Abstract

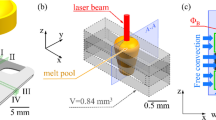

In this paper, laser welding of silicon in conduction mode is investigated numerically. In this study, the effects of laser beam characteristics on the welding have been studied. In order to model the welding process, heat conduction equation is solved numerically and laser beam energy is considered as a boundary condition. Time depended heat conduction equation is used in our calculations to model pulsed laser welding. Thermo-physical and optical properties of the material are considered to be temperature dependent in our calculations. Effects of spatial and temporal laser beam parameters such as laser beam spot size, laser beam quality, laser beam polarization, laser incident angle, laser pulse energy, laser pulse width, pulse repetition frequency and welding speed on the welding characteristics are assessed. The results show that how the temperature dependent thermo-physical and optical parameters of the material are important in laser welding modeling. Also the results show how the parameters of the laser beam influence the welding characteristics.

Similar content being viewed by others

References

Platte, W.N., Smith, J.F.: Laser techniques for metals joining. Weld. J. 42(11), 481–489 (1963)

Walsh, C.A.: LASER WELDING - Literature Review. Materials Science and Metallurgy Department, University of Cambridge, England (2002)

Noaker, P.M.: Lasers penetrate fabricating. Manuf. Eng. 10, 33–40 (1993)

Assuncao, E., Williams, S., Yapp, D.: Interaction time and beam diameter effects on the conduction mode limit. Opt. Lasers Eng. 50(6), 823–828 (2012)

Mazumder, J., Steen, W.M.: Heat transfer model for cw laser material processing. J. Appl. Phys. 51, 941–947 (1980)

Steen, W.M., Dowden, J., Davis, M., Kapadia, P.: A point and line source model of laser keyhole welding. J. Phys. D. Appl. Phys. 21(8), 1255 (1988)

Mohanty, P.S., Mazumder, J.: Workbench for keyhole laser welding. Sci. Technol. Weld. Join. 2, 133–138 (1997)

Mackwooda, A.P., Crafer, R.C.: Thermal modeling of laser welding and related processes: a literature review. Opt. Lasers Technol. 37, 99–115 (2005)

Verhaeghe, G., Hilton, P.: The effect of spot size and laser beam quality on welding performance when using high-power continuous wave solid-state lasers. ICALEO 2005, 24th International Congress on Applications of Lasers & Electro-Optics (2005)

Balasubramanian, K.R., Siva Shanmugam, N., Buvanashekaran, G., Sankaranarayanasamy, K.: Numerical and experimental investigation of laser beam welding of AISI 304 stainless steel sheet. Adv. Prod. Eng. Manag. 3(2), 93–105 (2008)

Duocastella, M., Arnold, C.B.: Bessel and annular beams for materials processing. Laser Photonics Rev. 6(5), 607–621 (2012)

Daniel, J.L., Hyungson, K., Jyoti, M.: Mass removal modes in the laser ablation of silicon by a Q-switched diode-pumped solid-state laser (DPSSL). J. Phys. D. Appl. Phys. 39, 2624–2635 (2006)

Luo, C., Lin, L.: The application of nanosecond-pulsed laser welding technology in MEMS packaging with a shadow mask. Sensor Actuator A 97–98, 398–404 (2002)

Heßmann, T.M.: Laser Welding of Silicon Foils for Thin-Film Solar Cell Manufacturing. Dissertation, Universität Erlangen (2014)

Brettschneider, T., Dorrer, C., Bründel, M., Zengerle, R., Daub, M.: Wafer-level packaging and laser bonding as an approach for silicon-into-lab-on-chip integration. J. Micromech. Microeng. 23(5), (2013)

Tangwarodomnukun, V.: Towards damage-free micro-fabrication of silicon. Doctoral Dissertation, School of Mechanical and Manufacturing Engineering, the University of New South Wales (2012)

Holman, J.P.: Heat Transfer, 10th edn. McGraw-Hill, New York (2010)

Sun, H.: A Practical Guide to Handling Laser Diode Beams. Springer, Netherlands (2015)

Dowden, J.M.: The Mathematics of Thermal Modeling. Chapman & Hall/CRC (2001)

Hodgson, N., Weber, H.: Laser Resonator and Beam Propagation, 2nd edn. Springer Science+Business Media, Inc, New York (2005)

Reitz, J.R., Milford, F.J., Christy, R.W.: Foundations of Electromagnetic Theory, 4th edn. Addison-Wesley, Boston (1993)

Ohsaka, K., Chung, S.K., Rhim, W.K., Holzer, J.C.: Densities of Si determined by an image digitizing technique in combination with an electrostatic levitator. Appl. Phys. Lett. 7(4), 423–425 (1997)

Touloukian, Y.S., Buyco, E.H.: Thermophysical Properties of Matter, vol. 2. IFI/Plenum, New York (1970)

Touloukian, Y.S., Makita, T.: Thermophysical Properties of Matter, vol. 6. IFI/Plenum, New York (1976)

Grigoropoulos, C.P., Buckholz, R.H., Domoto, G.A.: A heat transfer algorithm for the laser-induced melting and recrystallization of thin silicon layers. J. Appl. Phys. 60, 2304–2309 (1986)

Moody, J.E., Hendel, R.H.: Temperature profiles induced by a scanning cw laser beam. J. Appl. Phys. 53(6), 4364–4371 (1982)

Bergmann, J., Heusinger, M., Andr, G., Falk, F.: Temperature dependent optical properties of amorphous silicon for diode laser crystallization. Opt. Express 20(S6), A856–A863 (2012)

http://pveducation.org/pvcdrom/materials/optical-properties-of-silicon, last accessed 2/25/2015

Ion, J.C.: Laser Processing of Engineering Materials: Principles, Procedure and Industrial Application. Elsevier, Butterworth-Heinemann (2005)

Chien, J., Pepiot, P., Khayms, V.: Linear Algebra and Partial Differential Equations for Engineers. MATLAB Workbook. Cornell University MATH2940 http://www.learningace.com/doc/2716459/cfad8a2df94b9d7b954d3886ba22fd58/darve_cme104_matlab last accessed 10/16/2015

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shayganmanesh, M., Khoshnoud, A. Investigation of Laser Parameters in Silicon Pulsed Laser Conduction Welding. Lasers Manuf. Mater. Process. 3, 50–66 (2016). https://doi.org/10.1007/s40516-016-0022-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-016-0022-y