Abstract

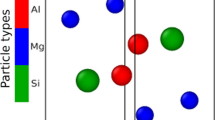

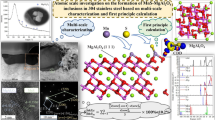

In the high-speed wheel steel, the composite inclusions of MnS–Al2O3 reduce the overall elastic modulus of the Al2O3 and avoid the fatigue crack around the inclusions. It is of great industrial significance to clarify the mechanism of formation progress of the composite inclusions. In this paper, the formation process of the composite inclusions is simulated on an atomic scale by the first principle calculations through the adsorption model. The structure of MnS–Al2O3 composite inclusion was optimized through a series of cases with different adsorption sequences of the Mn and S atoms on the surface of Al2O3 inclusions. The most stable adsorption positions of the Mn and S atoms are determined by comparing the adsorption energy through structural optimization. The adsorption of the atoms is further explained by the calculation results of the density of state (DOS), the partial density of state (PDOS), and charge density distribution (CDD).

Similar content being viewed by others

References

S.K. Dhua, A. Ray, S.K. Sen, M.S. Prasad, K.B. Mishra, S. Jha, Influence of nonmetallic inclusion characteristics on the mechanical properties of rail steel. J. Mater. Eng. Perform. 9, 700–709 (2000)

G. Mi, H. Nan, Y. Liu, B. Zhang, H. Zhang, G. Song, Influence of Inclusion on crack initiation in wheel rim. J. Iron. Steel Res. Int. 18, 49–54 (2011)

S. Chakraborty, R.J. O’Malley, L. Bartlett, M. Xu, Removal of alumina inclusions from molten steel by ceramic foam filtration. Inter Metalcast 15, 1006–1020 (2021). https://doi.org/10.1007/s40962-020-00537-9

Z. Wu, Z. Liu, S. Qiu, X. Li, Effect of composition and morphology of non-metallic inclusions on fracture toughness in as-cast AHSS. Metall. Res. Technol. 116, 623 (2019)

E.T. Turkdogan, S. Ignatowicz, J. Pearson, The solubility of sulphur in iron and iron-manganese alloys. J. Iron Steel Inst. 180, 349–354 (1955)

W.A. Spitzig, Effect of sulfides and sulfide morphology on anisotropy of tensile ductility and toughness of hot-rolled C-Mn steels. Metall. Trans. A 14, 471–484 (1983)

E. Aydın, C.F. Arısoy, M.K. Sesen, The effect of manganese sulfide inclusions and zirconium additions on the mechanical properties of heavy section cast steel. Inter Metalcast 12, 383–395 (2018). https://doi.org/10.1007/s40962-017-0175-2

R. Sakaguchi, T. Shiraiwa, P. Chivavibul, T. Kasuya, M. Enoki, N. Yamashita et al., Multiscale analysis of MnS inclusion distributions in high strength steel. ISIJ Int. 60, 1714–1723 (2020)

T. Koseki, G. Thewlis, Overview inclusion assisted microstructure control in C-Mn and low alloy steel welds. Mater. Sci. Technol. 21, 867–879 (2005)

Y. Min, Q. Zhang, H. Xu, J. Xu, C. Liu, Formation and evolution of inclusions with different adding order of magnesium and sulfur in Al-killed free-cutting steel. Metals 8, 1064 (2018)

Y. Tanaka, F. Pahlevani, S. Moon, R. Dippenaar, V. Sahajwalla, In situ characterisation of MnS precipitation in high carbon steel. Sci. Rep. 9, 10096 (2019)

D. You, S.K. Michelic, C. Bernhard, D. Loder, G. Wieser, Modeling of Inclusion formation during the Solidification of Steel. ISIJ Int. 56, 1770–1778 (2016)

F. Li, H. Li, D. Huang, S. Zheng, J. You, Mechanism of MnS precipitation on Al2O3–SiO2 inclusions in non-oriented silicon steel. Met. Mater. Int. 24, 1394–1402 (2018)

D. Kim, K. Han, B. Lee, I. Han, J.H. Park, C. Lee, Oxide formation mechanisms in high manganese steel welds. Metall. Mater. Trans. A. 45, 2046–2054 (2014)

J. Shim, J. Byun, Y.W. Cho, Y. Oh, J. Shim, D.N. Lee, Mn absorption characteristics of Ti2O3 inclusions in low carbon steels. Scripta Mater. 44, 49–54 (2001)

H. Ohta, H. Suito, Precipitation and dispersion control of MnS by deoxidation products of ZrO2, Al2O3, MgO and MnO–SiO2 particles in Fe–10mass%Ni alloy. ISIJ Int. 46, 480–489 (2006)

X.L. Xin, J. Yang, Y.N. Wang, R.Z. Wang, W.L. Wang, H.G. Zheng et al., Effects of Al content on non-metallic inclusion evolution in Fe–16Mn–xAl–0.6C high Mn TWIP steel. Ironmak. Steelmak. 43, 234–42 (2016)

J.M. Summers, S. Chakraborty, L.N. Bartlett, R.J. O’Malley, M.F. Buchely, R. Pilon, On the effect of hot rolling on inclusion size and distribution in a cast aisi 1070 steel railroad wheel. Inter Metalcast (2022). https://doi.org/10.1007/s40962-022-00854-1

M. Alba, M. Nabeel, N. Dogan, Investigation of inclusion formation in light-weight Fe–Mn–Al steels using automated scanning electron microscope equipped with energy-dispersive X-ray spectroscopy. Steel Res. Int. 91, 1900477 (2020)

M. Alba, M. Nabeel, N. Dogan, Effect of aluminium content on the formation of inclusions in Fe–5Mn–xAl steels. Ironmak. steelmak. 48(4), 379–386 (2020)

M. Nabeel, M. Alba, A. Karasev, P.G. Jönsson, N. Dogan, Characterization of inclusions in 3rd generation advanced high-strength steels. Metall. Mater. Trans. B. 50, 1674–1685 (2019)

L. Cheng, C. Xu, L. Lu, L. Yu, K. Wu, Experimental and first principle calculation study on titanium, zirconium and aluminum oxides in promoting ferrite nucleation. J. Alloy Compd. 742, 112–122 (2018)

H. Xue, X. Wei, W. Guo, X. Zhang, Bonding mechanism study of active Ti element and α-Al2O3 by using first-principle calculation. J Alloy Compd. 820, 153070 (2020)

Q. Tian, J. Li, X. Wu, J. Fu, G. Wang, Growth mechanism of MnS/Fe on TiN surface: first principle investigation. J. Alloy Compd. 844, 155831 (2020)

W. Lv, W. Jin, L. Yan, X. Pang, H. Yang, K. Gao, Interaction between Cu and Cr coadsorption on MnS inclusions in low alloy steels. Appl. Surf. Sci. 471, 425–434 (2019)

B.C. Zhou, T. Yang, G. Zhou, H. Wang, J.H. Luan, Z.B. Jiao, Mechanisms for suppressing discontinuous precipitation and improving mechanical properties of NiAl-strengthened steels through nanoscale Cu partitioning. Acta Mater. 205, 116561 (2021)

M.D. Segall, P.J.D. Lindan, M.J. Probert, C.J. Pickard, P.J. Hasnip, S.J. Clark et al., First-principles simulation: ideas, illustrations and the CASTEP code. J. Phys. Condens. Matter 14, 2717–2744 (2002)

A.E. Mattsson, P.A. Schultz, M.P. Desjarlais, T.R. Mattsson, K. Leung, Designing meaningful density functional theory calculations in materials science—a primer. Model. Simul. Mater. Sci. Eng. 13, R1-31 (2004)

V. Milman, B. Winkler, J.A. White, C.J. Pickard, M.C. Payne, E.V. Akhmatskaya et al., Electronic structure, properties, and phase stability of inorganic crystals: a pseudopotential plane-wave study. Int. J. Quant. Chem. 77, 895–910 (2000)

J.P. Perdew, K. Burke, M. Ernzerhof, Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996)

A. Pasquarello, R. Car, C. Lee, D. Vanderbilt, K. Laasonen, Car-parrinello molecular dynamics with vanderbilt ultrasoft pseudo potentials. Phys. Rev. B. 47, 10142–10153 (1993)

J.W. Elam, C.E. Nelson, M.A. Cameron, M.A. Tolbert, S.M. George, Adsorption of H2O on a single-crystal α-Al2O3(0001) surface. J. Phys. Chem. B 102, 7008–7015 (1998)

J. Ahn, J.W. Rabalais, Composition and structure of the Al2O3{0001}-(1 × 1) surface. Surf. Sci. 388, 121–131 (1997)

M. Gautier, G. Fenaud, L. Van Pham, B. Villette, M. Pollak, N. Thromat et al., alpha-Al2O3 (0001) surfaces: atomic and electronic structure. J. Am. Ceram. Soc. 77, 323–334 (1994)

E.A.A. Jarvis, E.A. Carter, Metallic character of the Al2O3(0001)-(√31 × √31)R ± 9° surface reconstruction. J. Phys. Chem. B 105, 4045–4052 (2001)

P.J. Eng, Structure of the hydrated -Al2O3 (0001) Surface. Science 288, 1029–1033 (2000)

Q. Fu, T. Wagner, M. Rühle, Hydroxylated α-Al2O3 (0001) surfaces and metal/α-Al2O3 (0001) interfaces. Surf. Sci. 600, 4870–4877 (2006)

Q. Xu, S. Wei, B. Huang, Theoretical study of corundum as an ideal gate dielectric material for graphene transistors. Phys. Rev. B. 84, 155406 (2011)

Y. Shao, C. Liu, Z. Yan, H. Li, Y. Liu, Formation mechanism and control methods of acicular ferrite in HSLA steels: a review. J. Mater. Sci. Technol. 34, 737–744 (2018)

H. Jin, J. Shim, Y. Cho, H. Lee, Formation of intragranular acicular ferrite grains in a Ti-containing low carbon steel. ISIJ Int. 43, 1111–1113 (2003)

Acknowledgement

The authors greatly acknowledge the support of the projects from the Excellent Youth Foundation of Hebei Province, China (E2021209039), Hebei Financial Support Project for the Introduced Overseas Student (C20210309); the National Natural Science Foundation of China (No. 52074056) and the Natural Science Foundation of Chongqing, China (No. cstc2020jcyj-msxmX0449).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, X., Tan, M., Li, T. et al. Investigation on the Formation Pathway of the MnS–Al2O3 Inclusions at Atomic Level in High-Speed Wheel Steel. Inter Metalcast 17, 2741–2753 (2023). https://doi.org/10.1007/s40962-022-00941-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-022-00941-3