Abstract

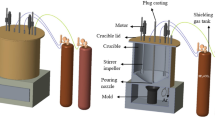

The microstructures, tribological and mechanical properties of TiC particulates reinforced AZ91 alloy have been investigated in this study. The effect of variation (3%, 6%, 9% and 12% by weight) of TiC particles (average size of 20 µm) are used to develop metal matrix composites of AZ91 Mg alloy in the current study. The composites were stirred, cast and characterized for their physical, mechanical and tribological behaviour. It was found that the addition of TiC refined the microstructure of the AZ91 composites. The porosity and density of the Magnesium (Mg) alloy composite increased with the percentage of TiC particulates. It was also found that the tensile strength initially decreased and then increased with an increase in TiC particulates in magnesium alloys. The wear rate of the TiC reinforced composites was lower than the unreinforced composites. The average coefficient of friction of the composite was also lower than the unreinforced alloy and decreased with the normal load.

Similar content being viewed by others

Data Availability

The authors confirm that this article contains all the data supporting the findings of this study.

References

P. Ajay Kumar, P. Rohatgi, D. Weiss, 50 Years of foundry-produced metal matrix composites and future ppportunities. Int. J. Met. 14, 291–317 (2019). https://doi.org/10.1007/s40962-019-00375-4

H.Z. Ye, X.Y. Liu, Review of recent studies in magnesium matrix composites. J. Mater. Sci. 39, 6153–6171 (2004). https://doi.org/10.1023/B:JMSC.0000043583.47148.31

J. Idris, J.C. Tan, C.W. Chang, The development of advanced materials -high performance properties of composite for automotive and aerospace applications. Pertanika J. Sci. Technol. Suppl. 9, 149–158 (2001)

S. Narayan, A. Rajeshkannan, Effect of titanium carbide addition on the workability behavior of powder metallurgy aluminum preforms during hot deformation. Mater. Phys. Mech. 32, 165–177 (2017). https://doi.org/10.18720/MPM.3222017-8

E. Bedolla, J. Lemus-Ruiz, A. Contreras, Synthesis and characterization of Mg-AZ91/AlN composites. Mater. Des. (2012). https://doi.org/10.1016/j.matdes.2012.02.001

I. Aatthisugan, A.R. Rose, D.J. Selwyn, Mechanical and wear behaviour of AZ91D magnesium matrix hybrid composite reinforced with boron carbide and graphite. J. Magnes. Alloy. 5, 20–25 (2017). https://doi.org/10.1016/j.jma.2016.12.004

S. Banerjee, S. Poria, G. Sutradhar, P. Sahoo, Nano-indentation and corrosion characteristics of ultrasonic vibration assisted stir-cast AZ31–WC–graphite nano-composites. Int. J. Met. (2020). https://doi.org/10.1007/s40962-020-00538-8

I.A. Ibrahim, F.A. Mohamed, E.J. Lavernia, Particulate reinforced metal matrix composites - a review. J. Mater. Sci. 26, 1137–1156 (1991). https://doi.org/10.1007/BF00544448

B.W. Chua, L. Lu, M.O. Lai, Influence of SiC particles on mechanical properties of Mg based composite. Compos. Struct. 47, 595–601 (1999). https://doi.org/10.1016/S0263-8223(00)00031-3

K.K. Deng, X.J. Wang, Y.W. Wu, X.S. Hu, K. Wu, W.M. Gan, Effect of particle size on microstructure and mechanical properties of SiCp/AZ91 magnesium matrix composite. Mater. Sci. Eng. A. 543, 158–163 (2012). https://doi.org/10.1016/j.msea.2012.02.064

A. Kumar, S. Kumar, N.K. Mukhopadhyay, A. Yadav, J. Winczek, Effect of SiC reinforcement and its variation on the mechanical characteristics of AZ91 composites. Materials (Basel). 13, 4913 (2020). https://doi.org/10.3390/ma13214913

A. Kumar, S. Kumar, N.K. Mukhopadhyay, A. Yadav, V. Kumar, J. Winczek, Effect of variation of SiC reinforcement on wear behaviour of AZ91 alloy composites. Materials (Basel). 14, 990 (2021). https://doi.org/10.3390/ma14040990

H. Mohammadi, M. Emamy, Z. Hamnabard, The statistical analysis of tensile and compression properties of the as-cast AZ91-X%B4C composites. Int. J. Met. 14, 505–517 (2020). https://doi.org/10.1007/s40962-019-00377-2

K.B. Nie, Y.C. Guo, P. Munroe, K.K. Deng, X.K. Kang, Microstructure and tensile properties of magnesium matrix nanocomposite reinforced by high mass fraction of nano-sized particles including TiC and MgZn2. J. Alloys Compd. 819, 153348 (2020). https://doi.org/10.1016/j.jallcom.2019.153348

D. Dash, R. Singh, S. Samanta, R.N. Rai, Influence of TiC on microstructure, mechanical and wear properties of magnesium alloy (AZ91D) matrix composites. J. Sci. Ind. Res. (India) 79, 164–169 (2020)

M.J. Shen, F.Y. Chen, J.M. Hou, T. Ying, Microstructural analysis and mechanical properties of the AZ31B matrix cast composites containing micron sic particles. Int. J. Met. 11, 287–293 (2017). https://doi.org/10.1007/s40962-016-0054-2

L. Falcon-Franco, E. Bedolla-Becerril, J. Lemus-Ruiz, J.G. Gonzalez-Rodríguez, R. Guardian, I. Rosales, Wear performance of TiC as reinforcement of a magnesium alloy matrix composite. Compos. Part B Eng. 42, 275–279 (2011). https://doi.org/10.1016/j.compositesb.2010.11.012

M. Srinivasan, C. Loganathan, M. Kamaraj, Q.B. Nguyen, M. Gupta, R. Narayanasamy, Sliding wear behaviour of AZ31B magnesium alloy and nano-composite. Trans. Nonferrous Met. Soc. China (English Ed.) 22, 60–65 (2012). https://doi.org/10.1016/S1003-6326(11)61140-0

Z.H. Zhu, K.B. Nie, P. Munroe, K.K. Deng, Y.C. Guo, J.G. Han, Synergistic effects of hybrid (SiC+TiC) nanoparticles and dynamic precipitates in the design of a high-strength magnesium matrix nanocomposite. Mater. Chem. Phys. 259, 124048 (2021). https://doi.org/10.1016/j.matchemphys.2020.124048

A.A. Luo, Magnesium casting technology for structural applications. J. Magnes. Alloy. 1, 2–22 (2013). https://doi.org/10.1016/j.jma.2013.02.002

A. Kumar, S. Kumar, N.K. Mukhopadhyay, Introduction to magnesium alloy processing technology and development of low-cost stir casting process for magnesium alloy and its composites. J. Magnes. Alloy. 6, 245–254 (2018). https://doi.org/10.1016/j.jma.2018.05.006

P. Mohazzab, Archimedes’ principle revisited. J. Appl. Math. Phys. 05, 836–843 (2017). https://doi.org/10.4236/jamp.2017.54073

S.F. Hassan, Effect of primary processing techniques on the microstructure and mechanical properties of nano-Y2O3 reinforced magnesium nanocomposites. Mater. Sci. Eng. A. 528, 5484–5490 (2011). https://doi.org/10.1016/j.msea.2011.03.063

ASTM E8 / E8M-16a: Standard Test Methods for Tension Testing of Metallic Materials

ASTM, E.-09(2018): Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature

ASTM G99 - 17: Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus

G. Gertsberg, E. Aghion, A.A. Kaya, D. Eliezer, Advanced production process and properties of die cast magnesium composites based on AZ91D and SiC. J. Mater. Eng. Perform. 18, 886–892 (2009). https://doi.org/10.1007/s11665-008-9306-5

N. Jit, A.K. Tyagi, N. Singh, A. Singh, Comparison of porosity and density for (A384.1)1−x [(Reinforcement)p]x MMC system using Adaptive Neuro-Fuzzy Inference system. Adv. Appl. Sci. Res. 2, 240–250 (2011)

P. Poddar, V.C. Srivastava, P.K. De, K.L. Sahoo, Processing and mechanical properties of SiC reinforced cast magnesium matrix composites by stir casting process. Mater. Sci. Eng. A. 460–461, 357–364 (2007). https://doi.org/10.1016/j.msea.2007.01.052

M. Malaki, A. Fadaei Tehrani, B. Niroumand, M. Gupta, Wettability in metal matrix composites. Materials (Basel). 11, 1034 (2021). https://doi.org/10.3390/met11071034

Q. Yuan, Z. Qiu, G. Zhou, X. Zeng, L. Luo, X.-X. Rao, Y. Ding, Y. Liu, Interfacial design and strengthening mechanisms of AZ91 alloy reinforced with in-situ reduced graphene oxide. Mater. Charact. 138, 215–228 (2018). https://doi.org/10.1016/j.matchar.2018.02.011

T. Özdemir Öge, M. Öge, V. Murat Yilmaz, F. Banu Özdemir, Effect of B4C addition on the microstructure, hardness and dry-sliding-wear performance of AZ91 composites produced with hot pressing. Mater. Tehnol. 53, 433–440 (2019). https://doi.org/10.17222/mit.2018.127

C. Wang, K. Deng, Y. Bai, Microstructure, and mechanical and wear properties of Grp/AZ91 magnesium matrix composites. Materials (Basel). 12, 1190 (2019). https://doi.org/10.3390/ma12071190

M. Jayamathy, S.V. Kailas, K. Kumar, S. Seshan, T.S. Srivatsan, The compressive deformation and impact response of a magnesium alloy: influence of reinforcement. Mater. Sci. Eng. A. 393, 27–35 (2005). https://doi.org/10.1016/j.msea.2004.09.070

S.F. Hassan, A.M. Al-Qutub, K.S. Tun, M. Gupta, Study of wear mechanisms of a novel magnesium based hybrid nanocomposite. J. Tribol. 137, 011601 (2015) https://doi.org/10.1115/1.4028078

J. Archard, Wear theory and mechanisms, in Wear Control Handbook, ed. by M. Peterson, W. Winer (ASME, New York, 1980), p. 35

H. Torres, M. Varga, K. Adam, M. Rodríguez Ripoll, The role of load on wear mechanisms in high temperature sliding contacts. Wear 364–365, 73–83 (2016). https://doi.org/10.1016/j.wear.2016.06.025

N. Suh, The delamination theory of wear. Wear 25, 111–124 (1973). https://doi.org/10.1016/0043-1648(73)90125-7

H. Chen, A. Alpas, Sliding wear map for the magnesium alloy Mg-9Al-0.9 Zn (AZ91). Wear. 246, 106–116 (2000). https://doi.org/10.1016/S0043-1648(00)00495-6

C.Y. Lim, S. Lim, M. Gupta, Wear behaviour of SiCp-reinforced magnesium matrix composites. Wear 255, 629–637 (2003). https://doi.org/10.1016/S0043-1648(03)00121-2

L. Prasad, N. Kumar, A. Yadav, A. Kumar, V. Kumar, J. Winczek, In situ formation of ZrB2 and its influence on wear and mechanical properties of ADC12 alloy mixed matrix composites. Materials (Basel). 14, 2141 (2021). https://doi.org/10.3390/ma14092141

K.S.A. Ali, V. Mohanavel, S.A. Vendan, M. Ravichandran, A. Yadav, M. Gucwa, J. Winczek, Mechanical and microstructural characterization of friction stir welded SiC and B4C reinforced aluminium alloy AA6061 metal matrix composites. Materials (Basel). 14, 3110 (2021). https://doi.org/10.3390/ma14113110

Acknowledgements

CSIR-CSMCRI PRIS number for this manuscript is 232/2021.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

A.K., S.K., N.K.M, A.Y., D.K.S. contributed to conceptualization, methodology, data curation, writing—original draft, visualization, investigation, writing—review and editing.

Corresponding authors

Ethics declarations

Conflicts of Interest

The authors declare that they have no conflict of interest. The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Consent for Publication

We here give our consent to publish the paper in this journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, A., Kumar, S., Mukhopadhyay, N.K. et al. Effect of TiC Reinforcement on Mechanical and Wear Properties of AZ91 Matrix Composites. Inter Metalcast 16, 2128–2143 (2022). https://doi.org/10.1007/s40962-021-00747-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00747-9