Highlights

-

Dimensional gradient structure of sheet–tube–dots was constructed with CoSe2@CNTs–MXene for fast ion and electron transportation.

-

Density functional theory study discloses the electrochemical difference of CoSe2@CNTs–MXene in ether/ester electrolyte system.

-

Phase transformation of CoSe2@CNTs–MXene was analyzed by in situ XRD. The full cell based on CoSe2@CNTs–MXene anode was also assembled.

Abstract

Recently, abundant resources, low-cost sodium-ion batteries are deemed to the new-generation battery in the field of large-scale energy storage. Nevertheless, poor active reaction dynamics, dissolution of intermediates and electrolyte matching problems are significant challenges that need to be solved. Herein, dimensional gradient structure of sheet–tube–dots is constructed with CoSe2@CNTs–MXene. Gradient structure is conducive to fast migration of electrons and ions with the association of ether electrolyte. For half-cell, CoSe2@CNTs–MXene exhibits high initial coulomb efficiency (81.7%) and excellent cycling performance (400 mAh g−1 cycling for 200 times in 2 A g−1). Phase transformation pathway from crystalline CoSe2–Na2Se with Co and then amorphous CoSe2 in the discharge/charge process is also explored by in situ X-ray diffraction. Density functional theory study discloses the CoSe2@CNTs–MXene in ether electrolyte system which contributes to stable sodium storage performance owing to the strong adsorption force from hierarchical structure and weak interaction between electrolyte and electrode interface. For full cell, CoSe2@CNTs–MXene//Na3V2 (PO4)3/C full battery can also afford a competitively reversible capacity of 280 mAh g−1 over 50 cycles. Concisely, profiting from dimensional gradient structure and matched electrolyte of CoSe2@CNTs–MXene hold great application potential for stable sodium storage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently, emerging sodium-ion batteries (SIBs) have been deemed to be the new-generation battery for large-scale energy storage applications benefitting for abundant resources, low cost and low standard hydrogen potential (− 2.71 V) [1,2,3,4]. In the last ten years, researchers have developed a great variety of anode electrode materials and different kinds of cathode materials for SIBs [5, 6]. Meanwhile, advanced SIBs systems, such as Na–S, Na–metal and Na–O2 batteries, have also achieved prominent energy density in the effort of researchers [7,8,9]. However, owing to its large ionic radius (1.02 Å) compared to Li ion (0.76 Å) and dense molar mass, poor reaction kinetics, bad rate performance and weak cycling performance limit the large-scale application of SIBs [10]. Therefore, constructing high specific capacity anode materials with good reaction kinetics is an effective method to build extraordinary energy density sodium-ion full cells. Meanwhile, appropriate electrolyte systems are another way to ensure long-term and high cycling performance for full batteries. So, it is necessary to develop compatible electrode materials and electrolyte system to promote the application of SIBs.

Transition metal chalcogenides (TMCs), a kind of narrow/zero bandgap materials with low cost, high electric conductivity and unique electrochemical properties, have been widely investigated as the potential active materials for alkali-ion batteries [11,12,13,14]. In most cases, pulverization caused by huge volume change and dissolution of intermediate in electrochemical processes leads to poor cycling performance. A generic strategy is encapsulating TMCs in functionalized carbon transferred from metal–organic frameworks (MOFs) [15]. MOFs can provide high surface area and controllable microstructure. After carbonization and selenylation process, the hollow functionalized carbon shell can tolerate tremendous phase change stress [16]. Meanwhile, heterogeneous element-doped carbon shell can also restrain the dissolution of sodium selenide in electrolyte [17]. Xu et al. synthesized ZnSe/N-doped hollow carbon architectures for SIBs with a revisable capacity of 250.8 mAh g−1 at 1 A g−1 exhibiting excellent stability [18]. CoSe2@N-CF/CNTs can give a capacity of 428 mAh g−1 at 1 A g−1 after cycling for 500 times [19]. Synergistic effect in hierarchical gradient structure can greatly enhance electron/ion diffusion, as well as carbon shell encapsulation strategy can guarantee the stabilization of active materials and impede the strain during electrochemical processes. Therefore, constructing hierarchical structure of TMCs transferring from MOFs is a potential method to acquire high-performance sodium-ion anode materials.

Electrolyte, an ion conductor, is another critical component of the rechargeable battery system [20]. Common carbonate ester-based solvents such as ethylene carbonate (EC) and propylene carbonate (PC) are widely applied in SIBs. These electrolyte systems can obtain high ionic conductivity, wide electrochemical window and stable solid electrolyte interphase (SEI) film on the surface of electrode materials [21]. However, low initial coulombic efficiency (ICE), poor cycling stability and the dissolution of reaction intermediate are severe challenges that need to be addressed. Compared with LIBs, the working voltage is usually lower than 4 V, which makes it possible for the adoption of ester electrolyte system [22]. On the other hand, the ester-based electrolyte can significantly improve ICE and rate performance of SIBs [23, 24]. Transition metal sulfides (TMDC) like ZnS showed a superior rate capability and outstanding long-term cyclability assisted by ether electrolyte [25]. Cu2MoS4–RGO exhibited excellent cycling stability (215 mAh g−1 after 2000 cycles) and good full cell performance (75.5% after 500 cycles) [26].

Herein, we report a dimensional gradient structure building with CoSe2@CNTs–MXene anode materials for SIBs by exploiting a NaPF6 in a new DEGDME electrolyte system. Cobalt (Co)–MOFs are deposited on the MXene by an easy coprecipitation method. Carbon nanotubes (CNTs) grow on the surface of MXene in the catalysis of Co particles, followed by selenylation process. MXene, acting as the flexible matrix, not just promotes the fast ion and electronic transmission by constructing a “sheet–tube–dots” hierarchical structure, but also impedes the dissolution of Na2Se in electrochemical processes. The CoSe2@CNTs–MXene in ether electrolyte maintains an outstanding cycling performance of 400 mAh g−1 after 200 cycles at 2 A g−1 with a high ICE of 81.7% and excellent rate stability of 347.5 mAh g−1 at 5 A g−1, which is much better than electrochemical behaviors in ester system (only 27 mAh g−1 for 200 cycles). The great electrochemical contrast of CoSe2@CNTs–MXene in disparate electrolyte systems is evidenced by DFT calculations. Meanwhile, phase transformation of CoSe2@CNTs–MXene in the first cycle was successfully analyzed by in situ XRD and dynamic electrochemical impedance spectroscopy (EIS) analysis. Importantly, CoSe2@CNTs–MXene and Na3V2 (PO4)3/C full cell is assembled, delivering outstanding cycle performance with a capacity of 280 mAh g−1 after 50 cycles at 100 mA g−1.

2 Experimental Section

2.1 Materials

2-Methylimidazole, Co (NO)3 6H2O, methanol, LiF and HCl were purchased from Shanghai Aladdin Bio-Chem Technology Co., Ltd. Ti3AlC2 powders were purchased from Jilin 11 Technology Co. Ltd., China. All chemical reagents were used without further purification. The ultrapure water was used throughout the experiment process.

2.2 Synthesis of Ti3C2Tx MXene Nanosheets

Firstly, 1 g LiF was dissolved in 10 mL 9 M HCl at room temperature. Then, 1 g Ti3AlC2 powders were added into LiF/HCl solution for 10 min to avoid overheating. The next, mixed solution was transferred into a Teflon autoclave and kept at 60 ℃ for 24 h. After cooling to room temperature, the etching product was washed with 3 M HCl and ultrapure water successively, until the pH of solution reached 7. Finally, the black jelly was sonicated in water under the protection of argon for 2 h and centrifuged at 3500 rpm. The concentration of final obtained Ti3C2Tx MXene nanosheets colloidal solution was about 8 mg mL−1.

2.3 Synthesis of CoSe2@CNTs–MXene

In a popular method, 0.6 mmol Co (NO)3·6H2O and 10 mL MXene colloidal solution were mixed in 40 mL methanol. Then, 6 mmol 2-methylimidazole in 50 mL methanol with 12 μL triethylamine was poured into the above solution followed by stirring continuously for 1 h. After washing with methanol, the ZIF-67@MXene was dried in vacuum at 80 ℃ for 12 h. Next, ZIF-67@MXene was annealed under Ar/H2 atmosphere at 700 ℃ for 2 h with a heating rate for 2 ℃ min−1, the Co@CNTs–MXene. At last, Co@CNTs–MXene was mixed with Se powder at a weight ratio of 1:3 and heated under Ar atmosphere at 500 ℃ for 3 h. The preparation of CoSe2@CNTs was synthesized by a similar method without MXene.

2.4 Materials Characterization

X-ray diffraction (XRD) was tested by Rigaku SmartLab SE with Cu Kα radiation (λ = 1.5406 Å). Thermogravimetric analysis (TGA) was measured by STA 449 F5 Jupiter. Raman spectrum was obtained by LabRAM HR Evolution using 532-nm laser. The surface composition of samples was analyzed by X-ray photoelectron spectroscopy (XPS, ESCALAB250Xi). Morphology was acquired by a field emission scanning electron microscope (FESEM, ZEISS SIGMA) and a field emission transmission electron microscope (FETEM, JEOL JEM-2100F); both of them were equipped with an EDX spectrometer (Oxford Instruments). In situ XRD was represented by a special electrochemical reaction unit with a beryllium (Be) window.

2.5 Electrochemical Measurements

For half-cell, active materials (AC), Super P and PVDF were stirred with a weight ratio of 8:1:1 by a high-speed homogenizer. The slurry was coated on copper foil with a scraper, and the mass load of AC is about 1.1 mg cm−2. Sodium foil and glass fiber (Whatman) were used as a counter electrode and a separator. Two different kinds of system ether (1 M NaPF6 in DEGDME) and ester (1 M NaPF6 in PC) were adopted as electrolyte, respectively. And the ratio of electrolyte/electrode in the half-cell is about 10 uL mg−1. For full cell, Na3V2 (PO4)3/C was adopted as cathode materials. The capacity matching was achieved by controlling the coating thickness and promoting the anode capacity having a 5–10% surplus compared with cathode capacity. The mass loading of cathode electrode slice is about 6 mg cm−2. Before assembling full cell, CoSe2@CNTs–MXene was activated for three cycles in advance. Cyclic voltammetry (CV) curves were obtained by CHI 660D workstation. A Neware BTS-4008 system was employed for charge/discharge and rate performance. Electrochemical impedance spectroscopy (EIS) was evaluated by using a Zahner IM6 system (0.01–105 Hz).

2.6 Computational Details

Quantum ESPRESSO v6.4.1 software packages were adopted for all density functional theory (DFT) calculation [27]. Perdew–Burke–Ernzerhof (PBE) in generalized gradient approximation (GGA) considering van der Waals force (VDW) was employed to analyze the exchange functional [28]. The kinetic energy cutoffs for the wavefunction were 60 Ry. 5 × 5 × 1 C–N surface and 3 × 3 × 1 Ti3C2O2 surface built with a 20 Å vacuum region. A 3 × 3 × 1 k-point mesh of Brillouin zone was put to use. The binding energy (Ebind) of Na2Se on different matrix could be calculated by Ebind = ENa2Se-matrix-ENa2Se-Ematrix. For all structure and adsorption models, the energy convergence accuracy was within 1 × 10–7 eV and 0.001 eV Å for force. Rietveld method was used to refine the XRD data of Na3V2 (PO4)3/C [29].

3 Results and Discussion

3.1 Synthesis and Characterization of CoSe2@CNTs–MXene

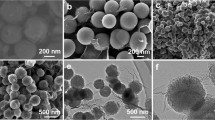

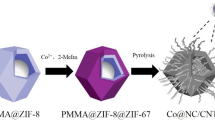

CoSe2@CNTs–MXene was prepared by a universal strategy followed by carbonization and selenylation processes, which is displayed in Fig. 1a. Typically, single-layer Ti3C2Tx was synthesized through a fluoride-based salt etchants method reported by Ghidiu [30, 31]. To avoid the oxidization of Ti3C2Tx during usage, appropriate sodium L-ascorbate was added in the colloidal solution [32]. XRD patterns (Fig. S1) indicate successful synthesis of Ti3C2Tx MXene. Microstructure of single-layer Ti3C2Tx characterized by TEM is shown in Fig. S2, and the individual Ti3C2Tx MXene looks ultrathin and transparent, with a size range from 100 to 700 nm [33]. Selected area electron diffraction (SAED) patterns reveal excellent crystallinity and unique hexagonal structure of single-layer Ti3C2Tx MXene [34]. Then, ZIF-67 nanocubes were prepared through a conventional co-precipitation method at ambient temperature [35]. SEM images of ZIF-67 (Fig. 1b) exhibit homogeneous octahedrons with a diameter of 150–250 nm. For ZIF-67/MXene, ZIF-67 with an average size of 25 nm covered the entire surface of MXene (Fig. 1c, d) evenly under the effect of electrostatic interaction [36]. The growth of ZIF-67 could well impede the reunion of MXene benefitting for construction the conductive network. XRD analysis in Fig. S3 also clearly shows the similarity between ZIF-67 and ZIF-67/MXene. After annealing treatment at 800 ℃ under Ar/H2 atmosphere, a novel “tube-on-nanosheet” structure of Co@CNTs–MXene was obtained (Fig. 1e). CNTs with hundreds of nanometers grew neatly on the surface of MXene. Co2+ ions were reduced to elemental cobalt (ICPDS No.15–0806) under the effect of H2 (Fig. S4). Pure cobalt nanoparticles constantly catalyze the growth of carbon nanotubes during the carbonization process of ZIF-67 [37]. The final product CoSe2@CNTs–MXene was acquired after selenylation at 500 ℃ for 3 h, as displayed in Fig. 1f, g. CoSe2 particles were encapsulated on the top of CNTs. Two crystal interplanar spacings, 0.253 and 0.319 nm, could be well fitted with the (221) of CoSe2 and (103) of carbon, respectively. The elemental mapping of CoSe2@CNTs–MXene is also displayed in Fig. S5. For comparison, CoSe2@CNTs was also prepared without the addition of MXene (Fig. S6). The construction of a “sheet–tube–dots” hierarchical structure can significantly enhance the transport of electrons and sodium ions.

The XRD patterns of CoSe2@CNTs and CoSe2@CNTs–MXene are displayed in Fig. 2a. Both of them clearly show a single-phase composition of cubic CoSe2 (ICPDS no. 65–3327, space group: Pa \(\stackrel{\mathrm{-}}{3}\)). No additional reflection appearing in the spectrogram means the high purity of products. At the same time, characteristic peaks of MXene at 5–10° could not be found in the diagram. This phenomenon indicates MXene has been evenly dispersed in CoSe2@CNTs–MXene. Raman spectroscopy (Fig. 2b) of CoSe2@CNTs–MXene shows two peaks at 186 and 673 cm−1, respectively, owning to the Ag and A1g modes for CoSe2. Some tiny peaks near 500 cm−1 can be attributable to the slight oxidation of CoSe2 surface. D and G peaks for sp3 and sp2 carbon are situated at 1345 and 1586 cm−1, respectively. The ID/IG scale is about 1.07, indicating a good degree of graphitization, which is conducive to the transfer of electrons and sodium ions.

TGA of CoSe2@CNTs–MXene was tested in hot air from 25 to 800 ℃ with a heating rate of 10 ℃ min−1, as shown in Fig. 2c. The mass increases between 400 and 500 ℃ owing to the formation of SeO2 and oxidization of MXene, respectively. The primary mass loss after 600 ℃ contributes to the transformation from CoSe2 to Co3O4 and the sublimation of SeO2 [19]. Based on the above TGA tests, the calculated mass percentage of CoSe2 in CoSe2@CNTs–MXene is about 63%. XPS was measured to invesitage chemical states of CoSe2@CNTs–MXene, total spectrogram of CoSe2@CNTs–MXene (Fig. 2d) is clearly observed the coexistence of Co, Se, Ti, C and N, relatively. Figure 2e–i exhibits the fine spectrogram of Co 2p, Se 3d, Ti 2p, C 1 s and N 1 s, respectively. The signal of Co 2p (Fig. 2e) shows two broad peaks locating at 781.1 and 797.2 eV corresponding to Co 2p3/2 and Co 2p1/2. Peaks at 778.4 and 793.7 eV can be corresponded to the Co–O bond due to the surface oxidization of CoSe2 [38]. Owing to the orbital between Co atoms and Se atoms, two satellite peaks also can be found in the spectrogram [35]. The Se 3d spectra (Fig. 2f) can be split into two main peaks at 54.5 and 55.4 eV for Se 3d5/2 and Se 3d3/2, respectively. Peaks between 57 and 62 eV belong to the existence of CoSe2 and SeO2 [39]. In the high-resolution Ti 2p spectra (Fig. 2g), peaks at 458.55 and 464.3 eV correspond to Ti 2p3/2 and Ti 2p1/2 [40]. For C 1 s in Fig. 2h, three peaks locating at 284.8, 286.6 and 287.55 eV can be assigned to sp2 C, C–O and C = O, respectively. Peaks from left to right for N 1 s are attributed to graphitic, pyrrolic and pyridinic nitrogen, in turn [18].

3.2 Electrochemical Performance of CoSe2@CNTs–MXene

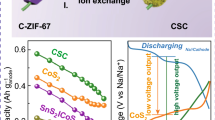

The unique structure of CoSe2@CNTs–MXene makes it a promising application in energy storage fields. Electrochemical performances of CoSe2@CNTs–MXene were investigated by assembling half-cell countering with sodium foil. Cyclic voltammetry (CV) curves of CoSe2@CNTs–MXene (Fig. 3a) in ether electrolyte were measured in 0.1–3 V at a scan rate of 0.1 mV s−1. In the first discharge, a broad cathodic peak at 1.065 V corresponds to the insertion of sodium ion into CoSe2, leading to the formation of NaxCoSe2. With further discharge, NaxCoSe2 was eventually broken into Na2Se and Co till to 0.1 V. Then, in the anodic process, peaks locating at 1.7–2.0 V stand for Na2Se, which regenerated to amorphous CoSe2 clusters [38, 41, 42]. For comparison, CV curves of CoSe2@CNTs are also displayed in Fig. S7. In order to reveal the electrochemical reaction progress of the first cycle, in situ XRD was also tested, which is displayed in Fig. 4. When the voltage decreased from 2.0 to 1.0 V, diffraction peaks of CoSe2 at 30.5°, 34.2° and 37.6° gradually vanished. At this stage, sodium ion embedded into CoSe2 and further formed NaxCoSe2. With the voltage down to 0.1 V, NaxCoSe2 was decomposed completely and peaks of Na2Se became apparent. In the charging process, Na2Se has sloughed the sodium ion and transformed to CoSe2 again. Reaction processes can be described as Eqs. 1 and 2:

a, b CV curves of CoSe2@CNTs–MXene in ether/ester electrolyte at a scan rate of 0.1 mV s−1 in the range of 0.1–3 V. c, d Discharge/charge curves of CoSe2@CNTs–MXene in ether/ester electrolyte. e Cycle performance of CoSe2@CNTs–MXene in ether and ester electrolyte at a current of 2 A g−1. f Rate performance of CoSe2@CNTs–MXene in ether

Due to the highly disordered structure of CoSe2 in charge course, the characteristic peaks of CoSe2 cannot be discovered in the spectra. In order to illustrate this mechanism clearly, ex situ Raman was measured. After charging to 3 V, the characteristic peak of CoSe2 is found in Fig. S8. All these pieces of evidence can prove the CoSe2–Na2Se–CoSe2 conversion process.

Figure 3b exhibits the CV graphs of CoSe2@CNTs–MXene in the ester environment, which presents a distinct electrochemical process. The cathodic peak in 0.8 V in the first cycle shifts left about 0.26 V than ether electrolyte, and a loose anodic peak exists around 2 V. However, reaction peaks could not fit commendably and disappeared gradually after the second cycle. Galvanostatic charge/discharge profiles of CoSe2@CNTs–MXene in ether at a current of 2 A g−1 are shown in Fig. 3c. In the first cycle, the discharge/charge capacities can be evaluated to 397.5/324.6 mAh g−1, with high coulombic efficiency (CE) about 81.7%. Irreversible capacity loss in the first cycle can be attributed to the generation of solid electrolyte interface (SEI) film. At the same time, the plateaus in discharge/charge processes can exhibit well fitness with CV curves. Reversible capacity for CoSe2@CNTs–MXene in ether retains at 315.7, 317.2, 346.6, 376.8 and 397.7 mAh g−1 after 2nd, 3rd, 20th, 50th and 100th cycles, with a CE of about 99.8%. Continuous capacity increase benefits from the improvement in electrode wettability and capacitance effect in electrochemical processes. On the other hand, a great deal of capacity loss was observed at CoSe2@CNTs–MXene in ester; discharge/charge capacities in the first cycle are 413/223.9 mAh g−1 with a low CE of 54.2% (Fig. 3d). Side reactions of electrolyte and serious dissolution of selenide lead to the low coulombic efficiency in the first cycle. Reversible capacity after 2nd, 3rd, 20th, 50th and 100th cycles is only 143.5, 122.9, 56.8, 40 and 31 mAh g−1, respectively. With the cycle proceeding in progress, discharge/charge plateaus disappear gradually and only matrix materials contributive capacity exists after 200 cycles. Cycle performances of CoSe2@CNTs–MXene in the different electrolyte systems at 2 A g−1 are displayed in Fig. 3e. CoSe2@CNTs–MXene in the ether can keep up a stable capacity at 400 mAh g−1 after 200 cycles, which is vastly superior to a low capacity of 27 mAh g−1 for the electrode in ester. For CoSe2@CNTs and pure MXene, the revisable capacity is only 215.34 mAh g−1 after 200 cycles (Figs. S9 and S10), respectively. Rate performances of CoSe2@CNTs–MXene in the ether (Fig. 3f) can obtain invertible capacities for 450.5, 423, 391.5, 366 and 347.5 mAh g−1 at a current of 1, 2, 3, 4 and 5 A g−1, respectively, which is superior to some other MXene-based anodes (Table S1). All of these performance tests indicate CoSe2@CNTs–MXene can exhibit great electrochemical properties in ether electrolyte. In order to explain the huge electrochemical performance discrepancy of CoSe2@CNTs–MXene in different electrolyte systems, XPS investigation for C 1 s, O 1 s and F 1 s of anode materials (after the first cycle) is shown in Fig. S11. The SEI layer comprises sodium inorganic/organic complex, organic matter and fluoride. For ether, an obvious peak locating at 686.7 eV can be contributed to the C–F bond. Such high fluorine content guarantees prominent mechanical strength of SEI layer, which can keep the cycling stability during electrochemical processes [7]. After cycling for 100 times, separators were disassembled for XPS analysis. Spectra in Fig. S12 can also verify the dissolution of selenide. A weak peak ranging from 58 to 60 eV can be found in the ester spectra, which belongs to selenide signals. In contrast, no signal was detected in the ether separator.

3.3 DFT Calculations

Density functional theory (DFT) was used to describe the polyselenide shuttling constraint mechanism in different electrolytes. The space group of cubic CoSe2 (Fig. 5a) is Pa \(\stackrel{\mathrm{-}}{3}\), which can be well fitted with XRD data. Band structure of CoSe2 demonstrates its metallic behavior and outstanding electron conductivity. For MXene, the bandgap of Ti3C2O2 is only 0.3 eV. In our previous research, sodium ion can migrate easily on the surface of MXene. CoSe2 nanoparticles, carbon nanotubes and MXene nanosheets together construct a spot–line–surface system that contributes to the ultrafast kinetics for ion transport and electron conduction. The lowest unoccupied molecular orbital (LUMO) and highest occupied molecular orbital (HOMO) of propylene carbonate (PC) and bis (2-methoxy ethyl) ether (DEGDME) are shown in Fig. S13. Energy gaps of PC and DEGDME are 6.0363 and 5.2606 eV, respectively; both of them can satisfy the requirement of SIBs. Relaxed adsorption geometries of Na2Se/PC, Na2Se/DEGDME, Na2Se/C-N and Na2Se/ Ti3C2O2 are demonstrated in Fig. 5e–h. The binding energy between PC, DEGDME and Na2Se is 0.69 and 0.6 eV. It follows that PC as the electrolyte solvent has an interaction with sodium selenide. DFT calculation further confirmed the binding strength of Na2Se on C–N nanosheet is only 0.62 eV. So, when NaxCoSe2 transferred into Na2Se and pure Co in the first discharge process, abundant Na2Se dissolved in the electrolyte, leading to the low initial coulombic efficiency and serious capacity loss. Charge density difference of Na2Se on Ti3C2O2 (Fig. S14) shows an electron-loss region around selenium atoms and an electron-rich region around MXene surface. Exposed Ti atoms and O atoms on MXene could capture electrons from selenium atoms under the effect of the Lewis acidity property [43]. Ti–Se bond and Se–O bond guarantee Na2Se can be anchored tightly (2.04 eV) on the surface of MXene [42]. The enormous binding energy prevents the dissolution of Na2Se in the process of electrochemical processes, which is in good agreement with experimental results.

3.4 Kinetics Analysis of CoSe2@CNTs–MXene

Capacitive/diffusion behavior analysis, galvanostatic intermittent titration technique (GITT) and electrochemical impedance spectroscopy (EIS) are adopted to investigate the excellent electrochemical kinetics of CoSe2@CNTs–MXene in detail. The cathode and anode peaks of CoSe2@CNTs–MXene (Fig. 6a) at different scan rates (from 0.5 to 2.5 mV s−1) show no significant deviation and can be repeatable at a high scan rate. This evidence can also explain the reason for outstanding rate performances of CoSe2@CNTs–MXene. The plot log (i) against log (v) and the fitting line are displayed in Fig. 5b. Calculation formulas of the capacitive contribution are Eqs. S1 and S2 described detail in supporting information. Capacitive contribution for specific capacity is 47.6, 56.2, 61.2, 64.5 and 67%, respectively, under the scan rate of 0.5, 1.0, 1.5, 2.0 and 2.5 mV s−1 (Fig. 6c). Higher contribution of capacitance at high scan rate is conducive to favorable cycle and rate properties [44, 45]. Diffusion stability of sodium ion in CoSe2@CNTs–MXene under different electrolytes could get further insight by GITT. Figure 6d shows the discharge curve from 3.0 to 0.1 V under an identical current of 100 mA g−1 for 5 min followed by a relaxation step for 30 min until the cutoff voltage. The ether battery shows evident cycling stability than ester than the good reaction kinetics of CoSe2@CNTs–MXene in ether electrolyte. Electrochemical impedance spectroscopy analysis of CoSe2@CNTs–MXene in different electrolytes was also explored. Nyquist plots of CoSe2@CNTs–MXene in ether and ester are displayed in Fig. 6e–f. EIS of CoSe2@CNTs was also tested (Fig. S15). EIS curves can be divided into three parts, inductive reactance and semicircle related to the resistance of electrode in high-frequency region and the linear part for ion diffusion in low frequency [46]. Both curves can be well fitted with the classic equivalent circuit model as shown in Fig. S16. Charge-transfer resistance between interfaces for CoSe2@CNTs–MXene in ether is 9.77 Ω, which is much lower than the ester system (239 Ω). Other parameters are also listed in Table S2. This phenomenon also proves the favorable invasion at interface. Low resistance for the interface of electrode and electrolyte contributes to high sodium-ion diffusion rate during electrochemical processes. Dynamic EIS analysis of CoSe2@CNTs–MXene in different kinds of electrolyte at first discharge/charge cycle (Fig. S17) can also prove the excellent reaction kinetics of ether. The addition of MXene can also improve interface situations owing to the contact of the solid–liquid interface.

a CV curves of CoSe2@CNTs–MXene at various currents from 0.5–2.5 mV s−1. b log i versus log v plots. c Contribution ratio of capacitive capacity of CoSe2@CNTs–MXene at various scan rates. d GITT of CoSe2@CNTs–MXene in ether at a current of 100 mA g−1. e, f Nyquist plots of CoSe2@CNTs–MXene in ether/ester electrolyte

3.5 Full Cells Evaluation of CoSe2@CNTs–MXene

To confirm the application value of CoSe2@CNTs–MXene as the anode in SIBs, Na3V2 (PO4)3/C cathode and CoSe2@CNTs–MXene anode full cell was assembled with NaPF6 in DEGDME as the electrolyte (Fig. 7c). The synthesis strategy of Na3V2 (PO4)3/C was reported in our previous work [47]. Figure 7a displays the experimental XRD pattern and calculated data of Na3V2 (PO4)3, with low Rwp (5.7%) and Rp (4.4%), indicating the high purity of Na3V2 (PO4)3 phase. Lattice parameters of Na3V2 (PO4)3 are a = 8.712798 Å, b = 8.712798 Å, c = 21.804346 Å with α = 90°, β = 90°, λ = 120° (R-3c), respectively, which can greatly match with preceding literature. Capacity–voltage curve of Na3V2 (PO4)3/C at the first cycle (Fig. 7b) shows the voltage plateau is at 3.4 V and Na3V2(PO4)3/C can provide an 80 mAh g−1 at 100 mA g−1 after 50 cycling periods (Fig. S18). For Na3V2 (PO4)3/C//CoSe2@CNTs–MXene full sodium-ion batteries, the cell can provide an initial charge/discharge capacity (Fig. 7d), 401 and 331 mAh g−1, under the current of 100 mA g−1, respectively, from 0.5 to 3 V (based on the weight of anode). Beyond that, the full cell can obtain an invertible capacity of about 280 mAh g−1 after 50 cycles (Fig. 7e), indicating the good application prospect in energy storage fields.

a XRD refinement of Na3V2 (PO4)3. b First discharge–charge curves of Na3V2 (PO4)3 half-cell at the current of 100 mA g−1. c Model structure of Na3V2 (PO4)//CoSe2@CNTs–MXene full cell. d Discharge–charge curves of Na3V2 (PO4)//CoSe2@CNTs–MXene full cell at the current of 100 mA g−1. e Cycle performance of Na3V2(PO4)//CoSe2@CNTs–MXene full cell at 100 mA g−1

4 Conclusions

Dimensional gradient structure of CoSe2@CNTs–MXene transferred from ZIF-67/MXene has been successfully designed. A particular “sheet–tube–dots” hierarchical structure can greatly promote the fast ion/electronic transmission and keep the stability of CoSe2 nanoparticles. Meanwhile, electrochemical performances of CoSe2@CNTs–MXene in two-electrode systems, ether/ester electrolyte systems were systematically explored. CoSe2@CNTs–MXene in ether exhibits outstanding cycling properties which can obtain 400 mAh g−1 after 200 cycles at 2 A g−1 with a high ICE of 81.7%, and excellent rate stability of 347.5 mAh g−1 at 5 A g−1 is much better than electrochemical behaviors in ester system (only 27 mAh g−1 for 200 cycles). Transformation mechanisms of CoSe2 were also explored by in situ XRD and ex situ Raman. Density functional theory study discloses that the CoSe2@CNTs–MXene in ether electrolyte system contributes to stable sodium storage performance owing to the strong adsorption force from hierarchical structure and weak interaction between electrolyte/electrode. For full cell, CoSe2@CNTs–MXene//Na3V2 (PO4)3/C can also afford a reversible capacity of 280 mAh g−1 over 50 cycles at a current of 100 mA g−1. Briefly, unique dimensional gradient structure and suitable electrolyte design promote potential application of CoSe2@CNTs–MXene in sodium storage fields.

References

Y. Huang, Y. Zheng, X. Li, F. Adams, W. Luo et al., Electrode materials of sodium-ion batteries toward practical application. ACS Energy Lett. 3(7), 1604–1612 (2018). https://doi.org/10.1021/acsenergylett.8b00609

R. Schmuch, R. Wagner, G. Hörpel, T. Placke, M. Winter, Performance and cost of materials for lithium-based rechargeable automotive batteries. Nat. Energy 3(4), 267–278 (2018). https://doi.org/10.1038/s41560-018-0107-2

C. Vaalma, D. Buchholz, M. Weil, S. Passerini, A cost and resource analysis of sodium-ion batteries. Nat. Rev. Mater. 3(4), 18013 (2018). https://doi.org/10.1038/natrevmats.2018.13

G.-L. Xu, R. Amine, A. Abouimrane, H. Che, M. Dahbi et al., Challenges in developing electrodes, electrolytes and diagnostics tools to understand and advance sodium-ion batteries. Adv. Energy Mater. 8(14), 1702403 (2018). https://doi.org/10.1002/aenm.201702403

L. Li, Y. Zheng, S. Zhang, J. Yang, Z. Shao et al., Recent progress on sodium ion batteries: Potential high-performance anodes. Energy Environ. Sci. 11(9), 2310–2340 (2018). https://doi.org/10.1039/C8EE01023D

Y. You, A. Manthiram, Progress in high-voltage cathode materials for rechargeable sodium-ion batteries. Adv. Energy Mater. 8(2), 1701785 (2018). https://doi.org/10.1002/aenm.201701785

X. Xu, D. Zhou, X. Qin, K. Lin, F. Kang et al., A room-temperature sodium–sulfur battery with high capacity and stable cycling performance. Nat. Commun. 9(1), 3870 (2018). https://doi.org/10.1038/s41467-018-06443-3

X. Xu, K. Lin, D. Zhou, Q. Liu, X. Qin et al., Quasi-solid-state dual-ion sodium metal batteries for low-cost energy storage. Chem 6(4), 902–918 (2020). https://doi.org/10.1016/j.chempr.2020.01.008

J.-L. Ma, F.-L. Meng, Y. Yu, D.-P. Liu, J.-M. Yan et al., Prevention of dendrite growth and volume expansion to give high-performance aprotic bimetallic Li-Na alloy–O2 batteries. Nat. Chem. 11(1), 64–70 (2019). https://doi.org/10.1038/s41557-018-0166-9

Y. Li, Y. Lu, C. Zhao, Y.-S. Hu, M.-M. Titirici et al., Recent advances of electrode materials for low-cost sodium-ion batteries towards practical application for grid energy storage. Energy Storage Mater. 7, 130–151 (2017). https://doi.org/10.1016/j.ensm.2017.01.002

N. Choudhary, M.A. Islam, J.H. Kim, T.-J. Ko, A. Schropp et al., Two-dimensional transition metal dichalcogenide hybrid materials for energy applications. Nano Today 19, 16–40 (2018). https://doi.org/10.1016/j.nantod.2018.02.007

W. Kang, Y. Wang, J. Xu, Recent progress in layered metal dichalcogenide nanostructures as electrodes for high-performance sodium-ion batteries. J. Mater. Chem. A 5(17), 7667–7690 (2017). https://doi.org/10.1039/C7TA00003K

R. Lv, J.A. Robinson, R.E. Schaak, D. Sun, Y. Sun et al., Transition metal dichalcogenides and beyond: Synthesis, properties and applications of single- and few-layer nanosheets. Acc. Chem. Res. 48(1), 56–64 (2015). https://doi.org/10.1021/ar5002846

L. Yang, W. Hong, Y. Tian, G. Zou, H. Hou et al., Heteroatom-doped carbon inlaid with Sb2X3 (X=S, Se) nanodots for high-performance potassium-ion batteries. Chem. Engin. J. 385, 123838 (2020). https://doi.org/10.1016/j.cej.2019.123838

H. Hu, J. Zhang, B. Guan, X.W. Lou, Unusual formation of CoSe@carbon nanoboxes, which have an inhomogeneous shell, for efficient lithium storage. Angew. Chem. Int. Ed. 55(33), 9514–9518 (2016). https://doi.org/10.1002/anie.201603852

M. Zhong, L. Kong, N. Li, Y.-Y. Liu, J. Zhu et al., Synthesis of MOF-derived nanostructures and their applications as anodes in lithium and sodium ion batteries. Coord. Chem. Rev. 388, 172–201 (2019). https://doi.org/10.1016/j.ccr.2019.02.029

H. Wang, Y. Jiang, A. Manthiram, Long cycle life, low self-discharge sodium–selenium batteries with high selenium loading and suppressed polyselenide shuttling. Adv. Energy Mater. 8(7), 1701953 (2018). https://doi.org/10.1002/aenm.201701953

Y. He, L. Wang, C. Dong, C. Li, X. Ding et al., In-situ rooting ZnSe/n-doped hollow carbon architectures as high-rate and long-life anode materials for half/full sodium-ion and potassium-ion batteries. Energy Storage Mater. 23, 35–45 (2019). https://doi.org/10.1016/j.ensm.2019.05.039

J. Yang, H. Gao, S. Men, Z. Shi, Z. Lin et al., CoSe2 nanoparticles encapsulated by n-doped carbon framework intertwined with carbon nanotubes: High-performance dual-role anode materials for both Li- and Na-ion batteries. Adv. Sci. 5(12), 1800763 (2018). https://doi.org/10.1002/advs.201800763

J.B. Goodenough, K.-S. Park, The Li-ion rechargeable battery: A perspective. J. Am. Chem. Soc. 135(4), 1167–1176 (2013). https://doi.org/10.1021/ja3091438

K. Xu, Nonaqueous liquid electrolytes for lithium-based rechargeable batteries. Chem. Rev. 104(10), 4303–4418 (2004). https://doi.org/10.1021/cr030203g

J. Zhang, D.-W. Wang, W. Lv, L. Qin, S. Niu et al., Ethers illume sodium-based battery chemistry: Uniqueness, surprise and challenges. Adv. Energy Mater. 8(26), 1801361 (2018). https://doi.org/10.1002/aenm.201801361

Y. Huang, L. Zhao, L. Li, M. Xie, F. Wu et al., Electrolytes and electrolyte/electrode interfaces in sodium-ion batteries: From scientific research to practical application. Adv. Mater. 31(21), 1808393 (2019). https://doi.org/10.1002/adma.201808393

Z. Lin, Q. Xia, W. Wang, W. Li, S. Chou, Recent research progresses in ether—and ester-based electrolytes for sodium-ion batteries. InfoMat 1(3), 376–389 (2019). https://doi.org/10.1002/inf2.12023

D. Su, K. Kretschmer, G. Wang, Improved electrochemical performance of Na-ion batteries in ether-based electrolytes: A case study of ZnS nanospheres. Adv. Energy Mater. 6(2), 1501785 (2016). https://doi.org/10.1002/aenm.201501785

J. Chen, L. Mohrhusen, G. Ali, S. Li, K.Y. Chung et al., Electrochemical mechanism investigation of Cu2MoS4 hollow nanospheres for fast and stable sodium ion storage. Adv. Funct. Mater. 29(7), 1807753 (2019). https://doi.org/10.1002/adfm.201807753

P. Giannozzi, O. Andreussi, T. Brumme, O. Bunau, M. Buongiorno Nardelli et al., Advanced capabilities for materials modelling with quantum espresso. J. Phys. Condes. Matter. 29(46), 465901 (2017). https://doi.org/10.1088/1361-648x/aa8f79

M. Dion, H. Rydberg, E. Schröder, D.C. Langreth, B.I. Lundqvist, Van der Waals density functional for general geometries. Phys. Rev. Lett. 92(24), 246401 (2004). https://doi.org/10.1103/PhysRevLett.92.246401

B. Toby, EXPGUI, a graphical user interface for GSAS. J. Appl. Crystallogr. 34(2), 210–213 (2001). https://doi.org/10.1107/S0021889801002242

M. Alhabeb, K. Maleski, B. Anasori, P. Lelyukh, L. Clark et al., Guidelines for synthesis and processing of two-dimensional titanium carbide (Ti3C2Tx MXene). Chem. Mat. 29(18), 7633–7644 (2017). https://doi.org/10.1021/acs.chemmater.7b02847

M. Ghidiu, M.R. Lukatskaya, M.-Q. Zhao, Y. Gogotsi, M.W. Barsoum, Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance. Nature 516(7529), 78–81 (2014). https://doi.org/10.1038/nature13970

X. Zhao, A. Vashisth, E. Prehn, W. Sun, S.A. Shah et al., Antioxidants unlock shelf-stable Ti3C2Tx (MXene) nanosheet dispersions. Matter 1(2), 513–526 (2019). https://doi.org/10.1016/j.matt.2019.05.020

M. Naguib, M. Kurtoglu, V. Presser, J. Lu, J. Niu et al., Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater. 23(37), 4248–4253 (2011). https://doi.org/10.1002/adma.201102306

O. Mashtalir, M. Naguib, V.N. Mochalin, Y. Dall’Agnese, M. Heon, et al., Intercalation and delamination of layered carbides and carbonitrides. Nat. Commun. 4(1), 1716 (2013). https://doi.org/10.1038/ncomms2664

L.-P. Lv, C. Zhi, Y. Gao, X. Yin, Y. Hu et al., Hierarchical “tube-on-fiber” carbon/mixed-metal selenide nanostructures for high-performance hybrid supercapacitors. Nanoscale 11(29), 13996–14009 (2019). https://doi.org/10.1039/C9NR03088C

W. Zhang, X. Jiang, X. Wang, Y.V. Kaneti, Y. Chen et al., Spontaneous weaving of graphitic carbon networks synthesized by pyrolysis of ZIF-67 crystals. Angew. Chem. Int. Ed. 56(29), 8435–8440 (2017). https://doi.org/10.1002/anie.201701252

J. Meng, C. Niu, L. Xu, J. Li, X. Liu et al., General oriented formation of carbon nanotubes from metal–organic frameworks. J. Am. Chem. Soc. 139(24), 8212–8221 (2017). https://doi.org/10.1021/jacs.7b01942

Y. He, M. Luo, C. Dong, X. Ding, C. Yin et al., Coral-like NixCo1−xSe2 for Na-ion battery with ultralong cycle life and ultrahigh rate capability. J. Mater. Chem. A 7(8), 3933–3940 (2019). https://doi.org/10.1039/C8TA10114K

J. Gao, Y. Li, L. Shi, J. Li, G. Zhang, Rational design of hierarchical nanotubes through encapsulating Cose2 nanoparticles into MoSe2/C composite shells with enhanced lithium and sodium storage performance. ACS Appl. Mater. Interfaces 10(24), 20635–20642 (2018). https://doi.org/10.1021/acsami.8b06442

H. Huang, J. Cui, G. Liu, R. Bi, L. Zhang, Carbon-coated MoSe2/MXene hybrid nanosheets for superior potassium storage. ACS Nano 13(3), 3448–3456 (2019). https://doi.org/10.1021/acsnano.8b09548

S.-K. Park, Y.C. Kang, MOF-templated n-doped carbon-coated CoSe2 nanorods supported on porous CNT microspheres with excellent sodium-ion storage and electrocatalytic properties. ACS Appl. Mater. Interfaces 10(20), 17203–17213 (2018). https://doi.org/10.1021/acsami.8b03607

D. Wang, F. Li, R. Lian, J. Xu, D. Kan et al., A general atomic surface modification strategy for improving anchoring and electrocatalysis behavior of Ti3C2T2 MXene in lithium–sulfur batteries. ACS Nano 13(10), 11078–11086 (2019). https://doi.org/10.1021/acsnano.9b03412

X. Wang, C. Yang, X. Xiong, G. Chen, M. Huang et al., A robust sulfur host with dual lithium polysulfide immobilization mechanism for long cycle life and high capacity Li-S batteries. Energy Storage Mater. 16, 344–353 (2019). https://doi.org/10.1016/j.ensm.2018.06.015

G. Fang, Q. Wang, J. Zhou, Y. Lei, Z. Chen et al., Metal organic framework-templated synthesis of bimetallic selenides with rich phase boundaries for sodium-ion storage and oxygen evolution reaction. ACS Nano 13(5), 5635–5645 (2019). https://doi.org/10.1021/acsnano.9b00816

H. Hou, C.E. Banks, M. Jing, Y. Zhang, X. Ji, Carbon quantum dots and their derivative 3d porous carbon frameworks for sodium-ion batteries with ultralong cycle life. Adv. Mater. 27(47), 7861–7866 (2015). https://doi.org/10.1002/adma.201503816

P.L. Taberna, P. Simon, J.F. Fauvarque, Electrochemical characteristics and impedance spectroscopy studies of carbon-carbon supercapacitors. J. Electrochem. Soc. 150(3), A292–A300 (2003). https://doi.org/10.1149/1.1543948

H. Wang, D. Jiang, Y. Zhang, G. Li, X. Lan et al., Self-combustion synthesis of Na3V2(PO4)3 nanoparticles coated with carbon shell as cathode materials for sodium-ion batteries. Electrochim. Acta 155, 23–28 (2015). https://doi.org/10.1016/j.electacta.2014.12.160

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. U1632151 and 21706048), the Key Research and Development Project of Anhui Province of China (Grant No. 1704a0902023) and the Open Project of Jiangsu Key Laboratory for Carbon-Based Functional Materials and Devices (No. JS1802).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xu, E., Li, P., Quan, J. et al. Dimensional Gradient Structure of CoSe2@CNTs–MXene Anode Assisted by Ether for High-Capacity, Stable Sodium Storage. Nano-Micro Lett. 13, 40 (2021). https://doi.org/10.1007/s40820-020-00562-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40820-020-00562-7