Highlights

-

This review introduces soft electronics for health monitoring assisted by machine learning, and discusses soft materials, physiological signals, and machine learning algorithms in sequence and their relationships.

-

The principles of classic machine learning algorithms and neural network algorithms are summarized and explained by representative examples combining with soft electronics.

-

The potential challenges of soft electronics assisted by machine learning especially in health monitoring field are outlined, and future research directions are outlooked.

Abstract

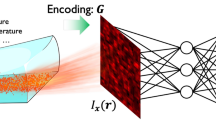

Due to the development of the novel materials, the past two decades have witnessed the rapid advances of soft electronics. The soft electronics have huge potential in the physical sign monitoring and health care. One of the important advantages of soft electronics is forming good interface with skin, which can increase the user scale and improve the signal quality. Therefore, it is easy to build the specific dataset, which is important to improve the performance of machine learning algorithm. At the same time, with the assistance of machine learning algorithm, the soft electronics have become more and more intelligent to realize real-time analysis and diagnosis. The soft electronics and machining learning algorithms complement each other very well. It is indubitable that the soft electronics will bring us to a healthier and more intelligent world in the near future. Therefore, in this review, we will give a careful introduction about the new soft material, physiological signal detected by soft devices, and the soft devices assisted by machine learning algorithm. Some soft materials will be discussed such as two-dimensional material, carbon nanotube, nanowire, nanomesh, and hydrogel. Then, soft sensors will be discussed according to the physiological signal types (pulse, respiration, human motion, intraocular pressure, phonation, etc.). After that, the soft electronics assisted by various algorithms will be reviewed, including some classical algorithms and powerful neural network algorithms. Especially, the soft device assisted by neural network will be introduced carefully. Finally, the outlook, challenge, and conclusion of soft system powered by machine learning algorithm will be discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Soft electronics have wide applications in radio frequency identification (RFID) [1], soft display [2], organic light emitting diode (OLED) display and lighting [3], chemical and biological sensors [4], soft photovoltaic [5], soft logic and storage [6], soft battery [7], wearable health monitoring devices [8] and other applications. With the rapid development of soft material and health care requirement, the soft electronic is being paid more and more attentions.

Traditional rigid sensors based on the silicon or other material have some disadvantages such as rigid substrate, no strain, low biocompatibility, which make it not suitable to be used in the large-strain and rough surface conditions [9]. The rigid morphology will greatly influence the wearing experience of the users, no more than long-time wearing. In addition, due to the low Young’s modulus of skin and other organs, the rigid electronics device cannot realize a tight interface with the skin. The air gap in the interface will greatly decrease the signal-to-noise ratio (SNR), introduce motion artifacts, and even destroy the original signal. The soft electronics with the good interface to skin can optimize the wearing experience and expand the number of users, which will enlarge the database size. Besides, more accurate physiological information can be distinguished from the high-quality signal. For the machine learning algorithms, the quantity and quality of data is important, which can help the algorithm to find the law in the data better. Therefore, soft electronics can improve the performance of the machine learning algorithms.

The machine learning algorithms can be used in data information and mining, pattern recognition, bioinformatics, etc., which can make the soft electronics more intelligent. The soft electronic device can monitor the physiological signal in real time and long time. After that, a dataset containing a great deal of physiological information with high quality to be learned and analyzed by machine learning algorithm will be built. Like human learning process, the more we learned, the more knowledge we will obtain. Large-quantity dataset can provide more knowledge to the algorithms, and the high-quality signal can provide more accurate knowledge for the algorithms to learn. Therefore, the interdiscipline containing soft electronics and machine learning has been widely studied to realize an intelligent system, which can not only detect the physiological signal but also diagnose it. Hence, the soft electronics and machine learning algorithms complement each other.

To meet the soft requirement, many structures such as serpentine [10], nanomesh [11, 12], and wavy [13] have been applied. In addition, many nanomaterials have been demonstrated to adapt to the complex interface, such as the two-dimensional (2D) material [14], carbon nanotube (CNT) [15], nanowire, and organic materials. These materials have been widely applied in soft solar cell [5], light emitting diode (LED) [16], sensors [15, 17], transistors [18], etc. Thus, the soft material will be discussed in the second section, which is the fundamental of soft electronics.

Among the applications of soft electronics, the health monitoring is an important function [8, 19]. Human body is full of physiological signals, which can reflect the conditions of ourselves. Some signals have been widely used in the diagnosis and prevention of diseases not only in hospital, but also in our daily life. For example, the pulse wave has been widely used in the diagnosis in the traditional Chinese medicine for 1000 years [20]. The respiration is an important parameter in health monitoring especially in the respiratory disease [21], particularly for the COVID (2019) [22]. Intraocular pressure (IOP) is the prime indicator for the diagnosis and treatment of glaucoma [23]. Electrocardiogram (ECG) is an important basis for judging cardiovascular diseases [24]. Electroencephalogram (EEG) can be used to diagnose epilepsy and mental diseases [25]. However, the transitory physical examination may have large uncertainty. The result may depend on the testing time and location. It is very meaningful to monitor the physiological signals whenever and wherever, which requires the good sensitivity, flexibility, and comfort of devices. Besides, the physiological signals provide the data for the algorithms to learn, which is the prerequisite of the machine learning. Therefore, the physiological signals and related soft monitoring devices will be discussed in the third section.

With the tight contact between the soft electronics and skin, the continuous and real-time physiological signal monitoring can be realized. Some sudden signals unable to be captured in hospital can be detected, which is important to the diagnosis. In addition, the good interface between skin and soft devices can further improve the SNR. The quantity and quality of physiological signal database can be optimized based on the soft electronics, which can improve the performance of machine learning algorithm, conversely. Before the extensive research of neural network algorithm, many classic algorithms have been used to classify the signals detected by the soft devices. Therefore, machine learning algorithm such as principal component analysis (PCA), linear discriminant analysis (LDA), Gaussian naive Bayes (GNB), support vector machine (SVM), k-nearest neighbor (kNN), K-means, decision tree (DT), etc., will be discussed combining with the soft electronics. Recently, due to the easy building and powerful characteristic, neural network has been investigated extensively. Hence, neural network algorithms including fully connected neural network (FNN), convolutional neural network (CNN), recurrent neural network (RNN), and spiking neural network (SNN) will be reviewed in detail in the fourth section.

Although the soft-electronics concept has been proposed for many years, the commercialization of soft devices has not been developed as fast as the research. The most notable application may be the soft screen, which doesn’t need the close contact with human body continuously. This can be attributed to many problems. First, compared with the silicon process, the production and fabrication of soft device are not stable and mature as the silicon device, which limits the mass production. In addition, the high price of the nanomaterials is also the obstruction of the commercialization. Secondly, most of the soft devices are fabricated on the dense polymer substrate such as polyethylene terephthalate (PET), polyimide (PI), polydimethylsiloxane (PDMS). With the interface mismatching to skin and low gas permeability, the wearing experience will be largely influenced. Therefore, the material is the key point of the high-comfort soft devices. Thirdly, the human body is a complex system with many kinds of physiological signals, each specific signal has its own characteristic. The soft electronics should be designed according to the signal. Fourthly, most of the research is still in the single device level, it is urged to realize the total soft system containing sensor, circuit, and intelligent algorithm, whose hardware parts all have the tight contact with skin. Finally, the signals obtained by the soft devices have the advantage of real-time, consecutive, and long-term. Large-scale datasets can be easy to build. Therefore, some datasets and algorithms for the soft devices need to be built and studied to realize the intelligent system, which can diagnose the physiological signals autonomously. According to the problems above, the challenge and outlook of soft electronics assisted by machine learning algorithm will be discussed in the fifth section.

In all, the soft electronics with good interface with skin can monitor the physiological signals in real time. Therefore, some sudden diseases can be alerted timely and the database of specific user can be built and enlarged. By combining with the machine learning algorithms, the soft system can not only detect the physiological signals but also diagnose them, which can reduce the burden on doctors. For example, during the popularity of COVID-19, a large number of inquiries increased the workload and the risk of infection of doctors. In a word, the intelligent soft electronic will lead to a healthier life, which is much meaningful to the human society. To realize the soft electronics, the materials and structures of the device should be designed. In addition, due to the variety of physiological signals, the structure of specific device should also be optimized. For easy reading, before talking about soft electronics assisted by the machine learning algorithms, soft materials and physiological signals will be discussed. In this review, we will first give an introduction to the soft material, physiological signals, and machine learning algorithms as well as their relationship. Then, some soft nanomaterials will be reviewed, respectively. After that, soft electronics based on the nanomaterials for physiologic signals monitoring will be discussed according to the signal types. The intelligent soft electronics assisted by machine learning algorithms will be reviewed. Finally, the challenge and outlook about the intelligent soft electronics will be given (Fig. 1).

Many new soft materials (2D material, CNT, nanowires, polymer nanomesh, hydrogel, etc.) have been applied to monitor physiological signals, such as EEG, EOG, IOP, breath, ECG, joint movement, blood pressure, pulse, photoplethysmography (PPG), EMG, and gait. The soft physiological monitoring system can be more and more intelligent assisted by algorithms such as SVM, DT, GNB, K-means, and neural network. Reproduced with permission [26,27,28,29]. Copyright (2016), (2020), (2022), American Association for the Advancement of Science. Reproduced with permission [30,31,32,33]. Copyright (2019), (2020), (2021), Nature Publishing Group. Reproduced with permission [34]. Copyright (2020), Wiley–VCH

2 Soft Nanomaterials

2.1 CNT

The extraordinary electrical and mechanical properties of CNT make it ideally suitable for soft electronics, especially high-performance wearable sensors, soft display, thin film transistors (TFTs), the implementation of complementary metal–oxide–semiconductor (CMOS) circuits, and the realization of medium-to-large-scale integrated circuits (ICs) and monolithic three-dimensional (3D) integration [35]. As one of promising candidates for next-generation electronic materials, CNT exhibits excellent properties for constructing high-performance soft electronics, including great mechanical flexibility [36], high carrier mobility [37], high current-carrying capacities [38], ultrathin body for effective electrostatic control, and the solution-processability for low-cost production [39]. Although there is still large room to improve the purity and density of the CNT for better performance, the currently available CNTs are adequate for the application in soft electronics with the large critical device dimensions. Many explorations have been carried out using CNT, and tremendous developments have revealed the superiority of the implementation of CNT in soft electronics [40, 41].

CNT has great potentials in soft displays (Fig. 2a) [42], wearable health (Fig. 2b) [43], sport monitors (Fig. 2c, d) [44,45,46], implantable medical devices (Fig. 2e) [47], etc. Electronic skin (e-skin) as a representative soft integrated sensor system usually consists of variable sensors on a soft platform that can spatially map or quantify certain stimuli, such as pressure [48], temperature [37], electromyograms (EMG) signals [49], ECG signals [50]. These platforms have drawn great attention for potential applications in wearable electronics, robotics, health monitoring, and medical prostheses. By closely integrating interface circuits with sensors, the SNR can be greatly enhanced by the in situ signal processing capability. For this purpose, the interface of circuits should also be mechanically soft with appropriate performance.

Microstructure and fabrication process of CNTs-based devices. a SEM image shows the SWCNT network between the printed Ag electrodes. The inset shows the incubated SWCNT network on the PET substrate as the channel region. Reproduced with permission [42]. Copyright (2016), American Chemical Society. b SEM image of the fractural structure of the SWCNT film grown from patterned catalysts using water-assisted CVD. Scale bar represents 5 µm. Inset: 3D image at 100% strain. Reproduced with permission [44]. Copyright (2011), Nature Publishing Group. c Top-view FE-SEM image of the PU-Poly(3,4-ethylenedioxythiophene)/Poly(styrenesulfonate) (PEDOT:PSS)-PDMS hybrid structure with SWCNT solution drop coated on it. Reproduced with permission [45]. Copyright (2015), American Chemical Society. d Implantable CNTs-based hybrid microfiber with tissues on it and e Schematic illustration of the wet-spinning setup for the fabrication of SWCNT hybrid microfibers with SWCNT concentration of 4 mg mL−1. Reproduced with permission [47]. Copyright (2019), American Chemical Society. f Fabrication process of the 3D patterned CNT array on aluminum substrate, and SEM micrographs of the vertically aligned CNTs on the aluminum substrate at different magnifications: g 200 × ; h 1 k × . Reproduced with permission [52]. Copyright (2017), Elsevier. i TEM image of a normal Pd-contacted CNT FET with gate length of 5 nm, the CNT FET synthesized by CVD. Reproduced with permission [65]. Copyright (2017), American Association for the Advancement of Science. j Removal of the aggregates CNTs on the wafer and the SEM image of it (the top-view CNT incubation pre-removed, and the bottom shows CNTs left on the wafer post-removed). Reproduced with permission [66]. Copyright (2019), Nature Publishing Group

CNTs are usually produced as a mixture of semiconducting and metallic nanotubes. Since only semiconducting nanotubes can be applied as the channel of transistors, the metallic nanotubes are typically not utilized, though it can be used as resistive load devices [51]. The purity of CNTs mainly depends on the preparing strategies, which will be discussed later.

Several strategies are currently available to prepare CNT networks and thin films, which can generally be classified in two categories: dry processes and solution processes. Dry processes are mainly chemical vapor deposition (CVD) and dry drawing from vertically aligned CNT arrays [52, 53]. As shown in Fig. 2f–h, CVD-grown single-walled CNT (SWCNT) films comprise ultralong nanotubes bonded by strong connections and thereby possess excellent conductivity, making them suitable for the electrode materials of many functional devices like super-fast actuators [54], stretchable supercapacitors [55], and strain sensors [56]. As for the solution-based process, where several methods have been reported including vacuum filtration [57], rod coating, drop coating, and printing [58, 59]. The solution process of CNTs can be achieved by successfully dissolving them in suitable organic solvents or in aqueous solution with the assistance of certain type of surfactants [36]. One disadvantage of CVD-grown SWCNT is purity. About one-third of the grown SWCNTs are metallic and two-thirds semiconducting SWCNTs (s-SWCNTs). Metallic-SWCNTs (m-SWCNTs) generally increase the current density of the film due to the higher current-carrying capacity, and can be used as the electrodes in various devices. However, the percolation path of m-SWCNTs connecting source to drain electrodes will lead to the short-circuit of the field effect transistor (FET) and the decreasing of the on/off ratio [60, 61]. The presence of m-SWCNTs also limits the channel length of the FET because shorter channels increase the probability of generating a percolating path of m-SWCNTs between the source/drain contacts. One of the common methods to remove m-SWCNTs in thin films of random networks or aligned SWCNTs is the selective electrical burning of m-SWCNTs [62]. Another method, particularly for random network of SWCNTs, is the strip method [63]. The SWCNT film is simply fabricated into narrow strips using conventional lithography and reactive-ion etching. Other than the methods mentioned above, selective plasma/gas etching, light irradiation, chemical surface reaction, and selective chiral growth have also been developed to selectively remove m-SWCNTs. These techniques have exhibited some success by fully or partially removing m-SWCNTs.

s-SWCNTs typically exhibit unipolar p-type behavior, which has been attributed to the doping of SWCNTs by oxygen in air or oxidizing acids during solution processing. To enable various applications such as diodes and complementary logic circuits, it is important to be able to fabricate n-type SWCNT transistors. Many techniques have been used to convert SWCNT FETs from p-type to n-type. One way is to change the contact metals from high work function metals to low work function metals, such as Al, Ca, and Sc, which aligns the metal Fermi level closer to the conductance band and reduces the barrier for electrons at the contacts [51]. Other techniques include electrostatic doping, annealing in hydrogen or in vacuum, passivation with inorganic oxides, and chemical doping with potassium, polyethyleneimine (PEI), hydrazine, polymer, electrolyte, viologen, and nicotinamide adenine dinucleotide [64].

ICs, being the core unit of electronic systems for information processing, are required to have decent electrical performance and mechanical flexibility and the ability to be integrated with other components. CMOS technology is the fundament of modern ICs and is also essential to pushing CNT-based soft electronics toward the next stage. Qiu et al. realized a 5 nm CNT FETs approached the quantum limit of FETs by using one electron per switching operation (Fig. 2i) [65]. Hills et al. have fabricated a 16-bit microprocessor based on the RISC-V instruction set, comprises more than 14,000 complementary metal–oxide–semiconductor CNT FETs (Fig. 2j) and is designed and fabricated using industry-standard design flows and process [66]. These works experimentally validate a promising path toward practical beyond-silicon electronic systems.

CNTs have been proven to be the material for high-performance soft electronics owing to the intrinsically great electric/mechanical properties and the low-temperature fabrication processes. The performance of CNT TFTs is much better than those using organic materials and metal oxide semiconductors, and surpassing those of silicon-based devices with similar channel lengths. In addition, CNTs are solution-processable, which can be deposited onto a large area of glass and soft substrates in a suspension at low temperature and cost. In one of the demonstrated works, integrating screen-printed active matrix CNT-based TFTs and electrochromic pixels showed a very good example of a cost-effective platform for large size soft displays [67].

2.2 Graphene

Graphene was discovered by Andre Geim and Konstantin Novoselov, who brought the monolayer graphene from the previous scientific hypothesis to the reality [68]. From then on, especially during the last decade, graphene has showed its revolutionary application potentials in wearable electronics and materials field, due to its excellent characteristics such as high electron mobility (350,000 cm2 V−1 s−1) [69], Young’s modulus (1 TPa) [70], thermal conductivity (5300 W m−1 K−1) [71], large specific surface area (2600 m2 g−1), and limited thickness (0.34 nm) [68].

Graphene is commonly referred as a 2D atomically thin sheet made of carbon atoms with a honeycomb lattice, densely packed by sp2 carbon atoms and can be rolled up to form zerodimensional (0D) fullerene and one dimensional (1D) CNT. Each carbon atom in the lattice has a π orbital that contributes to a delocalized network of electronics [72] and has three C–C bonds instead of four bonds like the diamond. These structures are the fundamental of the physical properties shown above. During the last decade, top-down and bottom-up methods have been developed to prepare graphene. The former is mainly based on bulk graphite [73]. External force could be used to peel out graphene, and this category of process can be divided into physical exfoliation and chemical exfoliation. Among them, physical exfoliation mainly refers to the exfoliation using a tape [68]. Meanwhile, chemical exfoliation including intercalation peeling [74], ultrasonic exfoliation [75], electrochemical exfoliation [76], and redox exfoliation [77]. The bottom-up method contains a series of complex reaction processes of carbon-containing precursor, such as CVD [69, 78], and chemical synthesis [79]. Among these methods, three classical methods are usually used: mechanical exfoliation, reduction of graphene oxide (GO), CVD (Fig. 3a–c) [69], etc. Meanwhile, 3D graphene films built by the 2D graphene flakes has potential in gas sensors and sound sources. The choice of graphene morphology should consider many factors, such as application, cost, and process [14]. Recently, the laser-scribed graphene (LSG) and laser-induced graphene (LIG) have drown much attention due to its low cost and fast fabrication of graphene (Fig. 3d). As shown in Fig. 3e, f, the LIG shows porous morphology on soft films, suitable for wearable application. LIG can also be prepared based on many different substrates, greatly enriched the raw materials to produce graphene [80].

Microstructure and fabrication process of graphene-based devices. a Illustration of the CVD furnace with a Cu enclosure inside. b Process schematic of the contamination-free transfer of CVD graphene from Cu onto hBN. c Optical microscopy image of grown graphene crystals on Cu foil. Reproduced with permission [69]. Copyright (2015), American Association for the Advancement of Science. d Schematic illustration of the fabrication process of LSG, and e the morphology of LIG sample produced at 290 mW under SEM. Scale bar represents 150 μm. f Cross-sectional view of LIG sample produced at 290 mW. Scale bar represents 12.5 μm. Reproduced with permission [101]. Copyright (2017), Nature Publishing Group. g SEM images of the tissue paper with rGO. Reproduced with permission [102]. Copyright (2017), American Chemical Society. h SEM image of the graphene textile. Reproduced with permission [103]. Copyright (2018), American Chemical Society. i Bioinspired graphene pressure sensor with a random distribution spinosum microstructure. Reproduced with permission [104]. Copyright (2018), American Chemical Society. j Self-overlapping graphene sheets and stacked structure with numerous interlayer gaps. Reproduced with permission [105]. Copyright (2018), American Chemical Society. k SEM images of porous graphene network. Reproduced with permission [21]. Copyright (2018), Elsevier. l Schematic illustration of the GO in PBS, and m Typical SEM images of rGO/Au nanoparticles (AuNPs) composite (Insert is the corresponding Energy dispersive X-ray spectrometry (EDS)) which can be used for electrocatalytic oxidation of nitrite at the electrode surface. Reproduced with permission [92]. Copyright (2018), Elsevier

Graphene can be fabricated into various forms (Fig. 3g–k). Based on the unique characteristics of graphene, more and more devices have been demonstrated. The high electron mobility and conical bandgap structure are suitable for high-performance photodetectors [81], and TFTs [82]. The ultrasmall thickness allows the bandgap of graphene to be easily tuned by applying a voltage. Therefore, spectrum-tunable LED [83] and window-tunable resistive random-access memory (RRAM) and synapses have been developed. Moreover, the high thermal conductivity is ideal for applications such as the heater [84], actuator [85], and thermoacoustic sources [86].

Among these applications, wearable graphene sensors applied for physiological signals monitoring show great potential. Physiological signals are highly complex, which are influenced by various factors of anatomical, psychological, physiological, social, environmental effects, etc. Wearable sensors should avoid rigid substrate, and have flexibility, biocompatibility, simple fabrication process, low cost. However, there are still many problems related to physiological sensors, the incompact interface and large impedance between human body and sensors will decrease the signal quality. Many physiological signals have been detected using graphene sensors such as mechanical signals like pulse [87], respiration [78], and human motions [88, 89], IOP [90], electrophysiological signals like ECG, EEG, EMG, and electrooculography (EOG) [88, 91]; electrochemical signals like ion and glucose concentration in fluids [92]. With the ultrahigh specific surface area, graphene is a suitable carrier (Fig. 3l, m) that can be modified as a chemical sensor to detect fluid [92] and gas [21].

Up to now, the 2D material has been developed into a system consisting of conductor (graphene [93] and MXene [94]), semiconductor (MoS2 [95] and other transition metal dichalcogenides (TMD) [96] and black phosphorus [97]), and insulator (hexagonal boron nitride [98]). The 2D system has potential in the soft electronics [99, 100].

2.3 MXene

In 2011, a new family of 2D carbides, carbonitrides, and nitrides labeled MXene was discovered. Their formula of MXene can be M1.33XTz or Mn+1XnTz (n = 1, 2 or 3), where M is an early transition metal, X is C and/or N and T represents various possible terminations (mainly hydroxyl, -OH, oxygen, -O and/or fluorine, -F) [106]. All known MAX phases (the abbreviation of Mn+1AXn phases, A is mainly a group IIIA or IVA element) are a group of layered hexagonal materials with P63/mmc symmetry, where the M layers are nearly closed packed, and the X atoms fill the octahedral sites. The Mn+1Xn layers are, in turn, interleaved with layers of A atoms. In other words, the MAX phase structure can be described as 2D layers of early transition metal carbides and /or nitrides ‘glued’ together with an A element [107]. The strong M–X bond has a mixed covalent/metallic/ionic character, whereas the M–A bond is metallic. Therefore, in contrast to other layered materials, such as graphite and transition metal chalcogenides, where weak van der Waals interactions hold the structure together, the bonds between the layers in the MAX phases are too strong to be broken by shear or any similar mechanical means. However, by taking advantage of the differences in character and relative strengths of the M–A compared with the M–X bonds, the A layers can be selectively etched by chemical method without disrupting the M–X bonds [108].

Due to the M–A bonds are weaker than the M–X bonds, MXene synthesis can be achieved by selective etching of the A element layers from the MAX phases at room temperature. The vast majority of MXene are obtained by etching the A layer from layered ternary MAX phases and their 2D nature [109], using concentrated hydrofluoric acid (HF) or a solution of lithium fluoride and HF.

Depending on the synthetic methods, the lattice parameter c (a parameter which indicates the interplanar spacing of MXene) of MXenes is different [109]. By using this parameter, the hydrated cations enter the space of MXene layers. For example, the lattice parameter c of Ti3C2 synthetic by etching Ti3AlC2 with 50% HF is 20.3 Å [110], but when etching with 40% HF, the lattice parameter c is about 20 Å [111], and the V2CTx with 50% HF is 23.96 Å [112]. In general, there are two methods of synthesizing MXene. The first is a bottom-up approach, such as CVD, which can produce high-quality films on various substrates. However, this approach is not generally used to fabricate MXene, because the films obtained are not single layer, but few-layer thin films [113]. The second approach is a top-down approach, involving the exfoliation of layered bulk. This approach can be further divided into mechanical and chemical exfoliation. The way to separate the graphene layers by adhesive tape is unsuitable for the MAX phases, because in contrast to most other 3D solids used as precursors to their 2D counterparts, the bonds between the M elements and A are strong covalent/metallic for the most part. Therefore, neither mechanical nor classical chemical exfoliation is possible. The first selectively etching the A layers is required. Recently, approaches to synthesizing MXene by top-down approaches including etching the MAX precursors for multilayers [114], and exfoliation for MXene [115] have been realized. Currently, about 30 different MXene compositions have been synthesized by top-down approaches. More compositions have been predicted by theoretical studies with stability.

For the combination of good properties and easy processing, MXene has various application potential, such as energy storage [116], electromagnetic shielding [117], electrodes [111, 118], electrocatalysis [119], and biosensors [120, 121]. In addition, MXene is easy to be combined with other nanomaterials as a nanosubstrate, which can greatly improve the malleability. When combined with 0D silver nanoparticles (AgNPs) and 1D silver nanowires (AgNWs) (Fig. 4a–c) [122], the elasticity and conductivity of traditional 1D materials can be improved, which ensures continuity and high gauge factor for soft fabric strain sensors for monitoring human motions. For wearable electrochemical biosensors, a MXene-based biosensor system has been proposed for in vitro perspiration analysis by simultaneously measuring physiochemistry signals (glucose and lactate level) using solid–liquid–air three-phase interface designed electrode [123]. As shown in Fig. 4d, the electrochemical detection platform is based on the Ti3C2Tx MXene, which consists of Ti3C2Tx/Prussian blue (PB) and CNTs porous film. The MXene thin film with low heat capacity and special layered structure is emerging as a promising candidate to build sound source [124]. Based on MXene’s thermoacoustic effect (Fig. 4e, f), the MXene earphone has a higher sound pressure level than that of graphene with the same thickness due to the better heat dissipation performance. After packed into a commercial earphone mold, MXene earphone has excellent performance especially at high frequencies, which is suitable for human audio equipment. Inspired by the human skin, a MXene-based piezoresistive sensor with randomly distributed spinous microstructures is designed (Fig. 4g) [120], and it can effectively promote the contact area of the conductive channels and improve performance. Sudeep et al. reported a facile fabrication of highly sensitive and reliable capacitive pressure sensor for ultralow pressure measurement by sandwiching MXene/PVDF-TrFE composite nanofibrous scaffolds (CNS) as a dielectric layer, as shown in Fig. 4h [125]. The proposed sensor can be used to determine the health condition of patients by monitoring physiological signals. Based on the Ti3C2Tx nanosheet, the proposed sensor can be used to determine the health condition of patients by monitoring physiological signals and represents a good candidate for the human–machine interfacing device. Tan et al. reported an optoelectronic spiking afferent nerve with neural coding, perceptual learning, and memorizing capabilities to mimic tactile sensing and processing, based on the Ti3C2Tx nanosheet (Fig. 4i). The system can detect the pressure by MXene-based sensors, and convert the pressure information to light pulses, and integrate light pulses using a synaptic photomemristor. With the dimensionality-reduced feature extraction and learning, the system can recognize and memorize handwritten alphabets and words, which provides a promising approach toward e-skin, neurorobotics and human–machine interaction technologies [121].

The structure and fabrication process of MXene. a Scheme of HF etching Al directly, by adding proportion of the DMSO solution, the MXene nanoblocks were delaminated into nanosheets. b AgNPs reduced by Ti3C2Tx mixed with AgNWs dipped into the surface of wrapped yarn modified by PDA, and c SEM image of yarns coated with MXene. Reproduced with permission [122]. Copyright (2019), American Chemical Society. d SEM image of porous and ultrathin Ti3C2Tx/PB and CNTs ternary film, with the inset (white box) displaying a zoomed‐in SEM image of the holes in the film. Reproduced with permission [123]. Copyright (2019), Wiley–VCH. e Schematic illustration of the Ti3C2 crystal structure and f TEM image of MXene nanoflakes, which has thermoacoustic effect for soft MXene earphone. Reproduced with permission [124]. Copyright (2019), American Chemical Society. g SEM images showing the rough surface and side of the randomly distributed microspinous MXene-based PDMS obtained using abrasive paper. Reproduced with permission [120]. Copyright (2020), American Chemical Society. h SEM image of the MXene composite nanofibrous scaffolds for wearable pressure sensor and the inset showing the morphology at a higher magnification. Reproduced with permission [125]. Copyright (2020), American Chemical Society. i Atomic resolution TEM image of a suspended Ti3C2Tx nanosheet from top view [121]. Copyright (2020), Nature Publishing Group

MXene occupies great potential in soft sensors because of its excellent conductivity, mechanical properties, hydrophilicity, and ease to control the morphology [126, 127]. By fully considering the advantages of MXene and the target requirements of devices, a new sensing system is formed by combining MXene materials with other suitable materials [125, 128], which can maximize the synergistic effect between MXene and other phase materials, and thus obtain a high-performance sensor with high sensitivity and wide response range.

2.4 AgNWs

With increasing demand for electronic and photovoltaic devices, it has become critical to ensure the electrical and mechanoelectric reliability of electrodes. Among various alternative materials for soft electrodes, such as metallic/carbon nanowires or meshes, AgNWs networks are regarded as promising candidate [129, 130]. Due to the high conductivity, high transparency, good thermal, chemical, and mechanical properties, more and more applications based on AgNWs have been discussed [131, 132].

Up to now, various methods for the synthesis of AgNWs have been proposed which can be originally derived from the metal nanoparticle preparation [133]. At early stages, AgNWs were mainly prepared via electrochemical methods with low yield and non-uniform size. Later, other methods including photochemical reduction [134], hydrothermal methods (Fig. 5a–d) [135, 136], and template techniques [137] were developed. Despite getting considerable progress, it remains a challenge to produce high-aspect ratio AgNWs via a facile and rapid process. More specifically, AgNWs networks are considered as promising alternative transparent conductive electrode materials because of network geometry, no dislocation activity, and high strength [138]. Transparent electrodes (TEs) are crucial for various optoelectronic devices including liquid–crystal displays (LCDs) [139], OLEDs [139], organic solar cells (OSCs) [140], touch screens [141], wearable electronics [142, 143], etc. Their performance highly depends on the fabrication method and the characteristics of AgNWs networks.

Fabrication process and structures for AgNWs in different fields. a Schematic diagram of synthesis and purification of AgNWs with hydrothermal method. b Schematic diagram of spin-coated AgNWs network on a glass substrate. c SEM image of the spin-coated AgNWs network on a glass substrate. d TEM image of the spin-coated AgNWs network on a lacey carbon-coated copper grid. Reproduced with permission [135]. Copyright (2017), Royal Society of Chemistry. e Close‐up of fused AgNWs junctions embedded into polymethyl-methacrylate (PMMA). Reproduced with permission [148]. Copyright (2013), Wiley–VCH. f SEM image of the interconnection with enlarged interconnection region. Inset showing the contact between AgNWs and ITO. Reproduced with permission [151]. Copyright (2015), Wiley–VCH. g Cross-sectional illustration of the screen‐printing process, and h SEM image of the dense AgNWs network structure in the screen‐printed AgNWs line for intrinsically stretchable AgNWs TFT array. Reproduced with permission [156]. Copyright (2016), Wiley–VCH. i SEM images of individual filaments, which used as a Joule heating element for woven heating fabric. Reproduced with permission [157]. Copyright (2020), American Chemical Society

Currently, the mainstream of TEs relies on the technique of high vacuum processes [131]. With the low-temperature processes and low cost, many solution coating processes have been studied to produce AgNWs electrodes through simple, reliable, and cost-efficient deposition techniques, such as spray coating, drop casting, spin coating, rod coating, dip coating, vacuum filtration, slot-die coating, and R2R coating [144]. Based on the fabrications and applications, the properties of AgNWs networks strongly depend on the following features: (i) individual nanowire properties, (ii) the interconnection (junctions) between them [132], and finally (iii) network density. Many works have been done to enhance these features, most of them are focused on the post treatment of the AgNWs network, including thermal annealing [145], mechanical pressing [132], light-induced plasmonic nanowelding [146].

Currently, the most efficient and widely used transparent conducting material is indium tin oxide (ITO). However, when compared with AgNWs, it shows less flexibility, and relatively high manufacturing costs [147]. AgNWs are suitable for preparing transparent soft electrode for its high conductivity, transparency, and mechanical flexibility. For soft OLED, high-efficiency white OLEDs fabricated using AgNWs-based composite TEs show almost perfectly Lambertian emission and superior angular color stability, imparted by electrode light scattering (Fig. 5e) [148]. Besides, 1D AgNWs and 2D graphene can be integrated for transparent OLEDs with similar behavior to the commercial ITO-based counterparts [149]. When used in photovoltaic (PV) modulus [144, 150], the AgNWs increased stability of the OSCs, suited for affordable PV modules. E-skin made by AgNWs electrodes (Fig. 5f) enables real-time super-resolution imaging of pressure distribution, which may have large impact on health care and security affairs [151]. Recently, with the rapid growth of soft electronics, carbon nanomaterial-based sensors have shown outstanding performance due to their superior mechanical and electrical properties. Highly sensitive strain sensors have been reported by using graphene sheets on the soft substrates [152]; with 1D structure and high transparency, AgNWs-based devices can gain higher stretchability and optical advantages than traditional carbon-based devices [142, 153]. It is easy to integrated with fibers for clothing-integrated sensors [142, 154]. Kim et al. proposed a soft smart sensor system integrated on soft contact lenses that achieved wireless ocular diagnostics [155], the AgNWs-graphene hybrid material was used to make field effect sensor and antenna, which is suitable for using in eyes. Since AgNWs can disperse homogeneously in water, Liang et al. fabricated a stretchable TFT array by screen-printed AgNWs (Fig. 5g, h), which revealed a low cost way for printed electronics [156]. Clothe can heat themselves spontaneously, based on the conductivity and thermal effect of AgNWs, Hwang et al., realized a soft heaters using AgNWs/PEDOT:PSS composition (Fig. 5i), which is machine-washable [157]. For electromagnetic interference (EMI) shielding, a soft device was demonstrated with AgNWs network on a PDMS substrate. Considering the increase in the EMI shielding effectiveness at low AgNWs density, this unique phenomenon is attributable to the effective shielding of the incoming EV wave [158].

AgNWs assembled into random networks have problems such as rough surface roughness, non-uniform networks, and high nanowires–nanowires junction resistance [141]. Recently, many studies have been carried out on techniques for the alignment of AgNWs, such as external magnetic or electric fields-based assembly [159], flow-enabled technique [160, 161], rod coating technique [141], and capillary printing technique [162]. Jung et al. fabricated a conductive nanomembrane with 540% elongation by float assembly method [163]. This method enabled monolayer compact packing of nanomaterials at the water–oil interface and fabrication of a nanomembrane with a cross-sectional structure in which metal nanomaterials are partially embedded in an ultrathin elastomeric membrane. The teeth-like nanowire structure allows high-resolution patterning of nanowires using photolithography without damaging elongation because nanowires are partially exposed from the elastomer. Moreover, contacts between nanowires can be consolidated further by cold welding of the partially exposed nanowires firming connections across nanowires. The conductivity of monolayer can differ depending on measurement directions, 103,100 S cm−1 in the parallel direction or 32,900 S cm−1 in the vertical direction. When two nanomembranes are stacked with the nanowires aligned to each other, a maximum conductivity of 165,700 S cm−1 was achieved. The stacked nanomembrane remained conductive up to ~ 400 or > 1,000% strain, parallel or vertical to the direction of nanowires, respectively.

AgNWs network offer opportunities for fundamental and applied research. Thanks to the easy fabrication, and the excellent electrical, optical, and thermal properties, AgNWs networks exhibit great potential for applying in various fields [164, 165]. Recently, investigations on enhancing the nanostructure for soft applications are increasing, such as nanomesh, nanofibers, and core-sheath structure to fulfill requirements in soft and implantable application [163, 166, 167]. Also, there are other kinds of metallic or nonmetallic nanowires (copper, gold, core–shell, organic nanofiber, etc.), which are suitable for a large variety of applications, which will not be discussed in this article.

2.5 Hydrogel

Hydrogel is a kind of extremely hydrophilic 3D polymer network, which can swell rapidly in water and hold a large volume of water without completely dissolving. Hydrogels exhibit many characteristics similar to natural soft tissues, such as good biocompatibility, adjustable physical and chemical properties, and high water content, and have always been one of the most widely used biological materials [168,169,170]. Furthermore, since the first report in 1994 of introducing conductive components into conventional hydrogels to obtain electroconductive hydrogels (CHs), the multifunctional CHs have been garnering tremendous interests in soft electronics, sensors and actuators, human–computer interfaces, as well as soft energy storage [171, 172]. Generally, CHs are composed of conductive components and soft hydrogel substrates. Considering the different conductive components, CHs can be divided into ionically conductive hydrogels (ICHs) and electronically conductive hydrogels (ECHs) (Fig. 6a) [173, 174]. ICHs are generally prepared by dissolving ionic salts (e.g., NaCl, LiCl) into hydrogels. As for the ECHs, the conductive components mainly include noble metal NPs and nanowires, carbon nanomaterials (CNTs, graphene, etc.) and other novel 2D materials (e.g., MXene), as well as several intrinsically conductive polymers with various ionic dopants, such as polypyrrole (PPy), polyaniline (PAni) and PEDOT [168, 175]. By integrating these conductive nanomaterials into the hydrogel matrix, the composite CHs can possess the ideal electronic conductivity, while retaining the reinforced biomechanical advantages of hydrogels. In addition, a wide range of natural polymers and synthetic polymers have also created infinite possibilities for the design and synthesis of CHs.

Hydrogel-based soft devices. a Material design of ICHs and ECHs. b Young's moduli of common electrode materials and cell/tissue. c Schematic illustration of the preparation and internal structure of conductive gelatin/nanofibrillated cellulose/Fe3+ hydrogels, and the relative resistance changes and GF with the increase of tensile strain (d), as well as their applications in monitoring elbow flexion, index finger flexion, throat vibration (e). Reproduced with permission [179]. Copyright (2022), Royal Society of Chemistry. f Principle and fabrication process of the PEDOT:PSS-PVA conducting polymer hydrogel, and the loading and unloading resistance responses of the PEDOT:PSS-PVA hydrogel strain sensor with a strain of 300% (g), as well as its application as robotic skins for sensory grasping (h). Reproduced with permission [178]. Copyright (2022), Wiley–VCH. i Schematic of the electrode and skin for sEMG and coupling process of the ionic fluxes in electrolytic tissue media and electronic current in the recording electrode. j 90° peel-off test of electrode based on Alg-PAAm gel and commercial gel. k Contact impedance verse frequency of the Alg-PAAm electrode and commercial electrode. l Needle grasping driven by sEMG signals obtained by as-prepared Alg-PAAm electrodes. Reproduced with permission [181]. Copyright (2020), Wiley–VCH. m Composition and synthesis of the conductive hydrogel composite composed of micrometer-scale Ag flakes and PAAm-alginate hydrogel (Ag-hydrogel composite). n Neuromuscular electrical stimulation electrodes made of the Ag-hydrogel composite with a commercial electrical muscle stimulator, and the relative changes in dorsiflexion angle as a function of stimulation time. Reproduced with permission [172]. Copyright (2021), Nature Publishing Group

Currently, multifunctional CHs have been broadly used in wearable and implantable soft bioelectronics due to their intrinsic skin-like and tissue-like properties [173, 176]. Overall, the advantages of CHs as soft bioelectronics are: (i) the adjustable conductivity over a wide range, (ii) the excellent biocompatibility (antibacterial, etc.), (iii) the ideal flexibility and elasticity, as well as favorable biomechanical interactions with biological tissues, (iv) the available bio adhesive properties at highly conformal electrode–tissue interfaces, even in humid environments, (v) the abundant and wide range of hydrogel materials for the “green” electronics. Briefly, for the design and synthesis of CHs in different applications, it is necessary to take into consideration the conductivity and mechanical properties of CHs, as well as the interaction between CHs and biological tissues. Yunsik et al. embedded Ag flakes into polyacrylamide (PAAm)–alginate hydrogel matrix [172], followed by the partial dehydration process, to obtain an electrically conductive hydrogel with high electrical conductivity (374 S cm−1), low Young’s modulus (< 10 kPa) matching several biological tissues, and high stretchability (250% strain). Apart from a variety of conductive fillers, the intrinsic hydrogel substrate materials have endowed the CHs with ideal biomechanical properties and adhesive properties. Conventional electronic materials are much stiffer than biological tissue, which may induce adverse biomechanical interactions at the electrode–tissue interface. Differently, in terms of Young’s modulus, the mechanical properties of CHs are similar to those of skin and other biological tissues, probably minimizing the mechanical mismatch with tissues (Fig. 6b). Besides, CHs with favorable bio adhesive properties are more likely to establish highly conformal and stable bioelectronic interfaces on the biological surfaces, which is beneficial to reduce interfacial impedance and promote bioelectrical signal transmission [177].

CHs-based stress/strain sensors have been widely used in human motion monitoring, prosthetic control, human–computer interaction (HMI), and touch panels [178, 179]. Different from traditional elastomer materials with brittle mechanical properties and insufficient biocompatibility, the comprehensive properties of CHs are expediently adjusted in terms of ionic and electronic conductivity, biocompatibility, antibacterial property, self-adhesion, elasticity, and flexibility, by means of reasonable material and structural design. Therefore, the CHs-based stress/strain sensors will exhibit excellent performance in mechanical stability, high strain sensitivity, wide linear range, fast response and recovery, low hysteresis, and fatigue resistance. As shown in Fig. 6c, Fu et al. constructed environmentally friendly, fully recyclable strain sensors based on self-healing, recyclable and conductive gelatin/nanofibrillated cellulose/Fe3+ hydrogels [179]. The multifunctional strain sensor possessed favorable strain sensitivity (Gauge factor (GF) = 2.24 under 6% strain) and compressive sensitivity (Sensitivity = 1.14 kPa−1 under 15 kPa) (Fig. 6d), and thus could accurately monitor and discern subtle bodily motions, handwriting, and personal signatures (Fig. 6e). Besides, Shen et al. developed a facile one-step compositing methodology combining PEDOT:PSS nanofibers with poly (vinyl alcohol) (PVA) [178], to create a unique microphase semi-separated network of CHs (Fig. 6f). The as-prepared PEDOT:PSS-PVA hydrogel strain sensor could exhibit high stretchability (300%) and ultralow hysteresis (< 1.5%) (Fig. 6g). The strain sensor with stable performance and high robustness could reliably enable precise, real-time remote control of industrial robots (Fig. 6h).

As a new generation of bioelectronic materials, the CHs have enabled the successful construction of highly conformal electrode–tissue interfaces, for high-quality bioelectronic stimulation and recording [30, 180]. Benefiting from the CHs with ideal stretchability and stiffness matching the biological tissue, the CHs-based patch electrode can closely fit on the uneven biological surface, even under the disturbance of dynamic mechanical deformation [181]. In addition, the CHs with intrinsic self-adhesive properties also ensure the high conformality and long-term stability of the hydrogel electrode–tissue interface. Pan et al. designed and fabricated compliant ionic electrodes based on highly self-adhesive Alg-PAAm/LiCl hydrogels, which were able to enhance the intermolecular interaction with the biological surface and eliminate the microgaps at the electrode–tissue interface (Fig. 6i) [181]. Therefore, the Alg-PAAm compliant electrode exhibited bioadhesive properties far superior to commercial electrodes (Fig. 6j), and had an ultralow interfacial impedance (20 kΩ) with skin (Fig. 6k). As shown in Fig. 6l, this electrode could record dynamically weak sEMG signals with high SNR and low crosstalk, for the successful and precise control of the prosthesis to perform fine and sophisticated motions. Yunsik et al. fabricated neuromuscular electrical stimulation electrodes based on Ag/Alg-PAAm hydrogels with high electrical conductivity and soft conformability (Fig. 5m) [172]. The Ag-hydrogel electrode could deliver high-frequency electrical signals with sufficient current to induce dorsiflexion in the foot, and drive more angular movements of the fingers compared with the normal ionic hydrogel electrodes (Fig. 5n).

2.6 Polymer Nanomesh

Recently, soft electronics have been widely used in the field of health care, playing a great role in monitoring biophysical signals, such as physiological electrical signals (ECG, EMG, etc.) and mechanical signals (pulse, respiration, joint bending, etc.) generated by vascular dynamics and human motions [8]. The monitoring of these signals is of great significance to the prevention and diagnosis of diseases and the recovery and reconstruction of motor function. Among the materials used to prepare sensors, polymer nanomesh with porous structure has shown great potential in the field of soft electronics due to its advantages, such as ultrasmall weight, high water vapor permeability, good skin compatibility, and good stability [11, 182, 183]. For example, Miyamoto et al. prepared an electrode based on the Au/PVA nanomesh as shown in Fig. 7a, which is inflammation-free, gas-permeable, lightweight, and stretchable [11]. After spraying water, PVA nanomesh can be dissolved so that nanomesh conductors can adhere to the skin closely (Fig. 7a, b). This electrode can not only be used as a pressure sensor to realize touch sensing (Fig. 7c), but also to monitor EMG, and the test results are almost the same as those of Ag–AgCl gel electrodes (Fig. 7d, e). The nanomesh can also be used to measure the skin impedance [184, 185]. Wang et al. realized a durable strain sensor based on the Au/PDMS/polyurethane (PU) nanomesh to monitor the facial tissue movements [186].

Application of polymer nanomesh in soft sensors. a Preparation process of the on-skin nanomesh electronics: first, Au is evaporated onto PVA nanomesh obtained by electrospinning; then, PVA meshes are dissolved by spraying water so that nanomesh conductors can adhere to the skin. b Picture of nanomesh conductor attached to the fingertip (Scale bar represents 1 mm) and the SEM image of the nanomesh conductor after dissolving PVA nanomesh (Scale bar represents 5 µm). c On-skin wireless sensor system based on the on-skin nanomesh electronics for touch sensing (Scale bar represents 3 mm). d Measuring the impedance of the skin/electrode interface by using nanomesh electrodes compared with Ag–AgCl gel electrodes. e EMG signals were measured on the forearm, while the wrist was flexed at 90° (two times) and at rest by both nanomesh and gel electrodes. Reproduced with permission [11]. Copyright (2017), Springer Nature. f Preparation of the PU/CNT/AgNWs strain sensor, and the SEM images of PU nanomesh, PU/CNT nanomesh and PU/CNT/AgNWs nanomesh. g Design concept of the double-layered conductive network for the PU/CNT/AgNWs strain sensor. h Applications of the PU/CNT/AgNWs strain sensor for monitoring different motion signals. Reproduced with permission [204]. Copyright (2020), American Chemical Society

Nanomesh can be prepared by many methods such as photolithography [187], natural fiber [188], and electrospinning [11]. In this review, the electrospinning polymer nanomesh was mainly discussed. The polymer nanomesh is manufactured by electrospinning technique as the matrix, and then functionalized by other materials to realize the construction of the sensing function. Therefore, the sensors are generally composed of nanomesh and functional modified materials. The former plays a role of structural support, and the latter acts as the signal response element of the sensor.

The polymer materials commonly be used to prepare nanomesh including PU [183, 189,190,191,192], PVA [11, 184, 185, 193], styrene butadiene styrene (SBS) [194], styrene ethylene butene styrene block copolymer (SEBS) [195], polyvinylpyrolidone (PVP) [196], etc. Under the electrostatic field, the viscous polymer solution in the syringe forms the Taylor cone at the needle tip due to the combined action of the electric field force, the surface tension and the viscoelastic stress of the solution, and extends into the uniform filament to deposit on the collector. The polymer can be changed into a 2D network film composed of micro- and nano-fibers by electrospinning, which leads to a large specific surface area for the next functional modification.

Functionalized modified materials are generally conductive materials, which can form conductive pathways in nanomesh to respond to external physical stimuli. Commonly used modified materials including CNTs [192, 195], reduced graphene oxide (rGO) [197, 198], MXene [191, 194], metal nanowires or NPs (Au [11, 184,185,186], Ag [192, 199], Pt [200], etc.). Functional modification methods can generally be divided into two types. One is to add functional materials to the electrospinning solution, forming nanomesh with polymer after electrospinning, and finally complete functional modification through subsequent treatment [196]. The other is to functionalize the surface of polymer nanomesh obtained by electrospinning. Here, due to the simplicity and convenience of preparation, the latter will be discussed. There are many methods of surface modification, the most common one is direct spraying, which is achieved by preparing functional substances into solutions and then coating them on the surface of polymer nanomesh by drop coating [201] or spraying [202, 203]. This modification method can only modify the surface layer of nanomesh. Functional materials can also be modified inside the nanomesh by soaking the nanomesh in the solution supplemented by ultrasound [197], so as to make the modification more solid. The above modification methods are mostly applicable to carbon nanomaterials, MXene, etc. For metal functional modifiers, the commonly used modification materials are generally NPs or nanowires. In addition to modifying the prepared metal nanowires by the above methods [202], the polymer nanomesh can also be soaked in the precursor solution and modified by in situ synthesis of metal NPs on the surface of the nanomesh through chemical reaction [204, 205], or the metal can be deposited on the surface of the nanomesh by sputtering [200]. In addition, in order to improve the stability, strain range, sensitivity, and other properties of the sensor, the nanomesh can be pre-modified before the modification of functional materials to improve the firmness of the modifier. For example, the nanomesh can be pre-modified with polydopamine (PDA) [195, 199] and other functional modifiers [190, 199]. Wang et al. used CNT and AgNWs to modify PU Nanomesh successively as shown in Fig. 7f [190]. The design principle of this sensor is to take advantage of different conductivities of the two conductive layers (Fig. 7g). The high-stretchability PU/CNT substrate layer acts as a structural support, which can realize the integrity of the conductive path even under a large strain. And the AgNWs layer offer a very low initial resistance. The combination of the two gives the strain sensor a wide working range (up to 150%) and a high sensitivity (up to 1477.7); therefore, this sensor can accurately detect the omnidirectional human motions, including subtle and large human motions (Fig. 7h).

2.7 Liquid Metal

Liquid metal and its alloys have become non-negligible materials for soft electronics due to their excellent thermal and electrical conductivity and rheological properties. Due to low vapor pressure, safety, and no pollution, gallium and its eutectic alloys formed with indium and tin are more widely used than highly toxic mercury, such as scalable RF electronics [206], strain sensor [207], thermal elastomer composite [208], microheater [209], epidermal strain sensors [210], electrically self-healing composite [211], and battery for stretchable electronics [212]. Liquid alloys have unique advantages in soft electronics with complex surface structures that require sufficient softness and deformation, including high resolution [213], conformal, stretchability, and self-healing to avoid failure or circuit breaking under cyclic deformation [211]. In an aerobic environment, the liquid alloys surface will form amphoterics solid oxide skin of nanometer thickness [214], which will affect the shape and adhesion of the liquid metal to various surfaces. A variety of technologies for liquid metal patterning have been implemented, such as atomized spraying [215], microchannel injection [216], inkjet printing [217], 3D printing [218], masked deposition [219], and transfer writing [220]. Among them, stencil print technology is undoubtedly the most attractive, because it can achieve economic, fast, mask free, automated, and mass production [221]. However, the high surface tension of liquid alloy and the existence of surface oxide make it difficult to print directly on the flexible substrate, and easy to fracture. Therefore, it is necessary to select a suitable transfer template and modify it, so that it cannot only selectively adsorb liquid metal, but also transfer completely on a variety of substrates [221, 222]. Recently, electron-beam lithography and soft lithography techniques can achieve high resolution at the sub-micron level [213]. In short, how to realize the patterning of liquid alloys in batch, high fidelity, high resolution, and low cost is still a hot research topic.

2.8 Brief Summary

As discussed above, to realize the soft electronics, the kinds and structures of material should be designed. Many novel nanomaterials (such as CNT, graphene, MXene, AgNWs, hydrogel, nanomesh, and liquid metal) have been prepared by well-designed methods (such as CVD, laser inducing, electrospinning, chemical synthesis, and solution-based method), which have great advantage to traditional materials in soft electronics. During the bending and stretching process, the materials must withstand large deformation without damage. Therefore, the breaking elongation of materials should be large enough. For example, the single-layer graphene can be used in the flexible devices. However, due to the fragility of single-layer structure, the materials will be damaged during the stretching process. The structure of materials should also be designed like the porous 3D structure. To some extent, not the thinner the better. In addition, for the large-scale commercial application, how to prepare the soft material in high efficiency and low cost is also crucial. Solution-based methods cooperated with pattern process may be a good choice.

3 Wearable Devices for Different Physiological Signals

3.1 Pulse

The pulse is driven by the heart and usually measured at the wrist (radial artery). It is affected by many factors, such as the conditions of blood, and muscle, skin. Therefore, it can reflect some physical conditions of human body. The pulse has been used in traditional Chinese medical science for more than 2000 years [223], where the pulse signals are picked at three acupoints (called ‘chi’, ‘guan’, ‘cun’) [20] with different applied force (small force call ‘fu’, middle force called ‘zhong’, large force called ‘chen’). This pulse condition of three acupoints under three pressure levels constitutes nine indexes.

The pulse rate of human is about 30–200 beats min−1. In the frequency domain, the pulse spectrum range is 0–20 Hz, and most of the energy is concentrated within 10 Hz. There are usually 3 peaks in a typical pulse wave (the percussion (P), tidal (T), and dicrotic (D) wave). The relative position and amplitude ratio of these peaks can be used to analyze cardiovascular status [20]. To detect the pulse signal, pressure/strain sensors are widely used, which be divided into three types: piezoresistive [224], piezoelectric [225], and piezocapacitive. Under the pressure, the resistance, voltage, and capacitance would be changed based on these three effects, respectively. Some typical pulse sensors are listed in Table 1.

Wu et al. demonstrated a soft pressure sensor with LSG based on the piezoresistive effect [226]. Different with common pressure sensor, this device has a positive resistance —pressure response. After optimizing the graphene pattern, the relative resistance variation of the sensor can be over 360,000% with good repeatability, and the sensitivity can be up to 434 kPa−1. In addition, the mechanical signal can be amplified like a mechanical triode under the external pressure bias. The pulse waves can be collected at the carotid artery (CA), brachial artery (BA), radial artery (RA), and dorsalis pedis artery (DPA), as shown in Fig. 8a. The systolic blood pressure (SBP) and diastolic blood pressure (DBP) can also be deduced from the pulse signals.

Soft sensors for pulse and respiration. a Blood pressure waveforms and values collected at the CA, BA, RA, and DPA. Gray areas indicate the BP range between the SBP and DBP values detected by a commercial sphygmomanometer. Reproduced with permission [226]. Copyright (2020), American Chemical Society. b Illustration of the pulse sensor with an exposed view of the bilayer coil structure for wireless data transmission and the cuff-type pulse sensor wrapped around the artery. Inset: Close-up view of the pressure-sensitive region of the sensor with the two variable capacitors C1 and C2. The two variable capacitors correspond to C1 and C2. The two inductors are in series with a fixed capacitor. Reproduced with permission [228]. Copyright (2019), Nature Publishing Group. c Photograph of a volunteer wearing the medical breathing mask with the humidity sensor fixed inside it. d Resistance variation response to fast, normal, and deep breathing. e Resistance variation response to mouth and nose breathing. Reproduced with permission [21]. Copyright (2018), Elsevier. f Photograph of the respiration sensor on the top of the upper lip with two motions, including pouting (left) and compressing lips (right). Reproduced with permission [237]. Copyright (2020), Elsevier

Piezoelectric effect is another way to detect the pulse signals. An important advantage of the piezoelectric sensor is the self-power. Chen et al. developed a soft piezoelectric pulse sensor (PPS) based on the single-crystalline group III-nitride thin film, which can be easily transferred and packaged by PDMS [227]. The piezoelectric sensor has good sensitivity. When dropped on a single drop of water with a mass of 38 ± 4 mg, the sensor can generate a voltage of about 20 mV. With the piezoelectric sensor, pulse waveform was measured at the carotid, brachial, radial, femoral, posterior tibial, dorsalis pedis, femoral, popliteal, fingertip, facial, and temporal artery.

Piezocapacitive effect is also a significate method of fabricating pressure sensors. Boutry et al. reported a piezocapacitive pressure sensor with biodegradable materials (Fig. 7b) [228]. The arterial blood flow can be detected in both contact and non-contact modes. Poly (glycerol sebacate) (PGS) with pyramidal patterns was applied as the dielectric layer. After the pressure loaded, the capacitance would be changed, leading to the shift of resonance frequency of the system consisting of the inductance and the piezocapacitive pressure sensor. More importantly, the sensor can realize the in vivo arterial pulse monitoring of the rat femoral artery.

3.2 Respiration

The total process of gas exchange between human body and external environment is called respiration. In the calm state, the normal respiratory rate of adults is about 16–20 times min−1. The monitoring and detection of human respiration is an important part of modern medical monitoring technology, especially in the treating of the COVID-2019 [22]. There are three typical sensors to detect the respiration signal, mechanical sensor [102], humidity sensor [21], and temperature sensor [237]. Some parameters of respiratory are shown in Table 2.

During the respiration process, the thorax expands when inhaling and shrinks when exhaling driven by the intercostal and diaphragmatic muscles. In addition, there will be pressure changes around the mouth or nose due to the flow of air. Therefore, the mechanical sensor can also be used to monitor the respiration signal, which is similar to the pulse sensor. Triboelectric nanogenerator (TENG) is another self-power device which can be utilized as not only energy harvester but also mechanical sensor. It relies on static electricity generated by friction between two materials to drive the flow of electrons and generate electricity. Wang et al. realized an integrated triboelectric respiration sensor for monitoring human respiration and NH3 concentration in exhaled gases [238]. Ce-doped ZnO and PDMS were used as the triboelectric layer and Au were coated as electrodes. The dissolution of water molecules into Ce-doped ZnO would enhance the relative permittivity of sensitive material and decrease the output voltage. Some gases such as NH3, CH4, CH2O, C2H5OH, and CO can also be detected.

Humidity sensor based on the electron transferring rather than mechanical interaction can also be used as the respiration sensor. Pang et al. fabricated the graphene on the nickel foam by CVD [21]. After etching the nickel, porous graphene networks were obtained. To enhance the sensing performance, the porous graphene was modified by the GO, PEDOT:PSS, and Ag colloids. The air flow force has no effect to the humidity sensor. Different breathing modes, such as slow, fast, deep, and normal, can be distinguished. The device can also be fixed inside the medical breathing mask to detect the respiration in real time (Fig. 8c, d). Huang et al. realized a soft, stretchable, and conductive nanofiber composite with acidified CNT decorated PU nanofiber [239]. As mentioned above, CNT is a typical p-type semiconductor. Electrons transferred from H2O molecules would reduce the density of holes in CNT and lead to the increase of the resistance. In addition, during a sensing test cycle, swelling and de-swelling caused by the H2O molecules would damage and recover the conductive network, also lead to the increase and decrease of the resistance. Other gas such as methanol, heptane, and acetone can also be detected.

During inhalation and exhalation, the temperature in the nasal cavity will change accordingly. Therefore, the temperature sensor can also be applied to detect the respiration signal. Liu et al. developed a respiration sensor based on metallic heating electrode (Cr/Au), thermistor, and PDMS package, as shown in Fig. 8e [237]. By adjusting the input power of heating electrode and increasing the temperature difference between the respiration sensor and environment, the sensitivity of the respiration sensor can be improved. In addition, various breathing patterns can be distinguished with the breath rate/depth of subjects, such as sitting, frightening, sleeping, meditating, and gasping.

3.3 Human Motion

Human motion signals including motions of the arm, hand, foot, knee, etc. Normally, the limbs would have large-strain changes during human activities. For example, walking is accompanied by the knee bending, arm swing, and foot compressing. More importantly, the detection of those motion signals can not only provide health care evaluation on our daily life, but also useful for posture correction in the rehabilitation treatment [244]. According to the position of limbs deformation, it can be classified into two major categories: (i) bending or stretching of arm or hand on the upper limb; (ii) bending and compressing of the knee or under the foot. The limbs bending and foot walking usually display large-strain variation and high-pressure impact, respectively. The strain and pressure sensors with large measuring range should be developed. To date, the strain sensors were widely used to monitor the large bending of elbow [245], wrist [246], finger [247], and knee [44, 103, 105, 224], while the pressure sensor with high measuring range were used to detect the different walking states [102, 248, 249].

The most frequently used limbs on the human body are supposed to be the arms and hands during the whole life. Almost all the actives involve the arm bending, and hand holding or releasing. Thus, it is necessary to develop highly sensitive, stable, reproducible, and durable strain sensors for this specific application. Yamada et al. reported a class of wearable and stretchable devices fabricated using thin films of aligned CNTs [44]. When stretched, the CNTs films were fractured into gaps, islands, and bundles bridging the gaps. This mechanism allows the films to be strain sensors with the measuring strains up to 280%, with high durability, fast response, and low creep. The CNTs sensors were assembled on stockings, bandages, and gloves to detect the movement. Yang et al. proposed a AgNPs bridged graphene strain sensor for simultaneously detecting subtle and intensive human motions [105]. AgNPs serve as the bridges to connect the self-overlapping graphene sheets, which endows the strain sensor with many excellent performances. With high GF of 475, it is suitable to be applied in human motion detection. Then, they fabricated a close-fitting and wearable graphene textile strain sensor based on a graphene textile without polymer encapsulation [103]. GO acts as a colorant to decorate the polyester fabric and is reduced by high temperature, which endows the graphene textile strain sensor with excellent performance. Compared with other strain sensors, the textile strain sensor exhibits a distinctive negative resistance variation with increasing strain. The graphene textile strain sensor can be knitted on clothing for detecting both subtle and large human motions, as shown in Fig. 9a, b. The wrist guard integrated with the graphene textile strain sensor can monitor wrist movement, including the resistance change with different English letters, such as “A”, “S”, and “V”. It can also be knitted on a single glove to monitor the response toward the bending of a finger.

Soft sensors for human motion. a Detection of various human motions using the wearable graphene textile strain sensor. b Detection of writing English letters. Reproduced with permission [103]. Copyright (2018), American Chemical Society. c Photograph of the honeycomb-like graphene composite structure. d Photograph of the foot with the HGN pressure sensor. e Response of the HGN pressure sensor under walking and running. Reproduced with permission [248]. Copyright (2020), Institute of Electrical and Electronics Engineers. f Tissue paper with rGO. g Response curves for the tester’s movements of jumping and push-ups. Reproduced with permission [102]. Copyright (2017), American Chemical Society. h Area of foot selected for sensors and i array of pressure sensor. j Gait cycles readings for left and right foot with FSR smart insole. Reproduced with permission [249]. Copyright (2020), MDPI

Walking is a basic capability that allows the human to carry out daily activities. When someone suffers the pathological gait disease, the motion capture technology can provide quantitative features for its analysis and diagnosis [250]. Generally, the walking states could be monitored by the pressure sensor under the foot or strain sensor on the knee. For the pressure sensor, it measures the force directly caused by the periodic foot stepping. Due to the body weight, pressure sensors with proper sensitivity in a wide pressure range are desirable. Besides, high flexibility and low thickness would bring a comfortable experience for long-term monitoring. Tian et al. fabricated a soft pressure sensor based on the honeycomb-like graphene network (HGN) by mixing cube sugar, graphene oxide solution, and PDMS (Fig. 9c, d) [248]. Attributing to the structure, the pressure working range can cover from 0 to 150 kPa. Benefiting from its advantages in pressure range, it shows good performance when monitoring working or running form (Fig. 9e). Based on the paper tissue, Tao et al. fabricated a graphene/paper pressure sensor (Fig. 9f), which can be applied in intense motion detections [102]. As shown in Fig. 9g, the sensor shows the difference between jumping and push-ups. For the systematic approach to detection and analysis gait, Tahir et al. provided a systematic design and characterization procedure for three different pressure sensors including a soft piezoelectric sensor, which can be used for detecting vertical ground reaction forces using a smart insole [249]. The pressure sensor array was placed in a customized shoe above the control circuit. Pressure data were digitized through a microcontroller before sent wirelessly to a host computer for post processing and analysis. The subsystem was powered by a battery with the help of a power management unit. Pressure data were analyzed to extract various gait characteristics for different gait applications. As shown in Fig. 9h, i, sixteen sensors were placed on each insole to record pressure values in these areas, the inputs were multiplexed to one output through a 16-to-1 multiplexer and applied to an analog-to-digital (ADC) conversion input of the microcontroller then sent to host computer. The gait cycle of 12 subjects were recorded while walking on a 10 m walkway in self-selected walking manner. In Fig. 9j, the gait cycles readings for left and right foot were clearly recorded by the system, and can be further analyzed for assessing walking behaviors.

3.4 Intraocular Pressure