Abstract

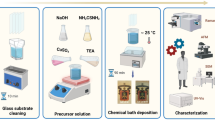

The higher-thermal conductive Cu–Al2O3 nanoparticles are deposited on the copper surface by using single-step electrodeposition technique. The developed Cu–Al2O3 nanocomposite-coated surfaces attained excellent adhesiveness with copper substrate. Again, the surface morphology parameters like wettability, roughness, porosity, and porous layer thickness, as per the necessity in structured surfaces, can be easily managed by managing the electrodeposition parameters like potential difference, deposition time, current density, and electrolyte concentration. The surface morphology characterization is carried out with respect to the wettability, roughness, coating thickness, porosity, and average pore diameter. The flow boiling heat transfer experiments at different mass flow rates with deionized (DI) water are carried out in a minichannel of developed experimental setup. The Cu–Al2O3 coating offers lower thermal resistance due to its higher thermal conductivity and lower coating thickness. Again, the percentage enhancement in critical heat flux (CHF) and boiling heat transfer coefficient (BHTC) of the Cu–Al2O3-coated surfaces is decreased with the increase in mass flow rate, which is owing to the partial wetting of the pores at higher mass flow rate. The maximum augmentations in BHTC and CHF for the coated surfaces are achieved up to 84% and 86% as compared to the bare surface, respectively, which are due to the improvement in surface wettability and formation of huge number of cavities/pores on coated surfaces. Thus, the porous surface with minichannel is the potential candidate for the microelectronics cooling devices due to its compact size, lower heating surface temperature, higher CHF, and higher BHTC.

Similar content being viewed by others

Abbreviations

- h :

-

Heat transfer coefficient

- k :

-

Thermal conductivity

- q :

-

Heat flux

- \(T_{\text{fa}}\) :

-

Fluid average temperature

- \(T_{\text{in}}\) :

-

Fluid inlet temperature

- \(T_{\text{out}}\) :

-

Fluid outlet temperature

- \(T_{\text{s}}\) :

-

Heating (boiling) surface temperature

- \(T_{\text{sa}}\) :

-

Average surface 1.5 mm below the heating surface temperature

- Δx :

-

Vertical distance between the thermocouples

References

Allahkaram SR, Golroh S, Mohammadalipour M (2011) Properties of Al2O3 nanoparticle reinforced copper matrix composite coatings prepared by pulse and direct current electroplating. Mater Des 32(8–9):4478–4484

Ammerman CN, You SM (2001) Enhancing small-channel convective boiling performance using a microporous surface coating. J Heat Transf 123:976–983

Bang IC, Chang SH (2005) Boiling heat transfer performance and phenomena of Al2O3–water nano-fluids from a plain surface in a pool. Int J Heat Mass Transf 48:2407–2419

Chang SH, Baek WP (1997) Critical Heat Flux, 1st edn., Seoul

Chang JY, You SM (1997a) Boiling heat transfer phenomena from micro-porous and porous surfaces in saturated FC-72. Int J Heat Mass Transf 40(18):4437–4447

Chang JY, You SM (1997b) Enhanced boiling heat transfer from micro-porous surfaces: effects of a coating composition and method. Int J Heat Mass Transf 40(18):4449–4466

Connor JP, You SM (1995) A painting technique to enhance pool boiling heat transfer in saturated FC-72. J Heat Transf 117(2):387–393

Cooper MG, Lloyd AJ (1969) The microlayer in nucleate pool boiling. Int J Heat Mass Transf 12:895–913

Dhir VK (2006) Mechanistic prediction of nucleate boiling heat transfer—achievable or a hopeless task? J Heat Transf 128:1–12

Gambill WR, Bundy RD (1963) High heat transfer characteristics of pure ethylene glycol in axial and swirl flow. AIChE J 9:55–59

Gan Y, Lee D, Chen X, Kysar JW (2005) Structure and properties of electrocodeposited Cu–Al2O3 nanocomposite thin films. J Eng Mater Technol 127(4):451–456

Gupta SK, Misra RD (2018a) An experimental investigation on flow boiling heat transfer enhancement using Cu–TiO2 nanocomposite coating on copper substrate. Exp Therm Fluid Sci 98:406–419

Gupta SK Misra RD (2018b) Experimental study of pool boiling heat transfer on copper surfaces with Cu–Al2O3 nanocomposite coatings. Int Commun Heat Mass Transf 97:47–55

Gupta SK, Misra RD. (2018c) An experimental investigation on pool boiling heat transfer enhancement using Cu–Al2O3 nano-composite coating. Exper Heat Transf 1:1–26. https://doi.org/10.1080/08916152.2018.1485785

Gupta SK, Misra RD (2018d) Effect of two-step electrodeposited Cu–TiO2 nanocomposite coating on pool boiling heat transfer performance. J Therm Anal Calorim. https://doi.org/10.1007/s10973-018-7805-7

Ho JY, Leong KC, Yang C (2014) Saturated pool boiling from carbon nanotube coated surfaces at different orientations. Int J Heat Mass Transf 79:893–904

Holman J (2007) Experimental methods for engineers, 7th edn. Tata McGraw Hill Education Private Limited, New York

Im Y, Dietz C, Lee SS, Joshi Y (2012) Flower-like CuO nanostructures for enhanced boiling. Nanoscale Microscale Thermophys Eng 16:145–153

Jaikumar A, Gupta A, Kandlikar SG, Yang CY, Su CY (2017) Scale effects of graphene and graphene oxide coatings on pool boiling enhancement mechanisms. Int J Heat Mass Transf 109:357–366

Jo HJ, Kim SH, Kim H, Kim J, Kim MH (2012) Nucleate boiling performance on nano/microstructures with different wetting surfaces. Nanoscale Res Lett 7:242–250

Kim JH, You SM, Choi Stephen US (2004) Evaporative spray cooling of plain and microporous coated surfaces. Int J Heat Mass Transf 47:3307–3315

Kim HD, Kim J, Kim MH (2006) Effect of nanoparticles on CHF enhancement in pool boiling of nano-fluids. Int J Heat Mass Transf 49:5070–5074

Kim HD, Kim J, Kim MH (2007) Experimental studies on CHF characteristics of nano-fluids at pool boiling. Int J Multiph Flow 33:691–706

Kim SJ, McKrell T, Buongiorno J, Hu L-W (2009) Experimental study of flow critical heat flux in alumina–water, zinc-oxide–water, and diamond–water nanofluid. Trans ASME 131:043204

Kim TI, Jeong YH, Chang SH (2010) An experimental study on CHF enhancement in flow boiling using Al2O3 nano-fluid. Int J Heat Mass Transf 53:1015–1022

Kim TI, Chang WJ, Chang SH (2011) Flow boiling CHF enhancement using Al2O3 nanofluid and an Al2O3 nanoparticle deposited tube. Int J Heat Mass Transf 54:2021–2025

Kim DE, In Yu Dong, Jerng DW, Kim MH, Ahn HS (2015) Review of boiling heat transfer enhancement on micro/nanostructured Surfaces. Exp Therm Fluid Sci 66:173–196

Li G, Thomas B, Stubbins J (2000) Modeling creep and fatigue of copper alloys. Metall Mater Trans A 31(10):2491–2502

Liter SG, Kaviany M (2001) Pool-boiling CHF enhancement by modulated porous layer coating: theory and experiment. Int J Heat Mass Transf 44(18):4287–4311

Moita AS, Teodori E, Moreira ALN (2012) Enhancement of pool boiling heat transfer by surface micro-structuring. J Phys Conf Ser 395:012175

Morshed AKMM, Yang F, Ali MY, Khan JA, Li C (2012) Enhanced flow boiling in a microchannel with integration of nanowires. Appl Therm Eng 32:68–75

Morshed AKMM, Paul Titan C, Jamil Khan (2013) Effect of Cu–Al2O3 nanocomposite coating on flow boiling performance of a microchannel. Appl Therm Eng 51:1135–1143

Nam Y, Wu J, Warrier G, Ju YS (2009) Experimental and numerical study of single bubble dynamics on a hydrophobic surface. J Heat Transf 131:120–124

Nikolic ND (2010) Fundamental aspects of copper electrodeposition in the hydrogen co-deposition range. Zastita Mater 51:1970203

Nimkar ND, Bhavnani SH, Jaeger RC (2006) Effect of nucleation site spacing on the pool boiling characteristics of a structured surface. Int J Heat Mass Transf 49:2829–2839

Patil CM, Santhanam KSV, Kandlikar SG (2014) Development of a two-step electrodeposition process for enhancing pool boiling. Int J Heat Mass Transf 79:989–1001

Rainey KN, Li G, You SM (2001) Flow boiling heat transfer from plain and microporous coated surfaces in subcooled FC-72. J Heat Transf 123:918–925

Sarwar MS, Jeong YH, Chang SH (2007) Subcooled flow boiling CHF enhancement with porous surface coatings. Int J Heat Mass Transf 50:3649–3657

Shin HC, Liu M (2004) Copper foam structures with highly porous nanostructured walls. Chem Mater 16:5460–5464

Sujith Kumar CS, Suresh S, Yang Q, Aneesh CR (2014) An experimental investigation on flow boiling heat transfer enhancement using spray pyrolysed alumina porous coatings. Appl Therm Eng 71:508–518

Takata Y, Hidaka S, Kohno M (2006) Enhanced nucleate boiling by superhydrophobic coating with checkered and spotted patterns. In: Proceedings of the sixth international conference on boiling heat transfer, Spoleto. Curran Associates Inc, New York, pp 240–244

Viskanta R (1961) Critical heat flux for water in swirling flow. Nucl Sci Eng 10:202–203

Webb R (1981) The evolution of enhanced surface geometries for nucleate boiling. Heat Transf Eng 2:46–69

Whalley PB (1979) The effect of swirl on critical heat flux in annular two-phase flow. Int J Multiph Flow 5:211–217

Yang F, Dai X, Peles Y, Cheng P, Li J, Khan C (2014) Flow boiling phenomena in a single annular flow regime in microchannels (I): characterization of flow boiling heat transfer. Int J Heat Mass Transf 68:703–715

You SM, Kim JH, Kim KH (2003) Effect of nanoparticles on critical heat flux of water in pool boiling heat transfer. Appl Phys Lett 83:3374–3376

Yu Q, Ma X, Wang M, Yu C, Bai T (2008) Influence of embedded particles on microstructure, corrosion resistance and thermal conductivity of CuO/SiO2 and NiO/SiO2 nanocomposite coatings. Appl Surf Sci 254(16):5089–5094

Zhang BJ, Kim KJ, Yoon H (2012) Enhanced heat transfer performance of alumina sponge-like nano-porous structures through surface wettability control in nucleate pool boiling. Int J Heat Mass Transf 55:7487–7498

Acknowledgements

The authors gratefully acknowledge SAIF, Indian Institute of Technology Mumbai, India, for providing FEG–SEM facility.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, S.K., Misra, R.D. Enhancement of Flow Boiling Heat Transfer Performance Using Single-Step Electrodeposited Cu–Al2O3 Nanocomposite Coating on Copper Substrate. Iran J Sci Technol Trans Mech Eng 44, 481–496 (2020). https://doi.org/10.1007/s40997-018-0274-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-018-0274-6