Abstract

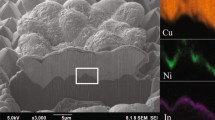

The silver (Ag) coated copper (Cu) paste were printed and sintered on silicon (Si) heterojunction solar cell via continuous intense pulsed light (IPL) as an electrode. The temperature of the electrode was monitored by thermocouple and infrared (IR) camera during IPL sintering process. To grasp more accurate temperature profile, a heat transfer simulation was also conducted by finite difference method. The line resistivity and contact resistivity of Ag coated Cu electrodes were evaluated with respect to light energy and the optimal IPL process parameter were chosen as light energy of 6 J/cm2 and 5 cm/s conveyor belt speed. I-V curve of the Si solar cell was measured and there was only 0.2% reduction in efficiency compared to conventional Ag thermal cured electrodes. The efficiency was decreased slightly due to the decrease in the short circuit current (Jsc). It is noteworthy that the open circuit voltage (Voc) of the Si solar cell with IPL sintered Ag coated Cu paste, increased by 2 mV because the surface passivation was improved by light exposure. In addition, it was confirmed that there is no Cu diffusion problem by measuring the pseudo fill factor (pFF) for 6 months to secure the reliability of the solar cell.

Similar content being viewed by others

References

Battaglia, C., Cuevas, A., & De Wolf, S. (2016). High-efficiency crystalline silicon solar cells: Status and perspectives. Energy and Environmental Science., 9(5), 1552–1576.

Hannebauer, H., Dullweber, T., Falcon, T., & Brendel, R. (2013). Fineline printing options for high efficiencies and low Ag paste consumption. Energy Procedia, 38, 725–731.

Lossen, J., Rudolph, D., Koduvelikulathu, L. J., Carvalho, R., Rossetto, M. P., Borsato, O., et al. (2016). Double printing nPERT cells with narrow contact layers. Energy Procedia, 92, 939–948.

Stodolny, M., Lenes, M., Wu, Y., Janssen, G., Romijn, I., Luchies, J., et al. (2016). n-Type polysilicon passivating contact for industrial bifacial n-type solar cells. Solar Energy Materials and Solar Cells., 158, 24–28.

Larionova, Y., Turcu, M., Reiter, S., Brendel, R., Tetzlaff, D., Krügener, J., et al. (2017). On the recombination behavior of p+-type polysilicon on oxide junctions deposited by different methods on textured and planar surfaces. Physica Status Solidi A, 214(8), 1700058.

Tao, Y., Vijaykumar, U., Keenan, J., & Ajeet, R. (2016). Tunnel oxide passivated rear contact for large area n-type front junction silicon solar cells providing excellent carrier selectivity. AIMS Materials Science, 3, 180–189.

Feldmann, F., Bivour, M., Reichel, C., Hermle, M., & Glunz, S. W. (2014). Passivated rear contacts for high-efficiency n-type Si solar cells providing high interface passivation quality and excellent transport characteristics. Solar Energy Materials and Solar Cells, 120, 270–274.

Melskens, J., Smets, A. H., Schouten, M., Eijt, S. W., Schut, H., Zeman, M. (2021). New insights in the nanostructure and defect states of hydrogenated amorphous silicon obtained by annealing. Conference New insights in the Nanostructure and Defect States of Hydrogenated Amorphous Silicon Obtained by Annealing. IEEE, pp. 1–8.

McIntosh, K. R., Abbott, M. D., Sudbury, B. A., Manzoor, S., Zhengshan, J. Y., Leilaeioun, M., et al. (2021). Absorption in each layer of a silicon heterojunction solar cell. Conference Absorption in Each Layer of a Silicon Heterojunction Solar Cell. IEEE, pp. 1322–1328.

Li, Y., Kim, H.-S., Yi, J., Kim, D., & Huh, J.-Y. (2018). Improved electrical performance of low-temperature-cured silver electrode for silicon heterojunction solar cells. IEEE Journal of Photovoltaics, 8(4), 969–975.

Louwen, A., Van Sark, W., Schropp, R., & Faaij, A. (2016). A cost roadmap for silicon heterojunction solar cells. Solar Energy Materials and Solar Cells, 147, 295–314.

Geissbühler, J., De Wolf, S., Faes, A., Badel, N., Jeangros, Q., Tomasi, A., et al. (2014). Silicon heterojunction solar cells with copper-plated grid electrodes: Status and comparison with silver thick-film techniques. IEEE Journal of Photovoltaics, 4(4), 1055–1062.

Amendola, V., Bakr, O. M., & Stellacci, F. (2010). A study of the surface plasmon resonance of silver nanoparticles by the discrete dipole approximation method: Effect of shape, size, structure, and assembly. Plasmonics, 5(1), 85–97.

Lee, K.-C., Lin, S.-J., Lin, C.-H., Tsai, C.-S., & Lu, Y.-J. (2008). Size effect of Ag nanoparticles on surface plasmon resonance. Surface and Coatings Technology, 202(22–23), 5339–5342.

Ringe, E., McMahon, J. M., Sohn, K., Cobley, C., Xia, Y., Huang, J., et al. (2010). Unraveling the effects of size, composition, and substrate on the localized surface plasmon resonance frequencies of gold and silver nanocubes: a systematic single-particle approach. The Journal of Physical Chemistry C, 114(29), 12511–12516.

Kim, H.-S., Dhage, S. R., Shim, D.-E., & Hahn, H. T. (2009). Intense pulsed light sintering of copper nanoink for printed electronics. Applied Physics A, 97(4), 791.

Dharmadasa, R., Jha, M., Amos, D. A., & Druffel, T. (2013). Room temperature synthesis of a copper ink for the intense pulsed light sintering of conductive copper films. ACS Applied Materials and Interfaces, 5(24), 13227–13234.

Joo, S.-J., Hwang, H.-J., & Kim, H.-S. (2014). Highly conductive copper nano/microparticles ink via flash light sintering for printed electronics. Nanotechnology, 25(26), 265601.

Ryu, C.-H., Moon, C.-J., & Kim, H.-S. (2019). A study on the relationship between print-ability and flash light sinter-ability of Cu nano/micro-ink for printed electronics. Thin Solid Films, 671, 36–43.

Hwang, Y.-T., Chung, W.-H., Jang, Y.-R., & Kim, H.-S. (2016). Intensive plasmonic flash light sintering of copper nanoinks using a band-pass light filter for highly electrically conductive electrodes in printed electronics. ACS Applied Materials and Interfaces, 8(13), 8591–8599.

Schube, J., Tutsch, L., Fellmeth, T., Bivour, M., Feldmann, F., Hatt, T., et al. (2018). Low-resistivity screen-printed contacts on indium tin oxide layers for silicon solar cells with passivating contacts. IEEE Journal of Photovoltaics, 8(5), 1208–1214.

Hwang, H.-J., Kim, D.-J., Jang, Y.-R., Hwang, Y.-T., Jung, I.-H., & Kim, H.-S. (2018). Multi-pulsed flash light sintering of copper nanoparticle pastes on silicon wafer for highly-conductive copper electrodes in crystalline silicon solar cells. Applied Surface Science, 462, 378–386.

Nakamura, K. M., Tanaka, A., Ohshita, Y. (2018). Newly developed Ag coated Cu paste for Si hetero-junction solar cell. In 35th European Photovoltaic Solar Energy Conference and Exhibition, pp. 704–706.

Jang, Y.-R., Ryu, C.-H., Hwang, Y.-T., & Kim, H.-S. (2020). Optimization of intense pulsed light sintering considering dimensions of printed Cu nano/micro-paste patterns for printed electronics. International Journal of Precision Engineering and Manufacturing-Green Technology, 8, 471–485.

Cengel, Y. A. (2007). Heat Transfer: A Practica Approach. . New Jersey: McGraw-Hill.

Granek, F., & Reichel, C. (2010). Back-contact back-junction silicon solar cells under UV illumination. Solar Energy Materials and Solar Cells, 94(10), 1734–1740.

Ye, F., Li, Y., Deng, W., Chen, H., Liao, G., Feng, Z., et al. (2018). UV-induced degradation in multicrystalline PERC cell and module. Solar Energy, 170, 1009–1015.

Kobayashi, E., De Wolf, S., Levrat, J., Christmann, G., Descoeudres, A., Nicolay, S., et al. (2016). Light-induced performance increase of silicon heterojunction solar cells. Applied Physics Letters, 109(15), 153503.

Mahtani, P., Varache, R., Jovet, B., Longeaud, C., Kleider, J.-P., & Kherani, N. P. (2013). Light induced changes in the amorphous—crystalline silicon heterointerface. Journal of Applied Physics, 114(12), 124503.

Liu, C., Liu, W., Chen, W., Hsieh, S., Tsai, T., & Yang, L. (2005). ITO as a diffusion barrier between Si and Cu. Journal of The Electrochemical Society, 152(3), G234–G239.

Hu, S., Lu, K., Ning, H., Fang, Z., Liu, X., Xie, W., et al. (2018). Effect of ITO Serving As A Barrier Layer for Cu electrodes on performance of a-IGZO TFT. IEEE Electron Device Letters, 39(4), 504–507.

Acknowledgements

The authors would like to thank Namics corporation for supporting Ag paste and Ag coated Cu paste. This work was also supported by Solar R&D Lab. Collaborative Project between Hanyang University and LG Electronics Co. Ltd. This work was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) and the Ministry of Trade, Industry & Energy (MOTIE) of the Republic of Korea (No. 20206910100160).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nam, JB., Jang, YR., Hwang, YT. et al. Intense Pulsed Light Sintering of Screen-Printed Paste Electrode on Silicon Solar Cell for High Throughput and Cost-Effective Low Temperature Metallization. Int. J. of Precis. Eng. and Manuf.-Green Tech. 9, 523–535 (2022). https://doi.org/10.1007/s40684-021-00346-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-021-00346-3