Abstract

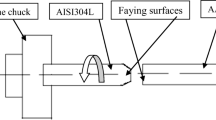

This study investigates the joining efficiency by analyzing the thermal behavior of friction stud welding of AISI 304 stainless steel and AA6063 alloys. Effects of the three most influential process variables including rotational speed (RS), friction time (FT) and friction pressure (FP) have been investigated on the thermal profile of joint interface region of dissimilar metals using peak temperature during the friction welding process. Thermal analysis of the joint interface is performed using finite element analysis (FEA) and finite difference method (FDM). The influence of different process variables has also been analyzed on the heating and cooling curves of the interface region at different moments. Microstructural analysis reveals that variation in the peak temperature also varies the grain size in the intermetallic phases formed in the interface region. At higher peak temperatures, finer grains yield a stronger bond between dissimilar metals. Peak values of the impact strength have been obtained at higher levels of RS, FT and FP. Maximum Vickers hardness of 325 HV has been observed at the joint interface, which has more than both parent metals.

Similar content being viewed by others

References

Ali MA et al (2020) Mechanical characterization of aged AA2026-AA2026 overcast joints fabricated by squeeze casting. Int J Adv Manuf Technol 107(7):3277–3297

Guo B, Zhang Z, Li R (2018) Ultrasonic and eddy current non-destructive evaluation for property assessment of 6063 aluminum alloy. NDT E Int 93:34–39

Winiczenko R (2016) Effect of friction welding parameters on the tensile strength and microstructural properties of dissimilar AISI 1020-ASTM A536 joints. Int J Adv Manuf Technol 84(5):941–955

Tisza M, Czinege I (2018) Comparative study of the application of steels and aluminium in lightweight production of automotive parts. Int J Lightweight Mater Manuf 1(4):229–238

Hynes NRJ, Velu PS (2018) Effect of rotational speed on Ti-6Al-4V-AA 6061 friction welded joints. J Manuf Process 32:288–297

Kulkarni N, Mishra RS, Yuan W (2015) Friction stir welding of dissimilar alloys and materials. Butterworth-Heinemann, USA

Mohammadi J et al (2015) Tool geometry, rotation and travel speeds effects on the properties of dissimilar magnesium/aluminum friction stir welded lap joints. Mater Des 75:95–112

Qin G et al (2015) Numerical simulation on MIG arc brazing-fusion welding of aluminum alloy to galvanized steel plate. Int J Adv Manuf Technol 78(9):1917–1925

Chen S et al (2011) Improving interfacial reaction nonhomogeneity during laser welding–brazing aluminum to titanium. Mater Des 32(8):4408–4416

Ai Y et al (2016) A defect-responsive optimization method for the fiber laser butt welding of dissimilar materials. Mater Des 90:669–681

Hynes NRJ, Nagaraj P, Sujana JAJ (2014) Mechanical evaluation and microstructure of friction stud welded aluminium–mild steel joints. Arab J Sci Eng 39(6):5017–5023

Uday MB et al (2012) Thermal analysis of friction welding process in relation to the welding of YSZ-alumina composite and 6061 aluminum alloy. Appl Surf Sci 258(20):8264–8272

Wang D et al (2014) Evolution of the microstructure and strength in the nugget zone of friction stir welded SiCp/Al–Cu–Mg composite. J Mater Sci Technol 30(1):54–60

Ratanathavorn W, Melander A (2015) Dissimilar joining between aluminium alloy (AA 6111) and thermoplastics using friction stir welding. Sci Technol Weld Join 20(3):222–228

Hynes NRJ, Nagaraj P, Sujana JAJ (2014) Ultrasonic evaluation of friction stud welded AA 6063/AISI 1030 steel joints. Mater Des 1980–2015 62:118–123

Muralimohan CH et al (2016) Analysis and characterization of the role of Ni interlayer in the friction welding of titanium and 304 austenitic stainless steel. Metall Mater Trans A 47(1):347–359

Matsuda T et al (2019) High-frequency linear friction welding of aluminum alloys to stainless steel. J Mater Process Technol 269:45–51

Sharma N, Khan ZA, Siddiquee AN (2017) Friction stir welding of aluminum to copper—An overview. Trans Nonferr Met Soc China 27(10):2113–2136

Kimura M et al (2016) Friction welding technique and joint properties of thin-walled pipe friction-welded joint between type 6063 aluminum alloy and AISI 304 austenitic stainless steel. Int J Adv Manuf Technol 82(1):489–499

Sahin M (2014) Characterization of properties in friction-welded austenitic-stainless steel and aluminium joints. Ind Lubr Tribol 66(2):260–271

Balta B, Arici AA, Yilmaz M (2016) Optimization of process parameters for friction weld steel tube to forging joints. Mater Des 103:209–222

Khidhir GI, Baban SA (2019) Efficiency of dissimilar friction welded 1045 medium carbon steel and 316L austenitic stainless steel joints. J Mater Technol 8(2):1926–1932

Liang Z et al (2015) Microstructural characterization and mechanical properties of dissimilar friction welding of 1060 aluminum to AZ31B magnesium alloy. Mater Sci Eng, A 645:170–180

Paventhan R, Lakshminarayanan PR, Balasubramanian V (2011) Prediction and optimization of friction welding parameters for joining aluminium alloy and stainless steel. Trans Nonferr Met Soc China 21(7):1480–1485

Song Q et al (2020) Improving joint quality of hybrid friction stir welded Al/Mg dissimilar alloys by RBFNN-GWO system. J Manuf Process 59:750–759

Hattingh DG et al (2011) Process parameter influence on performance of friction taper stud welds in AISI 4140 steel. Mater Des 32(6):3421–3430

Elatharasan G, Manikandan R, Karthikeyan G (2021) Multi-response optimization of process parameters in friction stir welding of dissimilar aluminum alloys by Grey relation analysis (AA 6061–T6 & AA5083-H111). Mater Today Proc 37:1172–1182

Suryanarayanan R, Sridhar VG (2020) Experimental investigation on the influence of process parameters in Friction stir spot welded dissimilar aluminum alloys. Mater Today Proc 27:529–533

Zhang G, Xiao C, Ojo OO (2021) Dissimilar friction stir spot welding of AA2024-T3/AA7075-T6 aluminum alloys under different welding parameters and media. Def Technol 17(2):531–544

Sadoun AM et al (2019) Effect of tool pin side area ratio on temperature distribution in friction stir welding. Results Phys 15:102814

Seli H et al (2010) Mechanical evaluation and thermal modelling of friction welding of mild steel and aluminium. J Mater Process Technol 210(9):1209–1216

Pandian V, Kannan S (2020) Numerical prediction and experimental investigation of aerospace-grade dissimilar aluminium alloy by friction stir welding. J Manuf Process 54:99–108

Derazkola HA, Eyvazian A, Simchi A (2020) Submerged friction stir welding of dissimilar joints between an Al-Mg alloy and low carbon steel: thermo-mechanical modeling, microstructural features, and mechanical properties. J Manuf Processes 50:68–79

Gopkalo O et al (2019) Non-isothermal thermal cycle process model for predicting post-weld hardness in friction stir welding of dissimilar age-hardenable aluminum alloys. Mater Sci Eng, A 754:205–215

Jedrasiak P et al (2016) Thermal modeling of Al-Al and Al-steel friction stir spot welding. J Mater Eng Perform 25(9):4089–4098

Patel NP et al (2019) Numerical modelling on cooling assisted friction stir welding of dissimilar Al-Cu joint. J Manuf Process 47:98–109

Raza MH et al (2021) Investigating the effects of gating design on mechanical properties of aluminum alloy in sand casting process. J King Saud Univ Eng Sci 33(3):201–212

Lakshminarayanan AK, Ramachandran CS, Balasubramanian V (2014) Feasibility of surface-coated friction stir welding tools to join AISI 304 grade austenitic stainless steel. Def Technol 10(4):360–370

Yin Y et al (2015) Material flow influence on the weld formation and mechanical performance in underwater friction taper plug welds for pipeline steel. Mater Des 88:990–998

Testing ASf, Materials (2014) ASTM A370: standard test methods and definitions for mechanical testing of steel products. ASTM West Conshohocken

Raza MH et al (2020) Investigation of surface roughness in face milling processes. Int J Adv Manuf Technol 111(9):2589–2599

Ishfaq K et al (2020) Optimization of WEDM for precise machining of novel developed Al6061-7.5% SiC squeeze-casted composite. Int J Adv Manuf Technol 111(7):2031–2049

Hynes NRJ, Nagaraj P, Selvaraj RM (2013) Finite element based thermal modeling of friction welding of dissimilar materials. International journal of modern physics: conference series. World Scientific

Holman J (2010) Heat transfer. The McGraw-Hill Companies, USA

International A (2011) ASTM E384-01: standard test method for microindentation hardnees of materials. ASTM West Conshoncken

Hynes RJN, Vivek Prabhu M, Nagaraj P (2017) Joining of hybrid AA6063-6SiCp-3Grp composite and AISI 1030 steel by friction welding. Def Technol 13(5):338–345

Raza MH et al (2021) Cryogenic treatment analysis of electrodes in wire electric discharge machining of squeeze casted Al2024/Al2O3/W composite. Int J Adv Manuf Technol 116(3–4):1179–1198

Leung WK, Raza MH, Zhong RY (2021) Optimization of support structure in multi-articulated joints of non-assembly mechanisms. Procedia CIRP 100:726–731

Raza MH et al (2019) Grain selection and crystal orientation in single-crystal casting: state of the art. Cryst Res Technol 54(2):1800177

Hynes N, Nagaraj P, Sujana J (2019) Regression modelling of joining aluminium studs to steel with AA 1100 interlayer. Exp Tech 43:491–500. https://doi.org/10.1007/s40799-019-00303-5

Rajendran TP, Hynes NRJ, Nikolova MP et al (2020) Influence of heat treatment on friction-welded joints made of high-carbon high-chromium tool steel/low-carbon steel for tooling applications. J Braz Soc Mech Sci Eng 42:87. https://doi.org/10.1007/s40430-019-2165-1

Packiaraj Rajendran T, Hynes RJN, Christopher T (2018) Characterization of high-carbon high-chromium tool steel/low-carbon steel friction-welded joints for industrial tooling applications. J Braz Soc Mech Sci Eng 40:316. https://doi.org/10.1007/s40430-018-1243-0

Hynes NRJ, Vivek Prabu M, Velu PS, Kumar R (2021) An experimental insight of friction stir welding of dissimilar AA 6061/Mg AZ31 B joints. Proc Inst Mech Eng Part B Eng Manuf. https://doi.org/10.1177/09544054211043474

Hynes NRJ, Velu PS (2018) Microstructural and mechanical properties on friction welding of dissimilar metals used in motor vehicles. Mater Res Express 5(2):26521–26532. https://doi.org/10.1088/2053-1591/aaabe6

Tharmaraj R, Hynes NRJ, Velu PS (2020) Investigation on friction stud welded AMC/AISI 304 steel joints with ceramic intercoating. J Braz Soc Mech Sci Eng 42:538. https://doi.org/10.1007/s40430-020-02621-x

Huang Y, Wan L, Si X, Huang T, Meng X, Xie Y (2018) Achieving high-quality Al/steel joint with ultrastrong interface. Metall Mater Trans A Phys Metall Mater Sci. https://doi.org/10.1007/s11661-018-5006-4

Xie Y, Meng X, Li Y, Mao D, Wan L, Huang Y (2021) Insight into ultra-refined grains of aluminum matrix composites via deformation-driven metallurgy. Compos Commun 26:1–4

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Izabel Fernanda Machado.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rajesh Jesudoss Hynes, N., Jones Joseph Jebaraj, D., Selvaraj, M. et al. Thermal behavior analysis and mechanical characterization of friction stud welded AISI 304/AA6063 joints. J Braz. Soc. Mech. Sci. Eng. 44, 114 (2022). https://doi.org/10.1007/s40430-022-03412-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03412-2