Abstract

In mining, due to the high environmental responsibility and the high load supported, the geomembrane-soil interface must guarantee parameters (such as friction angle and adhesion) that contribute to the stability of the barrier system. The use of a textured High-Density Polyethene (HDPE) geomembrane, known as a structured geomembrane, guarantees uniformity in asperity height due to the manufacturing process (flat-die). The present work presents the results of direct shear tests of the geomembrane-soil interface carried out for the liner project of a mining company, where the processing of bauxite, the primary natural source of aluminum, is carried out. The tests were performed with a textured geomembrane with different asperity heights, and two soil types representative of the site (in saturated and dry conditions). The results showed similar values for peak resistance and residual resistance. No influence of the asperity height on the interface parameters was observed, which suggests the need to evaluate other texture characteristics. The need to perform geomembrane-soil interface tests for any liner project, especially for mining, stands out.

Similar content being viewed by others

Availability of data and material

The data presented in this study are available on request from the corresponding author.

Code availability

Not applicable.

References

Sampaio JA, Andrade MCD, Dutra AJB (2005) Bauxita. In: CETEM/MCT (in Portuguese)

Bogatyrev BA, Zhukov VV (2009) Bauxite provinces of the world. Geol Ore Depos 51(5):339–355

Khairul MA, Zanganeh J, Moghtaderi B (2019) The composition. recycling and utilisation of Bayer red mud. Resour Conserv Recycl 141:483–498

Zhao Y, Wang J, Luan Z, Peng X, Liang Z, Shi L (2009) Removal of phosphate from aqueous solution by red mud using a factorial design. J Hazard Mate 165(1–3):1193–1199

Borra CR, Pontikes Y, Binnemans K, Van Gerven T (2015) Leaching of rare earths from bauxite residue (red mud). Miner Eng 76:20–27

Borra CR, Blanpain B, Pontikes Y, Binnemans K, Van Gerven T (2016) Recovery of rare earths and other valuable metals from bauxite residue (Red mud): a review. J Sustain Metall 2:365–386

Summaries MC (2021) Mineral commodity summaries. US Geological Survey, Reston

Aluminium W (2022) Alumina Production. In: International Aluminium Institute, London

Lyu F, Hu Y, Wang L, Sun W (2021) Dealkalization processes of bauxite residue: a comprehensive review. J Hazard Mater 403:123671

Reddy PS, Reddy NG, Serjun VZ, Mohanty B, Das SK, Reddy KR, Rao BH (2021) Properties and assessment of applications of red mud (bauxite residue): current status and research needs. Waste Biomass Valorization 12(3):1185–1217

Rowe RK (2005) Long-term performance of contaminant barrier systems. Geotechnique 55(9):631–678

Associação Brasileira de Normas Técnicas, ABNT NBR 16199:2020 (2013) Barreiras geossintéticas—Instalação de geomembranas poliméricas; Rio de Janeiro (in Portuguese)

Associação Brasileira de Geossintéticos. Recomendação IGS Brasil 004-2016 (2016) Aplicação de Geossintéticos em Áreas de Disposição de Resíduos. São José dos Campos (in Portuguese)

Lavoie FL, Kobelnik M, Valentin CA, da Silva JL (2020) Durability of HDPE geomembranes: an overview. Quim Nova 43:656–667

Struve F (1994) Extrusion of geomembranes. Proceedings of the 8th GRI Conference. Geosynthetic Resins. Formulation and Manufacturing. In: Hsuan G, Koerner RM (eds) Industrial FabricsAssociation International (IFAI), St Paul, pp 94–112

Scheirs J (2009) A guide to polymeric geomembranes: a practical approach. Wiley, Hoboken

Ewais AMR, Rowe RK (2014) Effects of blown film process on initial properties of HPDE geomembranes of different thicknesses. Geosynth Int 21(1):62–82

Frost JD, Evans TM, Hebeler GL, Giroud JP (2002) Influence of wear mechanisms on geosynthetic interface strengths. In: Proceedings of the Seventh International Conference on Geosynthetics, Nice, France, vol. 4, pp 1325–1328

Hebeler GL, Frost JD, Myers AT (2005) Quantifying hook and loop interaction in textured geomembrane–geotextile systems. Geotext Geomembr 23(1):77–105

Stark TD, Williamson TA, Eid HT (1996) HDPE geomembrane/geotextile interface shear strength. J Geotech Eng 122(3):197–203

Jones DRV, Dixon N (1998) Shear strength properties of geomembrane/geotextile interfaces. Geotext Geomembr 16(1):45–71

Li MH, Gilbert RB (1999) Shear strength of textured geomembrane and nonwoven geotextile interfaces. In: Proceedings of Geosynthetics ’99, vol 1, IFAI, Boston, pp. 505–516

Rigo JM, Rollin AL (1990) Geomembranes-identification and performance testing. CRC Press

O’rourke TD, Druschel SJ, Netravali AN (1990) Shear strength characteristics of sand-polymer interfaces. J Geotech Eng 116(3):451–469

Koerner RM (1998) Design with geosynthetics, 4th edn. Prentice Hall, Hoboken

Sharma HD, Lewis SP (1994) Waste containment systems waste stabilization and landfills: design and evaluation. Wiley, New York

Izgin M, Wasti Y (1998) Geomembrane–sand interface frictional properties as determined by inclined board and shear box tests. Geotext Geomembr 16(4):207–219

Lopes PC, Lopes ML, Lopes MP (2001) Shear behaviour of geosynthetics in the inclined plane test—influence of soil particle size and geosynthetic structure. Geosynth Int 8:327–342

Markou INE, ED, (2018) Shear resistance characteristics of soil–geomembrane interfaces. Int J Geosynth Ground Eng 4(4):1–16

Froble R (2007) Using structured geomembranes in final solid-waste landfill closure designs. Geosynthetics 25(1):12–18

Palmeira EM, Tatsuoka F, Bathurst RJ, Stevenson PE, Zornberg JG (2008) Advances in geosynthetics materials and applications for soil reinforcement and environmental protection works. Electron J Geotech 13:1–38

ABNT NBR 7180 (2016) Soil–plasticity limit dertermination. Brazilian Association of Norms Techniques

ABNT NBR 6459 (2017) Soil–liquid limit determination. Brazilian Association of Norms Techniques.

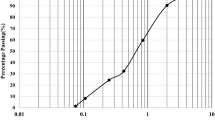

ABNT NBR 7181 (2018) Soil–Grain size analysis. Brazilian Association of Norms Techniques.

ASTM International (2017) ASTM D2487. Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). In: ASTM International, West Conshohocken, Pennsylvania, USA

ABNT NBR 7182 (2020) Soil—compaction test. Brazilian Association of Norms Techniques

Tsuchida H (1970) Prediction and Countermeasure against Liquefaction in Sand Deposits. Abstract of the Seminar of the Port and Harbour Research Institute. Ministry of Transport. Yokosuka, Japan, pp 3.1–3.33 (In Japanese)

GRI - GM13 (2021) Test methods. Test properties and testing frequency for high density polyethylene (HDPE) Smooth and Textured Geomembranes. Geosynthetic Institute

ASTM International (2015) ASTM D7466. Standard Test Method for Measuring Asperity Height of Textured Geomembranes. In: ASTM International. West Conshohocken, Pennsylvania, USA

ASTM International (2021) ASTM D5994. Standard test method for measuring core thickness of textured geomembranes. In: ASTM International. West Conshohocken, Pennsylvania, USA

ASTM International (2018) ASTM D1505. Standard test method for density of plastics by the density-gradient technique. In: ASTM International. West Conshohocken, Pennsylvania, USA

ASTM International (2020) ASTM D792. Standard test methods for density and specific gravity (relative density) of plastics by displacement. In: ASTM International. West Conshohocken, Pennsylvania, USA

ASTM International (2020) ASTM D6693. Standard test method for determining tensile properties of nonreinforced polyethylene and nonreinforced flexible polypropylene geomembranes. In: ASTM International, West Conshohocken, Pennsylvania, USA

ASTM International (2021) ASTM D1004. Standard test method for tear resistance (graves tear) of plastic film and sheeting. In: ASTM International. West Conshohocken, Pennsylvania, USA

ASTM International (2020) ASTM D4833. Standard test method for index puncture resistance of geomembranes and related products. In: ASTM International. West Conshohocken, Pennsylvania, USA

ASTM International (2020) ASTM D4218. Standard test method for determination of carbon black content in polyethylene compounds by the muffle-furnace technique. In: ASTM International. West Conshohocken, Pennsylvania, USA

ASTM International (2021) ASTM D8117. standard test method for oxidative induction time of polyolefin geosynthetics by differential scanning calorimetry. In: ASTM International. West Conshohocken, Pennsylvania, USA

ASTM International (2012) ASTM D5321. Standard test method for determining the shear strength of soil-geosynthetic and geosynthetic-geosynthetic interfaces by direct shear. In: ASTM International. West Conshohocken, Pennsylvania, USA

Acknowledgements

The authors would like to thank the Nortene group for providing the data.

Funding

This research was funded in part (support granted to the second author) by the Brazilian Federal Agency for Support and Evaluation of Graduate Education (Coordenação de Aperfeiçoamento de Pessoal de Nível; CAPES)-Finance Code 001.

Author information

Authors and Affiliations

Contributions

The individual contributions of each author are highlighted as follows: SLdCJ: methodology. data analysis. validation. and writing (original draft); MAA-A: conceptualization. methodology. investigation. and writing (original draft); CFP and JLS: conceptualization. project administration. resources. supervision. methodology. funding acquisition and resources. writing (reviewing and editing).

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Junior, S.L., Aparicio-Ardila, M.A., Palomino, C.F. et al. Analysis of Textured Geomembrane–Soil Interface Strength to Mining Applications. Int. J. of Geosynth. and Ground Eng. 9, 3 (2023). https://doi.org/10.1007/s40891-022-00423-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-022-00423-w