Abstract

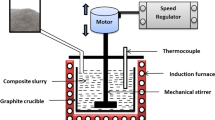

Composites of aluminium matrix with organic (rice husk ash, RHA) and inorganic (fly ash) reinforcement at different weight fractions were fabricated by double-stir casting. The tribological behaviour of the hybrid composites was investigated under dry sliding conditions using different applied loads, sliding distances and sliding speeds. The aims of this work are use of waste material and investigation of the tribological performance, economic issues, environmental impact on wear loss, and coefficient of friction to increase the lifespan of such materials. Attempts were made to examine the effect of addition of waste particles in the aluminium composites on the sliding wear rate, which is of significant importance in the engineering field. The wear mechanism was analysed based on the wear debris and examination of wear tracks on the worn surfaces. The results showed that the A356/10 %RHA–10 %fly ash hybrid composite exhibited superior wear resistance compared with the aluminium matrix for use in engineering applications.

Similar content being viewed by others

References

Singh J, Chauhan A (2016) Characterization of hybrid aluminum matrix composites for advanced applications—a review. J Mater Res Technol 5(2):159–169

Bodunrin MO, Alaneme KK, Chown LH (2015) Aluminium matrix hybrid composites: a review of reinforcement philosophies; mechanical, corrosion and tribological characteristics. J Mater Res Technol 4(4):434–445

Hashim J, Looney L, Hashmi MSJ (1999) Metal matrix composites: production by the stir casting method. J Mater Process Technol 92:1–7

Cree D, Pugh M (2011) Dry wear and friction properties of an A356/SiC foam interpenetrating phase composite. Wear 272(1):88–96

Elango G, Busuna KR, Kayaroganam P (2014) Experimental analysis of the wear behavior of hybrid metal-matrix composites of lm25al with equal volumes of SiC + TiO2. Mater Tehnol 48(6):803–810

Natarajan N, Vijayarangan S, Rajendran I (2006) Wear behaviour of A356/25SiCp aluminium matrix composites sliding against automobile friction material. Wear 261(7):812–822

Alhawari KS, Omar MZ, Ghazali MJ, Salleh MS, Mohammed MN (2013) Wear properties of A356/Al2O3 metal matrix composites produced by semisolid processing. Procedia Eng 68:186–192

Zhu J, Yan H (2017) Fabrication of an A356/fly-ash-mullite interpenetrating composite and its wear properties. Ceram Int 43(15):12996–13003

Subrahmanyam APSVR, Narsaraju G, Rao BS (2015) Effect of rice husk ash and fly ash reinforcements on microstructure and mechanical properties of aluminium alloy (AlSi10Mg) matrix composites. Int J Adv Sci Technol 76:1–8

Chandrasekhar S, Pramada PN (2006) Rice husk ash as an adsorbent for methylene blue-effect of ashing temperature. Adsorption 12(1):27–43

Alaneme KK, Akintunde IB, Olubambi PA, Adewale TM (2013) Fabrication characteristics and mechanical behaviour of rice husk ash-alumina reinforced Al-Mg-Si alloy matrix hybrid composites. J Mater Res Technol 2(1):60–67

Ravindran P, Manisekar K, Rathika P, Narayanasamy P (2013) Tribological properties of powder metallurgy-processed aluminium self lubricating hybrid composites with SiC additions. Mater Des 45:561–570

Anandajothi M, Ramanathan S, Ananthi V, Narayanasamy P (2017) Fabrication and characterization of Ti6Al4V/TiB2-TiC composites by powder metallurgy method. Rare Met 36(10):806–811

Padmavathi KR, Ramakrishnan R (2014) Tribological behaviour of aluminium hybrid metal matrix composite. Procedia Eng 97:660–667

Kumar KR, Mohanasundaram KM, Arumaikkannu G, Subramanian R (2012) Artificial neural networks based prediction of wear and frictional behaviour of aluminium (A380)-fly ash composites. Tribol Mater Surf Interfaces 6(1):15–19

Sharma VK, Singh RC, Chaudhary R (2017) Effect of flyash particles with aluminium melt on the wear of aluminium metal matrix composites. Eng Sci Technol Int J 20(4):1318–1323

Rohatgi PK, Guo RQ, Huang P, Ray S (1997) Friction and abrasion resistance of cast aluminum alloy-fly ash composites. Metall Mater Trans A 28(1):245–250

Surappa MK (2008) Synthesis of fly ash particle reinforced A356 Al composites and their characterization. Mater Sci Eng A 480(1):117–124

Basavarajappa S, Chandramohan G, Mahadevan A, Thangavelu M, Subramanian R, Gopalakrishnan P (2007) Influence of sliding speed on the dry sliding wear behaviour and the subsurface deformation on hybrid metal matrix composite. Wear 262(7):1007–1012

Xie HJ, Cheng YL, Li SX, Cao JH, Li CAO (2017) Wear and corrosion resistant coatings on surface of cast A356 aluminum alloy by plasma electrolytic oxidation in moderately concentrated aluminate electrolytes. Trans Nonferr Met Soc China 27(2):336–351

Ravindran P, Manisekar K, Narayanasamy P, Selvakumar N, Narayanasamy R (2012) Application of factorial techniques to study the wear of Al hybrid composites with graphite addition. Mater Des 39:42–54

Alaneme KK, Sanusi KO (2015) Microstructural characteristics, mechanical and wear behaviour of aluminium matrix hybrid composites reinforced with alumina, rice husk ash and graphite. Eng Sci Technol Int J 18(3):416–422

Selvakumar N, Ramkumar T (2016) Effects of high temperature wear behaviour of sintered Ti-6Al-4V reinforced with nano B4C particle. Trans Indian Inst Met 69(6):1267–1276

Sivakumar G, Ananthi V, Ramanathan S (2017) Production and mechanical properties of nano SiC particle reinforced Ti-6Al-4V matrix composite. Trans Nonferr Met Soc China 27(1):82–90

Acknowledgements

The authors wish to thank Professor Dr. N. Selvakumar, Director, Nano centre, Mepco Schlenk Engineering College, Sivakasi, Tamilnadu, India for provision of support for fabrication of hybrid composites. The authors also wish to acknowledge the extensive facilities provided by the Centralised Instrumentation Science Laboratory, Department of Physics, Annamalai University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vinod, B., Ramanathan, S. & Anandajothi, M. Effect of Organic and Inorganic Reinforcement on Tribological Behaviour of Aluminium A356 Matrix Hybrid Composite. J Bio Tribo Corros 4, 45 (2018). https://doi.org/10.1007/s40735-018-0157-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-018-0157-9