Abstract

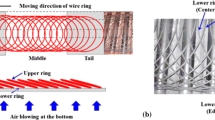

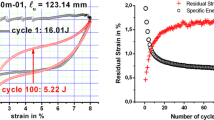

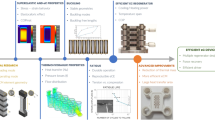

There is an urgent need to develop an alternative high-efficiency cooling technology that is affordable and environmentally friendly. Elastocaloric effect has attracted particular attention due to large available latent heat and large adiabatic temperature changes. The primary objective of this study is to control the deformation of NiTi solid-state cooling refrigerator simples rapidly and accurately. In the present study, coil specimens made of a pseudoelastic Ni50.8–Ti49.2 (at%) NiTi wires are utilized and elastocaloric effect behavior were studied by evaluating the temperature profiles and the tensile force characteristics during uncoiling-coiling cycle tests conducted at ambient conditions. The measured non-adiabatic temperature changes along the tested NiTi coiled wires varied with the test speed. A maximum temperature change of 13.5 °C was obtained for a speed of 1.2 mm s−1. The uncoiling-coiling test showed to be a suitable method for studying the elastocaloric effect and the mechanical behavior of NiTi alloys. From a practical point of view, pseudoelastic NiTi coiled wire can provide a NiTi wire high strain rate locally, and meanwhile provide a time long enough for heat transferring between active material and heat flow medium.

Similar content being viewed by others

References

Cavallini A, Zilio C (2007) Carbon dioxide as a natural refrigerant. Int J Low Carbon Tec 2(3):225–249

Scott JF (2010) Electrocaloric materials. Annu Rev Mater Sci 41(1):229–240

Tishin AM, Spichkin YI (2014) Recent progress in magnetocaloric effect: mechanisms and potential applications. Int J Refrig 37:223–229

Gómez RJ, Garcia FR, Catoira MA, Gómez RM (2013) Magnetocaloric effect: a review of the thermodynamic cycles in magnetic refrigeration. Renew Sust Energ Rev 17(1):74–82

Tuek J, Engelbrecht K, Millán-Solsona R, Maosa L, Vives E, Mikkelsen LP, Pryds N (2015) The elastocaloric effect: a way to cool efficiently. Adv Energy Mater 5(13):1500361

Liu YF, Shen Q, Wei ZY, Sun W, Liu J (2020) Enhanced barocaloric effect for Pd–In–Fe shape memory alloys with hydrostatic-pressure training. J Appl Phys 127(5):055109

Wu Y, Ertekin E, Sehitoglu H (2017) Elastocaloric cooling capacity of shape memory alloys: role of deformation temperatures, mechanical cycling, stress hysteresis and inhomogeneity of transformation. Acta Mater 135(15):158–176

Chauhan A, Patel S, Vaish R, Bowen CR (2015) A review and analysis of the elasto-caloric effect for solid-state refrigeration devices: challenges and opportunities. MRS Energ Sust 2:E16

Otubo J, Rigo OD, Coelho AA, Neto CM, Mei PR (2008) The influence of carbon and oxygen content on the martensitic transformation temperatures and enthalpies of NiTi shape memory alloy. Mater Sci Eng A 481(1):639–642

Frenzel J, Wieczorek A, Opahle I, Maaß B, Drautz R, Eggeler G (2015) On the effect of alloy composition on martensite start temperatures and latent heats in Ni–Ti-based shape memory alloys. Acta Mater 90(Suppl 16):213–231

Pieczyska EA, Gadaj SP, Nowacki WK, Tobushi H (2006) Phase-transformation fronts evolution for stress- and strain-controlled tension tests in TiNi shape memory alloy. Exp Mech 46(4):531–542

Schmidt M, Schütze A, Seelecke S (2016) Elastocaloric cooling processes: the influence of material strain and strain rate on efficiency and temperature span. APL Mater 4(6):064107

Pataky GJ, Ertekin E, Sehitoglu H (2015) Elastocaloric cooling potential of NiTi, Ni2FeGa, and CoNiAl. Acta Mater 96:420–427

Porenta L, Kabirifar P, Žerovnik A, Cebron M, Žužek B, Dolenec M, Brojan M, Tušek J (2020) Thin-walled Ni-Ti tubes under compression: ideal candidates for efficient and fatigue-resistant elastocaloric cooling. Appl Maters Today 20:100712

Buehler WJ, Gilfrich JV, Wiley RC (1963) Effect of low-temperature phase changes on the mechanical properties of alloys near composition TiNi. J Appl Phys 34(5):1475

Kauffman GB, Mayo I (1997) The story of Nitinol: the serendipitous discovery of the memory metal and its applications. Chem Edu 2(2):1–21

Qian S, Geng Y, Yi W, Muehlbauer J, Ling J, Hwang Y, Radermacher R, Takeuchi I (2016) Design of a hydraulically driven compressive elastocaloric cooling system. Hvac R Research 22(5):500–506

Ossmer H, Chluba C, Gueltig M, Quandt E, Kohl M (2015) Local evolution of the elastocaloric effect in TiNi-based films. Shape Mem Superelast 1(2):142–152

Miyazaki S, Imai T, Igo Y, Otsuka K (1986) Effect of cyclic deformation on the pseudoelasticity characteristics of Ti-Ni alloys. Metall Trans A 17(1):115–120

Wu Y, Patriarca L, Sehitoglu H, Chumlyakov Y (2016) Ultrahigh tensile transformation strains in new Ni50.5Ti36.2Hf13.3 shape memory alloy. Scripta Mater 118:51–54

Ossmer H, Lambrecht F, Gültig M, Chluba C, Quandt E, Kohl M (2014) Evolution of temperature profiles in TiNi films for elastocaloric cooling. Acta Mater 81:9–20

Zhao XK, Wang W, Chen L, Liu JF (2011) Martensitic transformation behaviour of non-equilibrium heat treated Ni509Ti491 alloys. Mater Sci Technol 27(1):437–439

Hou H, Simsek E, Stasak D, Al Hasan N, Qian S, Ott R, Cui J, Takeuchi I (2017) Elastocaloric cooling of additive manufactured shape memory alloys with large latent heat. J Phys D 50(40):404001

Tusek J, Engelbrecht K, Eriksen D, DallOlio S, Tusek J, Pryds N (2016) A regenerative elastocaloric heat pump. Nat Energy 1(10):16134

Takeuchi I, Sandeman K (2015) Solid-state cooling with caloric materials. Phys Today 68(12):48–54

Humbeeck JV (2010) Shape memory alloys: a material and a technology. Adv Eng Mater 3(11):837–850

Cui J, Wu Y, Muehlbauer J, Hwang Y, Radermacher R, Fackler S, Wuttig M, Takeuchi I (2012) Demonstration of high efficiency elastocaloric cooling with large ΔT using NiTi wires. Appl Phys Lett 101(7):073904

Sehitoglu H, Wu Y, Ertekin E (2017) Elastocaloric effects in the extreme. Scripta Mater 148:122–126

Acknowledgements

This work was supported by (a) Key-Area Research and Development Program of Guangdong Province (2019B90907002) and (b) Scientific and Technological Innovation Foundation of Shunde Graduate School, USTB (BK19BE026).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

All authors equally contributed to this work. The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, X., Neves, F. & Correia, J.B. Elastocaloric Performance of Pseudoelastic NiTi Coiled Wires. Shap. Mem. Superelasticity 7, 101–108 (2021). https://doi.org/10.1007/s40830-021-00310-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-021-00310-9