sulfur full cell based on solid-solid conversion. Angew. Chem. Int. Ed. 60, 17726–17734 (2021). https://doi.org/10.1002/anie.202106788

Li, X.Y., Feng, S., Zhao, C.X., et al.: Regulating lithium salt to inhibit surface gelation on an electrocatalyst for high-energy-density lithium-sulfur batteries. J. Am. Chem. Soc. 144, 14638–14646 (2022). https://doi.org/10.1021/jacs.2c04176

Qi, X.Q., Yang, F.Y., Sang, P.F., et al.: Electrochemical reactivation of dead Li2S for Li-S batteries in non-solvating electrolytes. Angew. Chem. Int. Ed. 62, e202218803 (2023). https://doi.org/10.1002/anie.202218803

Fan, L.L., Deng, N.P., Yan, J., et al.: The recent research status quo and the prospect of electrolytes for lithium sulfur batteries. Chem. Eng. J. 369, 874–897 (2019). https://doi.org/10.1016/j.cej.2019.03.145

Weng, W., Pol, V.G., Amine, K.: Ultrasound assisted design of sulfur/carbon cathodes with partially fluorinated ether electrolytes for highly efficient Li/S batteries. Adv. Mater. 25, 1608–1615 (2013). https://doi.org/10.1002/adma.201204051

Hou, L.P., Li, Z., Yao, N., et al.: Weakening the solvating power of solvents to encapsulate lithium polysulfides enables long-cycling lithium-sulfur batteries. Adv. Mater. 34, 2205284 (2022). https://doi.org/10.1002/adma.202205284

Zhang, X.Q., Jin, Q., Nan, Y.L., et al.: Electrolyte structure of lithium polysulfides with anti-reductive solvent shells for practical lithium-sulfur batteries. Angew. Chem. Int. Ed. 60, 15503–15509 (2021). https://doi.org/10.1002/anie.202103470

Carbone, L., Gobet, M., Peng, J., et al.: Comparative study of ether-based electrolytes for application in lithium-sulfur battery. ACS Appl. Mater. Interfaces 7, 13859–13865 (2015). https://doi.org/10.1021/acsami.5b02160

Chung, S.H., Manthiram, A.: Rational design of statically and dynamically stable lithium-sulfur batteries with high sulfur loading and low electrolyte/sulfur ratio. Adv. Mater. 30, 1705951 (2018). https://doi.org/10.1002/adma.201705951

Li, Z.H., Li, X.L., Zhou, L., et al.: A synergistic strategy for stable lithium metal anodes using 3D fluorine-doped graphene shuttle-implanted porous carbon networks. Nano Energy 49, 179–185 (2018). https://doi.org/10.1016/j.nanoen.2018.04.040

Meisner, Q.J., Rojas, T., Dietz Rago, N.L., et al.: Lithium-sulfur battery with partially fluorinated ether electrolytes: interplay between capacity, coulombic efficiency and Li anode protection. J. Power Sources 438, 226939 (2019). https://doi.org/10.1016/j.jpowsour.2019.226939

Barghamadi, M., Best, A.S., Bhatt, A.I., et al.: Effect of anion on behaviour of Li-S battery electrolyte solutions based on N-methyl-N-butyl-pyrrolidinium ionic liquids. Electrochim. Acta 180, 636–644 (2015). https://doi.org/10.1016/j.electacta.2015.08.132

Gu, S., Qian, R., Jin, J., et al.: Suppressing the dissolution of polysulfides with cosolvent fluorinated diether towards high-performance lithium sulfur batteries. Phys. Chem. Chem. Phys. 18, 29293–29299 (2016). https://doi.org/10.1039/c6cp04775k

Azimi, N., Xue, Z., Bloom, I., et al.: Understanding the effect of a fluorinated ether on the performance of lithium-sulfur batteries. ACS Appl. Mater. Interfaces 7, 9169–9177 (2015). https://doi.org/10.1021/acsami.5b01412

Drvarič Talian, S., Jeschke, S., Vizintin, A., et al.: Fluorinated ether based electrolyte for high-energy lithium-sulfur batteries: Li+ solvation role behind reduced polysulfide solubility. Chem. Mater. 29, 10037–10044 (2017). https://doi.org/10.1021/acs.chemmater.7b03654

Gao, M.Y., Su, C., He, M.N., et al.: A high performance lithium-sulfur battery enabled by a fish-scale porous carbon/sulfur composite and symmetric fluorinated diethoxyethane electrolyte. J. Mater. Chem. A 5, 6725–6733 (2017). https://doi.org/10.1039/C7TA01057E

Lu, H., Zhang, K., Yuan, Y., et al.: Lithium/sulfur batteries with mixed liquid electrolytes based on ethyl 1,1,2,2-tetrafluoroethyl ether. Electrochim. Acta 161, 55–62 (2015). https://doi.org/10.1016/j.electacta.2015.02.031

Chen, S.R., Yu, Z.X., Gordin, M.L., et al.: A fluorinated ether electrolyte enabled high performance prelithiated graphite/sulfur batteries. ACS Appl. Mater. Interfaces 9, 6959–6966 (2017). https://doi.org/10.1021/acsami.6b11008

Wang, X.W., Tan, Y.Q., Shen, G.H., et al.: Recent progress in fluorinated electrolytes for improving the performance of Li-S batteries. J. Energy Chem. 41, 149–170 (2020). https://doi.org/10.1016/j.jechem.2019.05.010

Azimi, N., Weng, W., Takoudis, C., et al.: Improved performance of lithium-sulfur battery with fluorinated electrolyte. Electrochem. Commun. 37, 96–99 (2013). https://doi.org/10.1016/j.elecom.2013.10.020

Weller, C., Thieme, S., Härtel, P., et al.: Intrinsic shuttle suppression in lithium-sulfur batteries for pouch cell application. J. Electrochem. Soc. 164, A3766–A3771 (2017). https://doi.org/10.1149/2.0981714jes

Yue, Z., Dunya, H., Aryal, S., et al.: Synthesis and electrochemical properties of partially fluorinated ether solvents for lithiumsulfur battery electrolytes. J. Power Sources 401, 271–277 (2018). https://doi.org/10.1016/j.jpowsour.2018.08.097

Wang, S.F., Ding, Y., Zhou, G.M., et al.: Durability of the Li1+xTi2–xAlx(PO4)3 solid electrolyte in lithium-sulfur batteries. ACS Energy Lett. 1, 1080–1085 (2016). https://doi.org/10.1021/acsenergylett.6b00481

Fu, K., Gong, Y.H., Xu, S.M., et al.: Stabilizing the garnet solid-electrolyte/polysulfide interface in Li-S batteries. Chem. Mater. 29, 8037–8041 (2017). https://doi.org/10.1021/acs.chemmater.7b02339

Wu, F., Zhu, Q.Z., Chen, R.J., et al.: Ionic liquid-based electrolyte with binary lithium salts for high performance lithium-sulfur batteries. J. Power Sources 296, 10–17 (2015). https://doi.org/10.1016/j.jpowsour.2015.07.033

Wang, L.N., Liu, J.Y., Yuan, S.Y., et al.: To mitigate self-discharge of lithium-sulfur batteries by optimizing ionic liquid electrolytes. Energy Environ. Sci. 9, 224–231 (2016). https://doi.org/10.1039/C5EE02837J

Zheng, J., Fan, X.L., Ji, G.B., et al.: Manipulating electrolyte and solid electrolyte interphase to enable safe and efficient Li-S batteries. Nano Energy 50, 431–440 (2018). https://doi.org/10.1016/j.nanoen.2018.05.065

Lahiri, A., Li, G.Z., Olschewski, M., et al.: Influence of polar organic solvents in an ionic liquid containing lithium bis(fluorosulfonyl)amide: effect on the cation-anion interaction, lithium ion battery performance, and solid electrolyte interphase. ACS Appl. Mater. Interfaces 8, 34143–34150 (2016). https://doi.org/10.1021/acsami.6b12751

Cheng, H., Zhang, S.C., Zhang, B., et al.: N-Hexane diluted electrolyte with ultralow density enables Li-S pouch battery toward > 400 Wh kg−1. Small 19, e2206375 (2023). https://doi.org/10.1002/smll.202206375

Pang, Q., Shyamsunder, A., Narayanan, B., et al.: Tuning the electrolyte network structure to invoke quasi-solid state sulfur conversion and suppress lithium dendrite formation in Li-S batteries. Nat. Energy 3, 783–791 (2018). https://doi.org/10.1038/s41560-018-0214-0

Park, J.W., Ueno, K., Tachikawa, N., et al.: Ionic liquid electrolytes for lithium-sulfur batteries. J. Phys. Chem. C 117, 20531–20541 (2013). https://doi.org/10.1021/jp408037e

Wang, J., Chew, S.Y., Zhao, Z.W., et al.: Sulfur-mesoporous carbon composites in conjunction with a novel ionic liquid electrolyte for lithium rechargeable batteries. Carbon 46, 229–235 (2008). https://doi.org/10.1016/j.carbon.2007.11.007

Wang, L.N., Byon, H.R.: N-Methyl-N-propylpiperidinium bis(trifluoromethanesulfonyl)imide-based organic electrolyte for high performance lithium-sulfur batteries. J. Power Sources 236, 207–214 (2013). https://doi.org/10.1016/j.jpowsour.2013.02.068

Tachikawa, N., Yamauchi, K., Takashima, E., et al.: Reversibility of electrochemical reactions of sulfur supported on inverse opal carbon in glyme-Li salt molten complex electrolytes. Chem. Commun. (Camb.) 47, 8157–8159 (2011). https://doi.org/10.1039/c1cc12415c

Dokko, K., Tachikawa, N., Yamauchi, K., et al.: Solvate ionic liquid electrolyte for Li-S batteries. J. Electrochem. Soc. 160, A1304–A1310 (2013). https://doi.org/10.1149/2.111308jes

Li, W.Y., Pang, Y., Zhu, T.C., et al.: A gel polymer electrolyte based lithium-sulfur battery with low self-discharge. Solid State Ion. 318, 82–87 (2018). https://doi.org/10.1016/j.ssi.2017.08.018

Cheng, J.Y., Yang, X.Y., Dong, L.B., et al.: Effective nondestructive evaluations on UHMWPE/Recycled-PA6 blends using FTIR imaging and dynamic mechanical analysis. Polym. Test. 59, 371–376 (2017). https://doi.org/10.1016/j.polymertesting.2017.02.021

Chen, P., Wu, Z., Guo, T., et al.: Strong chemical interaction between lithium polysulfides and flame-retardant polyphosphazene for lithium-sulfur batteries with enhanced safety and electrochemical performance. Adv. Mater. 33, 2007549 (2021). https://doi.org/10.1002/adma.202007549

Xue, Z.G., He, D., Xie, X.L.: Poly(ethylene oxide)-based electrolytes for lithium-ion batteries. J. Mater. Chem. A 3, 19218–19253 (2015). https://doi.org/10.1039/c5ta03471j

Judez, X., Zhang, H., Li, C.M., et al.: Lithium bis(fluorosulfonyl)imide/poly(ethylene oxide) polymer electrolyte for all solid-state Li-S cell. J. Phys. Chem. Lett. 8, 1956–1960 (2017). https://doi.org/10.1021/acs.jpclett.7b00593

Eshetu, G., Judez, X., Li, C.M., et al.: Ultrahigh performance all solid-state lithium sulfur batteries: salt anion’s chemistry-induced anomalous synergistic effect. J. Am. Chem. Soc. 140, 9921–9933 (2018). https://doi.org/10.1021/jacs.8b04612

Zhang, H., Oteo, U., Judez, X., et al.: Designer anion enabling solid-state lithium-sulfur batteries. Joule 3, 1689–1702 (2019). https://doi.org/10.1016/j.joule.2019.05.003

Zhang, Z.C., Sherlock, D., West, R., et al.: Cross-linked network polymer electrolytes based on a polysiloxane backbone with oligo(oxyethylene) side chains: synthesis and conductivity. Macromolecules 36, 9176–9180 (2003). https://doi.org/10.1021/ma0349276

Umeshbabu, E., Zheng, B.Z., Yang, Y.: Recent progress in all-solid-state lithium-sulfur batteries using high Li-ion conductive solid electrolytes. Electrochem. Energy Rev. 2, 199–230 (2019)

Liang, X., Wang, L.L., Wu, X.L., et al.: Solid-state electrolytes for solid-state lithium-sulfur batteries: comparisons, advances and prospects. J. Energy Chem. 73, 370–386 (2022). https://doi.org/10.1016/j.jechem.2022.06.035

Yen, Y.J., Chung, S.H.: Lithium-sulfur cells with a sulfide solid electrolyte/polysulfide cathode interface. J. Mater. Chem. A 11, 4519–4526 (2023). https://doi.org/10.1039/D2TA07806F

Li, S.Y., Ruan, J.F., Jiang, R.H., et al.: Inorganic all-solid-state lithium-sulfur batteries enhanced by facile thermal formation. Energy Storage Mater. 48, 283–289 (2022). https://doi.org/10.1016/j.ensm.2022.03.028

Wu, J.H., Liu, S.F., Han, F.D., et al.: Lithium/sulfide all-solid-state batteries using sulfide electrolytes. Adv. Mater. 33, e2000751 (2021). https://doi.org/10.1002/adma.202000751

Kamaya, N., Homma, K., Yamakawa, Y., et al.: A lithium superionic conductor. Nat. Mater. 10, 682–686 (2011). https://doi.org/10.1038/nmat3066

Kato, Y., Hori, S., Saito, T., et al.: High-power all-solid-state batteries using sulfide superionic conductors. Nat. Energy 1, 1–7 (2016). https://doi.org/10.1038/nenergy.2016.30

Murugan, R., Thangadurai, V., Weppner, W.: Fast lithium ion conduction in garnet-type Li7La3Zr2O12. Angew. Chem. Int. Ed. 46, 7778–7781 (2007). https://doi.org/10.1002/anie.200701144

Li, Y.T., Han, J.T., Wang, C.A., et al.: Optimizing Li+ conductivity in a garnet framework. J. Mater. Chem. 22, 15357–15361 (2012). https://doi.org/10.1039/C2JM31413D

Duan, H.H., Li, L.S., Fu, X.X., et al.: A functional additive to in situ construct stable cathode and anode interfaces for all-solid-state lithium-sulfur batteries. Chem. Eng. J. 450, 138208 (2022). https://doi.org/10.1016/j.cej.2022.138208

Yan, K., Lu, Z.D., Lee, H.W., et al.: Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth. Nat. Energy 1, 1–8 (2016). https://doi.org/10.1038/nenergy.2016.10

Fu, K.K., Gong, Y.H., Liu, B.Y., et al.: Toward garnet electrolyte-based Li metal batteries: an ultrathin, highly effective, artificial solid-state electrolyte/metallic Li interface. Sci. Adv. 3, e1601659 (2017). https://doi.org/10.1126/sciadv.1601659

Han, X.G., Gong, Y.H., Fu, K.K., et al.: Negating interfacial impedance in garnet-based solid-state Li metal batteries. Nat. Mater. 16, 572–579 (2017). https://doi.org/10.1038/nmat4821

Aono, H., Sugimoto, E., Sadaoka, Y., et al.: Electrical properties and sinterability for lithium germanium phosphate Li1+xMxGe2−x(PO4)3, M = Al, Cr, Ga, Fe, Sc, and In systems. Bull. Chem. Soc. Jpn. 65, 2200–2204 (1992). https://doi.org/10.1246/bcsj.65.2200

Hao, Y.J., Wang, S., Xu, F., et al.: A design of solid-state Li-S cell with evaporated lithium anode to eliminate shuttle effects. ACS Appl. Mater. Interfaces 9, 33735–33739 (2017). https://doi.org/10.1021/acsami.7b07057

Mercier, R., Malugani, J.P., Fahys, B., et al.: Superionic conduction in Li2S-P2S5-LiI-glasses. Solid State Ion. 5, 663–666 (1981). https://doi.org/10.1016/0167-2738(81)90341-6

Pradel, A., Ribes, M.: Electrical properties of lithium conductive silicon sulfide glasses prepared by twin roller quenching. Solid State Ion. 18(19), 351–355 (1986). https://doi.org/10.1016/0167-2738(86)90139-6

Kanno, R., Murayama, M.: Lithium ionic conductor thio-LISICON: the Li2S-GeS2-P2S5 system. J. Electrochem. Soc. 148, A742–A746 (2001). https://doi.org/10.1149/1.1379028

Yao, X.Y., Huang, N., Han, F.D., et al.: High-performance all-solid-state lithium-sulfur batteries enabled by amorphous sulfur-coated reduced graphene oxide cathodes. Adv. Energy Mater. 7, 1602923 (2017). https://doi.org/10.1002/aenm.201602923

Xu, R.C., Xia, X.H., Wang, X.L., et al.: Tailored Li2S-P2S5 glass-ceramic electrolyte by MoS2 doping, possessing high ionic conductivity for all-solid-state lithium-sulfur batteries. J. Mater. Chem. A 5, 2829–2834 (2017). https://doi.org/10.1039/C6TA10142A

Ji, Y.C., Yang, K., Liu, M.Q., et al.: PIM-1 as a multifunctional framework to enable high-performance solid-state lithium-sulfur batteries. Adv. Funct. Mater. 31, 2104830 (2021). https://doi.org/10.1002/adfm.202104830

Judez, X., Piszcz, M., Coya, E., et al.: Stable cycling of lithium metal electrode in nanocomposite solid polymer electrolytes with lithium bis(fluorosulfonyl)imide. Solid State Ion. 318, 95–101 (2018). https://doi.org/10.1016/j.ssi.2017.07.021

Judez, X., Eshetu, G.G., Gracia, I., et al.: Understanding the role of nano-aluminum oxide in all-solid-state lithium-sulfur batteries. ChemElectroChem 6, 326–330 (2019). https://doi.org/10.1002/celc.201801390

Suriyakumar, S., Gopi, S., Kathiresan, M., et al.: Metal organic framework laden poly(ethylene oxide) based composite electrolytes for all-solid-state Li-S and Li-metal polymer batteries. Electrochim. Acta 285, 355–364 (2018). https://doi.org/10.1016/j.electacta.2018.08.012

Wu, J.F., Guo, X.: MOF-derived nanoporous multifunctional fillers enhancing the performances of polymer electrolytes for solid-state lithium batteries. J. Mater. Chem. A 7, 2653–2659 (2019). https://doi.org/10.1039/C8TA10124H

Chen, L., Fan, L.Z.: Dendrite-free Li metal deposition in all-solid-state lithium sulfur batteries with polymer-in-salt polysiloxane electrolyte. Energy Storage Mater. 15, 37–45 (2018). https://doi.org/10.1016/j.ensm.2018.03.015

Jiang, J.H., Wang, A.B., Wang, W.K., et al.: P(VDF-HFP)-poly(sulfur-1,3-diisopropenylbenzene) functional polymer electrolyte for lithium-sulfur batteries. J. Energy Chem. 46, 114–122 (2020). https://doi.org/10.1016/j.jechem.2019.10.009

Inada, T., Kobayashi, T., Sonoyama, N., et al.: All solid-state sheet battery using lithium inorganic solid electrolyte, thio-LISICON. J. Power Sources 194, 1085–1088 (2009). https://doi.org/10.1016/j.jpowsour.2009.06.100

Sakuda, A., Kuratani, K., Yamamoto, M., et al.: All-solid-state battery electrode sheets prepared by a slurry coating process. J. Electrochem. Soc. 164, A2474–A2478 (2017). https://doi.org/10.1149/2.0951712jes

Zhu, G.L., Zhao, C.Z., Yuan, H., et al.: Interfacial redox behaviors of sulfide electrolytes in fast-charging all-solid-state lithium metal batteries. Energy Storage Mater. 31, 267–273 (2020). https://doi.org/10.1016/j.ensm.2020.05.017

Tan, D.H.S., Banerjee, A., Chen, Z., et al.: From nanoscale interface characterization to sustainable energy storage using all-solid-state batteries. Nat. Nanotechnol. 15, 170–180 (2020). https://doi.org/10.1038/s41565-020-0657-x

Wang, C.H., Liang, J.W., Zhao, Y., et al.: All-solid-state lithium batteries enabled by sulfide electrolytes: from fundamental research to practical engineering design. Energy Environ. Sci. 14, 2577–2619 (2021). https://doi.org/10.1039/D1EE00551K

Arora, P., Zhang, Z.M.: Battery separators. Chem. Rev. 104, 4419–4462 (2004). https://doi.org/10.1021/cr020738u

He, Y.B., Qiao, Y., Zhou, H.S.: Recent advances in functional modification of separators in lithium-sulfur batteries. Dalton Trans. 47, 6881–6887 (2018). https://doi.org/10.1039/c7dt04717g