Abstract

Loss minimization in a distribution network is a vital component for enhancing the efficiency and reliability of a power system. Integration of Distributed Generators (DGs) in the existing power system is comparatively an efficient method for loss reduction than other known solutions. Challenges lie in the optimal sizing and placement of distributed generator. Installation of DGs of higher size at non optimal buses leads to higher system losses. In this paper a two stage methodology is proposed for optimal sizing and placement of DGs. At first, the sizing of DGs is done by analytical approach based on exact loss formula for minimum loss at the allied buses. After that Fuzzy expert system (FES) is used for optimal Placement using Distribution Loss Reduction Index (DLRI) and Voltage Deviation Reduction Index (VDRI) as its input parameters. The proposed methodology is tested for a practical distribution system of Tezpur University, India. The results show the effectiveness of the algorithm in terms of the loss reduction and voltage profile improvement of the distribution system.

Similar content being viewed by others

Introduction

Electricity generation in the developing countries is growing at a rapid rate, but a majority of people in these countries are yet without electricity. In addition to inadequate generation of electricity, high transmission and distribution loss is one of the major causes of gap in the supply and demand of electricity. For example, the reported T&D losses in India are around 24%. However most of the developed countries are consuming electricity with less than 10% of T&D losses. Further, distribution losses account for up to 80% of total T&D loss. Therefore the need to reduce distribution losses has drawn global attention in the last decade. Distributed Generation (DG) is one of the most attractive options to solve many such modern power system issues such as high transmission and distribution loss, poor voltage regulation etc [1]. Also there is a requirement for providing economically feasible environment for the integration of distributed resources [2]. An economically feasible design model for sizing and placement of grid-interconnected Distributed Generators based system has to be formulated [3]. Smaller generator units which are equal to or less than 1 or 2 MW and installed in distribution systems are referred to as ‘distributed generation’ (DG) [4]. Distributed generators (DGs) are technically defined as the small scale generation units, which are based either on renewable energy sources (e.g., wind, solar photovoltaic, biomass etc.) or conventional energy sources (e.g., diesel generator, small scale gas engine etc.) and are connected near to the load in the distribution network. The consolidation of smart distribution grids is predictably related with the growth and actual employment of different functionalities proposed for future electric grids that includes DG’s functionalities also [5].

Integration of DGs in the existing power systems has been slowly increasing in the last few years. The increasing integration of renewable power and the transition from a centralized electricity production model to distributed generation would pose many challenges to the reliable and sustainable operation of future power systems [6]. According to an IEEE survey, DG penetration in power sector is expected to reach 32% and 26% in Europe and Asia Pacific regions, respectively over the next five years [7]. Installation of solar photovoltaic (SPV) based DGs in countries like India is a suitable energy option, where solar radiation is available all over the region. Implementation of SPV based DGs in distribution network would result in power loss reduction and improvement of voltage profile. Maintaining voltage stability is vital for an efficient power system operation, as the system losses are directly related to the voltage profile. Running cost of SPV based DGs that may be installed for improving the voltage profile of the distribution network, is quite low. Moreover, SPV generator installation would also provide environmental benefits as it does not cause greenhouse gas emission.

Smart Power Grids incorporates superior abilities envisioned to encounter present and future energy demands. These demands comprise enhanced implementation connected with the concepts of reliability, resiliency, environmentally friendly generation, transmission, and distribution as well as turning consumers into prosumers. A smart power grid also relates the state-of-the-art technologies to optimize the usage of its resources. For instance, optimized size is achievable with dynamic ratings, which permit resources to be expended at larger loads by constantly detecting and evaluating their capacities [2]. Two important aspects in this area of resource optimizations, are (i) Sizing and (ii) Placement of DGs that require attention to ensure reliable supply of electricity at minimum distribution loss. The size of the DG is decided by the load. Location of DGs should be optimally decided as it influences the distribution loss. Thus, the issue of DG Placement and sizing is of great importance. Present investigation has considered these two aspects for analysis.

Various methods have been proposed to find out the optimum size and location of DGs in a distribution network. Genetic Algorithm (GA), Particle Swarm Optimization (PSO), Fuzzy Logic, Tabu search algorithm are some of the popular computational tools that used in such optimization problems [11]. Genetic algorithm (GA) is a search heuristic method which is used to generate useful solutions to optimization and search problems. GA is used for optimal DG placement using different load models and multiple DG placement to evaluate the loss reduction [8, 9]. The energy-cost savings due to loss reduction by DG placement using GA is addressed in [10]. PSO is another technique to find out the optimal size and placement of DG by changing location and varying sizes of DGs [11, 12]. PSO method possesses some disadvantages in terms of regulation of particle velocity and hence sometimes leads to the inaccuracy. Hybrid Differential Evaluation Particle Swarm Optimization (HPSO) and Enhanced multi-objective particle swarm optimization (EMOPSO) are two methods proposed to overcome the disadvantages of PSO [13, 14].

Analytical approach and Fuzzy logic have some advantages over PSO [15] as PSO is computationally demanding and slow in convergence. Analytical approach based on exact loss formula along with loss sensitivity factor method can be effectively used for optimal sizing and placement of DGs [16,17,18]. Fuzzy logic is a popular computational tool for solving the optimization problems targeting capacitor Placement in distribution system to maximize the energy savings and minimize the loss [19, 20]. This logic is also found to be effectively applicable for DGs Placement and is addressed in recent literatures for similar areas [21, 22]. In this research work, analytical method based on “exact loss formula” is used for optimal sizing of DG and then most suitable bus location for DGs is estimated using Fuzzy Expert System. The bus-system considered in this analysis is an actual Existing Practical Distribution Power System of Tezpur University Campus in North Eastern India with original substation data. The factors of optimal Sizing and Placement of DGs have been addressed specifically as per the minimum loss formulae and by a novel algorithm designed by us since, that is the design requirement and critical issues to be addressed for the electrification of a remote rural location like Tezpur town where DG resources are limited along with limited T&D infrastructure, so using the actual Tezpur University bus system is the practical need of the research since, rural electrification is one of the identified objective for the development of smart microgrids [23].

This paper is organized in six sections “Introduction” gives the introduction. Section “Objectives for the Research Problem” comprises of objectives of the research problem along with constraints. Section “Methodology” discusses the analytical method based on “exact loss formula” and Fuzzy Expert system (FES) respectively, for optimal sizing and Placement of DG to reduce the distribution loss. Electrical distribution system of a University located in India with a connected load of 13 MW is considered as case study to investigate the prospect of DG installation. Description of the test system is given in the “Configuration of Test System”. This section is followed by results and discussion in “Results and Discussion”. Finally, recommendations and conclusions are summarized in “Conclusions”.

Objectives for the Research Problem

Proper voltage profile and availability of power supply as per the demand are the main requirements for a reliable distribution system [24]. Distribution system receives the power from the transmission system and delivers it to the end user. Normally the distribution systems are radial in nature because of their simple structure. Distribution system consists of feeders and distributors. The feeder originates from the substation and passes through the consumer load. It is impossible to deliver power from the sending end to the receiving end without any losses. Major losses in the distribution system are I2R losses which are dissipated as heat in the conductor. Placement of distributed generators of proper size at proper place results in the reduction in I2R losses as it can be placed near to the load. Initially, as the size of a distributed generator at a particular bus or location increases, the distribution loss decreases. It reaches a minimum (optimum) value at optimum size of DG and then again increases with further increase in size of DG. Therefore, optimal Placement and sizing of DG is very important, since the installation of DG of any size higher than its optimal size at improper place may result in higher system losses [25].

A Distributed Generator could be of either type, either renewable energy source based (e.g., wind, solar photovoltaic, biomass etc.) or conventional energy source based (e.g., diesel generator, small scale gas engine etc.). Since, in the north-eastern part of India, solar energy is available in abundance, solar photovoltaic (SPV) based DG is an attractive option. Implementation of SPV generator in distribution network would result power loss reduction and improvement of voltage profile along with environmental benefit as it does not cause greenhouse gas emission. Keeping in mind the “Off-Grid & Decentralized Solar Applications” Scheme in the 2nd Phase of the Jawaharlal Nehru National Solar Mission (JNNSM, any discrepancies in the size and placement of PV based DGs would ruin the underlying objective of this mission of developing sustainable solar power to rural areas. Moreover, the cost of SPV power produced is substantially higher than the conventional power, and it in turn depends upon the size of the SPV DG panel installed at an optimum location. Thus an oversized SPV panel placed at non optimal power bus will not only lead to more system loss but will also increase the per unit cost of solar power, making it an unattractive option for distributed generation schemes. Thus, this research work aims at optimizing the size and placement of PV based DGs for sustainable and reliable power supply.

In this paper both sizing and placement issues are considered as objectives as follows,

-

Optimal sizing of DG by considering the distribution loss and voltage deviation at each bus

-

Optimal placement of the DGs in the distribution network

Analytical method is used for optimal sizing of DG and then most suitable location for DG is selected using Fuzzy Expert System.

Methodology

Optimal Sizing of Distributed Generator at Particular Bus

For optimal sizing of the DGs at a particular bus the real power loss and voltage deviation are considered as decision parameters. The real power loss in a distribution system is given by exact loss formula

where,

Vi∠δi is the complex voltage at the i th bus;

rij + jxij = Zij is the ij th element of [Zbus] impedance matrix;

Pi and Pj active power injections at the i th and j th buses, respectively;

Qi and Qj reactive power injections at the i th and j th buses, respectively;

N number of buses

Now, for the occurrence of minimum loss in the system, the derivative of real power loss with respect to real power injection at a particular bus is zero. Hence, \(\frac {\partial P_{loss}}{\partial P_{i}}= 0\)

Here, Pi is the real power injected at ith bus which is the difference between real power generation and real power demand at that particular bus. Therefore,

PDgi is the optimum size of the DG to be installed in the distribution network to minimize the loss.

Placement of Distributed Generator Using Fuzzy Expert System

Fuzzy expert system (FES) uses the fuzzy logic which deals with approximate rather than fixed and exact reasoning. Unlike the classical Boolean set allowing only 0 or 1 value, the fuzzy set is a set with a smooth boundary allowing partial membership. The degree of membership in a set is expressed by a number between 0 and 1, with 0 indicating entirely not in the set, 1 indicating completely in the set and a number in between meaning partially in the set. A fuzzy set can be defined by a function that maps objects in the domain of concern. Such a function is called the membership function. The two most widely used membership functions are the triangular and trapezoidal functions[26].

Figure 1 represents the general approach of FES. Crisp input values are given in Fuzzy interface engine for fuzzification under some predefined rules with a degree of membership function. These rules are developed from qualitative description for reasoning. For two valued input this logic take the IF-THEN form, e.g. X is low AND Y is high Then Z is medium, where, X and Y are input variables and Z is output variables and low, high and medium are membership function. IF is called the antecedent which describes the degree of rule applies, while THEN is called the consequent,assigns a membership function to the output variable.

For optimal placement of Distributed Generator, two input variables are defined as Distribution Loss Reduction Index (DLRI) and Voltage Deviation Reduction Index (VDRI) to get output Distributed Generator Placement Index (DGAI). Mamdani type FES for is used for this work [27]. The FES system for fuzzification of DLRI and VDRI is shown in Fig. 2.

The input variables are defined as,

where, DL(i) is the distribution real power loss when DG is connected to the i th bus

DL(min) is the minimum distribution real power loss when DG is connected to any bus

other than slack bus

DL(base) is the distribution real power loss without DG

and

where, VDI(i) is the voltage deviation index at the i th bus when DG is connected to that bus

VDI(min) is the minimum voltage deviation index when DG is connected to any of the

buses

other than slack bus

VDI(base) is the voltage deviation index without DG

Now, the voltage deviation index (VDI) can be defined as the summation of squares of deviation of voltages from their specified value [14].i.e.

where, Vi is the voltage magnitude at the j th bus,

Vi,,sp is the specified voltage magnitude

After defining the input variables, the input variable DLRI is fuzzified into three trapezoidal membership function within the range 0 to 1 as shown in Fig. 3. The three membership functions of DLRI are High, Medium and Low. The value of 0 indicates largest reduction while value of 1 indicates smallest reduction of distribution power loss.

Similarly, another input variable VDRI is fuzzified into five triangular membership functions and scaled in the range from 0 to 1 as shown in Fig. 4. The five membership functions of VDRI are High, High-Medium, Medium, Low-Medium and Low. The value of 0 indicates better voltage profile whereas value of 1 indicates poor voltage profile of the distribution system.

A set of rules are defined for fuzzification of input variables DLRI and VDRI under the defined membership function shown in Figs. 3 and 4. The output fuzzy variable DGAI is evaluated for each bus from the input variables under these set of rules. The rules are summarized in the Fuzzy decision matrix given in the Table 1.

The output variable DGAI is also fuzzified into five triangular function as shown in the Fig. 5. The membership functions defined for DGAI are High, High-Medium, Medium, Low-Medium and Low. The lowest value of DGAI is most suitable location for DG Placement.

Defuzzification is done to assign crisp value to DGAI to rank the buses in terms of DG placement suitability. There are various methods for defuzzification. Centre of Area (COA) method is used for defuzzification in this case, which is given by,

μs is the membership function of DGAI, which is obtained from the MAX-MIN method of fuzzy logic. It consists of trimming the consequent membership function of each fired rule at the minimum membership value of all the predecessors. A final resultant membership function is realized by taking the combination of all the trimmed consequent membership functions of the fired rules. For the DG Placement problem, resulting DG placement suitability membership function μs of node I for k fired rules is given by,

μd and μv are membership function of input variable of DLRI and VDRI respectively.

Constraints of DG Placement

Optimal sized DG Placement in distribution network using proposed methodology is expected to reduce the losses in distribution network. But it has to satisfy the following constraints. First constraint is the power balance constraint and second one is the DG capacity constraint [28].

-

Power balance constraint: After installation of DG the power in the i th bus is should satisfy the following power balance equation.

where, Pi is the real power at the i th bus

PGi is the real power generation in the i th bus

PDgi is the real power injected from DG ati th bus

PL is the load connected to the i th bus respectively

Only real power is considered here in the power balance.

-

DG capacity constraint: To ensure the reliability every country has DG penetration limit. For India DG penetration factor is considered as 30% and hence second constraint is determined as follows,

Where \({\sum }_{i = 1}^{N} {PL}\) is the total load connected to the distribution network.

The overall methodology for DG sizing and placement using analytical method and Fuzzy expert system is shown in the Flowchart as shown in Fig. 6.

Configuration of Test System

The prospects of DG placement is investigated by selecting a practical distribution network of Tezpur University. Tezpur University is situated in the Napaam village of Sonitpur District, Assam at a distance of 8.4 km from NH 37A. The campus is spread over an area of 135 hectares, out of which 53.69 hectares is the built-up area as shown in Fig. 7. In different disciplines, a total 4000 students pursue their respective courses, among them 3,194 students stay in the campus at different hostels. Besides that 780 staff including family members also live in the Tezpur university campus.

The electrical energy demand of Tezpur University is fulfilled through a 33KV/11 KV power station. It has a connected load of 13.042 MW. Electrical energy is supplied to entire university through a distribution network, consisting of two feeders and distribution transformers. Voltage is stepped down by using 11KV/0.433 KV distribution transformers. It is a six bus system. Diesel Generators are used to deliver power during power outage.

For installation of Distributed Generator of optimal size at optimal place, the knowledge of entire test distribution system is required. The present status of existing distribution network, which includes voltage magnitude, power angle and existing distribution loss can be obtained by performing Load flow study. Estimation of Bus data and line parameters are required for the Load flow study.

Estimation of Bus Data

The bus data, which are essential for load flow study, can be estimated from the knowledge of active and reactive power demand at each bus. For this the data collection exercise was performed at all the departments, hostels and other supportive entities such as administration, engineering cell, institute power house, computer center etc. Following steps are taken for data collection:

-

Personally visit to all the departments and hostels to calculate the total connected load of each building.

-

Data regarding power consumptions of buildings was collected from the main control panel of power supply from the substation.

-

The details of usage of the appliances were collected by surveying.

Estimation of Line Parameters

Line parameters include resistance and reactance of the line connecting the buses. Resistance and reactance of the conductor used can be calculated by using standard formulae of power system. Data required for calculation of resistance and reactance between the buses of the test system includes conductor properties as well as installation practices. Conductor properties include the type of conductor used, resistivity of the material of the conductor, temperature coefficient of the conductor etc. The conductor properties are estimated from the electrical engineering handbook after collecting information about existing conductor installation. Information comprises of existing conductor type along with cross sectional area, spacing between conductors, frequency of operation, axial spacing between two conductors are collected from the substation of Tezpur University.

The resistance and reactance calculated by adopting proposed methodology gives resistance and reactance of the conductor for one kilometer. The actual length of the conductor is required for the estimation of actual line parameters between two buses. Geographic information system (GIS) is used to estimate the distance between two buses and then length of the conductor estimated by considering 5% sag. Finally, line parameters of the TU distribution network are estimated from available data.

Results and Discussion

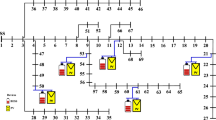

Tezpur University electricity distribution network is selected as the test system to investigate the prospects of DG installation. The distribution system of TU campus is a six bus system containing one slack bus as shown in Fig. 8. The other five buses in the system are PQ buses, where the active power and reactive power demand can be estimated. No PV buses are present in the system as no large generator connected to the system.

For analyzing the prospect of distributed generator in the existing distribution network, load flow study is required to investigate the present status (voltage magnitude and power angle at each bus) of the network. The bus data regarding the active power and reactive power demand at all the buses is estimated by earlier mentioned Load Flow studies and is given as shown in Table 2.

Line parameters include resistance and reactance of the system. Distance between two buses is measured by using Geographic Information System (GIS). The information regarding the conductor installation and properties are collected and finally, resistance and reactance between two buses are estimated using the standard formulae. The estimated line data is shown in the Table 3.

After estimating the required data, Load flow study is performed to determine the voltage magnitude and angle at each bus. The results of load flow analysis is shown in Fig. 9. It indicates that minimum voltage level at bus 6 is 0.8602 p.u., which is due to high voltage drop in the line 3. This voltage drop occurs as a result of high resistance and reactance provided by line 3 (between bus 3 and 6). The minimum voltage level should be within -6% to + 6% according to the Indian electricity rule [29]. Thus, the voltage level at bus 6 violating the prescribed limit which should be within 0.94 p.u. and 1.04 p.u.

The results of load flow analysis is used to estimate the system loss of the test system by using exact loss formula (Eq. 1). The unknown values of constant αij and βijin exact loss formula are calculated by using the voltage magnitude and power angle at each bus. The difference of power angle between two buses is almost zero. Thus, power angle difference does not affect the system loss and hence the system loss completely depends on the voltage magnitude of each bus [30]. The base case system loss is found as 812.5 kW. The estimated system loss in TU distribution network can be reduced by integrating the DG of optimal size. For the TU distribution network, the optimal size of DG is calculated by using Eq. 3 which gives,

-

1)

The projected optimal size of DG at bus 2, bus 4 and bus 6 are 1245.7 kW, 1718.4 kW and 1660 kW respectively.

-

2)

The Bus 3 and 5 are lightly loaded and hence the need of DG interconnection at these buses does not exist.

Optimal site selection of DG for its optimal placement in distribution network is very essential for better system planning. Installation of DG at improper location cause higher system losses. Fuzzy Expert System (FES) is used for optimal placement of distributed generator. After calculating the DG size, two variables Distribution loss reduction index (DLRI) and Voltage Deviation Reduction Index (VDRI) are calculated for each of the buses using Eqs. 4 and 5. Figure 10 shows the optimal DG sizes for buses 2, 4 and 6.

The values of DLRI and VDRI are used in the proposed FES to obtain Distributed Generator Placement Index (DGAI). The minimum value of DGAI is the most suitable position for DG Placement. Ranking is given to the buses as given in Table 4, in terms of DGAI value to identify the suitable location for DG installation. Bus 6 is found as the most suitable location for DG placement.

The effect of distribution loss as a result of DG placement is investigated by placing the DG of optimum size at the respective buses. The distribution loss reduction is estimated for both single DG placement at one bus and combination of DG placement at multiple buses. From Table 5, it is seen that single DG placement at most suitable position obtained from FES gives maximum reduction of loss. About 25 % of loss reduces due to placement of DG of optimum size at bus 6, which is ranked 1 from FES. Similarly, for DG placement at multiple buses; installation of DG at the best and second best location gives maximum loss reduction (about 45%). Table 6 shows the effect on real power loss due to DG placement at multiple buses.

In addition to the system loss, the voltage deviation between the sending end and receiving end in a distribution network is one of the major problems faced by the consumers. Distribution loss increases with the increase in voltage deviation and effect the system reliability. Optimal sizing and placement of DG in distribution network also results, improvement in voltage profile and hence it enhances the reliability of the entire distribution network. Figure 11 shows the voltage profile after DG placement at multiple buses. The minimum voltage which is 0.8602 p.u. for bus 6, increases to 0.9424 p.u. and satisfying the voltage limit.

Along with these technical benefits DG integration reduces the energy import from transmission system and supports the financial returns of the distribution system. It also opens the scope for renewable energy penetration in conventional power system. Thus, DG integration in a distribution network is a viable option for loss reduction and enhancing the power system efficiency.

Conclusions

The present study aims to develop a methodology for integrating Distributed Generator of optimal size at optimal place in any existing electrical distribution network. Methodology comprises of fundamental laws of electricity and optimization techniques including Fuzzy logic. This is also applicable for deciding the parameters of any new electrical network. For a given electrical distribution network the size and placement of DG governs the performance of electricity supply (distribution loss, voltage profile). The application of analytical method integrated with Fuzzy expert system (FES) enables to determine optimal size and optimal location of potential DG. The prospect of distributed renewable energy sources like SPV, wind, biomass have been prime consideration. The methodology for selection of optimal size and optimal location of DG is expected to be useful for deciding the location and sizes of DG for microgrids and off-grid –cum-decentralized power systems. The proposed method is tested on a practical electrical distribution network by considering power loss minimization and voltage profile improvement as decision parameters. The results of the study indicates the effectiveness of the proposed methodology in optimal sizing and placement of DGs based on better voltage profile and loss reduction in the tested system.

The future-research-work would be based on optimizing the size and location of DGs for a better steady state voltage stability index using modified teaching–learning based optimization algorithm and Genetic Algorithm bases Particle Swarm optimization (GAPSO) and compare the results of the two since, previously these techniques have not been widely researched for the same purpose and they overcome the disadvantage of a regular PSO algorithm when applied for sizing and placement of DGs.

References

Wang Z, Chen B, Wang J, Begovic MM (2015) Stochastic DG placement for conservation voltage reduction based on multiple replications procedure. IEEE Trans Power Delivery 30(3):1039–1047

Wang Z, Chen B, Wang J, Kim J, Begovic MM (2014) Robust optimization based optimal DG placement in microgrids. IEEE Trans Smart Grid 5(5):2173–2182

Katina PF, Keating CB, Zio E, Gheorghe AV (2016) A criticality-based approach for the analysis of smart grids. Technology and Economics of Smart Grids and Sustainable Energy 1 (1):14. https://doi.org/10.1007/s40866-016-0013-2

Ettehadi M, Ghasemi H, Vaez-Zadeh S (2013) Voltage Stability-Based DG placement in distribution networks. IEEE Trans Power Delivery 28(1):171–178

Tiwari P, Manas M et al. (2017) A Techno-Economic analysis of microgrids with hybrid renewable energy sources development in South-Asian perspective. Technology and Economics of Smart Grids and Sustainable Energy, Springer Inc. 2 (10):1–16. https://doi.org/10.1007/s40866-017-0026-5

Ameli A, Bahrami S, Khazaeli F, Haghifam MR (2014) A multiobjective particle swarm optimization for sizing and placement of DGs from DG owner’s and distribution company’s viewpoints. IEEE Trans Power Delivery 29(4):1831–1840

Saharia BJ, Manas M, Talukdar BK (2016) Comparative evaluation of photovoltaic mpp trackers: a simulated approach. In: Cogent engineering journal (SCOPUS Indexed), vol 3. Taylor and Francis Inc., Milton Park, pp 1–17. https://doi.org/10.1080/23311916.2015.1137206

Degef MZ, Humayun M, Safdarian A, Koivisto M, Millar RJ, Lehtonen M (2014) Unlocking distribution network capacity through real-time thermal rating for high penetration of DGs. Electr Power Syst Res 117:36–46

Gouveia C, Rua D, Soares FJ, Moreira C, Matos PG, Peças Lopes JA (2015) Development and implementation of Portuguese smart distribution system. Electr Power Syst Res 120:150–162

Zaheeruddin, Manas M (2015) Renewable energy management through microgrid central controller design: an approach to integrate solar, wind and biomass with battery. Energy Reports, Elsevier Inc., (SCI) 1:156–163. https://doi.org/10.1016/j.egyr.2015.06.00

Abookazemi K, Hassan MY, Majid MS (2010) A review on optimal placement methods of distribution generation sources. In: 2010 IEEE international conference on power and energy, Kuala Lumpur, pp 712–716. https://doi.org/10.1109/PECON.2010.5697672

Sattianadan D, Sudhakaran M, Dash SS, Vijayakumar K (2012) Power loss minimization by the placement of DG in distribution system using GA. Swarm, Evolutionary, and Memetic Computing Lecture Notes in Computer Science 767:259–266

Patnaik B, Sattianadan D, Sudhakaran M, Dash SS (2015) Optimal placement and sizing of solar and wind based DGs in distribution systems for power loss minimization and economic operation. Power Electronics and Renewable Energy Systems 326:351–360

Sheng W, Liu K, Liu Y, Meng X (2015) Optimal placement and sizing of distributed generation via an improved non-dominated sorting genetic algorithm II. IEEE Trans Power Delivery 30(2):569–578

Amanifar O (2011) Optimal distributed generation placement and sizing for loss and THD reduction and voltage profile improvement in distribution systems using particle swarm optimization and sensitivity analysis. In: IEEE 16th conference on electrical power distribution networks (EPDC)

Cheng S, Chen M, Wai R, Wang F (2014) Optimal placement of distributed generation units in distribution systems via an enhanced multi-objective particle swarm optimization algorithm. J Zhejiang Univ Sci C 15(4):300–311

Nagireddy, Kumar DV, Reddy K (2014) Optimal placement and sizing of multiple distributed generation using combined differential evaluation - HPSO method. International Journal of Engineering and Advanced Technology 4 (1):57–62

Zaheeruddin, Manas M (2015) Analysis of design of technologies, tariff structures and regulatory policies for sustainable growth of the Smart grid. Taylor and Franci’s Energy Technology and Policy Journal 2(1):28–38. https://doi.org/10.1080/23317000.2015.1015083

Acharya N, Mahat P, Mithulananthan N (2006) An analytical approach for DG placement in primary distribution network. Electr Power Energy Syst 28(10):669–678

Hosseini RK, Kazemzadeh R (2011) Optimal DG placement by extending an analytical method to minimize loss in radial distribution systems. In: 19th Iranian conference electrical engineering (ICEE), pp 278–286

Saharia BJ, Manas M, Talukdar BK (2016) Comparative evaluation of photovoltaic MPP trackers: a simulated approach. In: Cogent engineering journal (SCOPUS Indexed), vol 3. Taylor and Francis Inc., Milton Park, pp 1–17. https://doi.org/10.1080/23311916.2015.1137206

Hung DC, Mithulananthan N, Bansal R (2010) Analytical expressions for DG placement in primary distribution networks. IEEE Trans Energy Convers 25(3):814–820

Manas M (2015) Development of preferential regulations, transmission tariffs, and critical technological components for the promotion of smart grid globally. Economics and Policy of Energy and the Environment, Franco Angeli Inc.(SCI Indexed) 75(2):107–130. https://doi.org/10.3280/EFE2015-002008

Prasanna. HA, Kumar MV, Ananthapadmanabha T, Kulkarni AD (2014) Fuzzy-Expert system based optimal capacitor placement in distribution system. International Journal Of Electrical Engineering & Technology (IJEET) 5 (1):86–99

Jamil M, Kirmani S (2012) Optimal placement of SPV based DG system for loss reduction and voltage improvement in radial distribution systems using approximate reasoning. In: 5th India international conference on power electronics (IICPE). IEEE, Piscataway

Lalitha A, Prasad P, Sivanagaraju S (2010) Application of fuzzy and PSO for DG placement for minimum loss in radial distribution system. ARPN J Eng Appl Sci 5(4):30–37

Saharia B, Manas M (2017) Viability analysis of Photovoltaic/Wind hybrid standalone distributed generation based system as applicable in isolated community of north-east region of India. Distributed Generation and Alternative Energy Journal, SCI Taylor and Francis Inc. 32(1):49–80

Hung DQ, Mithulananthan N (2013) Multiple distributed generator placement in primary distribution networks for loss reduction. IEEE Trans Ind Electron 60(4):1700–1708

Electrical Estimation and Energy auditing, http://www.ustudy.in/eee/eest, accessed on 30-09-2014

Ng H, Salama MM, Chikhani A (2000) Capacitor placement by Approximate Reasoning: Fuzzy Capacitor Placement. IEEE Trans Power Delivery 15(1):393–398

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Manas, M., Saikia, B.J. & Baruah, D.C. Optimal Distributed Generator Sizing and Placement by Analytical Method and Fuzzy Expert System: a Case Study in Tezpur University, India. Technol Econ Smart Grids Sustain Energy 3, 1 (2018). https://doi.org/10.1007/s40866-018-0038-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40866-018-0038-9