Abstract

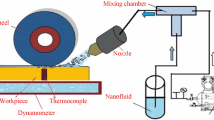

Although a lot has been done to enhance the machining performance of high strength materials, machining of these materials in an eco-friendly manner is still a challenge. Presently, researchers are actively working on MQL base cutting fluids to boost the heat transfer efficiency and lubricating capabilities of the cutting fluids with the application of nanoparticles. Therefore, the present study is focused on the exploration of cooling and lubrication capabilities of different vegetable oil-mixed nanofluids using different nanoparticles (i.e. Al2O3, MoS2, SiO2, CuO and graphene) in drilling under MQL technique. The main aim of the current research work is to compare the drilling performance of different cooling environments, viz. dry, flood, pure MQL (PMQL) and nanofluid MQL (NFMQL) with regard to drilling characteristics concerning the thrust force, torque, surface roughness, drill tip temperature and wear mechanism in drilling of AISI 321 stainless steel. The results obtained from the experiments confirm that NFMQL strategies have shown magnificent machining performance by improving machining characteristics. Among the nanofluids, 1.5 wt.% Al2O3 NFMQL cooling strategy delivered a superior cooling–lubricating effect and enhanced the machining characteristics followed by MoS2, SiO2, CuO and graphene NFMQL conditions. 1.5 wt.% Al2O3 NFMQL drilling had a thrust force, torque, surface roughness and drill tip temperature of 1035 N, 10.8 Nm, 2.902 µm and 56.5 °C, which reduced by 42.81, 64.7, 53.84 and 20.97%, respectively, than that obtained under flood drilling at 30th hole. Moreover, 1.5 wt.% Al2O3 NFMQL condition successfully drilled 30 holes with minimum wear of drill tool as compared to all other drilling conditions under study. The superior performance of Al2O3 NFMQL may be attributed to the fact that Al2O3 nanoparticles with soybean oil performed various tribological enhancement mechanism, i.e. self-repairing or mending mechanism, rolling or ball-bearing mechanism, polishing mechanism and tribo-film formation between the contacting surfaces, which enhance the drilling characteristics.

Similar content being viewed by others

References

Haj M, Mansouri H, Vafaei R, Ebrahimi GR, Kanani A (2013) Hot compression deformation behavior of AISI 321 austenitic stainless steel. Int J Miner Metall Mater 20(6):529–534

Leban MB, Tisu R (2013) The effect of TiN inclusions and deformation-induced martensite on the corrosion properties of AISI 321 stainless steel. Eng Fail Anal 33:430–438

Moura V, Kina AY, Tavares SSM, Lima L, Mainier FB (2008) Influence of stabilization heat treatments on microstructure, hardness and intergranular corrosion resistance of the AISI 321 stainless steel. J Mater Sci 43(2):536–540

Peckner D, Bernstein IM, Peckner D (1977) Handbook of stainless steels. McGraw-Hill, New York

Manimaran G, Venkatasamy R (2014) Influence of cryogenic cooling on surface grinding of stainless steel 316. Cryogenics 59:76–83

Akasawa T, Sakurai H, Nakamura M, Tanaka T, Takano K (2003) Effects of free-cutting additives on the machinability of austenitic stainless steels. J Mater Process Technol 143:66–71

Debnath S, Reddy MM, Yi QS (2014) Environmental friendly cutting fluids and cooling techniques in machining: a review. J Clean Prod 83:33–47

Ozcelik B, Kuram E, Cetin MH, Demirbas E (2011) Experimental investigations of vegetable based cutting fluids with extreme pressure during turning of AISI 304L. Tribol Int 44(12):1864–1871

Cetin MH, Ozcelik B, Kuram E, Demirbas E (2011) Evaluation of vegetable based cutting fluids with extreme pressure and cutting parameters in turning of AISI 304L by Taguchi method. J Clean Prod 19(17–18):2049–2056. https://doi.org/10.1016/j.jclepro.2011.07.013

Erhan SZ, Sharma BK, Perez JM (2006) Oxidation and low temperature stability of vegetable oil-based lubricants. Ind Crops Prod 24(3):292–299

Hamdan S, Chong W, Ng J-H, Chong C, Zhang H (2018) Nano-tribological characterisation of palm oil-based trimethylolpropane ester for application as boundary lubricant. Tribol Int 127:1–9

Najiha M, Rahman M, Yusoff A (2016) Environmental impacts and hazards associated with metal working fluids and recent advances in the sustainable systems: a review. Renew Sustain Energy Rev 60:1008–1031

Talib N, Rahim E (2018) Performance of modified jatropha oil in combination with hexagonal boron nitride particles as a bio-based lubricant for green machining. Tribol Int 118:89–104

Singh T, Dureja JS, Dogra M, Bhatti MS (2018) Environment friendly machining of Inconel 625 under nano-fluid minimum quantity lubrication (NMQL). Int J Precis Eng Manuf 19(11):1689–1697

Rahim EA, Ibrahim MR, Rahim AA, Aziz S, Mohid Z (2015) Experimental investigation of minimum quantity lubrication (MQL) as a sustainable cooling technique. Procedia CIRP 26:351–354. https://doi.org/10.1016/j.procir.2014.07.029

Ribeiro Filho SLM, Vieira JT, de Oliveira JA, Arruda ÉM, Brandão LC (2017) Comparison among different vegetable fluids used in minimum quantity lubrication systems in the tapping process of cast aluminum alloy. J Clean Prod 140:1255–1262. https://doi.org/10.1016/j.jclepro.2016.10.032

Lawal SA, Choudhury IA, Nukman Y (2013) A critical assessment of lubrication techniques in machining processes: a case for minimum quantity lubrication using vegetable oil-based lubricant. J Clean Prod 41:210–221

Boswell B, Islam MN, Davies IJ, Ginting Y, Ong AK (2017) A review identifying the effectiveness of minimum quantity lubrication (MQL) during conventional machining. Int J Adv Manuf Technol 92(1):321–340

Tawakoli T, Hadad M, Sadeghi M (2010) Influence of oil mist parameters on minimum quantity lubrication–MQL grinding process. Int J Mach Tools Manuf 50(6):521–531

Sharma VS, Singh G, Sørby K (2015) A review on minimum quantity lubrication for machining processes. Mater Manuf Process 30(8):935–953

Vazquez E, Gomar J, Ciurana J, Rodríguez CA (2015) Analyzing effects of cooling and lubrication conditions in micromilling of Ti6Al4V. J Clean Prod 87:906–913

Sayuti M, Sarhan AAD, Salem F (2014) Novel uses of SiO2 nano-lubrication system in hard turning process of hardened steel AISI4140 for less tool wear, surface roughness and oil consumption. J Clean Prod 67:265–276. https://doi.org/10.1016/j.jclepro.2013.12.052

Gajrani KK, Sankar MR (2017) Past and current status of eco-friendly vegetable oil based metal cutting fluids. Mater Today Procs 4(2):3786–3795

Gajrani KK, Ram D, Ravi Sankar M (2017) Biodegradation and hard machining performance comparison of eco-friendly cutting fluid and mineral oil using flood cooling and minimum quantity cutting fluid techniques. J Clean Prod 165:1420–1435. https://doi.org/10.1016/j.jclepro.2017.07.217

Bhowmick S, Lukitsch MJ, Alpas AT (2010) Dry and minimum quantity lubrication drilling of cast magnesium alloy (AM60). Int J Mach Tools Manuf 50(5):444–457. https://doi.org/10.1016/j.ijmachtools.2010.02.001

Meena A, El Mansori M (2011) Study of dry and minimum quantity lubrication drilling of novel austempered ductile iron (ADI) for automotive applications. Wear 271(9–10):2412–2416. https://doi.org/10.1016/j.wear.2010.12.022

Niketh S, Samuel G (2018) Drilling performance of micro textured tools under dry, wet and MQL condition. J Manuf Process 32:254–268

Silva LR, Corrêa EC, Brandão JR, de Ávila RF (2020) Environmentally friendly manufacturing: behavior analysis of minimum quantity of lubricant-MQL in grinding process. J Clean Prod 256:103287

Xu X, Huang S, Wang M, Yao W (2017) A study on process parameters in end milling of AISI-304 stainless steel under electrostatic minimum quantity lubrication conditions. Int J Adv Manuf Technol 90(1):979–989. https://doi.org/10.1007/s00170-016-9417-3

Li B, Li C, Zhang Y, Wang Y, Jia D, Yang M, Zhang N, Wu Q, Han Z, Sun K (2017) Heat transfer performance of MQL grinding with different nanofluids for Ni-based alloys using vegetable oil. J Clean Prod 154:1–11

Chan C, Lee W, Wang H (2013) Enhancement of surface finish using water-miscible nano-cutting fluid in ultra-precision turning. Int J Mach Tools Manuf 73:62–70

Sidik NAC, Samion S, Ghaderian J, Yazid MNAWM (2017) Recent progress on the application of nanofluids in minimum quantity lubrication machining: a review. Int J Heat Mass Transf 108:79–89

Sayuti M, Erh OM, Sarhan AA, Hamdi M (2014) Investigation on the morphology of the machined surface in end milling of aerospace AL6061-T6 for novel uses of SiO2 nanolubrication system. J Clean Prod 66:655–663

Zhang Z, Yan J, Kuriyagawa T (2011) Study on tool wear characteristics in diamond turning of reaction-bonded silicon carbide. Int J Adv Manuf Technol 57(1–4):117–125

Wang D, Lin Z, Wang T, Yao Z, Qin M, Zheng S, Lu W (2016) Where does the toxicity of metal oxide nanoparticles come from: the nanoparticles, the ions, or a combination of both? J Hazard Mater 308:328–334

Ng AMC, Guo MY, Leung YH, Chan CM, Wong SW, Yung MM, Ma AP, Djurišić AB, Leung FC, Leung KM (2015) Metal oxide nanoparticles with low toxicity. J Photochem Photobiol B 151:17–24

Wehmas LC, Anders C, Chess J, Punnoose A, Pereira CB, Greenwood JA, Tanguay RL (2015) Comparative metal oxide nanoparticle toxicity using embryonic zebrafish. Toxicol Rep 2:702–715

Parás LP, Cortés DM, Taha-Tijerina J (2019) Eco-friendly nanoparticle additives for lubricants and their tribological characterization. In: Handbook of ecomaterials. Springer International Publishing AG, pp 3247–3267

Cheraghian G (2021) Nanoparticles in drilling fluid: a review of the state-of-the-art. J Mater Res Technol 13:737–753

Wu Y, Tsui W, Liu T (2007) Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 262(7–8):819–825

Mao C, Huang Y, Zhou X, Gan H, Zhang J, Zhou Z (2014) The tribological properties of nanofluid used in minimum quantity lubrication grinding. Int J Adv Manuf Technol 71(5–8):1221–1228. https://doi.org/10.1007/s00170-013-5576-7

Chatha SS, Pal A, Singh T (2016) Performance evaluation of aluminium 6063 drilling under the influence of nanofluid minimum quantity lubrication. J Clean Prod 137:537–545

Uysal A, Demiren F, Altan E (2015) Applying minimum quantity lubrication (MQL) method on milling of martensitic stainless steel by using nano MoS2 reinforced vegetable cutting fluid. Procedia Soc Behav Sci 195:2742–2747. https://doi.org/10.1016/j.sbspro.2015.06.384

Padmini R, Krishna PV, Rao GKM (2016) Effectiveness of vegetable oil based nanofluids as potential cutting fluids in turning AISI 1040 steel. Tribol Int 94:490–501

Pal A, Chatha SS, Sidhu HS (2020) Experimental investigation on the performance of MQL drilling of AISI 321 stainless steel using nano-graphene enhanced vegetable-oil-based cutting fluid. Tribol Int 151:106508

Lee P-H, Nam TS, Li C, Lee SW (2010) Environmentally-friendly nano-fluid minimum quantity lubrication (MQL) meso-scale grinding process using nano-diamond particles. In: 2010 international conference on manufacturing automation, pp 44–49. IEEE

Behera BC, Setti D, Ghosh S, Rao PV (2017) Spreadability studies of metal working fluids on tool surface and its impact on minimum amount cooling and lubrication turning. J Mater Process Technol 244:1–16

Virdi RL, Chatha SS, Singh H (2020) Processing characteristics of different vegetable oil-based nanofluid MQL for grinding of Ni-Cr alloy. Adv Mater Process Technol 1–14

Zhang B-S, Xu B-S, Xu Y, Gao F, Shi P-J, Wu Y-X (2011) Cu nanoparticles effect on the tribological properties of hydrosilicate powders as lubricant additive for steel–steel contacts. Tribol Int 44(7–8):878–886

Lal Virdi R, Singh Chatha S, Singh H (2020) Performance Evaluation of Inconel 718 under vegetable oils based nanofluids using Minimum Quantity Lubrication Grinding. Mater Today Proc. https://doi.org/10.1016/j.matpr.2020.03.802

Minh DT, The LT, Bao NT (2017) Performance of Al2O3 nanofluids in minimum quantity lubrication in hard milling of 60Si2Mn steel using cemented carbide tools. Adv Mech Eng 9(7):1687814017710618

Emami M, Sadeghi MH, Sarhan AAD (2013) Investigating the effects of liquid atomization and delivery parameters of minimum quantity lubrication on the grinding process of Al2O3 engineering ceramics. J Manuf Process 15(3):374–388. https://doi.org/10.1016/j.jmapro.2013.02.004

Xu X, Lv T, Luan Z, Zhao Y, Wang M, Hu X (2019) Capillary penetration mechanism and oil mist concentration of Al2O3 nanoparticle fluids in electrostatic minimum quantity lubrication (EMQL) milling. Int J Adv Manuf Technol 104(5–8):1937–1951

Wang Y, Li C, Zhang Y, Li B, Yang M, Zhang X, Guo S, Liu G (2016) Experimental evaluation of the lubrication properties of the wheel/workpiece interface in MQL grinding with different nanofluids. Tribol Int 99:198–210

Şirin Ş, Kıvak T (2019) Performances of different eco-friendly nanofluid lubricants in the milling of Inconel X-750 superalloy. Tribol Int 137:180–192

Geng D, Liu Y, Shao Z, Lu Z, Cai J, Li X, Jiang X, Zhang D (2019) Delamination formation, evaluation and suppression during drilling of composite laminates: a review. Compos Struct 216:168–186

Najiha MS, Rahman MM, Kadirgama K (2016) Performance of water-based TiO2 nanofluid during the minimum quantity lubrication machining of aluminium alloy, AA6061-T6. J Clean Prod 135:1623–1636

Nam J, Kim JW, Kim JS, Lee J, Lee SW (2018) Parametric analysis and optimization of nanofluid minimum quantity lubrication micro-drilling process for titanium alloy (Ti-6Al-4V) using response surface methodology and desirability function. Procedia Manuf 26:403–414

Khanna N, Agrawal C, Gupta MK, Song Q (2020) Tool wear and hole quality evaluation in cryogenic Drilling of Inconel 718 superalloy. Tribol Int 143:106084

Uçak N, Çiçek A (2018) The effects of cutting conditions on cutting temperature and hole quality in drilling of Inconel 718 using solid carbide drills. J Manuf Process 31:662–673

Wang Y, Li C, Zhang Y, Yang M, Li B, Jia D, Hou Y, Mao C (2016) Experimental evaluation of the lubrication properties of the wheel/workpiece interface in minimum quantity lubrication (MQL) grinding using different types of vegetable oils. J Clean Prod 127:487–499

Kuram E, Ozcelik B, Huseyin Cetin M, Demirbas E, Askin S (2013) Effects of blended vegetable-based cutting fluids with extreme pressure on tool wear and force components in turning of Al 7075T6. Lubr Sci 25(1):39–52

Guo S, Li C, Zhang Y, Wang Y, Li B, Yang M, Zhang X, Liu G (2017) Experimental evaluation of the lubrication performance of mixtures of castor oil with other vegetable oils in MQL grinding of nickel-based alloy. J Clean Prod 140:1060–1076

Singh H, Sharma VS, Dogra M (2020) Exploration of graphene assisted vegetables oil based minimum quantity lubrication for surface grinding of TI-6AL-4V-ELI. Trib Int 144:106113

Xie H, Jiang B, He J, Xia X, Pan F (2016) Lubrication performance of MoS2 and SiO2 nanoparticles as lubricant additives in magnesium alloy-steel contacts. Tribol Int 93:63–70

Rahmati B, Sarhan AA, Sayuti M (2014) Morphology of surface generated by end milling AL6061-T6 using molybdenum disulfide (MoS2) nanolubrication in end milling machining. J Clean Prod 66:685–691

Pal A, Chatha SS, Sidhu HS (2021) Performance evaluation of the minimum quantity lubrication with Al2O3-mixed vegetable-oil-based cutting fluid in drilling of AISI 321 stainless steel. J Manuf Process 66:238–249

Belluco W, De Chiffre L (2004) Performance evaluation of vegetable-based oils in drilling austenitic stainless steel. J Mater Process Technol 148(2):171–176. https://doi.org/10.1016/s0924-0136(03)00679-4

Kuram E, Ozcelik B, Demirbas E, Şik E, Tansel IN (2011) Evaluation of new vegetable-based cutting fluids on thrust force and surface roughness in drilling of AISI 304 using Taguchi method. Mater Manuf Process 26(9):1136–1146

Mao C, Zou H, Huang X, Zhang J, Zhou Z (2013) The influence of spraying parameters on grinding performance for nanofluid minimum quantity lubrication. Int J Adv Manuf Technol 64(9):1791–1799. https://doi.org/10.1007/s00170-012-4143-y

Lv T, Huang S, Liu E, Ma Y, Xu X (2018) Tribological and machining characteristics of an electrostatic minimum quantity lubrication (EMQL) technology using graphene nano-lubricants as cutting fluids. J Manuf Process 34:225–237

Şirin E, Kıvak T, Yıldırım ÇV (2021) Effects of mono/hybrid nanofluid strategies and surfactants on machining performance in the drilling of Hastelloy X. Tribol Int 157:106894

Young H-T (1996) Cutting temperature responses to flank wear. Wear 201(1–2):117–120

Perçin M, Aslantas K, Ucun I, Kaynak Y, Cicek A (2016) Micro-drilling of Ti–6Al–4V alloy: the effects of cooling/lubricating. Precis Eng 45:450–462

Shokrani A, Dhokia V, Newman ST, Asrai RI (2012) An initial study of the effect of using liquid nitrogen coolant on the surface roughness of inconel 718 nickel-based. Procedia CIRP 3:121–125

Hadad M, Sadeghi B (2013) Minimum quantity lubrication-MQL turning of AISI 4140 steel alloy. J Clean Prod 54:332–343. https://doi.org/10.1016/j.jclepro.2013.05.011

Tunc LT, Gu Y, Burke MG (2016) Effects of minimal quantity lubrication (MQL) on surface integrity in robotic milling of austenitic stainless steel. Procedia CIRP 45:215–218. https://doi.org/10.1016/j.procir.2016.02.337

Molaie MM, Akbari J, Movahhedy MR (2016) Ultrasonic assisted grinding process with minimum quantity lubrication using oil-based nanofluids. J Clean Prod 129:212–222. https://doi.org/10.1016/j.jclepro.2016.04.080

Sharma AK, Singh RK, Dixit AR, Tiwari AK (2017) Novel uses of alumina-MoS2 hybrid nanoparticle enriched cutting fluid in hard turning of AISI 304 steel. J Manuf Process 30:467–482

Shahnazar S, Bagheri S, Hamid SBA (2016) Enhancing lubricant properties by nanoparticle additives. Int J Hydrog Energy 41(4):3153–3170

Setti D, Sinha MK, Ghosh S, Rao PV (2015) Performance evaluation of Ti–6Al–4V grinding using chip formation and coefficient of friction under the influence of nanofluids. Int J Mach Tools Manuf 88:237–248

Yu H, Xu Y, Shi P, Wang H, Wei M, Zhao K, Xu B (2013) Microstructure, mechanical properties and tribological behavior of tribofilm generated from natural serpentine mineral powders as lubricant additive. Wear 297(1–2):802–810

Shen B, Malshe AP, Kalita P, Shih AJ (2008) Performance of novel MoS2 nanoparticles based grinding fluids in minimum quantity lubrication grinding. Trans Namri SME 36(1):357–364

Wang Y, Li C, Zhang Y, Yang M, Li B, Dong L, Wang J (2018) Processing characteristics of vegetable oil-based nanofluid MQL for grinding different workpiece materials. Int J Precis Eng Manuf Green Technol 5(2):327–339

Li M, Yu T, Yang L, Li H, Zhang R, Wang W (2019) Parameter optimization during minimum quantity lubrication milling of TC4 alloy with graphene-dispersed vegetable-oil-based cutting fluid. J Clean Prod 209:1508–1522

Mathew NT, Vijayaraghavan L (2017) Environmentally friendly drilling of intermetallic titanium aluminide at different aspect ratio. J Clean Prod 141:439–452

Pal A, Chatha SS, Sidhu HS (2021) Performance evaluation of various vegetable oils and distilled water as base fluids using eco-friendly MQL technique in drilling of AISI 321 stainless steel. Int J Precis Eng Manuf Green Technol. https://doi.org/10.1007/s40684-021-00355-2

Abd Rahim E, Dorairaju H (2018) Evaluation of mist flow characteristic and performance in Minimum Quantity Lubrication (MQL) machining. Measurement 123:213–225

De Oliveira D, Da Silva R, Gelamo R (2019) Influence of multilayer graphene platelet concentration dispersed in semi-synthetic oil on the grinding performance of Inconel 718 alloy under various machining conditions. Wear 426:1371–1383

Virdi RL, Chatha SS, Singh H (2019) Experiment evaluation of grinding properties under Al2O3 nanofluids in minimum quantity lubrication. Mater Res Express 6(9):096574

Zhao J, He Y, Wang Y, Wang W, Yan L, Luo J (2016) An investigation on the tribological properties of multilayer graphene and MoS2 nanosheets as additives used in hydraulic applications. Tribol Int 97:14–20

Pal A, Chatha SS, Singh K (2020) Performance evaluation of minimum quantity lubrication technique in grinding of AISI 202 stainless steel using nano-MoS2 with vegetable-based cutting fluid. Int J Adv Manuf Technol 110(1):125–137

Wang B-X, Wu F, Zhang X, Yuan Y, Guo S, Barber GC (2021) Orthogonal tests of the lubricating performance of SnO2 nanoparticles in poly-alfa-olefine oil. Proc Inst Mech Eng Part J J Eng Tribol 13506501211037795

Sharma AK, Tiwari AK, Dixit AR, Singh RK, Singh M (2018) Novel uses of alumina/graphene hybrid nanoparticle additives for improved tribological properties of lubricant in turning operation. Tribol Int 119:99–111

Esfe MH, Bahiraei M, Mir A (2020) Application of conventional and hybrid nanofluids in different machining processes: a critical review. Adv Colloid Interface Sci 282:102199

Kumar P, Wani M (2017) Synthesis and tribological properties of graphene: a review. Jurnal Tribologi 13:36–71

Luo T, Wei X, Huang X, Huang L, Yang F (2014) Tribological properties of Al2O3 nanoparticles as lubricating oil additives. Ceram Int 40(5):7143–7149

Duc TM, Chien TQ (2019) Performance evaluation of MQL parameters using Al2O3 and MoS2 nanofluids in hard turning 90CrSi steel. Lubricants 7(5):40

Alves S, Barros B, Trajano M, Ribeiro K, Moura E (2013) Tribological behavior of vegetable oil-based lubricants with nanoparticles of oxides in boundary lubrication conditions. Tribol Int 65:28–36

Rapoport L, Leshchinsky V, Lapsker I, Volovik Y, Nepomnyashchy O, Lvovsky M, Popovitz-Biro R, Feldman Y, Tenne R (2003) Tribological properties of WS2 nanoparticles under mixed lubrication. Wear 255(7–12):785–793

Nunn N, Mahbooba Z, Ivanov M, Ivanov D, Brenner D, Shenderova O (2015) Tribological properties of polyalphaolefin oil modified with nanocarbon additives. Diam Relat Mater 54:97–102

Zulkifli N, Kalam M, Masjuki H, Yunus R (2013) Experimental analysis of tribological properties of biolubricant with nanoparticle additive. Procedia Eng 68:152–157

Yıldırım ÇV, Sarıkaya M, Kıvak T, Şirin Ş (2019) The effect of addition of hBN nanoparticles to nanofluid-MQL on tool wear patterns, tool life, roughness and temperature in turning of Ni-based Inconel 625. Tribol Int 134:443–456

Li M, Yu T, Zhang R, Yang L, Ma Z, Li B, Wang X, Wang W, Zhao J (2019) Experimental evaluation of an eco-friendly grinding process combining minimum quantity lubrication and graphene-enhanced plant-oil-based cutting fluid. J Cleaner Prod 244:118747

Shen B, Shih AJ, Tung SC (2008) Application of nanofluids in minimum quantity lubrication grinding. Tribol Trans 51(6):730–737

Yi S, Li G, Ding S, Mo J (2017) Performance and mechanisms of graphene oxide suspended cutting fluid in the drilling of titanium alloy Ti-6Al-4V. J Manuf Process 29:182–193

Sinha MK, Madarkar R, Ghosh S, Rao PV (2017) Application of eco-friendly nanofluids during grinding of Inconel 718 through small quantity lubrication. J Clean Prod 141:1359–1375. https://doi.org/10.1016/j.jclepro.2016.09.212

Astakhov VP (2004) The assessment of cutting tool wear. Int J Mach Tools Manuf 44(6):637–647

Mia M, Gupta MK, Singh G, Królczyk G, Pimenov DY (2018) An approach to cleaner production for machining hardened steel using different cooling-lubrication conditions. J Clean Prod 187:1069–1081

Salman B, Mohammed H, Munisamy K, Kherbeet AS (2013) Characteristics of heat transfer and fluid flow in microtube and microchannel using conventional fluids and nanofluids: a review. Renew Sustain Energy Rev 28:848–880

Lee J-H, Hwang KS, Jang SP, Lee BH, Kim JH, Choi SUS, Choi CJ (2008) Effective viscosities and thermal conductivities of aqueous nanofluids containing low volume concentrations of Al2O3 nanoparticles. Int J Heat Mass Transf 51(11–12):2651–2656. https://doi.org/10.1016/j.ijheatmasstransfer.2007.10.026

Rahim E, Sasahara H (2011) A study of the effect of palm oil as MQL lubricant on high speed drilling of titanium alloys. Tribol Int 44(3):309–317

Xu J, Ji M, Davim JP, Chen M, El Mansori M, Krishnaraj V (2020) Comparative study of minimum quantity lubrication and dry drilling of CFRP/titanium stacks using TiAlN and diamond coated drills. Compos Struct 234:111727

Dai W, Kheireddin B, Gao H, Kan Y, Clearfield A, Liang H (2016) Formation of anti-wear tribofilms via α-ZrP nanoplatelet as lubricant additives. Lubricants 4(3):28

Funding

It is certified that we have not received any funding from any agency for carrying out present research work.

Author information

Authors and Affiliations

Contributions

All the authors have equally participated and worked as a team to complete this research work. Problem formulation, related literature review, fabrication of the experimental set-up and procurement of material, conducting of experimentation, testing, analysis of the results and writing—original draft are done by AP. Discussion on the idea, help in the procurement and arranging of the facilities, conducting of experimentation, analysis of the results, writing—review and editing, and whole process monitoring are done by SSC and HSS. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Technical Editor: Adriano Fagali de Souza.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pal, A., Chatha, S.S. & Sidhu, H.S. Assessing the lubrication performance of various vegetable oil-based nano-cutting fluids via eco-friendly MQL technique in drilling of AISI 321 stainless steel. J Braz. Soc. Mech. Sci. Eng. 44, 148 (2022). https://doi.org/10.1007/s40430-022-03442-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03442-w