Abstract

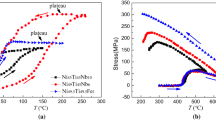

The martensite stabilization effect was studied in Ni − 50.0 at% Ti alloy after cooling under stress and compared to the same observed effect after deformation in the martensite state. After cooling under stress, three peaks of heat release were observed during the first heating, and an increase in the residual strain significantly increased the temperature of the third peak. The existence of three peaks was attributed to the formation of both non-oriented and oriented martensite upon cooling under stress. The way of the preliminary deformation hardly affected the shift in the finish temperature of the reverse transformation. Thus, the reason for the martensite stabilization effect did not depend on the type of deformation. It was assumed that the damaged intermartensite interfaces, which formed when the oriented martensite plates touched each other during growth, lost their mobility and overheating was needed to provide their movement upon subsequent heating. It was found that the way of the preliminary deformation influenced the martensite stabilization effect for the start temperature of the reverse transformation. It was assumed that this effect might be caused by different variations in the stored elastic energy during the active deformation in martensite or on cooling under stress.

Similar content being viewed by others

References

Razov AI (2004) Application of titanium nickelide-based alloys in engineering. Phys Met Metal 97:97–126

Jani JM, Leary M, Subic A, Gibson MA (2014) A review of shape memory alloy research, applications and opportunities. Mater Des 56:1078–1113

Kim Y, Jang T, Gurung H, Mansour NA, Ryu B, Shin B (2019) Bidirectional rotating actuators using shape memory alloy wires. Sens Actuators A 295:512–522

Otsuka K, Ren X (2005) Physical metallurgy of Ti–Ni-based shape memory alloys. Progress Mater Sci 50:511–678

Frenzel J, George EP, Dlouhy A, Somsen Ch, Wagner MF-X, Eggeler G (2010) Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater 58:3444–3458

Miller DA, Lagoudas DC (2000) Thermomechanical characterization of NiTiCu and NiTi SMA actuators: influence of plastic strains. Smart Mater Struct 9:640–652

Belyaev SP, Resnina NN, Volkov AE (2006) Influence of irreversible plastic deformation on the martensitic transformation and shape memory effect in TiNi alloy. Mater Sci Eng A 438–440:627–629

Lin HC, Wu SK, Chou TS, Kao HP (1991) The effects of cold rolling on the martensitic transformation of an equiatomic TiNi alloy. Acta Metal Mater 39:2069–2080

Piao M, Otsuka K, Miyazaki S, Horikawa H (1993) Mechanisms of the As temperature increase by pre-deformation in thermoelastic alloys. Mater Trans JIM 34:919–929

Liu Y, Favier D (2000) Stabilisation of martensite due to shear deformation via variant reorientation in polycrystalline NiTi. Acta Mater 48:3489–3499

Liu Y, Tan GS (2000) Effect of deformation by stress-induced martensitic transformation on the transformation behaviour of NiTi. Intermetallics 8:67–75

Tan G, Liu Y (2004) Comparative study of deformation-induced martensite stabilisation via martensite reorientation and stress-induced martensitic transformation in NiTi. Intermetallics 12:373–381

Liu Y (2004) Mechanistic simulation of deformation-induced martensite stabilisation. Mater Sci Eng A 378:459–464

Liu Y, Tan G, Miyazaki S (2006) Deformation-induced martensite stabilisation in [100] single-crystalline Ni–Ti. Mater Sci Eng A 438–440:612–616

Mahmud AS, Yang H, Tee S, Rio G, Liu Y (2008) Effect of annealing on deformation-induced martensite stabilisation of NiTi. Intermetallics 16:209–214

Kato H, Yasuda Y, Sasaki K (2011) Thermodynamic assessment of the stabilisation effect in deformed shape memory alloy martensite. Acta Mater 59:3955–3964

Yan X, Van Humbeeck J (2012) Effect of annealing on martensite stabilisation due to deformation via cooling under stress in cold-worked NiTi thin wire. Mater Sci Eng A 558:737–741

Belyaev S, Resnina N, Iaparova E, Ivanova A, Rakhimov T, Andreev V (2019) Influence of chemical composition of NiTi alloy on the martensite stabilisation effect. J Alloys Compd 787:1365–1371

Belyaev S, Resnina N, Rakhimov T, Andreev V (2020) Martensite stabilisation effect in Ni-rich NiTi shape memory alloy with different structure and martensitic transformations. Sens Actuators A 305:111911

Resnina N, Belyaev S (2009) Multi-stage martensitic transformations induced by repeated thermal cycling of equiatomic TiNi alloy. J Alloys Compd 486:304–308

Sibirev A, Belyaev S, Resnina N (2013) Unusual multistage martensitic transformation in TiNi shape memory alloy after thermal cycling. Mater Sci Forum 738–739:372–376

Laplanche G, Birk T, Schneider S, Frenzel J, Eggeler G (2017) Effect of temperature and texture on the reorientation of martensite variants in NiTi shape memory alloys. Acta Mater 127:143–152

Acknowledgements

This work was supported by Russian Science Foundation (Grant Number 18-19-00226). X-ray study was carried out using the equipment of X-ray Diffraction Centre, Saint-Petersburg State University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special issue of Shape Memory and Superelasticity to honor Prof. Dr.-Ing. Gunther Eggeler. This special issue was organized by Prof. Hüseyin Sehitoglu, University of Illinois at Urbana-Champaign, and Prof. Dr.-Ing. Hans Jürgen Maier, Leibniz Universität Hannover.

Rights and permissions

About this article

Cite this article

Belyaev, S., Resnina, N., Ivanova, A. et al. Martensite Stabilization Effect in the Ni50Ti50 Alloy After Preliminary Deformation by Cooling Under Constant Stress. Shap. Mem. Superelasticity 6, 223–231 (2020). https://doi.org/10.1007/s40830-020-00282-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-020-00282-2