Abstract

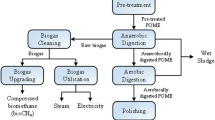

Worldwide, crude palm oil industries generate an overwhelming amount of palm oil mill effluent (POME). Since the past few decades, environmental issues associated with POME disposal have challenged the palm oil-producing nations which led them to reevaluate and develop their waste management strategies by using advanced biotreatment technologies. With the help of these technological advances, POME has emerged as a valuable biomass resource with great potential to produce sustainable renewable resources like biogas. This review entails various POME treatment methods in vogue and offers an insight into their improved applicability potential and pollution mitigation strategies by using proposed improved configurations like ponding system, open digesting tanks, anaerobic digestion based-bioreactors, aerobic anaerobic hybrid bioreactors, and membrane bioreactors. This review paper also gives an overview about the recent advancements in POME treatment bioreactor configurations and emphasizing their scope in large-scale applications on an industrial level. This review also critically analyzes their performance level to achieve the standard POME discharge limit by efficiently removing high COD (chemical oxygen demand), BOD (biological oxygen demand), and TSS (total suspended solid).

Similar content being viewed by others

Abbreviations

- POME:

-

Palm oil mill effluent

- BOD:

-

Biological oxygen demand

- COD:

-

Chemical oxygen demand

- HRT:

-

Hydraulic retention time

- OLR:

-

Organic loading rate

- TSS:

-

Total suspended solid

- OLR:

-

Organic load rate

- GHG:

-

Greenhouse gas

References

Komerath NM, Komerath PP. Terrestrial micro renewable energy applications of space technology. Physcs Proc. 2011;20:255–69.

Sivasangar S, Zainal Z, Salmiaton A, Taufiq-Yap YH. Supercritical water gasification of empty fruit bunches from oil palm for hydrogen production. Fuel. 2015;143:563–9.

Montafia P, Gnansounou E. Life cycle assessment of thermochemical conversion of empty fruit bunch of oil palm to biomethane. Life Cycle Assess Biorefine. 2017:167–97.

Achten WMJ, Vandenbempt P, Almeida J, Mathijs E, Muys B. Life cycle assessment of a palm oil system with simultaneous production of biodiesel and cooking oil in Cameroon. Environ Sci Technol. 2010;44(12):4809–15.

Loh SK, Lai ME, Ngatiman M, Lim WS, Choo YM, Zhang Z, et al. Zero discharge treatment technology of palm oil mill effluent. J Oil Palm Res. 2013;25:273–81.

Poh PE, Chong MF. Development of anaerobic digestion methods for palm oil mill effluent (POME) treatment. Bioresour Technol. 2009;100:1–9.

Loh SK, Chow MC, Mohamad AS. Determination of actual status of palm oil mill effluent in palm oil mills. VIVA No. 455/2009 (05). MPOB 135th VIVA Committee Meeting, Mustapha. 2009.

Zahrim AY. Palm oil mill biogas producing process effluent treatment: a short review. J Appl Sci. 2014;14:3149–55.

Suraruk B, Wandnai C, Chaiprasert P, Tanticharoen M. Performance of an anaerobic hybrid reactor combining a filter and a sludge bed. The 10th annual general meeting of the Thai society for biotechnology for a self sufficient economy. Bangkok, Thailand. 94–102. 1998.

Khemkhao M, Techkarnjanaruk S, Phalakornkule C. Simultaneous treatment of raw palm oil mill effluent and biodegradation of palm fiber in a high rate CSTR. Bioresour Technol. 2015;177:17–27.

Setiadi T, Husaini, Djajadiningrat A. Palm oil mill effluent treatment by anaerobic baffled reactors: recycle effects and biokinetic parameters. Wat Sci Tech. 1996;34(11):59–66.

Chan YJ, Chong MF, Law CL. An integrated anaerobic-aerobic bioreactor (IAAB) for the treatment of palm oil mill effluent (POME): start-up and steady state performance. Process Biochem. 2012;47:485–95.

Azoddein AAM, Haris HB, Azli FAM. Treatment of POME using membrane bioreactor. Malay J Analy Sci. 2015;19(3):463–71.

Abdulrahman HN, Nashrulmillah NA. Biomethanation of palm oil mill effluent (POME) by ultrasonic membrane anaerobic system (UMAS) using POME as substrate. Int J Eng Sci Res Technol. 2014;3(1):129–34.

Ohimain EI, Izah SC. A review of biogas production from palm oil mill effluents using different configurations of bioreactors. Renew Sustain Energ Rev. 2017;70:242–53.

Igwe JC, Onyegbado CC. A review of palm oil mill effluent (POME). Water Treatment. 2017.

Ahmad AL, Ismail S, Bhatia S. Membrane treatment for palm oil mill effluent: effect of transmembrane pressure and crossflow velocity. Desalination. 2005;179:245–55.

Ng WK, Koh CB. Farmed fish as biological agents for extracting residual palm oil in discarded spent bleaching clays from the palm oil refining industry. J Oil Palm Res. 2011;23(1):953–7.

Wu TY, Mohammad AW, Jahimb JM, Anuar N. Pollution control technologies for the treatment of palm oil mill effluent (POME) through end of pipe processes. J Environ Manag. 2010;91(7):1467–90.

Chan JY, Chong MF, Law CL. Optimization of palm oil mill effluent treatment in an integrated anaerobic aerobic bioreactor. Sustain Environ Res. 2013;23(3):153–70.

Fakhrul-l-razi A, Nik NNK, Harun RF. Batch process for biohydrogen production on small scale bioreactor from palm oil mill effluent (POME). Chem Process Eng Res. 2014;23:2224–5.

Habeeb SA, Latiff AAA, Daud Z, Ahmad Z. A biodegradation and treatment of palm oil mill effluent (POME) using a hybrid upflow anaerobic sludge bed (HUASB) reactor. Inter J Energ Environ. 2011;2(4):653–60.

Trisakti B, Manalu V, Taslim I, Turmuzi M. Acidogenesis of palm oil mill effluent to produce biogas: effect of hydraulic retention time and pH. Proc Soc Behav Sci. 2015;195:2466–74.

Bello MM, Raman AAA. Trend and current practices of palm oil mill effluent polishing: application of advanced oxidation processes and their future perspectives. J Environ Manag. 2017;198(1):170–82.

Lorestani AAZ. Biological treatment of palm oil effluent (POME) using an upflow anaerobic sludge fixed film (UASFF) bioreactor. 2006, 899–869.

Ahmad AL, Suzylawati I, Norliza I, Subhash B. Removal of suspended solid and residual oil from palm oil mill effluent. J Chem Tech Biotechnol. 2003;78(9):971–8.

Li Y, Park YS, Zhu J. Solid-state anaerobic digestion for methane production from organic waste. Renew Sustain Energ Rev. 2011;15:821–6.

Basiron Y, Weng CK. The oil palm and its sustainability. J Oil Palm Res. 2004;16:1–10.

Gutierrez LF, Sanchez OJ, Cardona CA. Process integration possibilities for biodiesel production from palm oil using ethanol obtained from lingocellulosic residues of oil palm industry. Bioresour Technol. 2009;100(3):1227–37.

Mandenius C-F. Bioreactors: design, operation and novel applications. WileyVCH, Verlag GmbH and co. KgaA, Boschstr, Weinheim, Germany, 2016.

Davis ML. Water and wastewater engineering: design principles and practice. New York: McGrawHill Education; 2010.

Alam MZ, Mamun AA, Qudsieh IY, Muyibi SA, Salleh HM, Omar NM. Solid state bioconversion of oil palm empty fruit bunches for cellulase enzyme production using a rotary drum bioreactor. Biochem Eng J. 2009;46:61–4.

Yaeed S, Suksaroj TT, Suksaroj C. Mechanical pretreatment processes for enhancement of biogas production from palm oil mill effluent (POME). Desalin Water Treat. 2017;67:133–9.

Salihu A, Alam Z. Palm oil mill effluent: a waste or a raw material? J Appl Sci Res. 2012;8(1):466–73.

Irvan, Trisakti B, Wongistani V, Tomiuchi Y. Methane emission from digestion of palm oil mill effluent (POME) in a thermophilic anaerobic reactor. Int J Sci Eng. 2012;3(1):32–5.

Spier MR, Vandenberghe LPS, Medeiros ABP, Soccol CR. Application of different types of bioreactors in bioprocesses. In: Antolli PG, Liu Z, editors. Bioreactors: design, properties and applications. Nova Science Publishers; 2011. p. 55–90.

Ammar E, Nasri M, Medhioub K. Isolation of phenol degrading Enterobacteria from the wastewater of olive oil extraction process. World J Microbiol Biotechnol. 2005;21(3):253–9. 3

Dhouib A, Ellouz M, Aloui F, Sayadi S. Effect of bioaugmentation of activated sludge with white rot fungi on olive mill wastewater detoxification. Lett Appl Microbiol. 2006;42(4):405–11.

Yacob S, Shirai Y, Hassan MA, Wakisaka M, Subash S. Startup operation of semicommercial closed anaerobic digester for palm oil mill effluent treatment. Process Biochem. 2006;41:962–4.

Wise DL. Bioenvironmental systems. Chapter-6. Boca Raton: CRC press; 1987. p. 135–59.

Tong SL, Bakar JA. Waste to energy: methane recovery from anaerobic digestion of palm oil mill effluent. Energy Smart. 2004.

Ma AN, Cheah SC, Chow MC. Current status of palm oil processing wastes management. In: Waste management in Malaysia: current status and prospects for bioremediation; 1993. p. 111–136.

Parthasarathy S, Gomes RL, Manickam S. Process intensification of anaerobically digested palm oil mill effluent (AD-POME) treatment using combined chitosan coagulation, hydrogen peroxide (H2O2) and Fenton’s oxidation. Clean Techn Environ Policy. 2016;18:219–30.

Del-Pozo R, Diez V. Integrated anaerobic-aerobic fixed-film reactor for slaughterhouse wastewater treatment. Water Res. 2005;39(6):1114–22.

Chan Y, Chong M, Law C. Optimization of thermophilic anaerobic-aerobic treatment system for palm oil mill effluent (POME). Front Environ Sci Eng. 2015;9(2):334–51.

Chan YJ, Chong MF, Law CL, Hassell DG. A review on anaerobic-aerobic treatment of industrial and municipal wastewater. Chem Eng J. 2009;155:1–18.

Tamrat A, Mebeaselassie A, Amare G. Co-digestion of cattle manure with organic kitchen waste to increase biogas production using rumen fluid as inoculums. Inter J Phys Sci. 2013;8(11):443–50.

Liu Y, Tay J. State of the art of biogranulation technology for wastewater treatment. Biotechnol Adv. 2004;22:533–63.

Khemkhao M, Nuntakumjorn B, Techkarnjanaruk S, Phalakornkule C. ASB performance and microbial adaptation during a transition from mesophilic to thermophilic treatment of palm oil mill effluent. J Environ Manag. 2012;103:74–82.

Bal AS, Dhagat NN. Upflow anaerobic sludge blanket reactor—a review. Indian J Environ Health. 2001;43(2):1–82.

Ebrahimi A, Najafpour GD. Biological treatment processes: suspended growth vs. attached growth. Iran J Energy Environ. 2016;7(2):114–23.

Hemalatha D, Sanchitha S, Keerthinarayana S. Anaerobic treatment of pulp and paper mill wastewater using hybrid upflow anaerobic sludge blanket reactor (HUASBR). Int J Innov Res Sci Eng Technol. 2014;3(4):11576–84.

Zinatizadeh AAL, Pirsaheb M, Bonakdari H, Younesi H. Response surface analysis of effects of hydraulic retention time and influent feed concentration on performance of an UASFF bioreactor. Waste Manag. 2010;30(10):1798–807.

Najafpour GD, Zinatizadeh AAL, Mohamed AR, Hasnain-Isa M, Nasrollahzadeh H. High-rate anaerobic digestion of palm oil mill effluent in an upflow anaerobic sludge-fixed film bioreactor. Process Biochem. 2006;41:370–9.

Coutte F, Lecouturier D, Firdaous L, Kapel R, Bazinet L, Cabassud C, Dhulster P. Recent trends in membrane bioreactors. Curr Develop Biotechnol Bioeng; 2017. p. 279–311.

Hassan SR, Dahlan I. Anaerobic wastewater treatment using anaerobic baffled bioreactor: a review. Cent Eur J Eng. 2013;3(3):389–99.

Kato MT, Field JS, Versteeg P, Lettinga G. Feasibility of expanded granular sludge bed reactors for the anaerobic treatment of low-strength soluble wastewaters. Biotechnol Bioeng. 1994;44:469–79.

Seengenyoung J, O-Thong S, Prasertsan P. Comparison of ASBR and CSTR reactor for hydrogen production from palm oil mill effluent under thermophilic condition. Adv Biosci Biotechnol. 2014;5:177–83.

Ahmad A, Krimly MZ. Palm oil mill effluent treatment process evaluation and fate of priority components in an open and closed digestion system. Curr World Environ. 2014;9(2):321–30.

Zhong JJ. Recent advances in bioreactor engineering. Korean J Chem Eng. 2010;27(4):1035–41.

Jaye IFM, Sadhukhan J, Murphy RJ. Renewable, local electricity generation from palm oil mills: a case study from peninsular Malaysia. Intern J Smart Grid Clean Energy. 2016;5(2):106–11.

Preliminary feasibility study on the palm oil mill wastes-fired power generation systems and cdm project for rural electrification in Sumatra, Indonesia. Engineering and Consulting Firms Association, Japan NTT GP-ECO communication, Inc. 2009.

Khairuddin MN, Zakaria AJ, Isa IM, Jol H, Rahman WMNWA, Salleh MKS. The potential of treated palm oil mill effluent (POME) sludge as an organic fertilizer. AGRIVITA J Agric Sci. 2016;38(2):142–54.

Onyia CO, Uyu AM, Akunna JC, Norulaini NA, Omar AK. Increasing the fertilizer value of palm oil mill sludge: bioaugmentation in nitrification. Water Sci Technol. 2001;44(10):157–62.

Foom KY, Hameed BH. Insight into the applications of palm oil mill effluent: a renewable utilization of the industrial agricultural waste. Renew Sustain Energ Rev. 2010;14(5):1445–52.

Wong YS, Kadir MOAB, Teng TT. Biological kinetics evaluation of anaerobic stabilization pond treatment of palm oil mill effluent. Bioresour Technol. 2009;100:4969–75.

Greenhouse gas emissions from palm oil production literature review and proposals from the RSPO. Working group on greenhouse gases. Brinkman Consultancy, Netherland, 2009.

Yacob S, Hassan MA, Shirai Y, Wakisaka M, Subash S. Baseline study of methane emission from anaerobic ponds of palm oil mill effluent treatment. Sci Total Environ. 2006;366:187–96.

Yacob S, Hassan MA, Shirai Y, Wakisaka M, Subash S. Baseline study of methane emission from open digesting tanks of palm oil mill effluent treatment. Chemosphere. 2005;59:1575–81.

Sulaiman A, Busu Z, Tabatabaei M, Yacob S, Abd-Aziz S, Hassan MA, et al. The effect of higher sludge recycling rate on anaerobic treatment of palm oil mill effluent in a semi-commercial closed digester for renewable energy. Am J Biochem Biotechnol. 2009;5:1–6.

Irvan, Trisakti B, Tomiuchi Y, Harahap U, Daimon H. Effect of recycle sludge on anaerobic digestion of palm oil mill effluent in a thermophilic continuous digester. 29th Symposium of malaysian chemical engineers (SOMChE). IOP Conf Series: Materials Science and Engineering. 2017. 206.

Damayanti A, Ujang Z, Salim MR, Olsson G, Sulaiman AZ. Respirometric analysis of activated sludge models from palm oil mill effluent. Bioresour Technol. 2010;101:144–9.

Fang C, O-Thong S, Boe K, Angelidaki I. Comparison of UASB and EGSB reactors performance, for treatment of raw and deoiled palm oil mill effluent (POME). J Hazard Materials. 2011;189:229–34.

Badroldin N, Latiff AA, Karim AT, Fulazzaky MA. Palm oil mill effluent (POME). Treatment using hybrid up flow anaerobic sludge blanket (HUASB) reactors: impact on COD removal and organic loading rates. Engineering Postgraduate Conference. 2008.

Lettinga G, Rebac S, Zeeman G. Challenge of psychrophilic anaerobic wastewater treatment. Trends Biotechnol. 2001;19:363–70.

Wang J, Mahmood Q, Qiu JP, Li YS, Chang YS, Li XD. Anaerobic treatment of palm oil mill effluent in pilot-scale EGSB reactor. Bio Med Res Int. 2015;2015:1–7.

Ghorbanian M, Lupitskyy RM, Satyavolu JV, Berson RE. Impact of supplemental hydrogen on biogas enhancement and substrate removal efficiency in a two stage expanded granular sludge bed reactor. Environ En Sci. 2014;31(5):253–60.

Zhang Y, Yan L, Chi L, Long X, Mei Z, Zhang Z. Startup and operation of anaerobic EGSB reactor treating palm oil mill effluent. J Environ Sci. 2008;20(6):658–66.

Najafpour G, Yieng HA, Younesi H, Zinatizadeh A. Effect of organic loading on performance of rotating biological contactors using palm oil mill effluents. Process Biochem. 2005;40(8):2879–84.

Mohammadi P, Ibrahim S, Annuar MSM, Khashij M, Mousavi SA, Zinatizadeh A. Optimization of fermentative hydrogen production from palm oil mill effluent in an up-flow anaerobic sludge blanket fixed film bioreactor. Sustain Environ Res.2016;1–8.

Zinatizadeh AAL, Mohamed AR, Abdullah AZ, Mashitah MD, Isa MH, Najafpour GD. Process modeling and analysis of palm oil mill effluent treatment in an up-flow anaerobic sludge fixed film bioreactor using response surface methodology (RSM). Water Res. 2006;40(17):3193–208.

Zinatizadeh AAL, Younesi H, Bonakdari H, Pirsaheb M, Pazouki M, Najafpour GD, et al. Effects of process factors on biological activity of granular sludge grown in an UASFF bioreactor. Renew Energy. 34(5):1245–51.

Lemmer A, Hans-Joachim N, Sondermann J. How efficient are agitators in biogas digesters? Determination of the efficiency of submersible motor mixers and incline agitators by measuring nutrient distribution in full-scale agricultural biogas digesters. Energies. 2013;6:6255–73.

Tong SL, Jaafar AB. POME biogas capture, upgrading and utilization. Palm Oil Eng Bull. 2006;78:11–7.

Wang J, Wan W. Factors influencing fermentative hydrogen production: a review. Int J Hydrogen Energ. 2009;34(2):799–811.

Khemkhao M, Techkarnjanaruk S, Phalakornkule C. Effect of chitosan on reactor performance and population of specific methanogens in a modified CSTR treating raw POME. Biomass Bioenergy. 2016;86:11–20.

Faisal M, Machdar I, Gani A, Daimon H. The combination of air flotation and a membrane bioreactor for the treatment of palm oil mill effluent. Int J Technol. 2016;5:767–77.

Mahboubi A, Ylitervo P, Doyen W, De Wever H, Taherzadeh MJ. Reverse membrane bioreactor: introduction to a new technology for biofuel production.

Oswal N, Sarma PM, Zinjarde SS, Pant A. Palm oil mill effluent treatment by tropical marine yeast. Bioresour Technol. 2002;85:35–7.

Shilton A. Pond treatment technology. London: IWA Publishing; 2006. p. 11–5.

Work of engineering, cost estimates and supervision for the project on promotion of green economy with palm oil industry for biodiversity conservation in Malaysia, Japan International Cooperation Agency, NJS Consultants CO, LTD. 2016.

Harper SR, Pohland FG. Recent developments in hydrogen management during anaerobic biological wastewater treatment. Biotechnol Bioeng. 1986;28:585–602.

Kleerebezem R, Macarie H. Treating industrial wastewater: anaerobic digestion comes of age: anaerobic treatment systems offer important advantages over conventionally applied aerobic processes for removing organic pollutants from water-based streams (cover story). Chemical Engineering; 2003. p. 56.

Jans TJM, de Man G. Reactor design considerations and experiences with various wastewaters: anaerobic treatment of industrial wastewaters. In: Torpy MF, editor. Poll Tech Rev; 1988. p. 49–68.

Khalid A, Arshad M, Anjum M, Mahmoo T, Dawson L. The anaerobic digestion of solid organic waste. Waste Manag. 2011;31:1737–44.

Khanal SK, Giri B, Nitayavardhana S, Gadhamshetty V. Anaerobic bioreactors/digesters: design and development. Curr Dev Biotechnol Bioeng. 2017;261–279.

Linke B. Kinetic study of thermophilic anaerobic digestion of solid wastes from potato processing. Biomass Bioenergy. 2006;30(10):892–6.

Al-Seadi T, Rutz D, Prassl H, Köttner M, Finsterwalder T, Volk S, et al. Biogas handbook. Esbjerg: University of Southern Denmark Esbjerg; 2008. p. 9–10.

Wong YS, Teng TT, Ong SA, Norhashimah M, Rafatullah M, Lee HC. Anaerobic acidogenesis biodegradation of palm oil mill effluent using suspended closed anaerobic bioreactor (SCABR) at mesophilic temperature. Procedia Environ Sci. 2013;18:433–41.

Lee DJ, Hallenbeck PC, Ngo HH, Jegatheesan V, Pandey A. Current developments in biotechnology and bioengineering: biological treatment of industrial effluents; 2016. p. 261–279.

Lim SJ, Kim TH. Applicability and trends of anaerobic granular sludge treatment processes. Biomass Bioenergy. 2014;60:189–202.

Debik E, Coskun T. Use of the static granular bed reactor (SGBR) with anaerobic sludge to treat poultry slaughterhouse wastewater and kinetic modeling. Bioresour Technol. 2009;100:2777–82.

Liu Y, Xu HL, Show KY, Tay JH. Anaerobic granulation technology for wastewater treatment. World J Microb Biotech. 2002;18(2):99–113.

Lettinga G. Anaerobic reactor technology: reactor and process design. In: International course on anaerobic treatment. Wageningen Agricultural University/IHE Delft, Wageningen; 1995. p. 17–28.

Annachhatre AP. Anaerobic treatment of industrial wastewaters. Resour Conserv Recy. 1996;16:161–6.

Ahmad A, Ghufran R, Wahid ZA. Role of calcium oxide in sludge granulation and methanogenesis for the treatment of palm oil mill effluent using UASB reactor. J Hazard Mater. 2011;198:40–8.

Saner AB, Mungray AK, Mistry NJ. Treatment of distillery wastewater in an upflow anaerobic sludge blanket (UASB) reactor. J Desalin Water Treat. 2016;57(10):4328–44.

Shivayogimath CB, Ramanujam TK. Treatment of distillery spent wash by hybrid UASB reactor. Bioprocess Eng. 1999;21:255–9.

Latif MF, Ghufran R, Wahid ZA, Ahmad A. Integrated application of upflow anaerobic sludge blanket reactor for the treatment of wastewaters. Water Res. 2011;45(16):4683–99.

Habeeb SA, Latiff AABA, Daud ZB, Ahmad ZB. A review on granules initiation and development inside UASB reactor and the main factors affecting granules formation process. Int J Energy Environ. 2011;2(2):311–20.

Rajakumar R, Meenambal T. Comparative study on start-up performance of HUASB and AF reactors treating poultry slaughterhouse wastewater. Int J Environ Res. 2008;2(4):401–10.

Rajathi RP. Efficiency of HUASB reactor for treatment of different types of wastewater—a review. Inte J Eng Res Technol. 2013;2(12):465–71.

Van Lier JB, Van-der Zee FP, Frijters CTMJ, Ersahin ME. Celebrating 40 years anaerobic sludge bed reactors for industrial wastewater treatment. Rev Environ Sci Biotechnol. 2015;14(4):681–702.

Wu W, Yang L, Wang J. Denitrification using PBS as carbon source and biofilm support in a packed-bed bioreactor. Environ Sci Pollut Res. 2013;20:333–9.

Van Lier JB, Rebac S, Lens P, van Bijnen F, Oude-Elferink SJWH, Stams AJM, et al. Anaerobic treatment of partly acidified wastewater in a two stage expanded granular sludge bed (EGSB) system at 8°C. Water Sci Technol. 1997;36:317–24.

Connelly S, Shin SG, Dillon RJ, Ijaz UZ, Quince C, Sloan WT, et al. Bioreactor scalability: laboratory-scale bioreactor design influences performance, ecology, and community physiology in expanded granular sludge bed bioreactors. Front Microbiol. 2017;8:664.

Ambuchi JJ, Haiman-Wang JL, Shan L, Zhou X, Mohammed MOA, Feng Y. Microbial community structural analysis of an expanded granular sludge bed (EGSB) reactor for beet sugar industrial wastewater (BSIW) treatment. Appl Microbio Biotechnol. 2016;100(10):4651–61.

Liao R, Li Y, Wang Z, Miao Y, Shen K, Shi P, et al. 454 pyrosequencing analysis on microbial diversity of an expanded granular sludge bed reactor treating high NaCl and nitrate concentration wastewater. Biotechnol Bioprocess Eng. 2014;19(1):183–90.

Oda TV. Treatment of dairy wastewater by expanded granular sludge bed (EGSB) reactor. 2016;2(3):852–855.

Nunez LA, Martínez B. Anaerobic treatment of slaughterhouse wastewater in an expanded granular sludge bed (EGSB) reactor. Water Sci Technol. 1999;40(8):99–106.

Tehrani NS, Najafpour GD, Rahimnejad M, Hossein A. Performance of up flow anaerobic sludge fixed film bioreactor for the treatment of high organic load and biogas production of cheese whey wastewater. Chem Ind Chem Eng Q. 2015;21(2):229–37.

Ismail I, Hassan MA, Rahman NAA, Soon CS. Thermophilic biohydrogen production from palm oil mill effluent (POME) using suspended mixed culture. Biomass Bioenergy. 2010;34:42–70.

Sahinkaya E. Biotreatment of zinc-containing wastewater in a sulfidogenic CSTR: performance and artificial neural network (ANN) modelling studies. J Hazard Mater. 2009;164(1):105–13.

Pisutpaisal N, Nathao C, Sirisukpoka U. Biological hydrogen and methane production in from food waste in two-stage CSTR. Energy Procedia. 2014;50:719–22.

Gargouri B, Karray F, Mhiri N, Aloui F, Sayadi S. Application of a continuously stirred tank bioreactor (CSTR) for bioremediation of hydrocarbon-rich industrial wastewater effluents. J Hazard Mater. 2011;189(1–2):427–34.

Mohan S, Sunny N. Study of biomethanization of waste water from jam industries. Bioresour Technol. 2008;99:210–3.

Kim M, Ahn YH, Speece RE. Comparative process stability and efficiency of anaerobic digestion: mesophilic vs. thermophilic. Water Res. 2002;36(17):4369–85.

Setiadi T, Faisal. Palm oil mill effluent treatment by anaerobic baffled reactors. Proc Aquatech Asia-94, Singapore. 1994;134–141.

Zhu G, Zou R, Jha AK, Huang X, Liu L, Liu C. Recent developments and future perspectives of anaerobic baffled bioreactor for wastewater treatment and energy recovery. Crit Rev Environ Sci Technol. 2015;45(12):1243–76.

Jeong JY, Son SM, Pyon JH, Park JY. Performance comparison between mesophilic and thermophilic anaerobic reactors for treatment of palm oil mill effluent. Bioresour Technol. 2014;165:122–8.

Wain HM, Aziz HA, Zaman NQ, Dahlan I. Effect of inoculums to substrate ratio on the performance of modified anaerobic inclining baffled reactor treating recycled paper mill effluent. J Desalin Water Treat. 2016;57(22):10169–80.

Pirsaheb M, Rostamifar M, Mansouri AM, Zinatizadeh AAL, Sharafi K. Performance of an anaerobic baffled reactor (ABR) treating high strength baker’s yeast manufacturing wastewater. J Taiwan Inst Chem Eng. 2015;47:137–48.

Thanwised P, Wirojanagud W, Reungsang A. Effect of hydraulic retention time on hydrogen production and chemical oxygen demand removal from tapioca wastewater using anaerobic mixed cultures in anaerobic baffled reactor (ABR). Int J Hydrog Energy. 2012;37(20):15503–10.

Kuscu OS, Sponza DT. Performance of anaerobic baffled reactor (ABR) treating synthetic wastewater containing p-nitrophenol. Enzym Microb Technol. 2005;36(7):888–95.

Wang Y, Huang X, Yuan Q. Nitrogen and carbon removals from food processing wastewater by an anoxic/aerobic membrane bioreactor. Process Biochem. 2005;40(5):1733–9.

Ezechi EH, Kutty SRBM, Isa MH, Malakahmad A, Ibrahim SU. Chemical oxygen demand removal from wastewater by integrated bioreactor. J Environ Sci Technol. 2015;8:238–43.

Mutamim NSA, Noor ZZ, Hassan MAA, Yuniarto A, Olsson G. Membrane bioreactor: applications and limitations in treating high strength industrial wastewater. Chem Eng J. 2013;225:109–19.

Giorno L, Gebreyohannes AY, Drioli E, Mazzei R. Biocatalytic membranes and membrane bioreactors. Reference module in chemistry, molecular sciences and chemical Engineering. 2017.

Yeon KM, Cheong WS, Oh HS, Lee WN, Hwang BK, Lee CH, et al. Quorum sensing: a new biofouling control paradigm in a membrane bioreactor for advanced wastewater treatment. Environ Sci Technol. 2009;43(2):380–5.

Krzeminski P, Leverette L, Malamis S, Katsou E. Mambrane bioreactors—a review on recent developments in energy reduction, fouling control, novel configurations, LCA and market prospects. Rev Articleo Memb Sci. 2017;527:207–27.

Friha I, Karray F, Feki F, Jlaiel L, Sayadi S. Treatment of cosmetic industry wastewater by submerged MBR with consideration of microbial community dynamics. Int Biodeterior Biodegrad. 2014;88:125–33.

Odriozola J, Beltran S, Dalmau M, Sancho L, Comas J, Rodríguez-Roda I, et al. Model based methodology for the design of optimal control strategies in MBR plants. Water Sci Technol. 2017;75(12):1–8.

Guglielmi G, Andreottola G. Selection and design of membrane bioreactors in environmental bioengineering. In: Wang L, Ivanov V, Tay JH, editors. Environmental biotechnology: handbook of environmental engineering. Totowa: Humana Press; 2010.

Park HD, Chang IS, Lee KJ. Principles of membrane bioreactors for wastewater treatment. Boca Raton: CRC Press. Taylor and Francis Group; 2015.

Bashir MJK, Chong WJ, Aun NC, Amr SSA. Electro persulphate oxidation for polishing of biologically treated palm oil mill effluent (POME). J Environ Manag. 2017;193:458–69.

Cheng YW, Cha YS, Nga KH, Wu TY, Cheng CK. Photocatalytic restoration of liquid effluent from oil palm agro industry in Malaysia using tungsten oxides catalyst. J Clean Prod. 2017;162:205–19.

Nura M. Amelia YA, Andi AF, Kinandana W, Zahar I, Susan AI, Wibawa JP. Dielectric barrier discharge plasma analysis and application for processing palm oil mill effluent (POME). Procedia Engineering 2017;170:325–331.

Zinatizadeh AA, Mohammadi P, Mirghorayshi M, Ibrahim S, Mohamedn YAR. An anaerobic hybrid bioreactor of granular and immobilized biomass for anaerobic digestion (AD) and dark fermentation (DF) of palm oil mill effluent: mass transfer evaluation in granular sludge and role of internal packing. Biomass Bioenergy. 2017;103:1–10.

Krishnana S, Singh L, Sakinah M, Thakur S, Wahid ZA, Ghrayeb OA. Role of organic loading rate in bioenergy generation from palm oil mill effluent in a two-stage up-flow anaerobic sludge blanket continuous-stirred tank reactor. Bioresour Technol. 2017;241:787–94.

Cheirsilp B, Thawechai T, Prasertsan P. Immobilized oleaginous microalgae for production of lipid and phytoremediation of secondary effluent from palm oil mill in fluidized bed photo bioreactor. Bioresour Technol. 2017;241:787–94.

Mishra P, Thakur S, Singh L, Wahid ZA, Sakinah M. Enhanced hydrogen production from palm oil mill effluent using two stage sequential dark and photo fermentation. Int J Hydrog Energ. 2016;41(41):18431–40.

Chan YJ, Tan WJR, How BS, Lee JJ, Lau VY. Up-flow anaerobic sludge blanket–hollow centered packed bed (UASB–HCPB) reactor. J Water Process Eng. 2015;5:112–7.

Mohammed RR, Ketabchi MR, McKay G. Combined magnetic field and adsorption process for treatment of biologically treated palm oil mill effluent (POME). Chem Eng J. 2014;243:31–42.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they no conflict of interest.

Additional information

This article is part of the Topical Collection on Water Pollution

Rights and permissions

About this article

Cite this article

Rana, S., Singh, L., Wahid, Z. et al. A Recent Overview of Palm Oil Mill Effluent Management via Bioreactor Configurations. Curr Pollution Rep 3, 254–267 (2017). https://doi.org/10.1007/s40726-017-0068-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40726-017-0068-2