Abstract

Computational modeling has played a key role in advancing the performance and durability of polymer electrolyte membrane fuel cells (PEMFCs). In recent years there has been a significant focus on PEMFC catalyst layers because of their determining impact on cost and and durability. Further progress in the design of better performance, cheaper and more durable catalyst layers is required to pave the way for large scale deployment of PEMFCs. The catalyst layer poses many challenges from a modeling standpoint: it consists of a complex, multi-phase, nanostructured porous material that is difficult to characterize; and it hosts an array of coupled transport phenomena including flow of gases, liquid water, heat and charged occurring in conjunction with electrochemical reactions. This review paper examines several aspects of state-of-the-art modeling and simulation of PEMFC catalyst layers, with a view of synthesizing the theoretical foundations of various approaches, identifying gaps and outlining critical needs for further research. The review starts with a rigorous revisiting of the mathematical framework based on the volume averaging method. Various macroscopic models reported in the literature that describe the salient transport phenomena are then introduced, and their links with the volume averaged method are elucidated. Other classes of modeling and simulation methods with different levels of resolution of the catalyst layer structure, e.g. the pore scale model which treats materials as continuum, and various meso- and microscopic methods, which take into consideration the dynamics at the sub-grid level, are reviewed. Strategies for multiscale simulations that can bridge the gap between macroscopic and microscopic models are discussed. An important aspect pertaining to transport properties of catalyst layers is the modeling and simulation of the fabrication processes which is also reviewed. Last but not least, the review examines modeling of liquid water transport in the catalyst layer and its implications on the overall transport properties. The review concludes with an outlook on future research directions.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- PEMFC:

-

polymer electrolyte membrane fuel cell

- GDL:

-

gas diffusion layer

- MPL:

-

microporous Layer

- CL:

-

catalyst layer

- MEA:

-

membrane electrode assembly

- CFD:

-

computational fluid dynamics

- MD:

-

molecular dynamics

- KMC:

-

kinetic Monte Carlo

- CPt:

-

carbon-platinum

- REV:

-

representative element volume

- VAM:

-

volume averaging method

- DNS:

-

direct numerical simulation

- LBM:

-

lattice Boltzmann model

References

Costamagna, P., Srinivasan, S.: Quantum jumps in the PEMFC science and technology from the 1960s to the year 2000 Part I. Fundamental scientific aspects. J. Power Sources 102, 242–252 (2001)

Costamagna, P., Srinivasan, S.: Quantum jumps in the PEMFC science and technology from the 1960s to the year 2000. Part II Engineering, technology development and application aspects. J. Power Sources 102, 253–269 (2001)

Weber, A.Z., Newman, J.: Modeling transport in polymer-electrolyte fuel cells. Chem. Rev. 104, 4679–4726 (2004). https://doi.org/10.1021/cr020729l

Wang, C.Y.: Fundamental models for fuel cell engineering. Chem. Rev. 104, 4727–4765 (2004). https://doi.org/10.1021/cr020718s

Djilali, N.: Computational modelling of polymer electrolyte membrane (PEM) fuel cells: challenges and opportunities. Energy. 32, 269–280 (2007). https://doi.org/10.1016/j.energy.2006.08.007

Djilali, N., Sui, P.C.: Transport phenomena in fuel cells: from microscale to macroscale. Int. J. Comut. Fluid Dyn. 22, 115–133 (2008). https://doi.org/10.1080/10618560701740017

Weber, A.Z., Borup, R.L., Darling, R.M.: A critical review of modeling transport phenomena in polymer-electrolyte fuel cells. J. Electrochem. Soc. 161, F1254–F1299 (2014). https://doi.org/10.1149/2.0751412jes

Mehta, V., Cooper, J.S.: Review and analysis of PEM fuel cell design and manufacturing. J. Power Sources 114, 32–53 (2003)

Litster, S., McLean, G.: PEM fuel cell electrodes. J. Power Sources 130, 61–76 (2004). https://doi.org/10.1016/j.jpowsour.2003.12.055

Antolini, E.: Recent developments in polymer electrolyte fuel cell electrodes. J. Appl. Electrochem. 34, 563–576 (2004)

Bernardi, D.M., Verbrugge, M.W.: A mathematical-model of the solid-polymer-electrolyte fuel-cell. J. Electrochem. Soc. 139, 2477–2491 (1992)

Debe, M.K., Schmoeckel, A.K., Vernstrorn, G.D., et al.: High voltage stability of nanostructured thin film catalysts for PEM fuel cells. J. Power Sources 161, 1002–1011 (2006). https://doi.org/10.1016/j.jpowsour.2006.05.033

Gancs, L., Kobayashi, T., Debe, M.K., et al.: Crystallographic characteristics of nanostructured thin-film fuel cell electrocatalysts: a HRTEM study. Chem. Mater. 20, 2444–2454 (2008). https://doi.org/10.1021/cm702992b

Mantzaras, J., Freunberger, S.A., Buchi, F.N., et al.: Fuel cell modeling and simulations. Chimia (Aarau). 58, 857–868 (2004)

Weber, A.Z., Newman, J.: Modeling transport in polymer-electrolyte fuel cells. Chem. Rev. 104, 4679–4726 (2004). https://doi.org/10.1021/Cr020729l

Biyikoglu, A.: Review of proton exchange membrane fuel cell models. Int. J. Hydrogen Energy 30, 1181–1212 (2005). https://doi.org/10.1016/j.ijhydene.2005.05.010

Promislow, K., Wetton, B.: PEM fuel cells: a mathematical overview. Soc. Ind. Appl. Math. 70, 369–409 (2009)

Shah, A.A., Luo, K.H., Ralph, T.R., et al.: Recent trends and developments in polymer electrolyte membrane fuel cell modelling. Electrochim. Acta 56(11), 3731–3757 (2011)

Sui, P.C., Djilali, N.: Fuel cells—proton-exchange membrane fuel cells|modeling. In: Jürgen, G. (ed.) Encyclopedia of electrochemical power sources, pp. 868–878. Elsevier, Amsterdam (2009)

Wang, Y., Chen, K.S., Mishler, J., et al.: A review of polymer electrolyte membrane fuel cells: technology, applications, and needs on fundamental research. Appl. Energy 88, 981–1007 (2011). https://doi.org/10.1016/j.apenergy.2010.09.030

Andreaus, B., Eikerling, M.: Catalyst layer operation in PEM Fuel cells: from structural pictures to tractable models. In: Paddison, S.J., Promislow, K.S. (eds.) Device and Materials Modeling in Pem Fuel Cells, pp. 41–90. Springer, Berlin (2009)

Eikerling, M.: Water management in cathode catalyst layers of PEM fuel cells: a structure-based model. J. Electrochem. Soc. 153, E58–E70 (2006). https://doi.org/10.1149/1.2160435

Lindermeir, A., Rosenthal, G., Kunz, U., et al.: On the question of MEA preparation for DMFCs. J. Power Sources 129, 180–187 (2004). https://doi.org/10.1016/j.jpowsour.2003.11.002

Maric, R.: Spray-based and CVD processes for synthesis of fuel cell catalysts and thin catalyst layers. In: Zhang, J. (ed.) PEM Fuel Cell Electrocatalysts and Catalyst Layers, pp. 917–963. Springer, London (2008)

Gurau, V., Mann, J.A.: A critical overview of computational fluid dynamics multiphase models for proton exchange membrane fuel cells. SIAM J. Appl. Math. 70, 410–454 (2009). https://doi.org/10.1137/080727993

Dai, W., Wang, H.J., Yuan, X.Z., et al.: A review on water balance in the membrane electrode assembly of proton exchange membrane fuel cells. Int. J. Hydrogen Energy 34, 9461–9478 (2009). https://doi.org/10.1016/j.ijhydene.2009.09.017

Jiao, K., Li, X.G.: Water transport in polymer electrolyte membrane fuel cells. Prog. Energy Combust. Sci. 37, 221–291 (2011). https://doi.org/10.1016/j.pecs.2010.06.002

Zhang, S.S., Yuan, X.Z., Hin, J.N.C., et al.: A review of platinum-based catalyst layer degradation in proton exchange membrane fuel cells. J. Power Sources 194, 588–600 (2009). https://doi.org/10.1016/j.jpowsour.2009.06.073

Kaviany, M.: Principles of heat transfer in porous media. Springer, New York (1995)

Whitaker, S.: The Method of Volume Averaging. Kluwer Academic, Dordrecht (1999)

Ishii, M., Hibiki, T.: Thermo-Fluid Dynamics of Two-Phase Flow. Springer, New York (2006)

DeVidts, P., White, R.E.: Governing equations for transport in porous electrodes. J. Electrochem. Soc. 144, 1343–1353 (1997)

Wang, C.Y., Gu, W.B., Liaw, B.Y.: Micro-macroscopic coupled modeling of batteries and fuel cells: I. Model development. J. Electrochem. Soc. 145, 3407–3417 (1998)

Baschuk, J.J., Li, X.G.: A general formulation for a mathematical PEM fuel cell model. J. Power Sources 142, 134–153 (2005)

Gelb, L.D., Gubbins, K.E., Radhakrishnan, R., et al.: Phase separation in confined systems. Reports Prog. Phys. 62, 1573–1659 (1999)

Nguyen, T.V., White, R.E.: A water and heat management model for proton-exchange-membrane fuel-cells. J. Electrochem. Soc. 140, 2178–2186 (1993)

Bradean, R., Promislow, K., Wetton, B.: Transport phenomena in the porous cathode of a proton exchange membrane fuel cell. Numer. Heat Transf. Part A Appl. 42, 121–138 (2002). https://doi.org/10.1080/10407780290059468

Kulikovsky, A.A.: Quasi-3D modeling of water transport in polymer electrolyte fuel cells. J. Electrochem. Soc. 150, A1432–A1439 (2003). https://doi.org/10.1149/1.1611489

Kazim, A., Liu, H.T., Forges, P.: Modelling of performance of PEM fuel cells with conventional and interdigitated flow fields. J. Appl. Electrochem. 29, 1409–1416 (1999). https://doi.org/10.1023/a:1003867012551

Singh, D., Lu, D.M., Djilali, N.: A two-dimensional analysis of mass transport in proton exchange membrane fuel cells. Int. J. Eng. Sci. 37, 431–452 (1999). https://doi.org/10.1016/s0020-7225(98)00079-2

Berning, T., Lu, D.M., Djilali, N.: Three-dimensional computational analysis of transport phenomena in a PEM fuel cell. J. Power Sources 106, 284–294 (2002)

Bernardi, D.M., Verbrugge, M.W.: Mathematical-model of a gas-diffusion electrode bonded to a polymer electrolyte. AIChE J. 37, 1151–1163 (1991)

Fuller, T.F., Newman, J.: Water and thermal management in solid-polymer-electrolyte fuel-cells. J. Electrochem. Soc. 140, 1218–1225 (1993)

Bevers, D., Wohr, M., Yasuda, K., et al.: Simulation of a polymer electrolyte fuel cell electrode. J. Appl. Electrochem. 27, 1254–1264 (1997)

Rowe, A., Li, X.G.: Mathematical modeling of proton exchange membrane fuel cells. J. Power Sources 102, 82–96 (2001)

You, L.X., Liu, H.T.: A parametric study of the cathode catalyst layer of PEM fuel cells using a pseudo-homogeneous model. Int. J. Hydrogen Energy 26, 991–999 (2001)

Perry, M.L., Newman, J., Cairns, E.J.: Mass transport in gas-diffusion electrodes: a diagnostic tool for fuel-cell cathodes. J. Electrochem. Soc. 145, 5–15 (1998). https://doi.org/10.1149/1.1838202

Um, S., Wang, C.Y., Chen, K.S.: Computational fluid dynamics modeling of proton exchange membrane fuel cells. J. Electrochem. Soc. 147, 4485–4493 (2000). https://doi.org/10.1149/1.1394090

Meng, H., Wang, C.Y.: Model of two-phase flow and flooding dynamics in polymer electrolyte fuel cells. J. Electrochem. Soc. 152, A1733–A1741 (2005). https://doi.org/10.1149/1.1955007

Jaouen, F., Lindbergh, G., Sundholm, G.: Investigation of mass-transport limitations in the solid polymer fuel cell cathode: I. Mathematical model. J. Electrochem. Soc. 149, A437–A447 (2002)

Siegel, N.P., Ellis, M.W., Nelson, D.J., et al.: Single domain PEMFC model based on agglomerate catalyst geometry. J. Power Sources 115, 81–89 (2003)

Broka, K., Ekdunge, P.: Modelling the PEM fuel cell cathode. J. Appl. Electrochem. 27, 281–289 (1997)

Ihonen, J., Jaouen, F., Lindbergh, G., et al.: Investigation of mass-transport limitations in the solid polymer fuel cell cathode: II. Experimental. J. Electrochem. Soc. 149, A448–A454 (2002)

More, K.L., Borup, R., Reeves, K.S.: Identifying contribution degradation phenomena in PEM fuel cell membrane electrode assemblies via electronic microscopy. ECS Trans. 3, 717–733 (2006)

Iczkowski, R.P., Cutlip, M.B.: Voltage Losses in Fuel-Cell Cathodes. J. Electrochem. Soc. 127, 1433–1440 (1980)

Sun, W., Peppley, B.A., Karan, K.: An improved two-dimensional agglomerate cathode model to study the influence of catalyst layer structural parameters. Electrochim. Acta 50, 3359–3374 (2005). https://doi.org/10.1016/j.electacta.2004.12.009

Gode, P., Jaouen, F., Lindbergh, G., et al.: Influence of the composition on the structure and electrochemical characteristics of the PEFC cathode. Electrochim. Acta 48, 4175–4187 (2003). https://doi.org/10.1016/s0013-4686(03)00603-0

Wang, Q.P., Eikerling, M., Song, D.T., et al.: Structure and performance of different types of agglomerates in cathode catalyst layers of PEM fuel cells. J. Electroanal. Chem. 573, 61–69 (2004)

Bird, R.B., Stewart, W.E., Lightfoot, E.N.: Transport phenomena. Wiley, New York (2007)

Ridge, S.J., White, R.E., Tsou, Y., et al.: Oxygen reduction in a proton-exchange membrane test cell. J. Electrochem. Soc. 136, 1902–1909 (1989)

Song, D.T., Wang, Q.P., Liu, Z.S., et al.: Numerical study of PEM fuel cell cathode with non-uniform catalyst layer. Electrochim. Acta 50, 731–737 (2004)

Sui, P.C., Chen, L.D., Seaba, J.P., et al.: Modeling and optimization of PEMFC active layer. In: Stobart, R., Seaba, J.P. (eds.) Fuel Cell Power for Transportation. SAE International, Detroit (1999)

Gloaguen, F., Leger, J.M., Lamy, C.: Electrocatalytic oxidation of methanol on platinum nanoparticles electrodeposited onto porous carbon substrates. J. Appl. Electrochem. 27, 1052–1060 (1997)

Gloaguen, F., Convert, P., Gamburzev, S., et al.: An evaluation of the macro-homogeneous and agglomerate model for oxygen reduction in PEMFCs. Electrochim. Acta 43, 3767–3772 (1998)

Rao, R.M., Rengaswamy, R.: Dynamic characteristics of spherical agglomerate for study of cathode catalyst layers in proton exchange membrane fuel cells (PEMFC). J. Power Sources 158, 110–123 (2006)

Pisani, L., Murgia, G., Valentini, M., et al.: A working model of polymer electrolyte fuel cells: comparisons between theory and experiments. J. Electrochem. Soc. 149, A898–A904 (2002)

Dannenberg, K., Ekdunge, P., Lindbergh, G.: Mathematical model of the PEMFC. J. Appl. Electrochem. 30, 1377–1387 (2000)

Song, D.T., Wang, Q.P., Liu, Z.S., et al.: A method for optimizing distributions of Nafion and Pt in cathode catalyst layers of PEM fuel cells. Electrochim. Acta 50, 3347–3358 (2005)

Wang, Q.P., Song, D.T., Navessin, T., et al.: A mathematical model and optimization of the cathode catalyst layer structure in PEM fuel cells. Electrochim. Acta 50, 725–730 (2004). https://doi.org/10.1016/j.electacta.2004.01.113

Wang, Q.P., Eikerling, M., Song, D.T., et al.: Functionally graded cathode catalyst layers for polymer electrolyte fuel cells: I. Theoretical modeling. J. Electrochem. Soc. 151, A950–A957 (2004)

Shah, A.A., Kim, G.S., Gervais, W., et al.: The effects of water and microstructure on the performance of polymer electrolyte fuel cells. J. Power Sources 160, 1251–1268 (2006). https://doi.org/10.1016/j.jpowsour.2006.02.085

Shah, A.A., Kim, G.S., Promislow, K.: Mathematical modelling of the catalyst layer of a polymer electrolyte fuel cell. Ima J. Appl. Math. 72, 302–330 (2007). https://doi.org/10.1093/imamat/hxm005

Harvey, D., Pharoah, J.G., Karan, K.: A comparison of different approaches to modelling the PEMFC catalyst layer. J. Power Sources 179, 209–219 (2008). https://doi.org/10.1016/j.jpowsour.2007.12.077

Secanell, M., Karan, K., Suleman, A., et al.: Multi-variable optimization of PEMFC cathodes using an agglomerate model. Electrochim. Acta 52, 6318–6337 (2007). https://doi.org/10.1016/j.electacta.2007.04.028

Das, P.K., Li, X.G., Liu, Z.S.: A three-dimensional agglomerate model for the cathode catalyst layer of PEM fuel cells. J. Power Sources 179, 186–199 (2008). https://doi.org/10.1016/j.jpowsour.2007.12.085

Kamarajugadda, S., Mazumder, S.: Numerical investigation of the effect of cathode catalyst layer structure and composition on polymer electrolyte membrane fuel cell performance. J. Power Sources 183, 629–642 (2008). https://doi.org/10.1016/j.jpowsour.2008.05.072

Malek, K., Eikerling, M., Wang, Q.P., et al.: Self-organization in catalyst layers of polymer electrolyte fuel cells. J. Phys. Chem. C 111, 13627–13634 (2007). https://doi.org/10.1021/jp072692k

Mazumder, S., Cole, J.V.: Rigorous 3-d mathematical modeling of PEM fuel cells: I. Model predictions without liquid water transport. J. Electrochem. Soc. 150, A1503–A1509 (2003). https://doi.org/10.1149/1.1615608

Li, S., Cao, J., Wangard, W., et al.: Modeling PEMFC with fluent: Numerical performance and validations with experimental data. Paper presented at the 3rd International Conference on Fuel Cell Science, Engineering, and Technology, Ypsilanti, Michigan, 23–25 May 2003 (2005)

Humby, S.J., Biggs, M.J., Tuzun, U.: Explicit numerical simulation of fluids in reconstructed porous media. Chem. Eng. Sci. 57, 1955–1968 (2002)

Wang, G.Q.: Direct numerical simulation of porous electrodes for fuel cells and advanced batteries. Dissertation, The Pennsylvania State University (2003)

Prat, M.: Recent advances in pore-scale models for drying of porous media. Chem. Eng. J. 86, 153–164 (2002). https://doi.org/10.1016/s1385-8947(01)00283-2

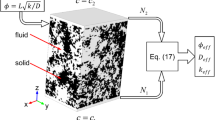

Lange, K.J., Sui, P.C., Djilali, N.: Pore scale simulation of transport and electrochemical reactions in reconstructed PEMFC catalyst layers. J. Electrochem. Soc. 157, B1434–B1442 (2010). https://doi.org/10.1149/1.3478207

Kohout, M., Grof, Z., Stepanek, F.: Pore-scale modelling and tomographic visualisation of drying in granular media. J. Colloid Interface Sci. 299, 342–351 (2006)

Mukherjee, P.P., Wang, C.Y., Kang, Q.: Mesoscopic modeling of two-phase behavior and flooding phenomena in polymer electrolyte fuel cells. Electrochim. Acta 54, 6861–6875 (2009). https://doi.org/10.1016/j.electacta.2009.06.066

Kohout, M., Collier, A.P., Stepanek, F.: Mathematical modelling of solvent drying from a static particle bed. Chem. Eng. Sci. 61, 3674–3685 (2006)

Parmigiani, A., Huber, C., Bachmann, O., et al.: Pore-scale mass and reactant transport in multiphase porous media flows. J. Fluid Mech. 686, 40–76 (2011). https://doi.org/10.1017/jfm.2011.268

Stepanek, F., Marek, M., Hanika, J., et al.: Mesoscale modeling in multiphase catalysis. Catal. Today 66, 249–254 (2001)

Koci, P., Stepanek, F., Kubicek, M., et al.: Modelling of micro/nano-scale concentration and temperature gradients in porous supported catalysts. Chem. Eng. Sci. 62, 5380–5385 (2007). https://doi.org/10.1016/j.ces.2006.12.033

Koci, P., Stepanek, F., Kubicek, A., et al.: Pore-scale modeling of non-isothermal reaction phenomena in digitally reconstructed porous catalyst. Mol. Simul. 33, 369–377 (2007). https://doi.org/10.1080/08927020601156426

Stepanek, F., Ansari, M.A.: Computer simulation of granule microstructure formation. Chem. Eng. Sci. 60, 4019–4029 (2005)

Antoine, O., Bultel, Y., Durand, R., et al.: Electrocatalysis, diffusion and ohmic drop in PEMFC: particle size and spatial discrete distribution effects. Electrochim. Acta 43, 3681–3691 (1998)

Flückiger, R.: Transport phenomena on the channel-rib scale of polymer electrolyte fuel cells. ETH, Zürich (2009)

Wang, G.Q., Mukherjee, P.P., Wang, C.Y.: Direct numerical simulation (DNS) modeling of PEFC electrodes: Part I. Regular microstructure. Electrochim. Acta. 51, 3139–3150 (2006)

Wang, G.Q., Mukherjee, P.P., Wang, C.Y.: Direct numerical simulation (DNS) modeling of PEFC electrodes: Part II. Random microstructure. Electrochim. Acta. 51, 3151–3160 (2006)

Mukherjee, P.P., Wang, C.Y.: Stochastic microstructure reconstruction and direct numerical simulation of the PEFC catalyst layer. J. Electrochem. Soc. 153, A840–A849 (2006)

Lange, K.J., Sui, P.C., Djilali, N.: Pore scale modeling of a proton exchange membrane fuel cell catalyst layer: effects of water vapor and temperature. J. Power Sources 196, 3195–3203 (2011). https://doi.org/10.1016/j.jpowsour.2010.11.118

Lange, K.J., Sui, P.C., Djilali, N.: Pore scale modeling of a proton exchange membrane fuel cell catalyst layer: effects of water vapor and temperature (vol 196, pg 3195, 2011). J. Power Sources 196, 8170–8171 (2011). https://doi.org/10.1016/j.jpowsour.2011.05.001

Torquato, S.: Statistical description of microstructures. Annu. Rev. Mater. Res. 32, 77–111 (2002)

Delerue, J.P., Perrier, E., Yu, Z.Y., et al.: New algorithms in 3D image analysis and their application to the measurement of a spatialized pore size distribution in soils. Phys. Chem. Earth Part A Solid Earth Geod. 24, 639–644 (1999). https://doi.org/10.1016/s1464-1895(99)00093-9

Delerue, J.F., Perrier, E.: DXSoil, a library for 3D image analysis in soil science. Comput. Geosci. 28, 1041–1050 (2002). https://doi.org/10.1016/s0098-3004(02)00020-1

Silin, D.B., Jin, G.D., Patzek, T.W.: Robust determination of the pore-space morphology in sedimentary rocks. J. Pet. Technol. 56, 69–70 (2004)

Arns, C.H., Bauget, F., Limaye, A., et al.: Pore-scale characterization of carbonates using X-ray microtomography. SPE J. 10, 475–484 (2005)

Oren, P.E., Bakke, S.: Process based reconstruction of sandstones and prediction of transport properties. Transp. Porous Media 46, 311–343 (2002)

Oren, P.E., Bakke, S.: Reconstruction of Berea sandstone and pore-scale modelling of wettability effects. J. Pet. Sci. Eng. 39, 177–199 (2003). https://doi.org/10.1016/s0920-4105(03)00062-7

Piri, M., Blunt, M.J.: Three-dimensional mixed-wet random pore-scale network modeling of two- and three-phase flow in porous media. Phys. Rev. E. 71, 026301 (2005). https://doi.org/10.1103/PhysRevE.71.026302

Joshi, M.: A class of stochastic models for porous materials. University of Kansas, Lawrence (1974)

Quiblier, J.A.: A new 3-dimensional modeling technique for studying porous-media. J. Colloid Interface Sci. 98, 84–102 (1984). https://doi.org/10.1016/0021-9797(84)90481-8

Adler, P.M., Jacquin, C.G., Quiblier, J.A.: Flow in simulated porous-media. Int. J. Multiph. Flow 16, 691–712 (1990). https://doi.org/10.1016/0301-9322(90)90025-e

Adler, P.M.: Porous Media: Geometry and Transport. Butterworth-Heinemann, Boston (1992)

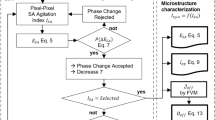

Yeong, C.L.Y., Torquato, S.: Reconstructing random media. Phys. Rev. E 57, 495–506 (1998)

Yeong, C.L.Y., Torquato, S.: Reconstructing random media. II. Three-dimensional media from two-dimensiomal cuts. Phys. Rev. E 58, 224–233 (1998)

Rong, F., Huang, C., Liu, Z.S., et al.: Microstructure changes in the catalyst layers of PEM fuel cells induced by load cycling Part I. Mechanical model. J. Power Sources 175, 699–711 (2008). https://doi.org/10.1016/j.jpowsour.2007.10.006

Kim, S.H., Pitsch, H.: Reconstruction and effective transport properties of the catalyst layer in PEM fuel cells. J. Electrochem. Soc. 156, B673–B681 (2009). https://doi.org/10.1149/1.3106136

Izzo, J.R., Joshi, A.S., Grew, K.N., et al.: Nondestructive reconstruction and analysis of SOFC anodes using x-ray computed tomography at sub-50 nm resolution. J. Electrochem. Soc. 155, B504–B508 (2008). https://doi.org/10.1149/1.2895067

Shan, X.W., Chen, H.D.: Lattice Boltzmann model for simulating flows with multiple phases and components. Phys. Rev. E 47, 1815–1819 (1993). https://doi.org/10.1103/PhysRevE.47.1815

Binder, K., Heermann, D.W.: Monte Carlo simulation in statistical physics: an introduction. Springer, Berlin (1988)

Succi, S.: The lattice Boltzmann equation for fluid dynamics and beyond. Oxford University Press, Oxford (2001)

Shi, Z., Zhang, J.J., Liu, Z.S., et al.: Current status of ab initio quantum chemistry study for oxygen electroreduction on fuel cell catalysts. Electrochim. Acta 51, 1905–1916 (2006)

Liu, X., Meng, C.G., Liu, C.H.: Adsorption and dissociation of O2 on NITI alloy (100) surface from first principle. Abstr. Pap. Am. Chem. Soc. 229, U758–U758 (2005)

Xu, Y., Ruban, A.V., Mavrikakis, M.: Adsorption and dissociation of O(2) on Pt-Co and Pt-Fe alloys. J. Am. Chem. Soc. 126, 4717–4725 (2004). https://doi.org/10.1021/ja031701+

Anderson, A.B., Albu, T.V.: Ab initio determination of reversible potentials and activation energies for outer-sphere oxygen reduction to water and the reverse oxidation reaction. J. Am. Chem. Soc. 121, 11855–11863 (1999)

Anderson, A.B., Albu, T.V.: Catalytic effect of platinum on oxygen reduction: an ab initio model including electrode potential dependence. J. Electrochem. Soc. 147, 4229–4238 (2000)

Wang, Y.X., Balbuena, P.B.: Roles of proton and electric field in the electroreduction of O-2 on Pt(111) surfaces: results of an ab initio molecular dynamics study. J. Phys. Chem. B. 108, 4376–4384 (2004)

Norskov, J.K., Rossmeisl, J., Logadottir, A., et al.: Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J. Phys. Chem. B. 108, 17886–17892 (2004)

Zhang, J.L., Vukmirovic, M.B., Xu, Y., et al.: Controlling the catalytic activity of platinum-monolayer electrocatalysts for oxygen reduction with different substrates. Angew. Chem. Int. Ed. 44, 2132–2135 (2005)

Buehler, M.J., vanDuin, A.C.T., Goddard, W.A.: Multiparadigm modeling of dynamical crack propagation in silicon using a reactive force field. Phys. Rev. Lett. 96, 095505 (2006). https://doi.org/10.1103/PhysRevLett.96.095505

Chenoweth, K., Cheung, S., vanDuin, A.C.T., et al.: Simulations on the thermal decomposition of a poly(dimethylsiloxane) polymer using the ReaxFF reactive force field. J. Am. Chem. Soc. 127, 7192–7202 (2005)

Cheung, S., Deng, W.Q., vanDuin, A.C.T., et al.: ReaxFF(MgH) reactive force field for magnesium hydride systems. J. Phys. Chem. A 109, 851–859 (2005)

Goddard, W.A., vanDuin, A., Chenoweth, K., et al.: Development of the ReaxFF reactive force field for mechanistic studies of catalytic selective oxidation processes on BiMoOx. Top. Catal. 38, 93–103 (2006)

Han, S.S., vanDuin, A.C.T., Goddard, W.A., et al.: Optimization and application of lithium parameters for the reactive force field, ReaxFF. J. Phys. Chem. A. 109, 4575–4582 (2005). https://doi.org/10.1021/jp051450m

Han, S.S., Kang, J.K., Lee, H.M., et al.: The theoretical study on interaction of hydrogen with single-walled boron nitride nanotubes. I. The reactive force field ReaxFF(HBN) development. J. Chem. Phys. 123, 114703 (2005)

Ludwig, J., Vlachos, D.G., vanDuin, A.C.T., et al.: Dynamics of the dissociation of hydrogen on stepped platinum surfaces using the ReaxFF reactive force field. J. Phys. Chem. B. 110, 4274–4282 (2006)

Nielson, K.D., vanDuin, A.C.T., Oxgaard, J., et al.: Development of the ReaxFF reactive force field for describing transition metal catalyzed reactions, with application to the initial stages of the catalytic formation of carbon nanotubes. J. Phys. Chem. A 109, 493–499 (2005)

Van Duin, A.C.T., Dasgupta, S., Lorant, F., et al.: Reax FF: a reactive force field for hydrocarbons. J. Phys. Chem. A 105, 9396–9409 (2001)

Vashishta, P., Kalia, R.K., Nakano, A.: Multimillion atom simulations of dynamics of oxidation of an aluminum nanoparticle and nanoindentation on ceramics. J. Phys. Chem. B. 110, 3727–3733 (2006)

Buehler, M.J, Van Duin, A., Jacob, T., et al.: Formation of water at a Pt(111) surface: A study using reactive force fields (ReaxFF). Proc. MRS Fall Meeting (2005). https://doi.org/10.1557/PROC-0900-O03-09

Commer, P., Hartnig, C., Seeliger, D., et al.: Modeling of proton transfer in polymer electrolyte membranes on different time and length scales. Mol. Simul. 30, 755–763 (2004)

Cui, S.T., Liu, J.W., Selvan, M.E., et al.: A molecular dynamics study of a nafion polyelectrolyte membrane and the aqueous phase structure for proton transport. J. Phys. Chem. B. 111, 2208–2218 (2007)

Urata, S., Irisawa, J., Takada, A., et al.: Molecular dynamics simulation of swollen membrane of perfluorinated ionomer. J. Phys. Chem. B. 109, 4269–4278 (2005)

Zhou, X.Y., Chen, Z., Delgado, F., et al.: Atomistic simulation of conduction and diffusion processes in Nafion polymer electrolyte and experimental validation. J. Electrochem. Soc. 154, B82–B87 (2007)

Wescott, J.T., Qi, Y., Subramanian, L., et al.: Mesoscale simulation of morphology in hydrated perfluorosulfonic acid membranes. J. Chem. Phys. 124, 134702 (2006)

Ioselevich, A.S., Kornyshev, A.A., Steinke, J.H.G.: Fine morphology of proton-conducting ionomers. J. Phys. Chem. B. 108, 11953–11963 (2004). https://doi.org/10.1021/jp049687

Kornyshev, A.A., Kuznetsov, A.M., Spohr, E., et al.: Kinetics of proton transport in water. J. Phys. Chem. B. 107, 3351–3366 (2003)

Kreuer, K.D.: On solids with liquidlike properties and the challenge to develop new proton-conducting separator materials for intermediate-temperature fuel cells. ChemPhysChem 3, 771–775 (2002)

Kreuer, K.D., Paddison, S.J., Spohr, E., et al.: Transport in proton conductors for fuel-cell applications: simulations, elementary reactions, and phenomenology. Chem. Rev. 104, 4637–4678 (2004)

Marx, D.: Proton transfer 200 years after von Grotthuss: insights from ab initio simulations. ChemPhysChem 7, 1848–1870 (2006). https://doi.org/10.1002/cphc.200600128

Paddison, S.J.: Proton conduction mechanisms at low degrees of hydration in sulfonic acid-based polymer electrolyte membranes. Annu. Rev. Mater. Res. 33, 289–319 (2003). https://www.annualreviews.org/doi/10.1146/annurev.matsci.33.022702.155102

Spohr, E., Commer, P., Kornyshev, A.A.: Enhancing proton mobility in polymer electrolyte membranes: lessons from molecular dynamics simulations. J. Phys. Chem. B. 106, 10560–10569 (2002)

Spohr, E.: Molecular dynamics simulations of proton transfer in a model Nafion pore. Mol. Simul. 30, 107–115 (2004)

Tsige, M., Mattsson, T.R., Grest, G.S.: Morphology of evaporated multiblock copolymer membranes studied by molecular dynamics simulations. Macromolecules 37, 9132–9138 (2004)

Chen, S., Doolen, G.D.: Lattice Boltzmann method for fluid flows. Annu. Rev. Fluid Mech. 30, 329–364 (1998)

Raabe, D.: Overview of the lattice Boltzmann method for nano- and microscale fluid dynamics in materials science and engineering. Model. Simul. Mater. Sci. Eng. 12, R13–R46 (2004)

Nourgaliev, R.R., Dinh, T.N., Theofanous, T.G., et al.: The lattice Boltzmann equation method: theoretical interpretation, numerics and implications. Int. J. Multiph. Flow 29, 117–169 (2003). https://doi.org/10.1016/s0301-9322(02)00108-8

Aidun, C.K., Clausen, J.R.: Lattice Boltzmann method for complex flows. Annu. Rev. Fluid Mech. 42, 439–472 (2010). https://doi.org/10.1146/annurev-fluid-121108-145519

Benzi, R., Succi, S., Vergassola, M.: The lattice boltzmann-equation - theory and applications. Phys. Rep. Rev. Sect. Phys. Lett. 222, 145–197 (1992). https://doi.org/10.1016/0370-1573(92)90090-m

Bhatnagar, P.L., Gross, E.P., Krook, M.: A model for collision processes in gases.1. Small amplitude processes in charged and neutral one-component systems. Phys. Rev. 94, 511–525 (1954). https://doi.org/10.1103/physrev.94.511

Guo, Z.L., Zhao, T.S.: Lattice Boltzmann model for incompressible flows through porous media. Phys. Rev. E., 036304 (2002). https://doi.org/10.1103/PhysRevE.66.036304

Frisch, U., Hasslacher, B., Pomeau, Y.: Lattice–gas automata for the Navier–Stokes equation. Phys. Rev. Lett. 56, 1505–1508 (1986). https://doi.org/10.1103/PhysRevLett.56.1505

Qian, Y.H., Dhumieres, D., Lallemand, P.: Lattice BGK models for Navier–Stokes equation. Europhys. Lett. 17, 479–484 (1992). https://doi.org/10.1209/0295-5075/17/6/001

Shan, X.W., Doolen, G.: Multicomponent Lattice Boltzmann model with interparticle interaction. J. Stat. Phys. 81, 379–393 (1995). https://doi.org/10.1007/bf02179985

Hou, S.L., Zou, Q., Chen, S.Y., et al.: Simulation of cavity flow by the lattice Boltzmann method. J. Comput. Phys. 118, 329–347 (1995). https://doi.org/10.1006/jcph.1995.1103

He, X.Y., Luo, L.S., Dembo, M.: Some progress in lattice Boltzmann method. I Nonuniform mesh grids. J. Comput. Phys. 129, 357–363 (1996). https://doi.org/10.1006/jcph.1996.0255

Chen, S.Y., Martinez, D., Mei, R.W.: On boundary conditions in lattice Boltzmann methods. Phys. Fluids 8, 2527–2536 (1996). https://doi.org/10.1063/1.869035

He, X.Y., Luo, L.S.: Theory of the lattice Boltzmann method: from the Boltzmann equation to the lattice Boltzmann equation. Phys. Rev. E 56, 6811–6817 (1997). https://doi.org/10.1103/PhysRevE.56.6811

Benzi, R., Biferale, L., Sbragaglia, M., et al.: Mesoscopic modeling of a two-phase flow in the presence of boundaries: the contact angle. Phys. Rev. E 74, 021509 (2006). https://doi.org/10.1103/PhysRevE.74.021509

Zheng, H.W., Shu, C., Chew, Y.T.: A lattice Boltzmann model for multiphase flows with large density ratio. J. Comput. Phys. 218, 353–371 (2006). https://doi.org/10.1016/j.jcp.2006.02.015

Cates, M.E., Desplat, J.C., Stansell, P., et al.: Physical and computational scaling issues in lattice Boltzmann simulations of binary fluid mixtures. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 363, 1917–1935 (2005). https://doi.org/10.1098/rsta.2005.1619

Martys, N.S., Chen, H.D.: Simulation of multicomponent fluids in complex three-dimensional geometries by the lattice Boltzmann method. Phys. Rev. E 53, 743–750 (1996)

Hou, S.L., Shan, X.W., Zou, Q.S., et al.: Evaluation of two lattice Boltzmann models for multiphase flows. J. Comput. Phys. 138, 695–713 (1997). https://doi.org/10.1006/jcph.1997.5839

Singh, M., Mohanty, K.K.: Permeability of spatially correlated porous media. Chem. Eng. Sci. 55, 5393–5403 (2000). https://doi.org/10.1016/s0009-2509(00)00157-3

Hazi, G., Imre, A.R., Mayer, G., et al.: Lattice Boltzmann methods for two-phase flow modeling. Ann. Nucl. Energy 29, 1421–1453 (2002). https://doi.org/10.1016/s0306-4549(01)00115-3

Kang, Q.J., Zhang, D.X., Chen, S.Y.: Displacement of a two-dimensional immiscible droplet in a channel. Phys. Fluids 14, 3203–3214 (2002). https://doi.org/10.1063/1.1499125

Sukop, M.C., Or, D.: Lattice Boltzmann method for modeling liquid–vapor interface configurations in porous media. Water Resour. Res. 40, W01509 (2004). https://doi.org/10.1029/2003wr002333

Inamuro, T., Ogata, T., Tajima, S., et al.: A lattice Boltzmann method for incompressible two-phase flows with large density differences. J. Comput. Phys. 198, 628–644 (2004). https://doi.org/10.1016/j.jcp.2004.01.019

Pan, C., Hilpert, M., Miller, C.T.: Lattice Boltzmann simulation of two-phase flow in porous media. Water Resour. Res. 40, W01501 (2004). https://doi.org/10.1029/2003wr002120

Lee, T., Lin, C.L.: A stable discretization of the lattice Boltzmann equation for simulation of incompressible two-phase flows at high density ratio. J. Comput. Phys. 206, 16–47 (2005). https://doi.org/10.1016/j.jcp.2004.12.001

Swift, M.R., Osborn, W.R., Yeomans, J.M.: Lattice Boltzmann simulation of nonideal fluids. Phys. Rev. Lett. 75, 830–833 (1995)

Shan, X.W., Chen, H.D.: Simulation of nonideal gases and liquid-gas phase-transitions by the lattice Boltzmann-equation. Phys. Rev. E 49, 2941–2948 (1994)

Luo, L.S.: Theory of the lattice Boltzmann method: lattice Boltzmann models for nonideal gases. Phys. Rev. E 62, 4982–4996 (2000). https://doi.org/10.1103/PhysRevE.62.4982

Yuan, P., Schaefer, L.: Equations of state in a lattice Boltzmann model. Phys. Fluids 18, 042101 (2006). https://doi.org/10.1063/1.2187070

Sukop, M.C., Or, D.: Lattice Boltzmann method for homogeneous and heterogeneous cavitation. Phys. Rev. E 71, 046703 (2005). https://doi.org/10.1103/PhysRevE.71.046703

Dawson, S.P., Chen, S., Doolen, G.D.: Lattice Boltzmann computations for reaction-diffusion equations. J. Chem. Phys. 98, 1514–1523 (1993)

Lee, T., Lin, C.L., Chen, L.D.: A lattice Boltzmann algorithm for calculation of the laminar jet diffusion flame. J. Comput. Phys. 215, 133–152 (2006). https://doi.org/10.1016/j.jcp.2005.10.021

Rothman, D.H., Keller, J.M.: Immiscible cellular-automaton fluids. J. Stat. Phys. 52, 1119–1127 (1988). https://doi.org/10.1007/bf01019743

Gunstensen, A.K., Rothman, D.H., Zaleski, S., et al.: Lattice Boltzmann model of immiscible fluids. Phys. Rev. A 43, 4320–4327 (1991)

Grunau, D., Chen, S.Y., Eggert, K.: A Lattice Boltzmann model for multiphase fluid-flows. Phys. Fluids Fluid Dyn. 5, 2557–2562 (1993)

Swift, M.R., Orlandini, E., Osborn, W.R., et al.: Lattice Boltzmann simulations of liquid-gas and binary fluid systems. Phys. Rev. E 54, 5041–5052 (1996)

He, X.Y., Doolen, G.D.: Thermodynamic foundations of kinetic theory and Lattice Boltzmann models for multiphase flows. J. Stat. Phys. 107, 309–328 (2002)

Luo, L.S., Girimaji, S.S.: Lattice Boltzmann model for binary mixtures. Phys. Rev. E 66, 035301 (2002)

Zhang, R.Y., He, X.Y., Chen, S.Y.: Interface and surface tension in incompressible lattice Boltzmann multiphase model. Comput. Phys. Commun. 129, 121–130 (2000)

Joshi, A.S., Grew, K.N., Peracchio, A.A., et al.: Lattice Boltzmann modeling of 2D gas transport in a solid oxide fuel cell anode. J. Power Sources 164, 631–638 (2007). https://doi.org/10.1016/j.jpowsour.2006.10.101

Asinari, P., Quaglia, M.C., von Spakovsky, M.R., et al.: Direct numerical calculation of the kinematic tortuosity of reactive mixture flow in the anode layer of solid oxide fuel cells by the lattice Boltzmann method. J. Power Sources 170, 359–375 (2007). https://doi.org/10.1016/j.jpowsour.2007.03.074

Koido, T., Furusawa, T., Moriyama, K.: An approach to modeling two-phase transport in the gas diffusion layer of a proton exchange membrane fuel cell. J. Power Sources 175, 127–136 (2008). https://doi.org/10.1016/j.jpowsour.2007.09.029

Niu, X.D., Munekata, T., Hyodo, S.A., et al.: An investigation of water-gas transport processes in the gas-diffusion-layer of a PEM fuel cell by a multiphase multiple-relaxation-time lattice Boltzmann model. J. Power Sources 172, 542–552 (2007). https://doi.org/10.1016/j.jpowsour.2007.05.081

Park, J., Matsubara, M., Li, X.: Application of lattice Boltzmann method to a micro-scale flow simulation in the porous electrode of a PEM fuel cell. J. Power Sources 173, 404–414 (2007). https://doi.org/10.1016/j.jpowsour.2007.04.021

VanDoorrnaal, M.A., Pharoah, J.G.: Determination of permeability in fibrous porous media using the lattice Boltzmann method with application to PEM fuel cells. Int. J. Numer. Methods Fluids. 59, 75–89 (2009). https://doi.org/10.1002/fld.1811

Hao, L., Cheng, P.: Lattice Boltzmann simulations of water transport in gas diffusion layer of a polymer electrolyte membrane fuel cell. J. Power Sources 195, 3870–3881 (2010). https://doi.org/10.1016/j.jpowsour.2009.11.125

Wang, L.P., Afsharpoya, B.: Modeling fluid flow in fuel cells using the Lattice Boltzmann approach. Math. Comput. Simul. 72, 242–248 (2006). https://doi.org/10.1016/j.matcom.2006.05.038

Hao, L., Cheng, P.: Lattice Boltzmann simulations of liquid droplet dynamic behavior on a hydrophobic surface of a gas flow channel. J. Power Sources 190, 435–446 (2009). https://doi.org/10.1016/j.jpowsour.2009.01.029

Luan, H.B., Xu, H., Chen, L., et al.: Numerical illustrations of the coupling between the lattice Boltzmann method and finite-type macro-numerical methods. Numer. Heat Transf. Part B Fundam. 57, 147–171 (2010). https://doi.org/10.1080/15421400903579929

Chen, L., Luan, H., Feng, Y., et al.: Coupling between finite volume method and lattice Boltzmann method and its application to fluid flow and mass transport in proton exchange membrane fuel cell. Int. J. Heat Mass Transf. 55, 3834–3848 (2012). https://doi.org/10.1016/j.ijheatmasstransfer.2012.02.020

Feng, Y.T., Han, K., Owen, D.R.J.: Coupled lattice Boltzmann method and discrete element modelling of particle transport in turbulent fluid flows: computational issues. Int. J. Numer. Methods Eng. 72, 1111–1134 (2007). https://doi.org/10.1002/nme.2114

Young, W.M., Elcock, E.W.: Monte Carlo studies of vacancy migration in binary ordered alloys: I. Proc. Phys. Soc. Ldn. 89, 735–746 (1966). https://doi.org/10.1088/0370-1328/89/3/329

Voter, A.F (ed).: Introduction to the kinetic Monte Carol method, in radiation efects in solids. In: The Kinetics of Radiation-Induced Point Defect Aggregation and Metallic Colloid Formation in Ionic Solids, pp.1–23. Springer, Netherland (2007)

Fichthorn, K.A., Weinberg, W.H.: Theoretical foundations of dynamic Monte-Carlo simulations. J. Chem. Phys. 95, 1090–1096 (1991)

Voter, A.F., Montalenti, F., Germann, T.C.: Extending the time scale in atomistic simulation of materials. Annu. Rev. Mater. Res. 32, 321–346 (2002)

Battaile, C.C., Srolovitz, D.J.: Kinetic Monte Carlo simulation of chemical vapor deposition. Annu. Rev. Mater. Res. 32, 297–319 (2002)

Battaile, C.C., Srolovitz, D.J., Butler, J.E.: A kinetic Monte Carlo method for the atomic-scale simulation of chemical vapor deposition: application to diamond. J. Appl. Phys. 82, 6293–6300 (1997)

Jensen, P.: Growth of nanostructures by cluster deposition: experiments and simple models. Rev. Mod. Phys. 71, 1695–1735 (1999)

Luque, N.B., Leiva, E.P.M.: On the application of computer simulations to the study of electrochemical nanostructuring and surface phase formation. Electrochim. Acta 50, 3161–3178 (2005)

Vvedensky, D.D.: Multiscale modelling of nanostructures. J. Physics-Condensed Matter. 16, R1537–R1576 (2004)

Panagiotopoulos, A.Z.: Monte Carlo methods for phase equilibria of fluids. J. Phys. Condensed Matter. 12, R25–R52 (2000)

Bieberle, A., Gauckler, L.J.: State-space modeling of the anodic SOFC system Ni, H(2)-H(2)O vertical bar YSZ. Solid State Ionics 146, 23–41 (2002). https://doi.org/10.1016/s0167-2738(01)01004-9

Ioselevich, A., Kornyshev, A.A., Lehnert, W.: Statistical geometry of reaction space in porous cermet anodes based on ion-conducting electrolytes: patterns of degradation. Solid State Ionics 124, 221–237 (1999). https://doi.org/10.1016/s0167-2738(99)00218-0

Modak, A.U., Lusk, M.T.: Kinetic Monte Carlo simulation of a solid-oxide fuel cell: i. Open-circuit voltage and double layer structure. Solid State Ionics 176, 2181–2191 (2005)

Pornprasertsuk, R., Ramanarayanan, P., Musgrave, C.B., et al.: Predicting ionic conductivity of solid oxide fuel cell electrolyte from first principles. J. Appl. Phys. 98, 555 (2005). https://doi.org/10.1063/1.2135889

Pornprasertsuk, R., Cheng, J., Huang, H., et al.: Electrochemical impedance analysis of solid oxide fuel cell electrolyte using kinetic Monte Carlo technique. Solid State Ionics 178, 195–205 (2007)

Zhdanov, V.P.: Electrochemical reactions on catalyst particles with three-phase boundaries. Phys. Rev. E 67, 042601 (2003)

Hu, R., Huang, S.P., Liu, Z.P., et al.: Water formation on Pt(111) surfaces at high temperatures studied by kinetic Monte Carlo simulations. Appl. Surf. Sci. 242, 353–361 (2005)

Deem, M.W.: Recent contributions of statistical mechanics in chemical engineering. AIChE J. 44, 2569–2596 (1998)

Raimondeau, S., Vlachos, D.G.: Recent developments on multiscale, hierarchical modeling of chemical reactors. Chem. Eng. J. 90, 3–23 (2002)

Kofke, D.A.: Getting the most from molecular simulation. Mol. Phys. 102, 405–420 (2004)

Zeng, Q.H., Yu, A.B., Lu, G.Q.: Multiscale modeling and simulation of polymer nanocomposites. Prog. Polym. Sci. 33, 191–269 (2008). https://doi.org/10.1016/j.progpolymsci.2007.09.002

Ghoniem, N.M., Busso, E.P., Kioussis, N., et al.: Multiscale modelling of nanomechanics and micromechanics: an overview. Philos. Mag. 83, 3475–3528 (2003)

Schmauder, S.: Computational mechanics. Annu. Rev. Mater. Res. 32, 437–465 (2002). https://doi.org/10.1146/annurev.matsci.32.103101.153157

Liu, W.K., Karpov, E.G., Zhang, S., et al.: An introduction to computational nanomechanics and materials. Comput. Methods Appl. Mech. Eng. 193, 1529–1578 (2004)

Broadbelt, L.J., Snurr, R.Q.: Applications of molecular modeling in heterogeneous catalysis research. Appl. Catal. A General. 200, 23–46 (2000)

Keil, F.J.: Modelling of phenomena within catalyst particles. Chem. Eng. Sci. 51, 1543–1567 (1996)

Centi, G., Perathoner, S.: Novel catalyst design for multiphase reactions. Catal. Today 79, 3–13 (2003)

Gummalla, M., Tsapatsis, M., Watkins, J.J., et al.: Multiscale hybrid modeling of film deposition within porous substrates. AIChE J. 50, 684–695 (2004)

Braatz, R.D., Alkire, R.C., Seebauer, E., et al.: Perspectives on the design and control of multiscale systems. J. Process Control 16, 193–204 (2006)

Cavallotti, C., DiStanislao, M., Moscatelli, D., et al.: Materials computation towards technological impact: the multiscale approach to thin films deposition. Electrochim. Acta 50, 4566–4575 (2005)

Chung, P.S., So, D.S., Biegler, L.T., et al.: Nanotechnology convergence and modeling paradigm of sustainable energy system using polymer electrolyte membrane fuel cell as a benchmark example. J. Nanoparticle Res. 14, 245–264 (2012). https://doi.org/10.1007/s11051-012-0853-1

Poulikakos, D., Arcidiacono, S., Maruyama, S.: Molecular dynamics simulation in nanoscale heat transfer: a review. Microscale Thermophys. Eng. 7, 181–206 (2003)

Glotzer, S.C., Paul, W.: Molecular and mesoscale simulation methods for polymer materials. Annu. Rev. Mater. Res. 32, 401–436 (2002)

Franco, A.A., Schott, P., Jallut, C., et al.: A multi-scale dynamic mechanistic model for the transient analysis of PEFCs. Fuel Cells. 7, 99–117 (2007). https://doi.org/10.1002/fuce.200500204

Li, J.H., Kwauk, M.: Exploring complex systems in chemical engineering: the multi-scale methodology. Chem. Eng. Sci. 58, 521–535 (2003)

Wang, W., Lu, B.N., Zhang, N., et al.: A review of multiscale CFD for gas-solid CFB modeling. Int. J. Multiph. Flow 36, 109–118 (2010). https://doi.org/10.1016/j.ijmultiphaseflow.2009.01.008

Yadigaroglu, G.: Computational fluid dynamics for nuclear applications: from CFD to multi-scale CMFD. Nucl. Eng. Des. 235, 153–164 (2005)

Charpentier, J.C., McKenna, T.F.: Managing complex systems: some trends for the future of chemical and process engineering. Chem. Eng. Sci. 59, 1617–1640 (2004)

Lidorikis, E., Bachlechner, M.E., Kalia, R.K., et al.: Coupling atomistic and continuum length scales in heteroepitaxial systems: multiscale molecular-dynamics/finite-element simulations of strain relaxation in Si/Si3N4 nanopixels. Phys. Rev. B. 72, 115338 (2005)

Nakano, A., Bachlechner, M.E., Kalia, R.K., et al.: Multiscale simulation of nanosystems. Comput. Sci. Eng. 3, 56–66 (2001)

Nakano, A., Kalia, R.K., Nomura, K., et al.: A divide-and-conquer/cellular-decomposition framework for million-to-billion atom simulations of chemical reactions. Comput. Mater. Sci. 38, 642–652 (2007)

Ghosh, S., Lee, K., Moorthy, S.: Two scale analysis of heterogeneous elastic-plastic materials with asymptotic homogenization and Voronoi cell finite element model. Comput. Methods Appl. Mech. Eng. 132, 63–116 (1996). https://doi.org/10.1016/0045-7825(95)00974-4

Smit, R.J.M., Brekelmans, W.A.M., Meijer, H.E.H.: Prediction of the mechanical behavior of nonlinear heterogeneous systems by multi-level finite element modeling. Comput. Methods Appl. Mech. Eng. 155, 181–192 (1998). https://doi.org/10.1016/s0045-7825(97)00139-4

Kouznetsova, V., Geers, M.G.D., Brekelmans, W.A.M.: Multi-scale constitutive modelling of heterogeneous materials with a gradient-enhanced computational homogenization scheme. Int. J. Numer. Methods Eng. 54, 1235–1260 (2002). https://doi.org/10.1002/nme.541

Wang, W., Chen, S., Li, J., et al.: Fabrication of catalyst coated membrane with screen printing method in a proton exchange membrane fuel cell. Int. J. Hydrogen Energy 40, 4649–4658 (2015). https://doi.org/10.1016/j.ijhydene.2015.02.027

Thanasilp, S., Hunsom, M.: Effect of MEA fabrication techniques on the cell performance of Pt-Pd/C electrocatalyst for oxygen reduction in PEM fuel cell. Fuel 89, 3847–3852 (2010). https://doi.org/10.1016/j.fuel.2010.07.008

Wengeler, R., Nirschl, H.: Turbulent hydrodynamic stress induced dispersion and fragmentation of nanoscale agglomerates. J. Colloid Interface Sci. 306, 262–273 (2007). https://doi.org/10.1016/j.jcis.2006.10.065

Hartley, P.A., Parfitt, G.D.: Dispersion of powders in liquids.1. The contribution of the vanderwaals force to the cohesiveness of carbon-black powders. Langmuir 1, 651–657 (1985)

Kralchevsky, P.A., Denkov, N.D.: Capillary forces and structuring in layers of colloid particles. Curr. Opin. Colloid Interface Sci. 6, 383–401 (2001)

Uchida, M., Aoyama, Y., Eda, N., et al.: Investigation of the microstructure in the catalyst layer and effects of both perfluorosulfonate ionomer and PTFE-Loaded carbon on the catalyst layer of polymer electrolyte fuel cells. J. Electrochem. Soc. 142, 4143–4149 (1995)

Uchida, M., Fukuoka, Y., Sugawara, Y., et al.: Effects of microstructure of carbon support in the catalyst layer on the performance of polymer-electrolyte fuel cells. J. Electrochem. Soc. 143, 2245–2252 (1996). https://doi.org/10.1149/1.1836988

Soboleva, T., Zhao, X.S., Mallek, K., et al.: On the micro-, meso- and macroporous structures of polymer electrolyte membrane fuel cell catalyst layers. ACS Appl. Mater. Interfaces. 2, 375–384 (2010). https://doi.org/10.1021/am900600y

Siddique, N.A., Liu, F.: Process based reconstruction and simulation of a three-dimensional fuel cell catalyst layer. Electrochim. Acta 55, 5357–5366 (2010). https://doi.org/10.1016/j.electacta.2010.04.059

Xiao, Y., Dou, M.L., Yuan, J.L., et al.: Fabrication process simulation of a PEM fuel cell catalyst layer and its microscopic structure characteristics. J. Electrochem. Soc. 159, B308–B314 (2012). https://doi.org/10.1149/2.064203jes

Xiao, Y., Yuan, J.L., Sunden, B.: Process based large scale molecular dynamic simulation of a fuel cell catalyst layer. J. Electrochem. Soc. 159, B251–B258 (2012). https://doi.org/10.1149/2.028203jes

Cosgrove, T.: Colloid Science: Principles, Methods and Applications. Blackwell, Oxford (2010)

Witten, T.A., Pincus, P.A.: Structured Fluids: Polymers, Colloids, Surfactants. Oxford University Press, New York (2010)

Gantt, J.A., Gatzke, E.P.: A stochastic technique for multidimensional granulation modeling. AIChE J. 52, 3067–3077 (2006). https://doi.org/10.1002/Aic.10911

Schueler, R., Petermann, J., Schulte, K., et al.: Agglomeration and electrical percolation behavior of carbon black dispersed in epoxy resin. J. Appl. Polym. Sci. 63, 1741–1746 (1997)

Zeidan, M., Jia, X.D., Williams, R.A., et al.: Simulation of aggregation with applications to soot laden lubricating fluids. Part. Part. Syst. Charact. 21, 473–482 (2005)

Cheng, C.H., Malek, K., Sui, P.C., et al.: Effect of Pt nano-particle size on the microstructure of PEM fuel cell catalyst layers: insights from molecular dynamics simulations. Electrochim. Acta 55, 1588–1597 (2010). https://doi.org/10.1016/j.electacta.2009.10.030

Liu, X.X., Martin, C.L., Delette, G., et al.: Microstructure of porous composite electrodes generated by the discrete element method. J. Power Sources 196, 2046–2054 (2011). https://doi.org/10.1016/j.jpowsour.2010.09.033

Suslick, K.S., Price, G.J.: Applications of ultrasound to materials chemistry. Annu. Rev. Mater. Sci. 29, 295–326 (1999)

Faeth, G.M., Hsiang, L.P., Wu, P.K.: Structure and breakup properties of sprays. Int. J. Multiph. Flow 21, 99–127 (1995)

Lienhard, J.H., Day, J.B.: Breakup of Superheated Liquid Jets. J. Basic Eng. 92, 515–521 (1970)

Sui, P.C.: Experimental and numerical investigations on the breakup and mixing processes during injection of supercritical fluid. Ph.D. Dissertation, The University of Iowa (1997)

Eslamian, M., Ahmed, M., Ashgriz, N.: Modelling of nanoparticle formation during spray pyrolysis. Nanotechnology 17, 1674–1685 (2006). https://doi.org/10.1088/0957-4484/17/6/023

Gasteiger, H.A., Kocha, S.S., Sompalli, B., et al.: Activity benchmarks and requirements for Pt, Pt-alloy, and non-Pt oxygen reduction catalysts for PEMFCs. Appl. Catal. B Environ. 56, 9–35 (2005). https://doi.org/10.1016/j.apcatb.2004.06.021

Chai, G.S., Yoon, S.B., Yu, J.S., et al.: Ordered porous carbons with tunable pore sizes as catalyst supports in direct methanol fuel cell. J. Phys. Chem. B. 108, 7074–7079 (2004). https://doi.org/10.1021/Jp0370472

Kim, H.T., You, D.J., Yoon, H.K., et al.: Cathode catalyst layer using supported Pt catalyst on ordered mesoporous carbon for direct methanol fuel cell. J. Power Sources 180, 724–732 (2008). https://doi.org/10.1016/j.jpowsour.2008.02.081

Job, N., Berthon-Fabry, S., Chatenet, M., et al.: Nanostructured carbons as platinum catalyst supports for proton exchange membrane fuel cell electrodes. Top. Catal. 52, 2117–2122 (2009). https://doi.org/10.1007/s11244-009-9384-0

Seidel, Y.E., Lindstroem, R.W., Jusys, Z., et al.: Stability of nanostructured Pt/glassy carbon electrodes prepared by colloidal lithography. J. Electrochem. Soc. 155, K50–K58 (2008). https://doi.org/10.1149/1.2829886

Schneider, A., Colmenares, L., Seidel, Y.E., et al.: Transport effects in the oxygen reduction reaction on nanostructured, planar glassy carbon supported Pt/GC model electrodes. Phys. Chem. Chem. Phys. 10, 1931–1943 (2008). https://doi.org/10.1039/b719775f

Gasda, M.D., Eisman, G.A., Gall, D.: Pore formation by in situ etching of nanorod PEM fuel cell electrodes. J. Electrochem. Soc. 157, B113–B117 (2010). https://doi.org/10.1149/1.3244589

Chisaka, M., Daiguji, H.: Design of ordered-catalyst layers for polymer electrolyte membrane fuel cell cathodes. Electrochem. Commun. 8, 1304–1308 (2006). https://doi.org/10.1016/j.elecom.2006.06.009

Du, C.Y., Cheng, X.Q., Yang, T., et al.: Numerical simulation of the ordered catalyst layer in cathode of proton exchange membrane fuel cells. Electrochem. Commun. 7, 1411–1416 (2005). https://doi.org/10.1016/j.elecom.2005.09.022

Rao, S.M., Xing, Y.C.: Simulation of nanostructured electrodes for polymer electrolyte membrane fuel cells. J. Power Sources 185, 1094–1100 (2008). https://doi.org/10.1016/j.jpowsour.2008.07.062

Lee, M.S., Chen, T.H., Lee, W.S., et al.: From microstructure to the development of water and major reaction sites inside the catalyst layer of the cathode of a proton exchange membrane fuel cell. J. Power Sources 196, 7411–7419 (2011). https://doi.org/10.1016/j.jpowsour.2011.04.022

Berning, T., Djilali, N.: A 3D, multiphase, multicomponent model of the cathode and anode of a PEM fuel cell. J. Electrochem. Soc. 150, A1589–A1598 (2003). https://doi.org/10.1149/1.1621412

Zheng, W., Kim, S.: The effects of catalyst layer microstructure and water saturation on the effective diffusivity in PEMFC. J. Electrochem. Soc. 165, F468–F478 (2018)

Kulikovsky, A.A.: The voltage-current curve of a polymer electrolyte fuel cell: “Exact” and fitting equations. Electrochem. Commun. 4, 845–852 (2002). https://doi.org/10.1016/S1388-2481(02)00466-6

Kulikovsky, A.A.: Catalyst layer performance in PEM fuel cell: analytical solutions. Electrocatalysis. 3, 132–138 (2012). https://doi.org/10.1007/s12678-012-0091-4

Kulikovsky, A.A.: Approximate analytical solution to MHM equations for PEM fuel cell cathode performance. Electrochem. Commun. 77, 36–39 (2017). https://doi.org/10.1016/j.elecom.2017.02.007

Boyer, C.C., Anthony, R.G., Appleby, A.J.: Design equations for optimized PEM fuel cell electrodes. J. Appl. Electrochem. 30, 777–786 (2000). https://doi.org/10.1023/A:1004088505222

Xia, Z., Wang, Q., Eikerling, M., et al.: Effectiveness factor of Pt utilization in cathode catalyst layer of polymer electrolyte fuel cells. Can. J. Chem. 86, 657–667 (2008). https://doi.org/10.1139/v08-053

He, W.S., Yi, J.S., VanNguyen, T.: Two-phase flow model of the cathode of PEM fuel cells using interdigitated flow fields. AIChE J. 46, 2053–2064 (2000). https://doi.org/10.1002/aic.690461016

Wang, Z.H., Wang, C.Y., Chen, K.S.: Two-phase flow and transport in the air cathode of proton exchange membrane fuel cells. J. Power Sources 94, 40–50 (2001). https://doi.org/10.1016/s0378-7753(00)00662-5

You, L.X., Liu, H.T.: A two-phase flow and transport model for the cathode of PEM fuel cells. Int. J. Heat Mass Transf. 45, 2277–2287 (2002). https://doi.org/10.1016/s0017-9310(01)00322-2

Nam, J.H., Kaviany, M.: Effective diffusivity and water-saturation distribution in single- and two-layer PEMFC diffusion medium. Int. J. Heat Mass Transf. 46, 4595–4611 (2003). https://doi.org/10.1016/s0017-9310(03)00305-3

Epting, W.K., Gelb, J., Litster, S.: Resolving the three-dimensional microstructure of polymer electrolyte fuel cell electrodes using nanometer-scale x-ray computed tomography. Adv. Funct. Mater. 22, 555–560 (2012). https://doi.org/10.1002/adfm.201101525

Karan, K.: Assessment of transport-limited catalyst utilization for engineering of ultra-low Pt loading polymer electrolyte fuel cell anode. Electrochem. Commun. 9, 747–753 (2007). https://doi.org/10.1016/j.elecom.2006.10.057

Krishna, R., Wesselingh, J.A.: Review article number 50—the Maxwell–Stefan approach to mass transfer. Chem. Eng. Sci. 52, 861–911 (1997). https://doi.org/10.1016/s0009-2509(96)00458-7

Secanell, M., Karan, K., Suleman, A., Djilali, N.: Optimal design of ultra-low platinum PEMFC anode electrodes. J. Electrochem. Soc. 155, B125–B134 (2008). https://doi.org/10.1149/1.2806171

Choo, M.-J., Oh, K.-H, Park, J.-K., Kim, H.-T.: Analysis of oxygen transport in cathode catalyst layer of low-Pt-loaded fuel cells. ChemElectroChem 2, 382–388 (2015). https://doi.org/10.1002/celc.2014023

Srouji, A.K., Zheng, L.J., Dross, R., Aaron, D., Mench, M.M.: The role of water management on the oxygen transport resistance in polymer electrolyte fuel cell with ultra-low precious metal loading. J. Power Sources 364, 92–100 (2017). https://doi.org/10.1016/j.jpowsour.2017.07.036

Darling, R.: A comparison of models for transport resistance in fuel-cell catalyst layers. J. Electrochem. Soc. 165, F1331–F1339 (2018). https://doi.org/10.1149/2.0881816jes

Acknowledgements

The authors would like to acknowledge the financial support in part from Canada Research Chair, National Research Council Canada, Natural Science and Engineering Research Council of Canada, MITACS Centre of Excellences, and the CaRPE-FC research network. This work resulted in part from a Fellowship at the Hanse-Wissenschaftskolleg Institute for Advanced Study, Delmenhorst, Germany. PCS also acknowledges the support of the National Natural Science Foundation of China (NSFC 21776226), National Key Research and Development Program of China (No. 2017YFB0102702),and the Hubei-100 Plan of China. The authors also benefited from many insightful discussions with Drs. Kyle Lange and Marc Secanell.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Definition of Volume Averaging

The volume average of a variable ψ over a control volume, i.e. \( \left\langle {{\varvec{\psi}}_{k} } \right\rangle \), is defined as

Where Vk is the volume of phase k and V is the total control volume for averaging, i.e., \( V = \sum\limits_{k} {V_{k} } \).

The intrinsic volume average of variable ψ in phase k is

The volume fraction of phase k is then \( \varepsilon_{k} = \frac{{V_{k} }}{V} \) and naturally, \( \sum\nolimits_{k} {\varepsilon_{k} } \).From (60) and (61), we have

The fluctuating component, i.e., deviation due to the presence of other phases, is defined as

Following (61), the intrinsic volume average of the product for two variables becomes

The volume average of a time derivative is

Where wk is the velocity of interface and nk is the normal vector of the interface.

The volume average of a gradient or divergent:

Appendix 2: Derivation of the Agglomerate Model and the PDL Model with the Volume Averaging Method

The following discussion is continued from Chapter 2.1.

The agglomerate model and the PDL model are similar in that there exists a difference of oxygen concentration between the bulk pore phase and the catalyst surface. For both models, we can derive from the VAM equations by making further assumptions.

Assumption 7

Zero net flux of oxygen through the ionomer phase in the REV. This eliminates the first term on the LHS of (6), i.e. \( \nabla \cdot \left( {\left\langle {\varvec{j}_{{{\text{O}}_{2} }} } \right\rangle_{\text{m}} } \right) = 0 \). This implies that oxygen consumed on the CPt surface is solely from the pore phase. This may not be valid under circumstances, e.g. when the pore phase is flooded, in which case oxygen could still diffuse through the ionomer pathway.

Adding (5) and (6), which cancels out the fluxes across interface Apm, we have:

Equation (67) simply states that the net flux of oxygen gas through the REV equals the consumption of oxygen (in ionomer) at the CPt surface.

2.1 Model closure: Mass Transfer in Pore Phase

Next we can provide model closure based on (67) with oxygen as an example. The mass diffusion in porous media is often modeled with an effective diffusivity:

The effective diffusivity can be measured by experiment or computed by microscale models, e.g. [84, 97], with zero oxygen source, i.e.

Both Fickian diffusion and Knudsen diffusion can be formulated. It is noted that Assumption 3 can be relaxed and the diffusive mass flux can then be modeled according to the Stefan–Maxwell formulation [296].

2.2 Model Closure: Reactions and Phase Equilibrium

The model closure for the diffusion-reaction processes in the CL is the major difference among the aforementioned macroscopic models. From (67) and (68), the transport of gas species can be expressed in this form:

Assumption #8

Phase equilibrium at the pore-ionomer interface.

The concentration of gas species on the ionomer surface can be related to that in the pore phase by the Henry’s law, which means the chemical potential of oxygen and that in the ionomer phase are the same and phase equilibrium is established. Another assumption of chemical equilibrium on the reaction site can be made to describe the balance of surface coverage, e.g. [73].

Assumption #9

First-order reaction for ORR

A first-order reaction for the oxygen reduction reaction can be assumed:

For the ORR the parameter k takes the form of either the Butler–Volmer equation or the Tafel equation. Assuming a constant parameter k in (71) and a 1D configuration, Fig. 16, with boundary conditions of

the solution of (70) is

where

For the macro-homogeneous model, the effective diffusivity is the mass diffusivity of gas species in the ionomer phase. For the agglomerate model and the pore-diffusion limited model, the effective diffusivity of gas species in the pore is used. For the latter two models, which assume that there exists certain mass diffusion obstacles between the pore and the reaction site, further assumptions can be made about the interface condition and the reaction term in (70).

Consider a configuration that the ionomer phase in the REV is characterized by an equivalent thickness, or the inversed specific surface area (V/S), where V is the volume of the ionomer in the REV and S is the surface area of carbon/ionomer interfaces. This surface area can be later extended to the area of the catalyst if discrete distribution of catalysts on the carbon surface is assumed. The concentration to be used for (71) is then the concentration on the surface of catalyst, c*(x) as opposed to that in the “bulk”, c(x), i.e.,

The local reaction can then be related to diffusion in ionomer by assuming a local flux as

where A is the surface area of the catalyst, δ is the characteristic thickness of the ionomer.

Equating (74) & (75) and rewriting for c*, we have

Substituting (76) into (74) and (75), we have

The agglomerate model in essence considers two mass transfer resistances along the transport pathway, i.e., mass diffusion through the ionomer coating and through the agglomerate. The final flux (oxygen consumption) is then related to oxygen concentration at the agglomerate surface by two resistors in series, i.e.

and

The effective resistance (diffusivity) through the ionomer is in general a function of ionomer thickness, oxygen diffusivity, etc. The effective resistance for the transport inside the agglomerate is a function of the geometrical form of the agglomerate and the relative strength of diffusion versus the reaction rate, i.e. the Damköhler number.

As the reaction takes place in the reaction zone, concentration varies along the penetration direction and a gradient of concentration, therefore a deviation from the highest reaction rate, is formed. An effectiveness factor η can be introduced to relate the actual flux (oxygen consumption) into the agglomerate and the flux in the absence of mass transfer through it. In the catalyst industry the effectiveness factor is often expressed as a function of the Thiele modulus, which is a function of kinetics, diffusivity, catalyst pellet geometry, etc. For instance, effectiveness factor for a sphere can be expressed as

where An0 is the zeroth order of the Aris number, or a modified Thiele modulus. The idea of a structure-based model is then to establish a rational approach to determine the Thiele modulus (or equivalent formula) that represents the reconstructed microstructure and transport/kinetic parameters for a given catalyst layer.

Rights and permissions

About this article

Cite this article

Sui, PC., Zhu, X. & Djilali, N. Modeling of PEM Fuel Cell Catalyst Layers: Status and Outlook. Electrochem. Energ. Rev. 2, 428–466 (2019). https://doi.org/10.1007/s41918-019-00043-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41918-019-00043-5