Abstract

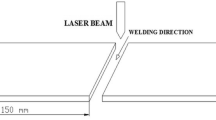

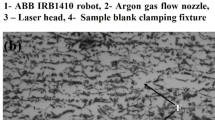

Laser Welding is extensively used in many applications including aerospace, automotive, ship building, electronics, home appliance etc., due to its advantage of very low heat input to the weld, resulting in minimum distortion and the ability to weld heat sensitive materials. In this paper, an experimental investigation on laser welding of 2205 Duplex stainless steel has been carried out using a pulsed Nd: YAG laser source. The objective of the present research is to study the effects of welding speed and other parameters such as laser power and pulse width kept as constant on the quality of the butt weld. The quality of butt joints along with base material have been characterized in terms of microstructure and tensile properties. The effect of the welding speed on laser melt pool geometry i.e. penetration depth and bead width is simulated by anisotropic enhanced thermal conductivity approach and those are compared with experimental results. The study reveals that the weld strength increases with scanning speed up to a certain level, and thereafter it starts to reduce. It is also observed that the depth of penetration and bead width decreases with the increase in scanning speed. Moreover, all welded samples contains ferrite content is relatively higher and subsequently, austenite content is lower due to higher cooling rate. The Vickers micro hardness tests across the base material and butt joint samples have been carried out. The results show that the microhardness continuously decreasing from the fusion zone to the base material due to changes in metallurgical phase constituents due to higher cooling rate.

Similar content being viewed by others

References

Yang, Y., Yan, B., Li, J., Wang, J.: The effect of large heat input on the microstructure and corrosion behaviour of simulated heat affected zone in 2205 duplex stainless steel. Corros Sci. 53, 3756–3763 (2011)

Pekkarinen, J., Kujanpaa, V.: The effects of laser welding parameters on the microstructure of ferritic and duplex stainless steels welds. Phys Procedia. 5, 517–523 (2010)

Shanmugam, N.S., Buvanashekaran, G., Sankaranarayanasamy, K.: Some studies on weld bead geometries for laser spot welding process using finite element analysis. Mater Des. 34, 412–426 (2012)

Soltysiak, R.: Effect of laser welding parameters of duplex 2205 steel welds on fatigue life. Solid State Phenom. 223, 11–18 (2015)

Hu, S., Yang, B., Zeng, B., Zheng, D., Yang, Z.: Experimental study of laser welding process and properties of 2205 duplex stainless sheet steels. Mater Sci Forum. 861, 141–146 (2016)

Soltysiak, R., Gietka, T., Soltysiak, A.: The effect of laser welding power on the properties of the joint made of 1.4462 duplex stainless steel. Advances in Mechanical Engineering. 10(1), 1–12 (2018)

Hosseini, V.A., Bermejo, M.A.V., Gardstam, J., Hurtig, K., Karlsson, L.: Influence of multiple thermal cycles on microstructure of heat-affected zone in TIG-welded super duplex stainless steel. Weld World. 60, 233–245 (2016)

Zhang, Z., Jing, H., Xu, L., Han, Y., Zhao, L.: Investigation on microstructure evolution and properties of duplex stainless steel joint multi-pass welded by using different methods. Mater Des. 109, 670–685 (2016)

Asif, M.M., Shrikrishnaa, K.A., Sathiya, P., Goel, S.: The impact of heat input on the strength, toughness, microhardness, microstructure and corrosion aspects of friction welded duplex stainless steel joints. J Manuf Process. 18, 92–106 (2015)

Capello, E., Chiarello, P., Previtali, B., Vedani, M.: Laser welding and surface treatment of a 22Cr-5Ni-/3Mo duplex stainless steel. Mater Sci Eng. A351, 334–343 (2003)

Batahgy, A.M., Khourshid, A.F., Sharef, T.: Effect of laser beam welding parameters on microstructure and properties of duplex stainless steel. Mater Sci Appl. 2, 1443–1145 (2011)

Safdar, S., Pinkerton, J.A., Li, L., Sheikh, A.M., Withers, J.P.: An anisotropic enhanced thermal conductivity approach for modelling laser melt pools for Ni-base superalloys. Appl Math Model. 37, 1187–1195 (2013)

Acherjee, B., Kuar, A.S., Mitra, S., Misra, D.: Effect of carbon black on temperature field and weld profile during laser transmission welding of polymers: a FEM study. Opt Laser Technol. 44, 514–521 (2012)

Daha, M.A., Nassef, G.A., Abdallah, I.A., AbouSeeda, H.M.: Three-dimensional thermal finite element modeling for keyhole plasma arc welding of 2205 duplex stainless steel plates. International Journal of Engineering and Technology. 2, 2049–3444 (2012)

Daneshkhah, R., Najafi, M., Torabian, H.: Numerical simulation of weld pool shape during laser beam welding. International Research Journal of Applied and Basic Sciences. 3(8), 1624–1630 (2012)

Marimuthu, S., Eghlio, R.M., Pinkerton, A.J., Li, L.: Coupled computational fluid dynamic and finite element multiphase modeling of laser weld bead geometry formation and joint strengths. J Manuf Sci Eng. 135, 011004–011001 (2013)

Acherjee, B., Kuar, A.S., Mitra, S., Misra, D., Acharyya, S.: Experimental investigation on laser transmission welding of PMMA to ABS via response surface modeling. Opt Laser Technol. 44, 1372–1383 (2012)

Badji, R., Bouabdallah, M., Bacroix, B., Kahloun, C., Belkessa, B., Maza, H.: Phase trans-formation and mechanical behaviour in annealed 2205 duplex stainless steel welds. Mater Charact. 59, 447–453 (2008)

Mourada, A.H.I., Khourshid, A., Sharef, T.: Gas tungsten arc and laser beam welding processes effects on duplex stainless steel 2205 properties. Mater Sci Eng A. 549, 105–113 (2012)

Mirshekari, G.R., Saatchi, A., Kermanpur, A., Sadrnezhaad, S.K.: Laser welding of NiTi shape memory alloy: comparison of the similar and dissimilar joints to AISI 304 stainless steel. Opt Laser Technol. 54, 151–158 (2013)

Shanmugarajan, B., Shrivastava, R., Sathiya, P., Buvanashekaran, G.: Optimisation of laser welding parameters for welding of P92 material using Taguchi based grey relational analysis. Defence Technology. 12, 343–350 (2016)

Acknowledgements

Author Aritra Ghosh expresses gratitude for the grants received for his Junior Research Fellowship under TEQIP Phase-II of Jadavpur University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghosh, A., Misra, D. & Acharyya, S.K. Experimental and Numerical Investigation on Laser Welding of 2205 Duplex Stainless Steel. Lasers Manuf. Mater. Process. 6, 228–246 (2019). https://doi.org/10.1007/s40516-019-00090-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-019-00090-2