Highlights

-

The single-atom Cu species with S = 0 spin ground state in CuIII-HHTP have been fabricated.

-

The CuIII-HHTP exhibits remarkable performance with a high urea yield of 7.780 mmol h−1 g−1 with the corresponding Faradaic efficiency of 23.09% at − 0.6 V (vs. RHE).

-

Low spin state and empty (\({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{0}\)) orbitals are favorable to enhance the production urea of C–N coupling process.

Abstract

The catalytic activities are generally believed to be relevant to the electronic states of their active center, but understanding this relationship is usually difficult. Here, we design two types of catalysts for electrocatalytic urea via a coordination strategy in a metal–organic frameworks: CuIII-HHTP and CuII-HHTP. CuIII-HHTP exhibits an improved urea production rate of 7.78 mmol h−1 g−1 and an enhanced Faradaic efficiency of 23.09% at − 0.6 V vs. reversible hydrogen electrode, in sharp contrast to CuII-HHTP. Isolated CuIII species with S = 0 spin ground state are demonstrated as the active center in CuIII-HHTP, different from CuII with S = 1/2 in CuII-HHTP. We further demonstrate that isolated CuIII with an empty \({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{0}\) orbital in CuIII-HHTP experiences a single-electron migration path with a lower energy barrier in the C–N coupling process, while CuII with a single-spin state (\({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{1}\)) in CuII-HHTP undergoes a two-electron migration pathway.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

As an important raw material for the chemical industry, urea is generally synthesized by reacting NH3 and CO2 under harsh conditions (> 400 °C, > 100 bar). The electrocatalysis route toward urea synthesis seems to be another better choice, which obviously is a moderate reaction (N2 + CO2 + 6H+ + 6e− → CO(NH2)2 + H2O) [1,2,3]. The essential issue in the electrocatalytic urea field remains the design of efficient catalysts. Recently, some attractive progress has been made in this area [4,5,6,7]. For example, Yu and co-workers employed the In(OH)3-S electrocatalyst for direct and selective urea synthesis from nitrate and carbon dioxide at ambient conditions [8]. In addition, Wang et al. fabricated a new class of oxygen vacancy-enriched CeO2 catalyst with the stabilization of the crucial intermediate of *NO via inserting into vacant sites, which was conducive to the subsequent C–N coupling process rather than protonation [9]. Moreover, Zhang’s group reported a novel Mott–Schottky Bi-BiVO4 hetero-structures with a remarkable urea yield rate [10]. Furthermore, Ozin and co-workers realized a novel direct urea synthesis from NH3 and CO2 over new Pd/LTA-3A catalysts powered solely by solar energy, in which Pd nanoparticles served the dual functions for urea formation and LTA-3A removed by-product H2O to shift the equilibrium toward urea production [11].

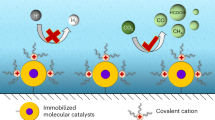

It is well-known that the catalytic activities of heterogeneous catalysts are generally believed to be relevant to the electronic states (including the spin and orbital of electrons) of the active center, but designing efficient catalysts and then understanding the relationship is usually difficult due to the catalysts’ complexity [12,13,14,15,16,17,18]. Metal–organic frameworks (MOFs)-based isolated catalysts as unambiguously models make it viable owing to the well-defined feature [19,20,21,22,23,24,25,26]. However, it is still a big challenge to design suitable MOFs-based isolated electrocatalysts for simultaneous fixation of N2 and CO2 into urea, aiming to investigate the relationship between spin states of single-atom active species and electrocatalytic performance [27,28,29,30,31,32,33,34,35].

To address the issue “whether the spin states of isolated active species in a catalyst affect the electrocatalytic urea performance?”, herein, we reported on two kinds of MOFs-based single-atom catalysts through a feasible coordination reaction method: CuIII-HHTP and CuII-HHTP. When tested in electrocatalytic urea production, CuIII-HHTP catalyst exhibited an enhanced urea production rate of 7.78 mmol h−1 g−1 and an improved Faradaic efficiency of 23.09% at − 0.6 V vs. reversible hydrogen electrode (RHE), which much outperformed CuII-HHTP. We demonstrated that isolated CuIII species with S = 0 spin ground state served as the active center in CuIII-HHTP, which differed from the isolated CuII one with S = 1/2 spin ground state in CuII-HHTP. Based on in situ Attenuated Total Reflectance Fourier transform Infrared (ATR-FTIR), X-ray emission spectroscopy (XES), operando XAFS measurements, in situ Raman characterization and the density-functional theory (DFT) calculations, we showed that spin states of single-atom copper site played the key role in producing urea. For CuIII-HHTP, single-atom CuIII active site possibly experienced a single-electron migration path with a lower energy barrier to facilitate C–N coupling, namely, the σ orbital electron of N2 leaped into the empty Cu-3d electron orbital (\({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{0}\)). For CuII-HHTP, isolated CuII species possibly underwent a two-electrons migration path with a higher barrier during C–N coupling, that is, the σ orbital electron of N2 leaped into the Cu-3d orbital electron (\({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{1}\)) and then migrated into the empty N2-π* orbital.

2 Experimental and Calculation

2.1 Materials

2,3,6,7,10,11-Hexahydroxytripheny-lene (HHTP, 97%), Potassium hydrogen carbonate (KHCO3, ≥ 99.7%, Alfa), Thiosemicarbazide (CH5N3S, 99%), Diacetylmonoxime(C4H7NO2, AR), phosphoric acid (H3PO4, ≥ 85%), sulfuric acid (H2SO4, ≥ 85%), iron chloride (FeCl3, 99.9%), Cuprouschloride (98%), Cupric acetate anhydrous (Cu2(OAc)4, 99%), N,N-Dimethylformamide (DMF, ≥ 99%) were purchased from Alfa Aesar China Co., Ltd. All reagents were used without further purification.

2.2 Synthesis of CuII-HHTP and CuIII-HHTP

The 0.04 mmol Cu2(OAc)4 and 0.02 mmol HHTP powder were dispersed in 10 mL of deionized water in a 20 mL glass vial, which was sonicated at 60 Hz for 15 min. Adding 1.5 mL DMF to the mixed solution and heating at 60 °C for 12 h to obtain blue CuII-HHTP powder [36]. The resulting products were centrifuged and washed three times in water, ethanol and DMF, alternately. The collected solids were dried at room temperature and saved for further use. CuIII-HHTP was slightly modified according to the previous literature report [37]. The preparation of CuIII-HHTP was similar to CuII-HHTP catalyst, except for the reaction temperature of 80 °C and in H2O2. Then, the CuIII-HHTP was washed with ethanol and deionized water to remove any impurities and dried in a vacuum oven at 60 °C overnight.

2.3 Characterizations

2.3.1 Materials Characterization

Scanning electron microscope (SEM) was performed on a JSM-7800F Prime electron microscope. A transmission electron microscope (TEM) was operated by a JEM-2100F working at 200 kV. X-ray absorption spectra (XAS) measurements were collected at the beamline 1W1B of the Beijing Synchrotron Radiation Facility (BSRF, Beijing). X-ray photoelectron spectroscopy (XPS) was carried out on an ESCALAB250Xi using an Al Kα X-rays as the excitation source. Raman spectra of as-made materials were measured by using HORIBA France, LABRAM HR Evolution. In situ Raman spectroscopy analysis was carried out on a confocal Raman spectrometer with a wavelength of 532 nm. Nitrogen temperature programmed desorption (N2-TPD) and carbon dioxide temperature programmed desorption (CO2-TPD) were carried out on the AutoChem II 2920. X-ray diffraction pattern (XRD) was conducted by PANanalytical X’PERT PRO MPD diffractometer (Cu Kα radiation = 0.15418 Å, scanned range of 3–90°) to identify the crystalline structure of the as-prepared MOFs. Fourier Transform Infrared Spectrometer (FT-IR) and the spin state of the catalysts were used by VERTEX 70v Bruker spectrometer and MPMS-3 (Quantum Design), respectively. 1H NMR spectra were carried out in Bruker AVANCE III HD 700 MHz spectrometer.

2.3.2 Electrochemical Measurements

The electrochemical measurements were collected on a three-electrode configuration workstation CHI 660E (Chenhua, Shanghai), where the reference and counter electrodes were Ag/AgCl and graphite rod, correspondingly. The H-type cell was divided by Nafion 211 membrane and used as the electrolyzer for CO2 and N2 electrochemical reduction reaction in 0.1 M KHCO3 solution. Electrocatalytic synthesis of urea measurements is carried out by constant potential electrolysis with a potential window ranging from − 0.3 to − 0.7V (vs. RHE) [1]. Based on the Nernst equation: E (vs. RHE) = E (vs. Ag/AgCl) + 0.0591 × pH + 0.197 (pH = 6.8 in CO2-saturated electrolyte and N2 + CO2-saturated electrolyte in 0.1 M KHCO3; pH = 8.3 for N2-saturated electrolyte in 0.1 M KHCO3). All the potentials were recorded relative to the reversible hydrogen electrode (RHE). The high purity N2 (99.999% purity) and CO2 (99.99% purity) inlet gases contain traces of impurities such as nitrogen oxides which need to be pre-cleaned by a saturator filled with 0.05 M NaOH and a saturator filled with a 0.05 M H2SO4 solution to remove the impurities. The electrosynthesis of urea is carried out in a carbon dioxide and nitrogen saturated 0.1 M KHCO3 solution for 2 h by electrolysis at room temperature and atmospheric pressure. The results of the double-layer capacitance were used to assess the electrochemically active surface area (ECSA) of the samples, measured in the potential range of − 0.3 ~ − 0.7V against RHE.

2.3.2.1 Analysis and Calculation of Urea and NH 3 Yield Rate

The urea products were acquired and analyzed by UV–Vis spectrophotometers of Thermo Fisher (GENSYS 150), which was automated for high-throughput options and room-light resistance. The liquid products of electrolysis were measured by Bruker AVANCE III HD 700 MHz spectrometer. The liquid product was quantified with a linear regression standard equation. The Faradaic efficiency was defined as the amount of electric charge devoted to the synthesis of urea divided by the total charge passed through the electrodes during the electrolysis. Based on the chemical equation (N2 + CO2 + 6H + + 6e– → CON2H4 + H2O), six electrons are needed to produce one urea molecule [5]. Thus, the FE can be calculated using Eq. 1:

The rate of formation of urea is calculated using Eq. 2:

where FE is the Faradaic efficiency of the urea product; Q is the total number of the charge consumed during the reaction and Qurea is the charge corresponding to reduction products; F is Faraday constant (96,485 C mol−1); V is the volume of the cathodic reaction electrolyte in the H-type electrolyzer; Curea represents the measurement of the mass concentration of urea in the solution after electrolysis using a UV spectrophotometer; Murea is the mass of the catalyst loaded on the carbon cloth. T is the time at which the reduction potential is applied [1].

Analysis and calculation of NH3 yield rate: The Faradaic efficiency was defined as the amount of electric charge devoted to the synthesis of NH3 divided by the total charge passed through the electrodes during the electrolysis [38, 39]. Based on the chemical equation (N2 + 6H+ + 6e– → 2NH3), three electrons are needed to produce one urea molecule. Thus, the FE can be calculated using Eq. 3:

The rate of urea formation was calculated using Eq. 4:

where FE is the Faradaic efficiency of the urea product; Q is the total number of the charge consumed during the reaction and QNH3 is the charge corresponding to reduction products; F is Faraday constant (96,485 C mol−1); V is the volume of the cathodic reaction electrolyte in the H-type electrolyzer; \({\text{C}}_{\text{NH4Cl}}\) represents the measurement of the mass concentration of urea in the solution after electrolysis using a UV spectrophotometer; \({\text{M}}_{\text{NH4Cl}}\) is the mass of the catalyst loaded on the carbon cloth. T is the time at which the reduction potential is applied.

2.3.3 XAFS Measurements

The X-ray absorption finds structure spectra (Cu K-edge) were collected at 1W1B station in Beijing Synchrotron Radiation Facility (BSRF). The storage rings of BSRF were operated at 2.5 GeV with a maximum current of 250 mA. Using Si (111) double-crystal monochromator, the data collection was carried out in transmission mode using ionization chamber. All spectra were collected in ambient conditions. Operando XAFS measurements: The working electrode was prepared and mounted onto a homemade in situ XAFS fluorescence cell with a three-electrode configuration, where Ag/AgCl (saturated with potassium chloride) and graphite rod were served as the reference and counter electrodes, respectively [40]. During operando XAFS measurements, CO2 and N2 were continuously bubbled with a flow rate of 20 mL min−1 to saturate the 0.1 M KHCO3 solution. All operando XAFS spectra were collected in fluorescence mode at room temperature. The linear combination fitting (LCF) was conducted to calculate the content of Cu2+ and Cu3+ in these treated samples.

2.3.4 XES Measurements

The operando Cu Kβ XES measurements were conducted at the 4W1B beamline in Beijing Synchrotron Radiation Facility (BSRF). In a homemade single-chamber XES apparatus, Ag/AgCl (with saturated KCl solution) and graphite rod were selected as reference and counter electrodes, respectively. The Cu Kβ XES spectra were recorded at operating potentials in a decreasing sequence from 0.00, − 0.30, − 0.40, − 0.50 to − 0.70 V vs. RHE, respectively.

2.3.5 In situ ATR-FTIR Measurements

The experimental catalyst was obtained by adding 4 mg of catalyst and 20 µL of Nafion (5%) solution to 2 mL of deionized water and sonicating for 1 h. Three-electrode electrochemical cell of a single chamber contains a working electrode, a graphite rod as counter electrode, and a saturated silver chloride electrode as a reference electrode. Electric current was applied to a homemade infrared reflector cell using a CHI 660E electrochemical workstation (Chenhua). All ATR-FTIR spectral acquisitions were carried out after a constant potential was applied to the electrode for 30 min. In situ ATR-IR spectra were measured on a Thermo-Fisher Nicolet II spectrometer, equipped with an MCT cryogenic detector. The measurements were all obtained by 64 scans at a spectral resolution of 4 cm−1. The chronoamperometric tests from− 0.3 to− 0.7 VRHE were carried out on a CHI 660E electrochemical workstation accompanied by the spectrum collection.

2.4 Computational Details

All of the calculations were performed by means of spin-polarized density-functional theory (DFT) methods using the Vienna Ab initio Simulation Package (VASP) [41]. The exchange–correlation energy was described using the revised Perdew–Burke–Ernzerhof exchange–correlation density functional (PBE) within the generalized-gradient approximation (GGA) [42]. Description of electron–ion interactions by the projector-enhanced wave (PAW) method. The plane-wave cutoff energy was set to 400 eV. The convergence criteria of energy and force were set to 10–4 and 0.03 eV Å−1, respectively. A vacuum layer of 15 Å was adopted to avoid the interaction between the periodic slabs.

3 Results and Discussion

3.1 Characterization of CuII-HHTP and CuIII-HHTP

Both CuIII-HHTP and CuII-HHTP catalysts were synthesized via a coordination reaction of 2,3,6,7,10,11-hexahydroxytri-phenylene (HHTP) with Cu2+ ions (Fig. 1a), the former was fabricated with the help of the oxidizing agent (H2O2). Field emission scanning electron microscopy (FESEM) and transmission electron microscopy (TEM) were used to observe their rod-like morphologies (Figs. S1-S2). As illustrated in the energy-dispersive X-ray spectroscopy (EDS) mapping of CuIII-HHTP (Fig. 1b), there was a homogeneous distribution of Cu, C, and O elements in it, indicating successful introduction of Cu into a MOF of HHTP. Another evidence from the Fourier transform infrared (FTIR) spectra of two catalysts (Fig. S3), the peak centered at 1211 cm−1 was attributed to Cu–O bond, which confirmed formation of Cu–O species in them. The valence states of Cu species in CuIII-HHTP and CuII-HHTP catalysts were analyzed by X-ray photoelectron spectroscopy (XPS). As shown in Cu 2p XPS spectra of CuIII-HHTP (Fig. 1c), the Cu 2p3/2 and Cu 2p1/2 signals with the binding energy of 935.5/955.1 eV could be ascribed to Cu3+, suggesting the formation of Cu3+ species in it. Similarly, the peaks of Cu 2p3/2 and Cu 2p1/2 (Fig. S4) were observed at 932.0/934.6 and 951.8/954.5 eV, respectively, demonstrating that the presence of Cu2+ species in CuII-HHTP. Nearly the same XRD pattern of two catalysts indicated that CuIII-HHTP retained the same crystalline structure as CuII-HHTP (Fig. S5). Raman spectra of two catalysts (Fig. S6) also demonstrated the little differences between them due to the similar ID/IG ratio.

To find out the difference in catalytic performance between CuIII-HHTP and CuII-HHTP, two catalysts were characterized in detail. The X-ray absorption near-edge structure (XANES) and Extended X-ray absorption fine structure (EXAFS) spectroscopy were conducted to study their chemical states and coordination environment of the Cu center [17, 18]. As shown in Fig. 2a, Cu K-edge XANES spectra of CuIII-HHTP show a slight shift to higher energy compared with CuII-HHTP, suggesting a rise of the Cu valence state in CuIII-HHTP catalyst. Importantly, The CuIII-HHTP pre-edge peak is more obvious than the CuII-HHTP, due to CuIII species with more empty d orbitals allowing for an increased electronic transition. As depicted in Fig. 2b, a sole Cu–O peak centered at 1.50 Å can be observed, while no Cu–Cu peak located at 2.34 Å (corrected distance) can be discerned, indicating the isolated Cu-atom structure of CuIII-HHTP and CuII-HHTP. As shown in Figs. 2c and S7, the well-defined single-atom structures were then confirmed by the aberration-corrected high-angle annular darkfield scanning TEM (AC HAADF-STEM). The spin states of single-atom Cu species and electronic configuration of the Cu-3d orbitals in two catalysts were measured by X-ray emission spectroscopy (XES) and the temperature variable magnetic susceptibility. XES is a powerful tool to confirm the spin states, in which the number of unpaired 3d electrons can be analyzed by the Kβ' satellite peak due to 3p-3d exchange coupling [27]. As depicted in Fig. 2d, CuIII-HHTP had an insignificant Kβ' intensity splitting similar to the reference KCuO2, implying that the Cu-3d orbitals of CuIII-HHTP did not hold the unpaired electron with the possible electron configuration (\({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{0}\)). In contrast, CuII-HHTP showed distinct Kβ', indicating that its Cu-3d orbitals contained unpaired electrons with the possible electronic configuration (\({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{1}\)) as compared with the reference CuO. The peak position and intensity of CuIII-HHTP are almost identical to KCuO2, which may imply that the two Cu species are in a similar valence state and both in the Cu-O4 coordination mode. In addition, the comparison of the characteristic peaks of Cu Kβ1,3 with the reference samples again suggested that the average oxidation state of single-atom Cu species was + 3 for CuIII-HHTP, whereas the value of single-atom Cu species was + 2 for CuII-HHTP. From temperature-dependent susceptibility curves (Fig. 2e, f), it can be seen that the isolated Cu species embedded in CuIII-HHTP and CuII-HHTP were CuIII with S = 0 spin ground state and CuII with 1/2 spin ground state, respectively [14]. In addition, μeff values of CuII-HHTP/CuIII-HHTP were calculated of 4.47/2.04, which were related to the number of unpaired electrons in them (Fig. S8, Table S1). Therefore, the 3d electron configuration of single-atom Cu center in two catalysts are illustrated in the insets shown in Fig. 2e, f. That is, there was an empty Cu-3d electron orbital (\({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{0}\)) in CuIII-HHTP and the single-spin state (\({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{1}\)) in CuII-HHTP.

3.2 Electrocatalytic Performance

An H-shaped electrochemical cell with a three-electrode configuration was used to measure the urea performance of above two catalysts (Fig. S9). In situ ATR-FTIR tests were performed under working conditions to understand the catalytic process (Fig. S10). Herein, an independent evaluation approach consisting of the diacetyl monoxime and indophenol blue tests were utilized (Figs. S11-S12), where the urea, NH3 and other gas by-products (e.g., H2 and CO) were analyzed by the UV–vis spectrophotometry and online gas chromatography. And, the possible liquid by-products, including N2H4, NO2−, and NO3−, were quantified by ultraviolet–visible (UV–Vis) spectrophotometry (Figs. S13-S15) [43]. More importantly, the potential by-product of N2H4, NO2− and NO3− was not detected in the solution that had been reacted for 2 h in the N2 + CO2 saturated 0.1 M KHCO3 electrolyte at each potential (Figs. S16-S18). As depicted in the typical linear sweep voltammogram (LSV) (Fig. S19), CuIII-HHTP catalyst in a CO2 + N2 saturated electrolyte (pink curve) showed much stronger current density compared with the cases in CO2 or N2 saturated electrolytes, demonstrating urea electrocatalysis happened in it. It is noted that CuIII-HHTP catalyst obviously exhibited superior electrocatalytic activity than CuII-HHTP (Fig. 3a), since it had higher current density over the same potential range. Therefore, CuIII-HHTP delivered an ultrahigh urea yield of 7.78 mmol h−1 gcat−1 and corresponding improved Faradaic efficiency (FE) of 23.09% (Figs. 3b and S20) at the optimal potential of − 0.6 V vs. reversible hydrogen electrode (RHE). As can be seen from Fig. 3c and Table S2, this urea yield value was 2 times higher than that of CuII-HHTP and surpassed the reported hitherto electrocatalysts for urea synthesis in the N2 + CO2 testing system. However, the higher potential inhibited urea synthesis (Fig. S21) possibly due to the excessive CO release and enhanced competing hydrogen evolution reactions (HER). More importantly, CuIII-HHTP exhibited good catalytic stability. The time-dependent current density curves recorded for 2 h at various potentials illustrate its superior durability (Fig. S22), and there was almost negligible decay in the current density at − 0.6 V (vs. RHE) after 18 h chronoamperometry test (Fig. S23). Notably, the urea yield and FE kept well for five consecutive cycles (Fig. S24). Moreover, the electrochemical impedance spectra (EIS) of two catalysts also indicated that it might be related to the charge transfer (Fig. S25). Furthermore, we measured and then calculated the electrochemically active surface area (ECSA) of two catalysts (Figs. S26-S27), which was an essential parameter for the evaluation of electrochemical reactivity. It is obvious that CuIII-HHTP had larger ECSA than CuII-HHTP (570.0 vs. 337.5 cm−2), indicating that the CuIII species were more active than CuII one. Isotope-labeled nuclear magnetic resonance (NMR) was used to disclose the origin of urea product over CuIII-HHTP. As shown in Fig. 3d, the doublet coupling peak of CO(15NH2)2 appeared on the 1H NMR spectrum only when 15N2 and CO2 were used as feeding gases, suggesting that the urea production was derived from an electrocatalytic process on CuIII-HHTP catalyst rather than the contamination nitrogen species from the ambient environment. It is also noted that the urea concentrations calculated by 1H-NMR were essentially identical to the UV/Vis method (Figs. S28-S29). Therefore, it is demonstrated that the detected urea came from the simultaneous catalyzed reaction of N2 and CO2 over the CuIII-HHTP catalyst. This was further testified by a series of control experiments (Fig. S30), including a CO2/N2 saturated solution at − 0.6 V, a mixed gas (N2 + CO2)-saturated electrolyte at open circuit potential, CO2 + N2 saturated solution without applied voltage and before/after 2 h electrolysis at bare carbon cloth.

a The linear sweep voltammetry (LSV) of CuIII-HHTP and CuII-HHTP catalysts in CO2 + N2 saturated electrolyte. b The urea yield rate and Faradaic efficiencies of CuIII-HHTP and CuII-HHTP at− 0.6 V versus RHE during a testing period of 2 h. c Comparison of CuIII-HHTP with the established electrocatalysts at their maximum reported urea yield. d 1H NMR spectra of electrolyte saturated with 15N2 + CO2 / 14N2 + CO2 after 2 h electrolysis, standard 15NH2CO15NH2 / 14NH2CO14NH2 solution and before electrolysis

To further study the target adsorption sites of CO2 and N2 and their coupling effect over two catalysts, the N2-temperature programmed desorption (N2-TPD) and CO2-TPD spectra were measured. As illustrated by the N2-TPD spectrum (Fig. 4a), the CuIII-HHTP sample exhibits new prominent TPD peaks at 130 and 272 ℃, which can be attributed to the physical adsorption of N2 [44]. This indicates that N2 binding is stronger on the surface of the CuIII-HHTP catalyst than on that of the CuII-HHTP. The N2 desorption peak of CuIII-HHTP spectrum presents a peak located at 406 °C, while the N2 desorption peak shifts to 446 ℃ for CuII-HHTP, and an additional peak at 384 °C appears. The peak shift to a higher temperature and the additional appearance prove that the desorption of N2 is more difficult, cumbersome and unfavorable to facilitate the desorption of subsequent electrocatalytic synthesis products. As shown in Fig. 4b, the CO2 desorption peaks of CuIII-HHTP were at 235, 289 and 385 °C, which were slightly higher than those of CuIII-HHTP (224, 283 and 374 °C, respectively). The CuIII-HHTP with a low spin state has a higher chemisorption capacity for CO2 compared to CuII-HHTP. It demonstrated that the stronger N2 and CO2 binding strength over CuIII-HHTP catalysts might facilitate the subsequent C-N coupling process of urea.

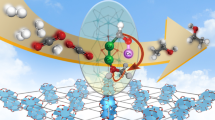

To reveal the possible intermediates and reaction paths during urea synthesis, in situ ATR-FTIR spectra were then measured (Fig. 5a). The most remarkable feature in it is that the strongest peak located at 1449 cm−1 was attributed to the stretching mode of C–N, which consequently provided strong evidence on urea electrocatalytic synthesis. The simultaneous emergence of other peaks such as -CO and -NH2 meant the *NCONH intermediate products formed in the catalysis, which were regarded as the key factor in effective urea production. The infrared band at around 1694 cm−1 has been observed to be the consequence of *NHCO species. The generation of NHCO intermediates, representing the intermediate species for N2 and CO2 reduction, respectively, implying that urea production is associated with the co-adsorption of N2 and CO2 [4]. Notably, the C–N infrared signal of CuIII-HHTP was considerably stronger than CuII-HHTP (Fig. S31), and the intensity maximum was found at -0.6 V vs. RHE, which coincides with the electrocatalytic tests. These meant that the C–N coupling pathways over two catalysts were different and CuIII-HHTP was more favorable to C–N coupling. Herein we employed climbing image nudged elastic band (CI-NEB) to calculate the transition states of the C–N bond formation step over two catalysts. As shown in Fig. S32, for CuIII-HHTP, a lower barrier of 1.405 eV needed to surmount for the formation of *NCONH*, as compared with 2.398 eV for CuII-HHTP, indicating the more kinetically accessible of CuIII-HHTP. It is worth noting that the energy barrier of N2 activation was the largest in the whole C–N coupling process, it again demonstrated that it was a rate-determining step in the urea synthesis. The possible electron configuration evolution of single-atom Cu species was investigated by an in situ XES. Figure S33a shows the Cu Kβ XES spectra of CuIII-HHTP with the scan range from− 0.3 to− 0.9 V (vs. RHE), which were regularly recorded by electrolysis under saturated solution (CO2 + N2) for 2 h. It can be found that there was a negative shift in the Cu Kβ1,3 emission energy with reaction potential, indicating that the oxidation state (+ 3) of CuIII decreased during C–N coupling. The in situ XES spectra with a slight negative shift (0.1 eV) of the main Kβ1,3 line at OCP to− 0.7V vs. RHE. That is, the electrons from the σ orbitals of N2 were most likely to migrate into the empty orbitals (\({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{0}\)) of single-atom CuIII site. In comparison, there were little changes in the in situ XES for CuII-HHTP under the same conditions (Fig. S33b). These once more suggested that CuIII-HHTP indeed preferred to produce urea compared with CuII-HHTP owing to its special spin states, since both catalysts had isolated Cu structure and similar Cu–O coordination numbers. In addition, a slight Kβ' for CuIII-HHTP appears during the reaction, demonstrating that spin states of single-atom Cu site might change. Therefore, the Cu oxidation state (+ 2 or + 3) obviously had a dramatical influence on the spin states and in turn decided the Cu-3d electron distribution/configuration, leading to the significantly different N2 activation pathways on the single-atom Cu active centers over two catalysts. The investigation of the ratio evolution of CuIII /CuII over electrolysis time during the electrocoupling of N2 and CO2 under operating conditions is critical to reveal the intrinsic reaction mechanisms [40]. The operando XAFS experiment was used to directly monitor the change in actual catalytic central valence state of CuIII-HHTP catalyst. With increased electrolysis time, the empty \({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{0}\) orbitals of CuIII-HHTP with a low spin state are continuously filled with σ electrons from N2, which may mean that the valence state of the active center decreases. First-order derivatives absorption of Cu K-edge CuIII-HHTP was measured for each spectrum at the corresponding time of electrolysis. As shown in Fig. 5b, the XANES dramatically changed with the electrolysis time indicating that a fall of Cu valence state in CuIII-HHTP. It is noted that the linear combination fitting (LCF) of the XANES spectrum of CuIII-HHTP, all fitted by similar method (Fig. S34), revealing that they are all composed of Cu2+ and Cu3+ (Fig. 5c). It can be obviously seen that the accumulation of electrolysis time leads to more σ electrons transfer to the empty \({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{0}\) orbitals of CuIII−HTP, which in turn leads to the changes of the ratio of Cu3+ /Cu2+. More importantly, 69% of the Cu3+ was still present in the CuIII-HHTP catalyst at the end of the reaction (Table S3). Furthermore, EXAFS curve-fitting (Table S4) suggested that CuII-HHTP and CuIII-HHTP catalysts had the same Cu–O coordination number, which was also consistent with Cu K-edge wavelet transform (WT)-EXAFS (Figs. S35-S36). In addition, a weakening of the Raman intensity of the Cu–O bond was observed at the reduction potential compared to the open circuit voltage, which may be related to the breakage of the Cu–O bond during catalysis and the formation of the Cu-Ox intermediate species (Fig. S37) [45]. The reaction pathways of *NCONH* formation over the two catalysts are summarized in Fig. 5d. Note that the single-electron migration path occurred toward N2 activation during C–N coupling for CuIII-HHTP (S = 0), where the σ orbital electron of N2 leaped into the empty Cu-3d electron orbital (\({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{0}\)). In comparison, there were two-electron migration steps in above process for CuII-HHTP (S = 1/2), where the σ orbital electron of N2 leaped in the Cu-3d orbital electron (\({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{1}\)) and then transferred into the empty N2-π* orbital (Fig. S38). It is obvious that more efficient N2 activation way existed in CuIII-HHTP (S = 0) compared with CuII-HHTP (S = 1/2), resulting in improved catalytic activity.

a In situ ATR-FTIR spectra with negative scan from− 0.3 to− 0.7 V vs. RHE. b Cu K-edge first-order derivatives of the CuIII-HHTP recorded over time at − 0.6 V versus RHE. c The linear combination (LCF) fitting result of the Cu K-edge XANES spectra recorded over time at − 0.6 V versus RHE. d Illustration of the single-electron migration pathway of CuIII-HHTP during C–N coupling

The possible reaction pathways of CuIII-HHTP and CuII-HHTP catalysts were also explored by using DFT calculations (Fig. 6 and Table S5). In order to decode the possible CO2 and N2 absorption sites over CuIII-HHTP, the density-functional theory (DFT) was conducted. The electron density theoretical simulation analysis (Fig. S39) revealed that the isolated CuIII site and the adjacent O site in CuIII-HHTP possibly acted as the active centers toward the coupling of N2 and CO2 due to the electronic interaction. As shown in Fig. S40, their density of states (DOS) demonstrates that the spin states of the two materials are different. The urea reactions over CuIII-HHTP initiated with the reaction of N2 and CO2 and dissociated to form Cu-N2 and *CO subsequently. Then, an effective C–N coupling happened. Then, a series of thermodynamically downhill hydrogenation steps occurred for following reactions over two catalysts. The first two hydrogen atoms tent to bond on two nitrogen atoms, the third hydrogen was prone to bonding at the nitrogen in Cu–N owing to the smaller electron delocalization. Followed by the last hydrogenation step, urea molecule was produced. It can be seen that CuIII-HHTP was more favorable for the C–N coupling to produce urea than CuII-HHTP. That is, the spin-state transition of single-atom Cu site in CuIII-HHTP greatly affected N2 activation and thus C–N coupling over CuIII (S = 0) site, achieving the much high urea production rate and FE compared with previous reports (Table S2).

4 Conclusions

In summary, we reported novel MOFs-based isolated copper catalysts (CuIII-HHTP and CuII-HHTP) through a coordination method and aimed to answer the question: whether the spin states of isolated active species in a catalyst affect the electrocatalytic urea performance. As tested in the electrocatalytic urea production, CuIII-HHTP catalyst showed an improved urea activity of 7.78 mmol h−1 g−1 with the corresponding Faradaic efficiency of 23.09% at − 0.6 V (vs. RHE), as compared with CuII-HHTP. Multiple characterizations including in situ ATR-FTIR, XES, operando XAFS measurements, in situ Raman and the theoretical calculations revealed that spin states of isolated copper sites play a key role in producing urea: CuIII active center in CuIII-HHTP had the empty Cu-3d electron orbital (\({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{0}\))and possibly experienced a single-electron migration path with a lower energy barrier in the C–N coupling process; while the CuII site in CuII-HHTP had a single-spin state (\({d}_{{{\text{x}}^{2}\text{-y}}^{2}}^{1}\)) and might undergo a two-electron migration pathway, leading to produce few urea. Therefore, engineering spin states of single-atom active species in catalysts is envisaged to be a new effective approach to improve electrocatalytic activities of urea synthesis.

References

C. Chen, X. Zhu, X. Wen, Y. Zhou, L. Zhou et al., Coupling N2 and CO2 in H2O to synthesize urea under ambient conditions. Nat. Chem. 12(8), 717–724 (2020). https://doi.org/10.1038/s41557-020-0481-9

C. Guo, W. Zhou, X. Lan, Y. Wang, T. Li et al., Electrochemical upgrading of formic acid to formamide via coupling nitrite co-reduction. J. Am. Chem. Soc. 144(35), 16006–16011 (2022). https://doi.org/10.1021/jacs.2c05660

J. Yang, H. Qi, A. Li, X. Liu, X. Yang et al., Potential-driven restructuring of Cu single atoms to nanoparticles for boosting the electrochemical reduction of nitrate to ammonia. J. Am. Chem. Soc. 144(27), 12062–12071 (2022). https://doi.org/10.1021/jacs.2c02262

X. Zhang, X. Zhu, S. Bo, C. Chen, M. Qiu et al., Identifying and tailoring C-N coupling site for efficient urea synthesis over diatomic Fe–Ni catalyst. Nat. Commun. 13(1), 5337 (2022). https://doi.org/10.1038/s41467-022-33066-6

X. Zhu, X. Zhou, Y. Jing, Y. Li, Electrochemical synthesis of urea on mbenes. Nat. Commun. 12(1), 4080 (2021). https://doi.org/10.1038/s41467-021-24400-5

J. Geng, S. Ji, M. Jin, C. Zhang, M. Xu et al., Ambient electrosynthesis of urea with nitrate and carbon dioxide over iron-based dual-sites. Angew. Chem. Int. Ed. 62(6), e202210958 (2023). https://doi.org/10.1002/anie.202210958

S.-K. Geng, Y. Zheng, S.-Q. Li, H. Su, X. Zhao et al., Nickel ferrocyanide as a high-performance urea oxidation electrocatalyst. Nat. Energy 6(9), 904–912 (2021). https://doi.org/10.1038/s41560-021-00899-2

C. Lv, L. Zhong, H. Liu, Z. Fang, C. Yan et al., Selective electrocatalytic synthesis of urea with nitrate and carbon dioxide. Nat. Sustain. 4(10), 868–876 (2021). https://doi.org/10.1038/s41893-021-00741-3

X. Wei, X. Wen, Y. Liu, C. Chen, C. Xie et al., Oxygen vacancy-mediated selective C–N coupling toward electrocatalytic urea synthesis. J. Am. Chem. Soc. 144(26), 11530–11535 (2022). https://doi.org/10.1021/jacs.2c03452

M. Yuan, J. Chen, Y. Bai, Z. Liu, J. Zhang et al., Unveiling electrochemical urea synthesis by co-activation of CO2 and N2 with mott-schottky heterostructure catalysts. Angew. Chem. Int. Ed. 60(19), 10910–10918 (2021). https://doi.org/10.1002/anie.202101275

M. Xia, C. Mao, A. Gu, A.A. Tountas, C. Qiu et al., Solar urea: towards a sustainable fertilizer industry. Angew. Chem. Int. Ed. 61(1), e202110158 (2022). https://doi.org/10.1002/anie.202110158

S. Al Shehimy, O. Baydoun, S. Denis-Quanquin, J.-C. Mulatier, L. Khrouz et al., Ni-centered coordination-induced spin-state switching triggered by electrical stimulation. J. Am. Chem. Soc. 144(39), 17955–17965 (2022). https://doi.org/10.1021/jacs.2c07196

Y.-N. Gong, W. Zhong, Y. Li, Y. Qiu, L. Zheng et al., Regulating photocatalysis by spin-state manipulation of cobalt in covalent organic frameworks. J. Am. Chem. Soc. 142(39), 16723–16731 (2020). https://doi.org/10.1021/jacs.0c07206

G. Yang, J. Zhu, P. Yuan, Y. Hu, G. Qu et al., Regulating Fe-spin state by atomically dispersed Mn-N in Fe-N-C catalysts with high oxygen reduction activity. Nat. Commun. 12(1), 1734 (2021). https://doi.org/10.1038/s41467-021-21919-5

Y. Jia, Z. Xue, J. Yang, Q. Liu, J. Xian et al., Tailoring the electronic structure of an atomically dispersed zinc electrocatalyst: Coordination environment regulation for high selectivity oxygen reduction. Angew. Chem. Int. Ed. 61(2), e202110838 (2022). https://doi.org/10.1002/anie.202110838

S. Luo, K. Elouarzaki, Z.J. Xu, Electrochemistry in magnetic fields. Angew. Chem. Int. Ed. 61(27), e202203564 (2022). https://doi.org/10.1002/anie.202203564

F. Lu, W. Xie, D. Yi, Y. Wang, F. Zhang et al., Revealing the role of d orbitals of transition-metal-doped titanium oxide on high-efficient oxygen reduction. CCS Chem. 3(11), 180–188 (2021). https://doi.org/10.31635/ccschem.020.202000659

D. Yi, F. Lu, F. Zhang, S. Liu, B. Zhou et al., Regulating charge transfer of lattice oxygen in single-atom-doped titania for hydrogen evolution. Angew. Chem. Int. Ed. 59(37), 15855–15859 (2020). https://doi.org/10.1002/anie.202004510

S. Chen, W.-H. Li, W. Jiang, J. Yang, J. Zhu et al., MOF encapsulating n-heterocyclic carbene-ligated copper single-atom site catalyst towards efficient methane electrosynthesis. Angew. Chem. Int. Ed. 61(4), e202114450 (2022). https://doi.org/10.1002/anie.202114450

Y. Chen, P. Wang, H. Hao, J. Hong, H. Li et al., Thermal atomization of platinum nanoparticles into single atoms: An effective strategy for engineering high-performance nanozymes. J. Am. Chem. Soc. 143(44), 18643–18651 (2021). https://doi.org/10.1021/jacs.1c08581

H. Kim, D. Shin, W. Yang, D.H. Won, H.-S. Oh et al., Identification of single-atom Ni site active toward electrochemical CO2 conversion to CO. J. Am. Chem. Soc. 143(2), 925–933 (2021). https://doi.org/10.1021/jacs.0c11008

S. Zhao, Y. Yang, Z. Tang, Insight into structural evolution, active sites, and stability of heterogeneous electrocatalysts. Angew. Chem. Int. Ed. 61(11), e202110186 (2022). https://doi.org/10.1002/anie.202110186

L. Wang, C. Zhu, M. Xu, C. Zhao, J. Gu et al., Boosting activity and stability of metal single-atom catalysts via regulation of coordination number and local composition. J. Am. Chem. Soc. 143(45), 18854–18858 (2021). https://doi.org/10.1021/jacs.1c09498

C. Pan, F. Wu, J. Mao, W. Wu, G. Zhao et al., Highly stable and selective sensing of hydrogen sulfide in living mouse brain with NiN4 single-atom catalyst-based galvanic redox potentiometry. J. Am. Chem. Soc. 144(32), 14678–14686 (2022). https://doi.org/10.1021/jacs.2c04695

M. Chung, K. Jin, J.S. Zeng, T.N. Ton, K. Manthiram, Tuning single-atom dopants on manganese oxide for selective electrocatalytic cyclooctene epoxidation. J. Am. Chem. Soc. 144(38), 17416–17422 (2022). https://doi.org/10.1021/jacs.2c04711

J. Qin, H. Liu, P. Zou, R. Zhang, C. Wang et al., Altering ligand fields in single-atom sites through second-shell anion modulation boosts the oxygen reduction reaction. J. Am. Chem. Soc. 144(5), 2197–2207 (2022). https://doi.org/10.1021/jacs.1c11331

B.L. Geoghegan, Y. Liu, S. Peredkov, S. Dechert, F. Meyer et al., Combining valence-to-core x-ray emission and Cu k-edge x-ray absorption spectroscopies to experimentally assess oxidation state in organometallic Cu(I)/(II)/(III) complexes. J. Am. Chem. Soc. 144(6), 2520–2534 (2022). https://doi.org/10.1021/jacs.1c09505

X. Bai, X. Zhao, Y. Zhang, C. Ling, Y. Zhou et al., Dynamic stability of copper single-atom catalysts under working conditions. J. Am. Chem. Soc. 144(37), 17140–17148 (2022). https://doi.org/10.1021/jacs.2c07178

H. Gu, G. Shi, L. Zhong, L. Liu, H. Zhang et al., A two-dimensional van der waals heterostructure with isolated electron-deficient cobalt sites toward high-efficiency CO2 electroreduction. J. Am. Chem. Soc. 144(47), 21502–21511 (2022). https://doi.org/10.1021/jacs.2c07601

Y. Deng, Y. Guo, Z. Jia, J.-C. Liu, J. Guo et al., Few-atom Pt ensembles enable efficient catalytic cyclohexane dehydrogenation for hydrogen production. J. Am. Chem. Soc. 144(8), 3535–3542 (2022). https://doi.org/10.1021/jacs.1c12261

C.T. Kelly, S. Dunne, I.A. Kühne, A. Barker, K. Esien et al., Proton-induced spin state switching in an feiii complex. Angew. Chem. Int. Ed. 62, e202217388 (2023). https://doi.org/10.1002/anie.202217388

P. Li, X. Zhang, J. Wang, Y. Xue, Y. Yao et al., Engineering O-O species in boron nitrous nanotubes increases olefins for propane oxidative dehydrogenation. J. Am. Chem. Soc. 144(13), 5930–5936 (2022). https://doi.org/10.1021/jacs.1c13563

T. He, Y. Chen, Q. Liu, B. Lu, X. Song et al., Theory-guided regulation of FeN4 spin state by neighboring Cu atoms for enhanced oxygen reduction electrocatalysis in flexible metal–air batteries. Angew. Chem. Int. Ed. 61(27), e202201007 (2022). https://doi.org/10.1002/anie.202201007

J. Hao, S. Xie, Q. Huang, Z. Ding, H. Sheng et al., Spin-enhanced C-C coupling in CO2 electroreduction with oxide-derived copper. CCS Chem. (2022). https://doi.org/10.31635/ccschem.022.202202263

Y. Gao, Q. Yin, Q. Wang, Z. Li, J. Cai et al., Spontaneous (anti)meron chains in the domain walls of van der waals ferromagnetic Fe5−xGeTe2. Adv. Mater. 32(48), 2005228 (2020). https://doi.org/10.1002/adma.202005228

R.W. Day, D.K. Bediako, M. Rezaee, L.R. Parent, G. Skorupskii et al., Single crystals of electrically conductive two-dimensional metal–organic frameworks: structural and electrical transport properties. ACS Cent. Sci. 5(12), 1959–1964 (2019). https://doi.org/10.1021/acscentsci.9b01006

A.N. Pham, G. Xing, C.J. Miller, T.D. Waite, Fenton-like copper redox chemistry revisited: Hydrogen peroxide and superoxide mediation of copper-catalyzed oxidant production. J. Catal. 301, 54–64 (2013). https://doi.org/10.1016/j.jc-at.2013.01.025

Y. Sun, Z. Deng, X.-M. Song, H. Li, Z. Huang et al., Bismuth-based free-standing electrodes for ambient-condition ammonia production in neutral media. Nano-Micro Lett. 12(1), 133 (2020). https://doi.org/10.1007/s40820-020-00444-y

M. Yuan, J. Chen, H. Zhang, Q. Li, L. Zhou et al., Host–guest molecular interaction promoted urea electrosynthesis over a precisely designed conductive metal–organic framework. Energy Environ. Sci. 15, 2084–2095 (2022). https://doi.org/10.1039/d1ee03918k

X. Su, Z. Jiang, J. Zhou, H. Liu, D. Zhou et al., Complementary operando spectroscopy identification of in-situ generated metastable charge-asymmetry Cu2-CuN3 clusters for CO2 reduction to ethanol. Nat. Commun. 13(1), 1322 (2022). https://doi.org/10.1038/s41467-022-29035-8

G. Kresse, J. Furthmüller, Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54(16), 11169–11186 (1996). https://doi.org/10.1103/PhysRevB.54.11169

S. Grimme, Semiempirical GGA-type density functional constructed with a long-range dispersion correction. J. Comput. Chem. 27(15), 1787–1799 (2006). https://doi.org/10.1002/jcc.20495

Z. Shen, Y. Yu, Z. Zhao, M.A. Mushtaq, Q. Ji et al., N, O trans-coordinating silver single-atom catalyst for robust and efficient ammonia electrosynthesis from nitrate. Appl. Catal. B 331, 122687 (2023). https://doi.org/10.1016/j.apcatb.2023.122687

Y. Zhao, F. Li, W. Li, Y. Li, C. Liu et al., Identification of M-NH2-NH2 intermediate and rate determining step for nitrogen reduction with bioinspired sulfur-bonded few catalyst. Angew. Chem. Int. Ed. 60(37), 20331–20341 (2021). https://doi.org/10.1002/anie.202104-918

Y. Deng, B.S. Yeo, Characterization of electrocatalytic water splitting and CO2 reduction reactions using in situ/operando Raman spectroscopy. ACS Catal. 7(11), 7873–7889 (2017). https://doi.org/10.1021/acscatal.7b02561

Acknowledgements

This work was supported by “Key Program for International S&T Cooperation Projects of China” from the Ministry of Science and Technology of China (Grant No. 2019YFE0123000), the National Natural Science Foundation of China (Grant Nos. 91961125 and 21905019), Science and Technology Project of Guangdong Province (No. 2020B0101370001), and Chemistry and Chemical Engineering Guangdong Laboratory (No. 1932004) and the Project from China Petrochemical Corporation (No. S20L00151). We thank the beamlines 1W1B and 4W1B at Beijing Synchrotron Radiation Facility (BSRF).

Funding

Open access funding provided by Shanghai Jiao Tong University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gao, Y., Wang, J., Yang, Y. et al. Engineering Spin States of Isolated Copper Species in a Metal–Organic Framework Improves Urea Electrosynthesis. Nano-Micro Lett. 15, 158 (2023). https://doi.org/10.1007/s40820-023-01127-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40820-023-01127-0