Abstract

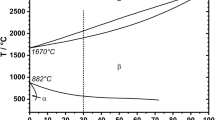

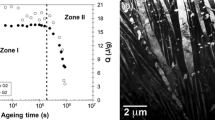

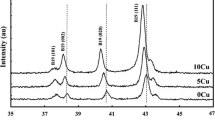

Due to their ability to provide a shape memory effect at elevated temperatures, high-temperature shape memory alloys (HT-SMAs) came into focus of academia and industry in the last decades. Ternary and quaternary Ni–Ti-based HT-SMAs have been in focus of a large number of studies so far. Ti–Ta HT-SMAs feature attractive shape memory properties along with significantly higher ductility and lower costs for alloying elements compared to conventional Ni–Ti-based HT-SMAs, which qualifies them as promising candidate alloys for high-temperature applications. Unfortunately, precipitation of undesired phases, e.g., the ω-phase, leads to significant functional degradation upon cyclic loading in binary Ti–Ta. Therefore, additions of ternary elements, such as Al, which suppress the ω-phase formation, are important. In the present study, the influence of different heating–cooling rates on the cyclic functional properties of a Ti–20Ta–5Al HT-SMA is investigated. Transmission electron microscopy as well as in situ synchrotron analysis revealed unexpected degradation mechanisms in the novel alloy studied. Elementary microstructural mechanisms leading to a degradation of the functional properties were identified, and the ramifications with respect to application of Ti–Ta–Al HT-SMAs are discussed.

Similar content being viewed by others

References

Otsuka K (1999) Shape memory materials. Cambridge Univ. Press, Cambridge

Lagoudas DC (2011) Shape memory alloys: modeling and engineering applications. Springer, New York

Gall K, Sehitoglu H, Chumlyakov YI, Kireeva IV (1999) Tension–compression asymmetry of the stress–strain response in aged single crystal and polycrystalline NiTi. Acta Mater 47:1203–1217

Gall K, Maier HJ (2002) Cyclic deformation mechanisms in precipitated NiTi shape memory alloys. Acta Mater 50:4643–4657

Dasgupta R (2014) A look into Cu-based shape memory alloys: present scenario and future prospects. J Mater Res 29:1681–1698

Morgan NB (2004) Medical shape memory alloy applications—the market and its products. Mater Sci Eng 378:16–23

Ma J, Karaman I, Noebe RD (2013) High temperature shape memory alloys. Int Mater Rev 55:257–315

Miyazaki S, Imai T, Igo Y, Otsuka K (1986) Effect of cyclic deformation on the pseudoelasticity characteristics of Ti-Ni alloys. Metall Trans A 17:115–120

Otsuka K, Ren X (2005) Physical metallurgy of Ti–Ni-based shape memory alloys. Prog Mater Sci 50:511–678

Belbasi M, Salehi MT, Mousavi SAAA, Ebrahimi SM (2013) A study on the mechanical behavior and microstructure of NiTiHf shape memory alloy under hot deformation. Mater Sci Eng 560:96–102

Atli KC, Karaman I, Noebe RD, Bigelow G, Gaydosh D (2015) Work production using the two-way shape memory effect in NiTi and a Ni-rich NiTiHf high-temperature shape memory alloy. Smart Mater Struct 24:125023

Sehitoglu H, Wu Y, Patriarca L (2017) Shape memory functionality under multi-cycles in NiTiHf. Scripta Mater 129:11–15

Sehitoglu H, Patriarca L, Wu Y (2017) Shape memory strains and temperatures in the extreme. Curr Opin Solid State Mater Sci 21:113–120

Buenconsejo PJS, Kim HY, Hosoda H, Miyazaki S (2009) Shape memory behavior of Ti–Ta and its potential as a high-temperature shape memory alloy. Acta Mater 57:1068–1077

Buenconsejo PJS, Kim HY, Miyazaki S (2009) Effect of ternary alloying elements on the shape memory behavior of Ti–Ta alloys. Acta Mater 57:2509–2515

Buenconsejo PJS, Kim HY, Miyazaki S (2011) Novel β-TiTaAl alloys with excellent cold workability and a stable high-temperature shape memory effect. Scripta Mater 64:1114–1117

Kim HY, Fukushima T, Buenconsejo PJS, Nam T-H, Miyazaki S (2011) Martensitic transformation and shape memory properties of Ti–Ta–Sn high temperature shape memory alloys. Mater Sci Eng 528:7238–7246

Niendorf T, Krooß P, Batyrsina E, Paulsen A, Frenzel J, Eggeler G, Maier HJ (2014) On the functional degradation of binary titanium–tantalum high-temperature shape memory alloys—A new concept for fatigue life extension. Funct Mater Lett 07:1450042

Niendorf T, Krooß P, Batyrsina E, Paulsen A, Motemani Y, Ludwig A, Buenconsejo P, Frenzel J, Eggeler G, Maier HJ (2015) Functional and structural fatigue of titanium tantalum high temperature shape memory alloys (HT SMAs). Mater Sci Eng 620:359–366

Niendorf T, Krooß P, Somsen C, Rynko R, Paulsen A, Batyrshina E, Frenzel J, Eggeler G, Maier HJ (2015) Cyclic degradation of titanium–tantalum high-temperature shape memory alloys—the role of dislocation activity and chemical decomposition. Funct Mater Lett 08:1550062

Maier HJ, Karsten E, Paulsen A, Langenkämper D, Decker P, Frenzel J, Somsen C, Ludwig A, Eggeler G, Niendorf T (2017) Microstructural evolution and functional fatigue of a Ti–25Ta high-temperature shape memory alloy. J Mater Res 32:4287–4295

Zhang J, Rynko R, Frenzel J, Somsen C, Eggeler G (2013) Ingot metallurgy and microstructural characterization of Ti–Ta alloys. J Mater Res 104:1–12

Rynko R, Marquardt A, Paulsen A, Frenzel J, Somsen C, Eggeler G (2015) Microstructural evolution in a Ti–Ta high-temperature shape memory alloy during creep. J Mater Res 4:331–341

Ferrari A, Paulsen A, Frenzel J, Rogal J, Eggeler G, Drautz R (2018) Unusual composition dependence of transformation temperatures in Ti-Ta-X shape memory alloys. Phys Rev Mater 2:593

Dippel A-C, Liermann H-P, Delitz JT, Walter P, Schulte-Schrepping H, Seeck OH, Franz H (2015) Beamline P02.1 at PETRA III for high-resolution and high-energy powder diffraction. J Synchrotron Radiat 22:675–687

Kadletz PM, Krooß P, Chumlyakov YI, Gutmann MJ, Schmahl WW, Maier HJ, Niendorf T (2015) Martensite stabilization in shape memory alloys—Experimental evidence for short-range ordering. Mater Lett 159:16–19

Niendorf T, Krooß P, Somsen C, Eggeler G, Chumlyakov YI, Maier HJ (2015) Martensite aging: avenue to new high temperature shape memory alloys. Acta Mater 89:298–304

Krooß P, Kadletz PM, Somsen C, Gutmann MJ, Chumlyakov YI, Schmahl WW, Maier HJ, Niendorf T (2016) Cyclic degradation of Co49Ni21Ga30 high-temperature shape memory alloy: on the roles of dislocation activity and chemical order. Shape Mem Superelast 2:37–49

Miyazaki S, Igo Y, Otsuka K (1986) Effect of thermal cycling on the transformation temperatures of Ti–Ni alloys. Acta Metall 34:2045–2051

Grossmann C, Frenzel J, Sampath V, Depka T, Eggeler G (2009) Elementary transformation and deformation processes and the cyclic stability of NiTi and NiTiCu shape memory spring actuators. Metall Mater Trans A 40:2530–2544

Settefrati A, Aeby-Gautier E, Dehmas M, Geandier G, Appolaire B, Audion S, Delfosse J (2011) Precipitation in a near beta titanium alloy on ageing: influence of heating rate and chemical composition of the beta-metastable phase. Solid State Phenom 172–174:760–765

Acknowledgements

Financial support by the German Research Foundation (DFG) within the Research Unit Program “Hochtemperatur-Formgedächtnislegierungen” (Project Number 200999873; Contract Nos. FR2675/3-2; NI1327/3-2; MA1175/34-2; SCHM 930/13-2; SO505/2-2 and EG101/22-2) is gratefully acknowledged. DESY (Hamburg, Germany), a member of the Helmholtz Association HGF, is thanked for the provision of experimental facilities. Parts of this research were carried out at PETRA III. Jozef Bednarcik is thanked for assistance in using the photon beamline P02.1 and the support laboratory.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krooß, P., Lauhoff, C., Langenkämper, D. et al. Impact of Heating–Cooling Rates on the Functional Properties of Ti–20Ta–5Al High-Temperature Shape Memory Alloys. Shap. Mem. Superelasticity 5, 95–105 (2019). https://doi.org/10.1007/s40830-019-00207-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-019-00207-8