Abstract

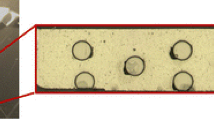

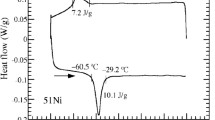

In an effort to further develop shape memory alloys (SMAs) for functional applications, much focus has been given in recent years to design and create innovative forms of SMAs, such as functionally graded SMAs, architecture SMAs, and SMA-based metallic composites. This paper reports on the progress in creating NiTi-based composites of exceptional properties stimulated by the recent discovery of the principle of lattice strain matching between the SMA matrix and superelastic nanoinclusions embedded in the matrix. Based on this principle, different SMA–metal composites have been designed to achieve extraordinary shape memory performances, such as complete pseudoelastic behavior at as low as 77 K and stress plateau as high as 1600 MPa, and exceptional mechanical properties, such as tensile strength as high as 2000 MPa and Young’s modulus as low as 28 GPa. Details are given for a NiTi–W micro-fiber composite prepared by melt infiltration, hot pressing, forging, and cold rolling. The composite contained 63% in volume of W micro-fibers of ~0.6 μm thickness. In situ synchrotron X-ray diffraction revealed that the NiTi matrix underwent martensite transformation during tensile deformation while the W micro-fiber deformed elastically with a maximum strain of 0.83% in the loading direction, implying a W fiber stress of 3280 MPa. The composite showed a maximum high tensile strength of 2300 MPa.

Similar content being viewed by others

References

Köhl M, Bram M, Moser A, Buchkremer HP, Beck T, Stöver D (2011) Characterization of porous, net-shaped NiTi alloy regarding its damping and energy-absorbing capacity. Mater Sci Eng A 528:2454–2462

Bansiddhi A, Sargeant TD, Stupp SI, Dunand DC (2008) Porous NiTi for bone implants: a review. Acta Biomater 4:773–782

Zhao Y, Taya M, Kang Y, Kawasaki A (2005) Compression behavior of porous NiTi shape memory alloy. Acta Mater 53:337–343

Grummon DS, Shaw JA, Foltz J (2006) Fabrication of cellular shape memory alloy materials by reactive eutectic brazing using niobium. Mater Sci Eng A 438–440:1113–1118

Shaw JA, Grummon DS, Foltz J (2007) Superelastic NiTi honeycombs: fabrication and experiments. Smart Mater Struct 16:S170–S178

Michailidis PA, Triantafyllidis N, Shaw JA, Grummon DS (2009) Superelasticity and stability of a shape memory alloy hexagonal honeycomb under in-plane compression. Int J Solids Struct 46:2724–2738

Delobelle V, Delobelle P, Liu Y, Favier D, Louche H (2013) Resistance welding of NiTi shape memory alloy tubes. J Mater Process Technol 213:1139–1145

Pilch J, Heller L, Sittner P (2009) Final thermomechanical treatment of thin NiTi filaments for textile applications by electric current

Villa E, Arnaboldi S, Tuissi A, Giacomelli M, Turco E (2009) Mechanical analysis of hybrid textile composites with NiTi wires. J Mater Eng Perform 18:517–521

Heller L, Vokoun D, Sittner P, Finckh H (2012) 3D flexible NiTi-braided elastomer composites for smart structure applications. Smart Mater Struct 21

Mahmud AS, Liu Y, Nam T-H (2008) Gradient anneal of functionally graded NiTi. Smart Mater Struct 17:015031

Mahmud AS, Liu Y, Nam TH (2007) Design of functionally graded NiTi by heat treatment. Phys Scr T129:222–226

Meng Q, Yang H, Liu Y, Nam T-H, Favier D (2013) Ti–50.8at.% Ni wire with variable mechanical properties created by spatial electrical resistance over-ageing. J Alloys Compd 577:S245–S250

Meng Q, Liu Y, Yang H, Nam T-H (2011) Laser annealing of functionally graded NiTi thin plate. Scr Mater 65:1109–1112

Meng Q, Liu Y, Yang H, Shariat BS, Nam T-H (2012) Functionally graded NiTi strips prepared by laser surface anneal. Acta Mater 60:1658–1668

Meng Q, Yang H, Liu Y, Nam T-H (2012) Compositionally graded NiTi plate prepared by diffusion annealing. Scr Mater 67:305–308

Shariat BS, Liu Y, Meng Q, Rio G (2013) Analytical modelling of functionally graded NiTi shape memory alloy plates under tensile loading and recovery of deformation upon heating. Acta Mater 61:3411–3421

Meng Q, Wu Z, Bakhtiari R, Shariat BS, Yang H, Liu Y, Nam T-H (2017) A unique “fishtail-like” four-way shape memory effect of compositionally graded NiTi. Scr Mater 127:84–87

Xiu Z, Laeng J, Sun X, Li Q, Hur SK, Liu Y (2008) Phase formation of Al2O3/Ti(C, N)–NiTi composite. J Alloys Compd 458:398–404

Strutt ER, Olevsky EA, Meyers MA (2008) Combustion synthesis/quasi-isostatic pressing of TiC–NiTi cermets: processing and mechanical response. J Mater Sci 43:6513–6526

Cheng F, Hu L, Reddy JN, Karaman I, Hoffman E, Radovic M (2014) Temperature-dependent thermal properties of a shape memory alloy/MAX phase composite: experiments and modeling. Acta Mater 68:267–278

Namli OC, Taya M (2011) Design of piezo-SMA composite for thermal energy harvester under fluctuating temperature. J Appl Mech 78:031001

Ni Q-Q, Zhang R-X, Natsuki T, Iwamoto M (2007) Stiffness and vibration characteristics of SMA/ER3 composites with shape memory alloy short fibers. Compos Struct 79:501–507

Kirkby EL, Michaud VJ, Månson JAE, Sottos NR, White SR (2009) Performance of self-healing epoxy with microencapsulated healing agent and shape memory alloy wires. Polymer 50:5533–5538

Lomas-González O, López-Cuellar E, López-Walle E, Araujo CJD, Reyes-Melo E, Gonzalez CH (2015) Thermomechanical behavior of a composite based on a NiTi ribbon with a magnetic hybrid polymer. Mater Today 2:S785–S788

Armstrong WD, Lorentzen T (1997) Fiber phase transformation and matrix plastic flow in a room temperature tensile strained NiTi shape memory alloy fiber reinforced 6082 aluminum matrix composite. Scr Mater 36:1037–1043

Coughlin JP, Williams JJ, Chawla N (2009) Mechanical behavior of NiTi shape memory alloy fiber reinforced Sn matrix “smart” composites. J Mater Sci 44:700–707

Esen Z (2012) The effect of processing routes on the structure and properties of magnesium–TiNi composites. Mater Sci Eng A 558:632–640

Aydogmus T (2015) Processing of interpenetrating Mg–TiNi composites by spark plasma sintering. Mater Sci Eng A 624:261–270

Coughlin JP, Williams JJ, Crawford GA, Chawla N (2008) Interfacial reactions in model NiTi shape memory alloy fiber-reinforced Sn matrix “Smart” composites. Metall Mater Trans A 40:176–184

Kuang KSC, Cantwell WJ (2003) The use of plastic optical fibres and shape memory alloys for damage assessment and damping control in composite materials. Meas Sci Technol 14:1305

Cortes P, Terzak J, Kubas G, Phillips D, Baur JW (2014) The morphing properties of a vascular shape memory composite. Smart Mater Struct 23:015018

Hao S, Cui L, Jiang D, Han X, Ren Y, Jiang J, Liu Y, Liu Z, Mao S, Wang Y, Li Y, Ren X, Ding X, Wang S, Yu C, Shi X, Du M, Yang F, Zheng Y, Zhang Z, Li X, Brown DE, Li J (2013) A transforming metal nanocomposite with large elastic strain, low modulus, and high strength. Science 339:1191–1194

Yang F, Ni D, Hao S, Li S, Ma Z, Liu Y, Feng C, Cui L (2015) Microstructure and phase stress partition of Mo fiber reinforced CuZnAl composite. Mater Sci Eng A 628:419–422

Hao S, Cui L, Wang H, Jiang D, Liu Y, Yan J, Ren Y, Han X, Brown DE, Li J (2016) Retaining large and adjustable elastic strains of kilogram-scale Nb nanowires. ACS Appl Mater Interfaces 8:2917–2922

Li GF, Zheng HZ, Shu XY, Peng P (2015) Structural stability of characteristic interface for NiTi/Nb nanowire: first-principle study. Met Mater Int 22:69–74

Zang K, Mao S, Cai J, Liu Y, Li H, Hao S, Jiang D, Cui L (2015) Revealing ultralarge and localized elastic lattice strains in Nb nanowires embedded in NiTi matrix. Sci Rep 5:17530

Li J, Shan Z, Ma E (2014) Elastic strain engineering for unprecedented materials properties. MRS Bull 39:108–114

Schlom DG, Chen L-Q, Fennie CJ, Gopalan V, Muller DA, Pan X, Ramesh R, Uecker R (2014) Elastic strain engineering of ferroic oxides. MRS Bull 39:118–130

Yildiz B (2014) “Stretching” the energy landscape of oxides—effects on electrocatalysis and diffusion. MRS Bull 39:147–156

Bedell SW, Khakifirooz A, Sadana DK (2014) Strain scaling for CMOS. MRS Bull 39:131–137

Zhang J, Liu Y, Ren Y, Huan Y, Hao S, Yu C, Shao Y, Ru Y, Jiang D, Cui L (2014) In situ synchrotron X-ray diffraction study of deformation behavior and load transfer in a Ti2Ni–NiTi composite. Appl Phys Lett 105:041910

Yu C, Liu Z, Liu Y, Shao Y, Ren Y, Cui L (2016) Load transfer in phase transforming matrix–nanowire composite revealing the significant load carrying capacity of the nanowires. Mater Des 89:721–726

Yue Y, Liu P, Zhang Z, Han X, Ma E (2011) Approaching the theoretical elastic strain limit in copper nanowires. Nano Lett 11:3151–3155

Wu B, Heidelberg A, Boland JJ (2005) Mechanical properties of ultrahigh-strength gold nanowires. Nat Mater 4:525–529

Richter G, Hillerich K, Gianola DS, Monig R, Kraft O, Volkert CA (2009) Ultrahigh strength single crystalline nanowhiskers grown by physical vapor deposition. Nano Lett 9:3048–3052

Zhu T, Li J (2010) Ultra-strength materials. Prog Mater Sci 55:710–757

Otsuka K, Ren X (2005) Physical metallurgy of Ti–Ni-based shape memory alloys. Prog Mater Sci 50:511–678

Mohd Jani J, Leary M, Subic A, Gibson MA (2014) A review of shape memory alloy research, applications and opportunities. Mater Des 56:1078–1113

Ogata S, Li J, Yip S (2002) Ideal pure shear strength of aluminum and copper. Science 298:807–811

Thilly L, Petegem SV, Renault P-O, Lecouturier F, Vidal V, Schmitt B, Swygenhoven HV (2009) A new criterion for elasto-plastic transition in nanomaterials: application to size and composite effects on Cu–Nb nanocomposite wires. Acta Mater 57:3157–3169

Zhang J, Cui L, Jiang D, Liu Y, Hao S, Ren Y, Han X, Liu Z, Wang Y, Yu C, Huan Y, Zhao X, Zheng Y, Xu H, Ren X, Li X (2015) A biopolymer-like metal enabled hybrid material with exceptional mechanical prowess. Sci Rep 5:8357

Sun QP, He YJ (2008) A multiscale continuum model of the grain-size dependence of the stress hysteresis in shape memory alloy polycrystals. Int J Solids Struct 45:3868–3896

Kim Y-H, Cho G-B, Hur S-G, Jeong S-S, Nam T-H (2006) Nanocrystallization of a Ti–50.0Ni(at.%) alloy by cold working and stress/strain behavior. Mater Sci Eng A 438–440:531–535

Hao S, Cui L, Jiang D, Yu C, Jiang J, Shi X, Liu Z, Wang S, Wang Y, Brown DE, Ren Y (2013) Nanostructured Nb reinforced NiTi shape memory alloy composite with high strength and narrow hysteresis. Appl Phys Lett 102:231905

Jiang D, Hao S, Zhang J, Liu Y, Ren Y, Cui L (2014) In situ synchrotron investigation of the deformation behavior of nanolamellar Ti5Si3/TiNi composite. Scr Mater 78–79:53–56

Hao SJ, Cui LS, Wang YD, Jiang DQ, Yu C, Jiang J, Brown DE, Ren Y (2011) The ultrahigh mechanical energy-absorption capability evidenced in a high-strength NbTi/NiTi nanocomposite. Appl Phys Lett 99:024102

Wang S, Cui L, Hao S, Jiang D, Liu Y, Liu Z, Mao S, Han X, Ren Y (2014) Locality and rapidity of the ultra-large elastic deformation of Nb nanowires in a NiTi phase-transforming matrix. Sci Rep 4:6753

Jiang D, Liu Y, Yu C, Liu W, Yang H, Jiang X, Ren Y, Cui L (2015) Deformation behavior of Nb nanowires in TiNiCu shape memory alloy matrix. Mater Sci Eng A 646:52–56

Wang S, Guo FM, Jiang DQ, Liu Y, Cui LS (2014) In situ W-NiTi shape memory alloy composite of high radiopacity. Scr Mater 81:4–7

Shao Y, Yu K, Jiang D, Yu C, Ren Y, Jiang X, Guo F, Cui L (2016) High strength W/TiNi micro-laminated composite with transformation-mediated ductility. Mater Des 106:415–419

Piao M, Miyazaki S, Otsuka K, Nishida N (1992) Effects of Nb addition on the microstructure of Ti–Ni alloys. Mater Trans JIM 33:337–345

Luo W, Ishikawa K, Aoki K (2008) Hydrogen permeable Ta–Ti–Ni duplex phase alloys with high resistance to hydrogen embrittlement. J Alloys Compd 460:353–356

Song G, Dolan MD, Kellam ME, Liang D, Zambelli S (2011) V-Ni–Ti multi-phase alloy membranes for hydrogen purification. J Alloys Compd 509:9322–9328

Zhang H, He Y, Yang F, Liu H, Jin Z (2013) Thermodynamic assessment of Cu–Ni–Ti ternary system assisted with key measurements. Thermochim Acta 574:121–132

Hammersley AP, Svensson SO, Hanfland M, Fitch AN, Hausermann D (1996) Two-dimensional detector software: from real detector to idealised image or two-theta scan. High Press Res 14:235–248

Wei Q, Kecskes LJ (2008) Effect of low-temperature rolling on the tensile behavior of commercially pure tungsten. Mater Sci Eng A 491:62–69

Ma B, Rao Q-H, He Y-H (2014) Effect of crystal orientation on tensile mechanical properties of single-crystal tungsten nanowire. Trans Nonferr Met Soc 24:2904–2910

Acknowledgement

This work was supported by the National Natural Science Foundation of China (NSFC) in Grant #51231008 (key program project scheme) and Grant #11474362, the Australian Research Council in Grant DP160105066. The use of the Advanced Photon Source was supported by the US Department of Energy, Office of Science, and Office of Basic Energy Science, Office of Basic Energy Sciences, under Contract No. DE-AC02-06CH11357.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shao, Y., Guo, F., Ren, Y. et al. NiTi-Enabled Composite Design for Exceptional Performances. Shap. Mem. Superelasticity 3, 67–81 (2017). https://doi.org/10.1007/s40830-017-0101-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-017-0101-8