Abstract

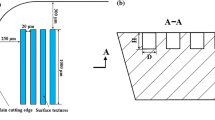

Microtextures were successfully fabricated on the rake face of the cemented carbide (WC/TiC/Co) tools through inductively coupled plasma etching technology. Two types of microtextured tools were designed and fabricated. Their performance in cutting the AISI 1045 medium carbon steel was tested and compared to that of conventional non-textured tools. The comparison involved cutting forces, cutting temperature, friction coefficient, tool wear, chip adhesion, and machined workpiece surface roughness. The results show that microtextures on the rake face of the cutting tool can make the cutting process more stable than a conventional non-textured tool, and different textures may be suitable for different ranges of the cutting speed. In the latter range 100–200 m/min, microtextures significantly reduce the cutting force, cutting temperature, friction coefficient at the tool–chip interface, while the anti-adhesion property of textured tools and the surface quality of machined workpieces attain their maximal values. The effectiveness of textures is shown to be affected by chip adhesion and blockage resulting from derivative cutting, which appears at high cutting speeds. Moreover, the violation of the structural integrity of textures and their damage can strongly deteriorate the cutting process at low cutting speeds.

Similar content being viewed by others

References

Oh, N. S., Woo, W. S., & Lee, C. M. (2018). A study on the machining characteristics and energy efficiency of Ti–6Al–4V in laser-assisted trochoidal milling. International Journal of Precision Engineering and Manufacturing-Green Technology International Journal of Precision Engineering and Manufacturing-Green Technology, 5(1), 37–45.

Faga, M. G., Priarone, P. C., Robiglio, M., Settineri, L., & Tebaldo, V. (2017). Technological and sustainability implications of dry, near-dry, and wet turning of Ti–6Al–4V alloy. International Journal of Precision Engineering and Manufacturing-Green Technology International Journal of Precision Engineering and Manufacturing-Green Technology, 4(2), 129–139.

Sugihara, T., & Enomoto, T. (2012). Improving anti-adhesion in aluminum alloy cutting by micro stripe texture. Precision Engineering, 36(2), 229–237.

Xing, Y. Q., Deng, J. X., Zhao, J., Zhang, G. D., & Zhang, K. D. (2014). Cutting performance and wear mechanism of nanoscale and microscale textured Al2O3/TiC ceramic tools in dry cutting of hardened steel. International Journal of Refractory Metals and Hard Materials, 43, 46–58.

Schultheiss, F., Fallqvist, M., M’Saoubi, R., Olsson, M., & Ståhl, J.-E. (2013). Influence of the tool surface micro topography on the tribological characteristics in metal cutting—Part II Theoretical calculations of contact conditions. Wear, 298–299, 23–31.

Wei, Y., Kim, M. R., Lee, D. W., Park, C., & Park, S. S. (2017). Effects of micro textured sapphire tool regarding cutting forces in turning operations. International Journal of Precision Engineering and Manufacturing-Green Technology International Journal of Precision Engineering and Manufacturing-Green Technology, 4(2), 141–147.

Deng, J. X., Wu, Z., Lian, Y. S., Qi, T., & Cheng, J. (2012). Performance of carbide tools with textured rake-face filled with solid lubricants in dry cutting processes. International Journal of Refractory Metals and Hard Materials, 30(1), 164–172.

Li, N., Chen, Y. J., Kong, D. D., & Tan, S. L. (2017). experimental investigation with respect to the performance of deep submillimeter-scaled textured tools in dry turning titanium alloy Ti–6Al–4V. Applied Surface Science, 403, 187–199.

Arulkirubakaran, D., Senthilkumar, V., & Kumawat, V. (2016). Effect of micro-textured tools on machining of Ti–6Al–4V alloy: An experimental and numerical approach. International Journal of Refractory Metals and Hard Materials, 54, 165–177.

Deng, J. X., Lian, Y. S., Wu, Z., & Xing, Y. Q. (2013). Performance of femtosecond laser-textured cutting tools deposited with WS2 solid lubricant coatings. Surface & Coatings Technology, 222, 135–143.

Kawasegi, N., Ozaki, K., Morita, N., Nishimura, K., & Yamaguchi, M. (2017). Development and machining performance of a textured diamond cutting tool fabricated with a focused ion beam and heat treatment. Precision Engineering, 47, 311–320.

Ling, T. D., Liu, P. Z., Xiong, S. W., Grzina, D., Cao, J., Wang, Q. J., et al. (2013). Surface texturing of drill bits for adhesion reduction and tool life enhancement. Tribology Letters, 52(1), 113–122.

Li, Y., Deng, J. X., Chai, Y. S., & Fan, W. L. (2016). Surface textures on cemented carbide cutting tools by micro EDM assisted with high-frequency vibration. International Journal of Advanced Manufacturing Technology, 82(9–12), 2157–2165.

Jahan, M. P., Rahman, M., & Wong, Y. S. (2011). A review on the conventional and micro-electrodischarge machining of tungsten carbide. International Journal of Machine Tools and Manufacture, 51(12), 837–858.

Xie, J., Li, Y. H., & Yang, L. F. (2015). Study on 5-axial milling on microstructured freeform surface using the macro-ball cutter patterned with micro-cutting-edge array. CIRP Annals-Manufacturing Technology, 64(1), 101–104.

Pal, V. K., & Choudhury, S. K. (2014). Fabrication and analysis of micro-pillars by abrasive water jet machining. Procedia Materials Science, 6, 61–71.

Andersson, P., Koskinen, J., Varjus, S., Gerbig, Y., Haefke, H., & Georgiou, S. (2007). Microlubrication effect by laser-textured steel surfaces. Wear, 262(3–4), 369–379.

Lian, Y. S., Deng, J. X., Xing, Y. Q., Lei, S. T., & Yu, X. M. (2013). Periodic and uniform nanogratings formed on cemented carbide by femtosecond laser scanning. Applied Surface Science, 282(10), 518–524.

Kawasegi, N., Sugimori, H., Morimoto, H., Morita, N., & Hori, I. (2009). Development of cutting tools with microscale and nanoscale textures to improve frictional behavior. Precision Engineering, 33(3), 248–254.

Sugihara, T., & Enomoto, T. (2013). Crater and flank wear resistance of cutting tools having micro textured surfaces. Precision Engineering, 37(4), 888–896.

Koshy, P., & Tovey, J. (2011). Performance of electrical discharge textured cutting tools. CIRP Annals-Manufacturing Technology, 60(1), 153–156.

Lee, S. H., & Li, X. P. (2001). Study of the effect of machining parameters on the machining characteristics in electrical discharge machining of tungsten carbide. Journal of Materials Processing Technology, 115(3), 344–358.

Deng, J. X., Song, W. L., & Zhang, H. (2009). Design, fabrication and properties of a self-lubricated tool in dry cutting. International Journal of Machine Tools and Manufacture, 49(1), 66–72.

Xie, J., Luo, M. J., He, J. L., Liu, X. R., & Tan, T. W. (2012). Micro-grinding of micro-groove array on tool rake surface for dry cutting of titanium alloy. International Journal of Precision Engineering and Manufacturing, 13(10), 1845–1852.

Xie, J., Luo, M. J., Wu, K. K., Yang, L. F., & Li, D. H. (2013). Experimental study on cutting temperature and cutting force in dry turning of titanium alloy using a non-coated micro-grooved tool. International Journal of Machine Tools and Manufacture, 73, 25–36.

Brinksmeier, E., Riemer, O., & Twardy, S. (2010). tribological behavior of micro structured surfaces for micro forming tools. International Journal of Machine Tools and Manufacture, 50(4), 425–430.

Xing, Y. Q., Deng, J. X., Wang, X. S., Ehmann, K., & Cao, J. (2016). Experimental assessment of laser textured cutting tools in dry cutting of aluminum alloys. ASME Journal of Manufacturing Science and Engineering, 138, 1301–1314.

Zhang, K. D., Deng, J. X., Xing, Y. Q., Li, S. P., & Gao, H. H. (2015). Effect of microscale texture on cutting performance of WC/Co-based TiAlN coated tools under different lubrication conditions. Applied Surface Science, 326, 107–118.

Duan, R., Deng, J. X., Ai, X., Liu, Y. Y., & Chen, H. (2017). Experimental assessment of derivative cutting of micro-textured tools in dry cutting of medium carbon steels. International Journal of Advanced Manufacturing Technology, 92(9–12), 3531–3540.

Kim, D. M., Bajpai, V., Kim, B. H., & Park, H. W. (2015). Finite element modeling of hard turning process via a micro-textured tool. International Journal of Advanced Manufacturing Technology, 78(9–12), 1393–1405.

Acknowledgements

This work is supported by National Natural Science Foundation of China (Grant no. 51505399) and Natural Science Foundation of Fujian Province of China (Grant no. 2017J05088).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lian, Y., Chen, H. & Mu, C. Performance of Microtextured Tools Fabricated by Inductively Coupled Plasma Etching in Dry Cutting Tests on Medium Carbon Steel Workpieces. Int. J. of Precis. Eng. and Manuf.-Green Tech. 6, 175–188 (2019). https://doi.org/10.1007/s40684-019-00088-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-019-00088-3