Abstract

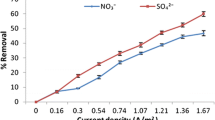

Manufacturing industries synthesize new chemical products every day, which eventually find their way into domestic and industrial wastewaters. As a result, wastewater is becoming increasingly more complex in nature. The emerging pollutants escape the treatment systems and appear in the receiving water bodies. Wastewater treatment plants in India still report effluent parameters in terms of biological oxygen demand (BOD) and chemical oxygen demand (COD) at the ppm level, whereas these emerging pollutants, many of whom are non-biodegradable, can be toxic and carcinogenic at the ppb level. Therefore, it is imperative to look for alternatives or upgrade the existing systems which safely remove these harmful compounds from wastewater. In this research, efficiency of electrocoagulation process was assessed in a laboratory-scale setup in removing recalcitrant carbon from a real wastewater. The wastewater was collected from an effluent treatment plant that receives domestic wastewater and industrial effluents from chemical, bulk drugs and allied industries, for treatment. In this study, the wastewater sample was analyzed for total dissolved solids (TDS) and total organic carbon (TOC), and then treated biologically in a respirometer using aerobic microorganisms. After the oxygen uptake curve plateaued, indicating a cessation of biological process, the sample was analyzed for TDS and TOC and put in a lab-scale electrocoagulation setup. Iron and Aluminium electrodes were used in the study and efficiency of the system in removing the recalcitrant/residual carbon and TDS was studied with respect to the reaction time. The results showed that electrocoagulation can be a potential post-biological treatment system for removal of recalcitrant carbon from wastewaters.

Similar content being viewed by others

References

Ilhan F, Kurt U, Apaydin O, Gonullu MT (2008) Treatment of leachate by electrocoagulation using aluminum and iron electrodes. J Hazard Mat 154(1–3):381–389

Asadollahfardi G, Rezaee M, Tavakoli G (2016) Simulation of unenhanced electrokinetic process for lead removal from Kaolinite clay. Int J Civil Eng 14:263–270. doi:10.1007/s40999-016-0049-7

Battula SK, Cheukuri J, Raman NVVSS, Bhagawan D (2014) Effective removal of fluoride from ground water using electro- coagulation. Int J Eng Res Appl 4(2):439–445

Wang CT, Chou WL, Kuo YM (2009) Removal of COD from laundry wastewater by electrocoagulation/electro flotation. J Hazard Mat 164(1):81–86

Drogui P, Asselin M, Brar SK, Benmoussa H, Blais JF (2008) Electrochemical removal of pollutants from agro-industry wastewaters. Sep Purif Technol 61(3):301–310

Faraji A, Asadollafardi G, Shevidi A (2013) A pilot study for the application of one- and two-stage tube settlers as a secondary clarifier for wastewater treatment. Int J Civil Eng 11(4):272–280

Bazrafshan E, Moein H, Mostafapour FK, Nakhaie S (2013) Application of electrocoagulation process for dairy wastewater treatment. J Chem 2013:1155–1163

Sengil AI, Ozacar M (2006) Treatment of dairy wastewaters by electrocoagulation using mild steel electrodes. J Hazard Mater 137(2):1197–1205

Tchamango S, Nanseu-njiki CP, Ngameni E, Hadjiev D, Darchen A (2010) Treatment of dairy effluents by electrocoagulation using aluminium electrodes. Sci Total Environ 408(4):947–952

Khandegar V, Saroha AK (2012) Electrochemical treatment of distillery spent wash using aluminum and iron electrodes. Chin J Chem Eng 20(3):439–443

Kumar M, Ponselvan FIA, Malviya JR, Srivastava VC, Mall ID (2009) Treatment of bio-digester effluent by electrocoagulation using iron electrodes. J Hazard Mat 165:345–352

Sridhar R, Sivakumar V, Immanuel VP, Maran JP (2011) Treatment of pulp and paper industry bleaching effluent by electrocoagulant process. J Hazard Mat 186:1495–1502

Zaied M, Bellakhal N (2009) Electrocoagulation treatment of black liquor from paper industry. J Hazard Mat 163:995–1000

Nasution A, Ng BL, Ali E, Yaakob Z, Kamarudin SK (2014) Electrocoagulation of palm oil mill effluent for treatment and hydrogen production using response surface methodology. Pol J Environ Stud 23(5):1669–1677

Zaroual Z, Azzi M, Saib N, Chainet E (2006) Contribution to the study of electrocoagulation mechanism in basic textile effluent. J Hazard Mat 131:73–78

Drouiche N, Ghaffour N, Lounici H, Mameri N (2008) Electrochemical treatment of chemical mechanical polishing wastewater: removal of fluoride—sludge characteristics—operating cost. Desalination 223:134–142

Koparal AS, Ogutveren UB (2002) Removal of nitrate from water by electroreduction and electrocoagulation. J Hazard Mat 89:83–94

Vasudevan S, Lakshmi J, Jayaraj J, Sozhan G (2009) Remediation of phosphate-contaminated water by electrocoagulation with aluminium, aluminium alloy and mild steel anodes. J Hazard Mat 164:1480–1486

Gao P, Chen X, Shen F, Chen G (2005) Removal of chromium (VI) from wastewater by combined electrocoagulation–electroflotation without a filter. Sep Purif Technol 43:117–123

Vasudevan S, Lakshmi J (2011) Effects of alternating and direct current in electrocoagulation process on the removal of cadmium from water—a novel approach. Sep Purif Technol 80(3):643–651

Hasnain M, Henry E, Ahmed Z (2014) Boron removal by electrocoagulation and recovery. Water Res 51:113–123

Kabdasli I, Arslan T, Hansi TO, Arslan-alaton I, Tünay O (2009) Complexing agent and heavy metal removals from metal plating effluent by electrocoagulation with stainless steel electrodes. J Hazard Mat 165:838–845

Melnik ES. Alternative design for electrocoagulation treatment of cromium containing electroplating wastewater. J Water Chem Technol 38 (1): 45–50. doi:10.3103/S1063455X16010082

Moreno-casillas HA, Cocke DL, Gomes JAG, Morkovsky P, Parga JR, Peterson E (2007) Electrocoagulation mechanism for COD removal. Sep Purif Technol 56:204–211

Marsili-Libelli S, Tabani F (2002) Accuracy analysis of a respirometer for activated sludge dynamic modelling. Water Res 36(5):1181–1192

Jing-wei Feng, Ya-bing Sun, Zheng Zheng, Ji-biao Zhang, Shu Li, Yuan-chun Tian (2007) Treatment of tannery wastewater by electrocoagulation. J Environ Sci 19(12):1409–1415

Kobya M, Can OT, Bayramoglu M (2003) Treatment of textile wastewaters by electrocoagulation using iron and aluminum electrodes. J Hazard Mat 100(1–3):163–178

Mollah MYA, Morkovsky P, Gomes JAG, Kesmez M, Parga J, Cocke DL (2004) Fundamentals, present and future perspectives of electrocoagulation. J Hazard Mat 114(1–3):199–210

Varank G, Erkan H, Yazycy S, Demir A, Engin G (2014) Electrocoagulation of tannery wastewater using monopolar electrodes: process optimization by response surface methodology. Int J Environ Res 8(1):165–180

Standards for Emission or Discharge of Environmental Pollutants from various industries. http://www.cpcb.nic.in/Industry-Specific-Standards/Effluent/446-1.pdf.

Acknowledgements

We express our sincere gratitude to the Department of Civil Engineering at IIT Hyderabad for providing the necessary infrastructure for undertaking this research. We also thank wholeheartedly Rahyals Envergy India Pvt Ltd for providing necessary funds for the project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Damaraju, M., Bhattacharyya, D. & Kurilla, K.K. Removal of Recalcitrant Carbon from an Industrial Wastewater Using Electrocoagulation. Int J Civ Eng 15, 697–703 (2017). https://doi.org/10.1007/s40999-017-0187-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-017-0187-6